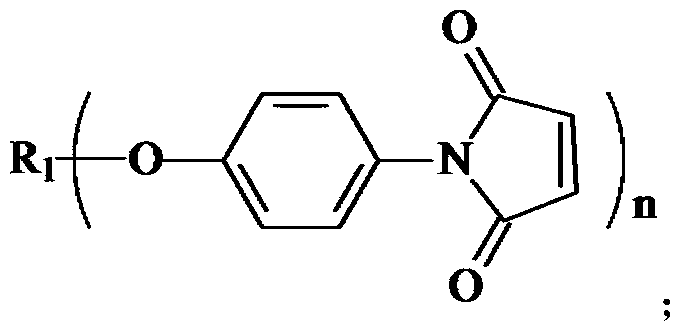

Heat-resisting reaction type phosphorate containing flame retardant with maleimide structure and preparation method thereof

A technology of maleimide and maleimide-based phenol, which is applied in the field of heat-resistant reactive maleimide structure phosphorus-containing flame retardants and its preparation, and can solve the problem of material heat resistance degradation and purification The problem of cumbersome process and low flame retardant efficiency can overcome the damage of heat resistance, the post-processing process is simple, and it is not easy to migrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

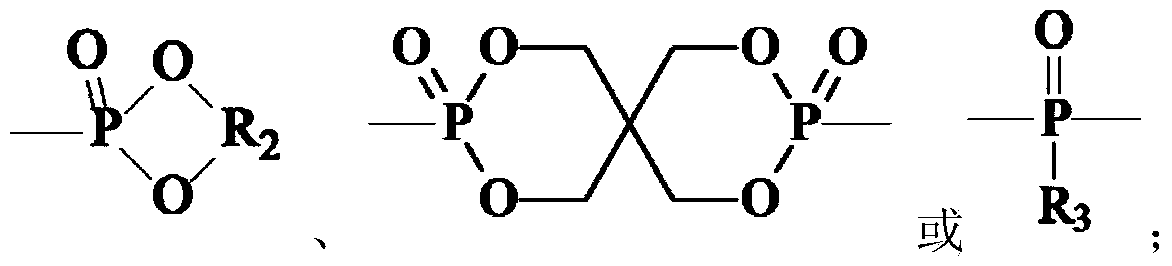

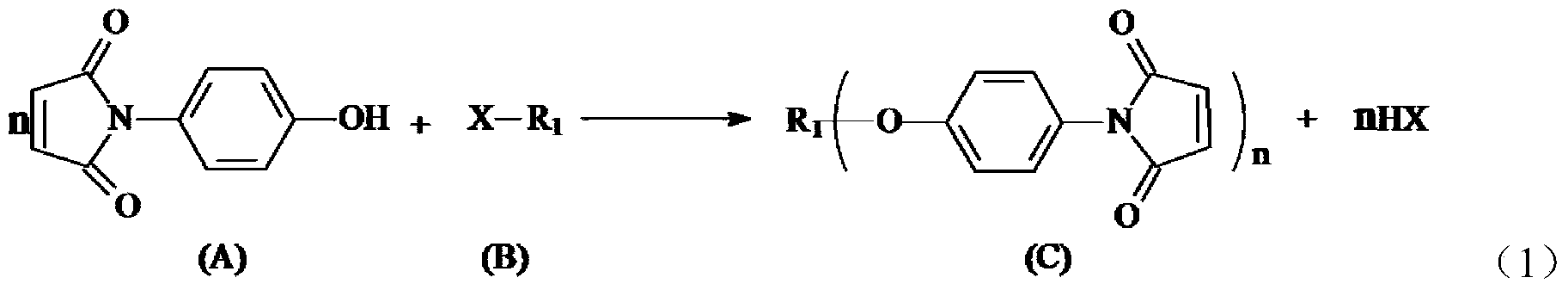

Method used

Image

Examples

Embodiment 1

[0029] Add 37.8g (0.2mol) of maleimidophenol, 250ml of anhydrous tetrahydrofuran and 29.7g (0.1mol) of pentaerythritol diphosphate diphosphoryl chloride into a 500ml three-necked flask equipped with a stirrer, nitrogen inlet and condenser , feed nitrogen, and heat the material in the reactor to 70 ° C, while heating and stirring continuously, after constant temperature, continue to stir until no HCl gas is released, cool to room temperature, and remove the reaction solvent by distillation under reduced pressure, the obtained orange product is heat-resistant Phosphorus-containing flame retardant with reactive maleimide structure, the yield is 90%.

[0030] The proton nuclear magnetic resonance spectrum analysis of the resulting product, the peak position of the chemical shift at 6.80-6.85ppm is the hydrogen vibration signal on the double bond on the nitrogen-containing five-membered ring, and the chemical shift is between 7.05-7.11ppm and 7.12-7.14ppm The peaks between are the ...

Embodiment 2

[0034] Add 18.9g (0.1mol) of maleimidophenol, 150ml of anhydrous acetonitrile and 18.5g (0.1mol) of neopentyl glycol phosphorus oxychloride into a 500ml three-neck flask equipped with a stirrer, an argon inlet and a condenser , feed argon, and heat the material in the reactor to 85 ° C, while heating, continue to stir, after constant temperature, continue to stir until no HCl gas is released, cool to room temperature, and remove the reaction solvent by distillation under reduced pressure, the obtained orange-yellow product is resistant to Phosphorus-containing flame retardant with heat-reactive maleimide structure, the yield is 92%.

[0035]The proton nuclear magnetic resonance spectrum analysis of the resulting product, the peak position of the chemical shift at 6.80-6.86ppm is the hydrogen vibration signal on the double bond on the nitrogen-containing five-membered ring, and the chemical shift is between 7.06-7.11ppm and 7.11-7.14ppm The peaks between are the hydrogen vibrat...

Embodiment 3

[0039] Add 37.8g (0.2mol) of maleimidophenol, 250ml of anhydrous toluene and 21.1g (0.1mol) of phenyl dichlorophosphate into a 500ml three-necked flask equipped with a stirrer, a helium inlet and a condenser , feed helium, and heat the material in the reactor to 100 ° C, while heating and stirring continuously, after constant temperature, continue stirring until no HCl gas is released, cool to room temperature, and distill off the reaction solvent under reduced pressure, the obtained orange-yellow product is resistant Phosphorus-containing flame retardant with heat-reactive maleimide structure, the yield is 88%.

[0040] The proton nuclear magnetic resonance spectrum analysis of the resulting product, the peak position of the chemical shift at 6.80-6.86ppm is the hydrogen vibration signal on the double bond on the nitrogen-containing five-membered ring, and the chemical shift is between 7.05-7.11ppm and 7.12-7.14ppm The peaks between are the hydrogen vibration signals on the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| heat release | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com