Grinding roller sealing ring materials and preparation method thereof

A sealing ring, grinding roller technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of complex graphene modification process, affecting graphene promotion effect, etc., to achieve good toughening effect and improve heat resistance. , the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

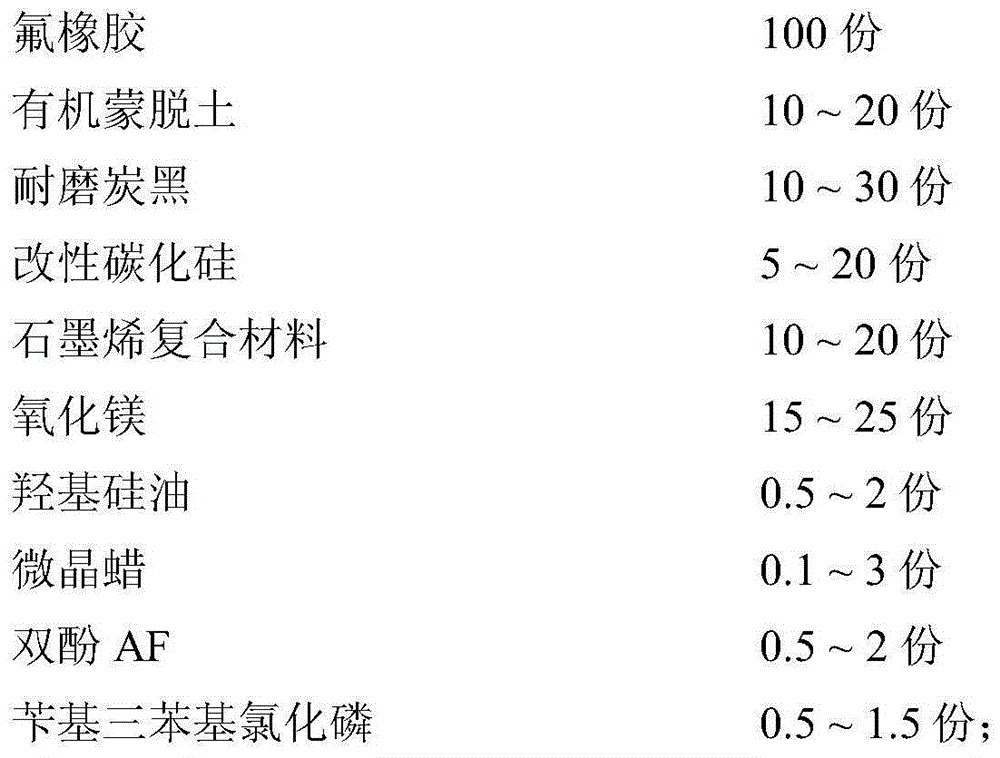

[0030] The grinding roller sealing ring material of the present embodiment comprises the following components by weight:

[0031]

[0032] The preparation method of the grinding roller sealing ring material of the present embodiment comprises the following steps:

[0033] (1) Preparation of graphene composite material:

[0034] Under ultrasonic conditions, disperse 100 parts of graphene oxide powder in 150 parts of tetrahydrofuran by weight, after graphene oxide forms an amorphous suspension in tetrahydrofuran, add 100 parts of hydrogenated Styrene-butadiene-styrene system mixture, the weight ratio of hydrogenated styrene, butadiene and styrene in the mixture is 1:0.5:1.7;

[0035] After reacting for 1.5h, carry out vacuum distillation, remove the organic solvent and dry to obtain graphene / hydrogenated styrene-butadiene-styrene composite;

[0036] The graphene / hydrogenated styrene-butadiene-styrene composite was melt-blended at 220°C, and the in-situ reduction reaction wa...

Embodiment 2

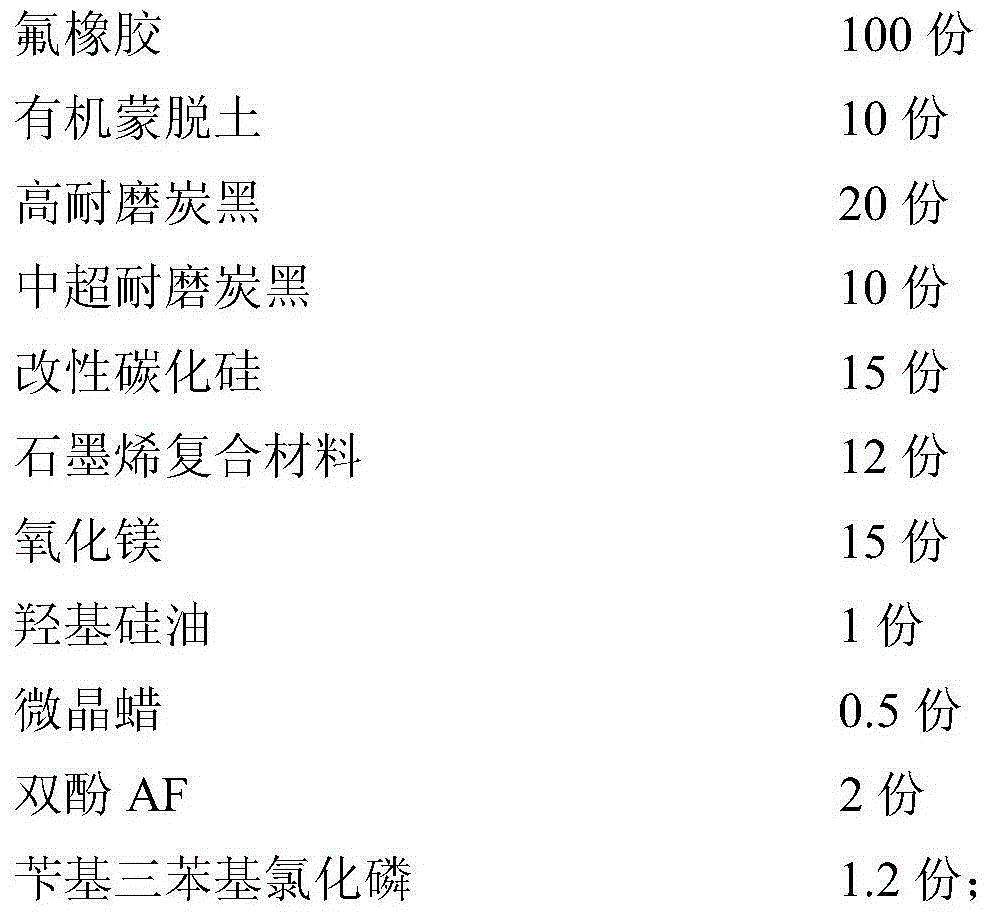

[0044] The grinding roller sealing ring material of the present embodiment comprises the following components by weight:

[0045]

[0046] The preparation method of the grinding roller sealing ring material of the present embodiment comprises the following steps:

[0047] (1) Preparation of graphene composite material:

[0048] Under ultrasonic conditions, disperse 100 parts of graphene oxide powder in 160 parts of tetrahydrofuran by weight, after graphene oxide forms an amorphous suspension in tetrahydrofuran, add 110 parts of hydrogenation powder to the above suspension under stirring conditions. Styrene-butadiene-styrene system mixture, the weight ratio of hydrogenated styrene, butadiene and styrene in the mixture is 1:0.8:1.7;

[0049] After reacting for 1.8h, carry out vacuum distillation, remove the organic solvent and dry to obtain graphene / hydrogenated styrene-butadiene-styrene composite;

[0050] The graphene / hydrogenated styrene-butadiene-styrene composite was m...

Embodiment 3

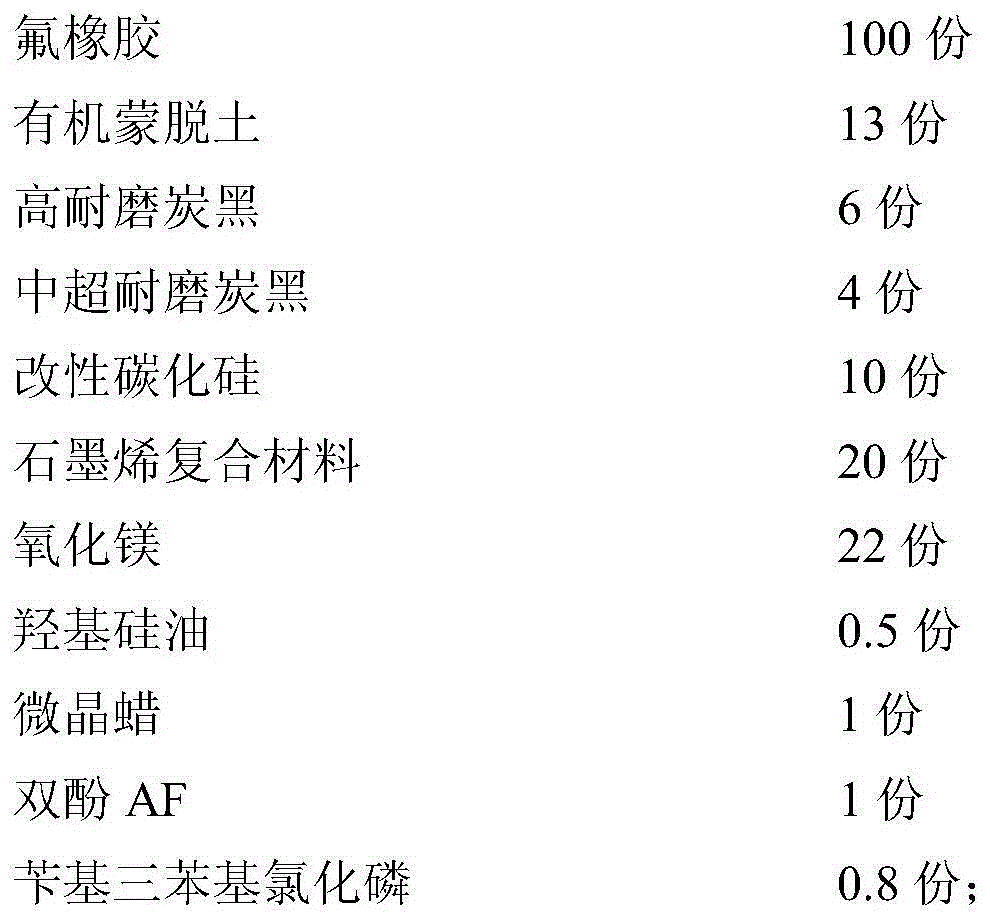

[0058] The grinding roller sealing ring material of the present embodiment comprises the following components by weight:

[0059]

[0060]

[0061] The preparation method of the grinding roller sealing ring material of the present embodiment comprises the following steps:

[0062] (1) Preparation of graphene composite material:

[0063] Under ultrasonic conditions, disperse 100 parts of graphene oxide powder in 180 parts of tetrahydrofuran by weight, after graphene oxide forms an amorphous suspension in tetrahydrofuran, add 120 parts of hydrogenated Styrene-butadiene-styrene system mixture, the weight ratio of hydrogenated styrene, butadiene and styrene in the mixture is 1:0.8:2;

[0064] After reacting for 2 hours, carry out vacuum distillation, remove the organic solvent and dry to obtain graphene / hydrogenated styrene-butadiene-styrene composite;

[0065] Melt and blend the graphene / hydrogenated styrene-butadiene-styrene composite at 230°C, perform an in-situ reducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com