Combustion inhibitor and preparing method and flame-proof acrylic fibre using the same

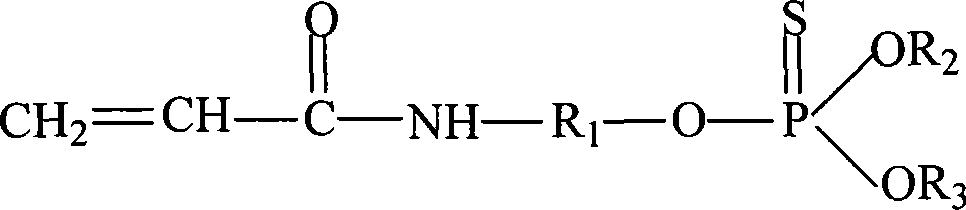

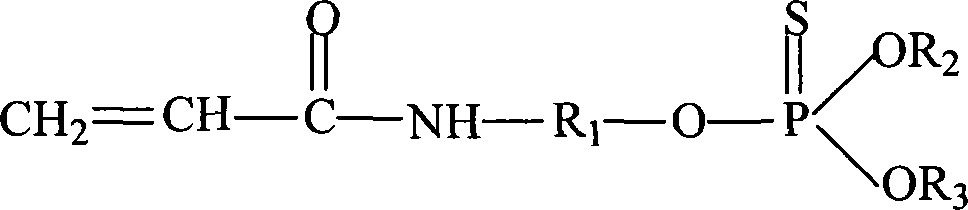

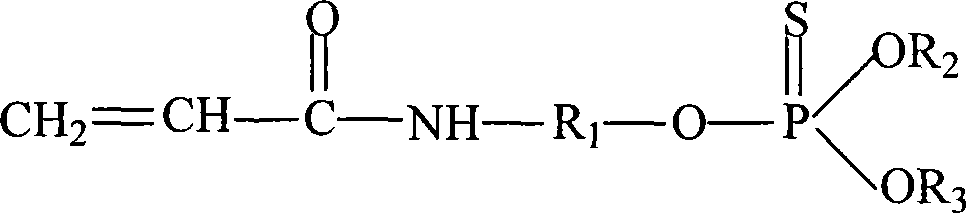

A technology of flame retardant, ethylacrylamide phosphorothioate, which is applied in the field of flame retardant acrylic fiber, can solve the problem of copolymer heat resistance, weather resistance, dyeability and dimensional stability, affect the use effect and popularize the application , application prospect constraints and other issues, to achieve the effect of easy industrial production, wide application range, and durable flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the flame-retardant acrylic fiber of the present invention is based on the mass percentage formula of the flame-retardant acrylic fiber of the present invention, and the following process is adopted: first, 1.6% to 2.4% of the amount of acrylonitrile is mixed with sodium bisulfite and 1% of the amount of acrylonitrile 3.7-6.8% sodium lauryl sulfate is put into distilled water which is 5-10 times of the total amount of sodium bisulfite and sodium lauryl sulfate, after dissolving, pour it into an autoclave washed with distilled water ; Mix and stir the four kinds of comonomers according to the proportion of the formula of the present invention, and then pour them into the reactor; In the reaction kettle; feed nitrogen to drive off the air in the reaction kettle, close the reaction kettle; start the stirring device to stir for 5-10 minutes, and react at a temperature of 40-65°C for 0.5-1 hour, then stop the reaction; move the reaction product into ...

Embodiment 1

[0043] Synthetic flame retardant.

[0044] Dissolve the newly distilled 0.5mol N-methylolacrylamide in 250ml of dry ether and pour it into a 500ml four-neck reaction flask equipped with a constant pressure dropping funnel, a reflux condenser and a magnetic stirrer, and Add 0.52 mol of distilled triethylamine, start the magnetic stirrer, keep the reaction temperature at 0°C, then drop 0.5 mol of distilled O, O-dimethylphosphorous thio into the reaction flask through the constant pressure dropping funnel Acyl chloride, control the drop within 6h; then stop the reaction after reacting at room temperature for 48h, filter to remove triethylamine hydrochloride, wash the filtrate with 5% aqueous sodium hydroxide solution, then wash with distilled water, and distill off ether and water, and then dried with anhydrous magnesium sulfate, the O, O-dimethyl-O-methacrylamido phosphorothioate can be obtained; the yield is 85%.

Embodiment 2

[0046] Synthetic flame retardant.

[0047] The N-methylolacrylamide in Example 1 is replaced by N-Hydroxyethylacrylamide, the synthesis process is the same as in Example 1, and O, O-dimethyl-O-ethylacrylamide sulfur can be obtained Phosphate generation; yield 83.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com