Non-aqueous electrolyte battery

A non-aqueous electrolyte and battery technology, applied in the direction of non-aqueous electrolyte batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve insufficient problems, achieve low impedance, suppress voltage drop, and excellent pulse discharge characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

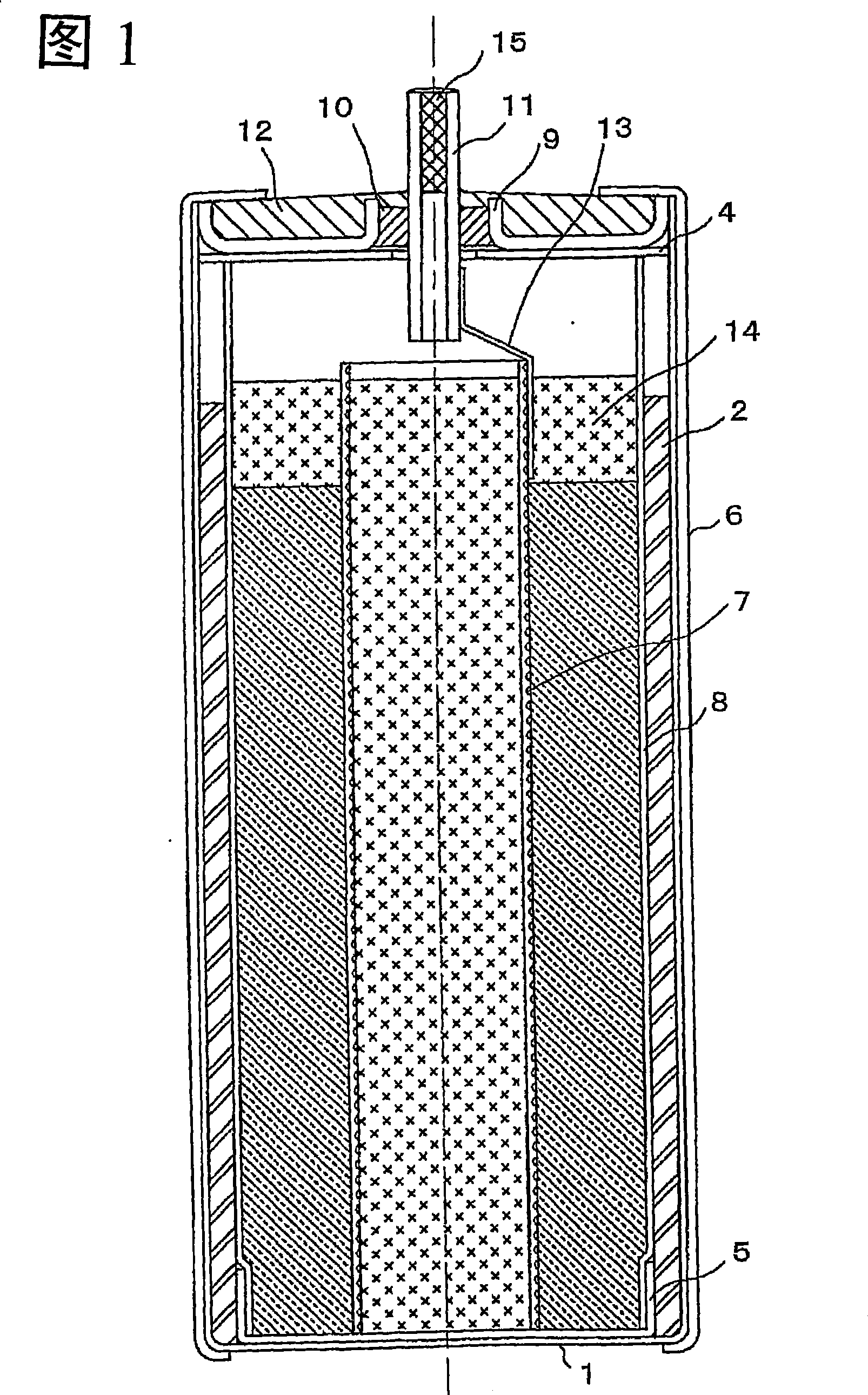

[0039] FIG. 1 shows cross-sectional views of batteries of Examples and Comparative Examples of the present invention. 1 is a cross-sectional view of an A-sized thionyl chloride-lithium battery using lithium as a negative electrode function material and thionyl chloride as a positive electrode function material.

[0040] In FIG. 1 , 1 is a stainless steel battery case with a diameter of 16 mm also serving as a negative electrode connector, and a cylindrical negative electrode 2 is pressed on the inner peripheral surface of the battery case. 3 is a porous carbon positive electrode body, which is formed as follows: 45% by mass of acetylene carbon black, 45% by mass of furnace black, 10% by mass of polytetrafluoroethylene and a mixed solution of water and ethanol are kneaded together, and the mixture is formed on a positive electrode assembly with a diameter of 10 mm and a height of 35 mm. The surroundings of the electrode 7 were vacuum-dried at 150° C. for 8 hours. The above-men...

Embodiment 2

[0046] A battery was produced in the same manner as in Example 1, except that a Li-Ga alloy containing 0.25 atomic % of Ga was used as the negative electrode.

Embodiment 3

[0059] A battery was fabricated in the same manner as in Example 1, except that a Li—Zn alloy containing 0.1 atomic % of Zn was used as the negative electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com