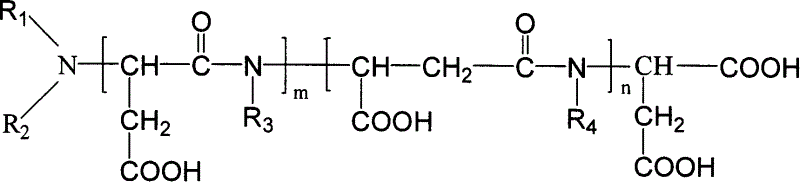

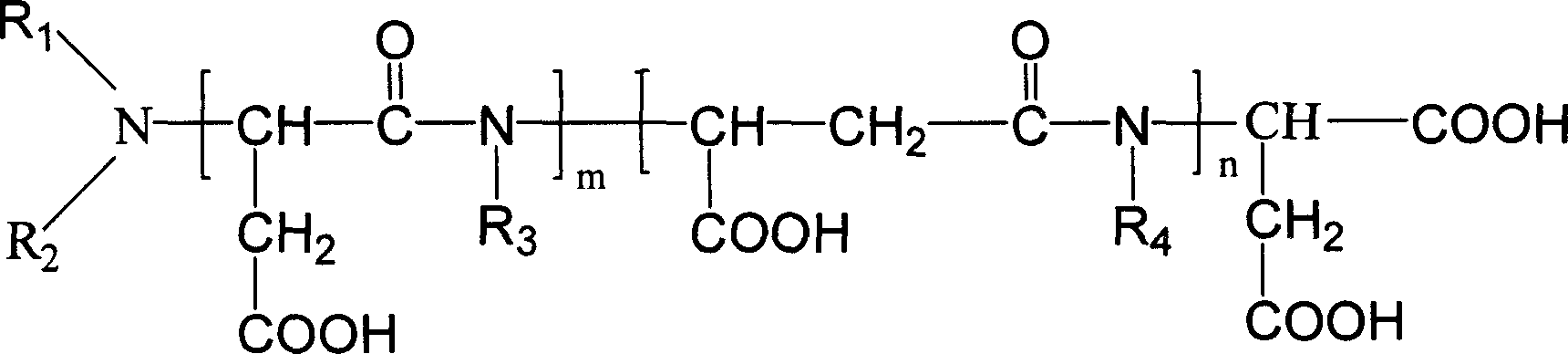

Asparagic acid possessing phosphinic group, its preparation method and uses in water processing

A technology of phosphonic acid-based polyaspartic acid and polyaspartic acid, applied in water/sludge/sewage treatment, chemical instruments and methods, descaling and water softening, etc., can solve polyaspartic acid scaling and poor performance of stable zinc salt, to achieve great economic and social benefits, good synergistic effect, and simple synthetic route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Add polyaspartic acid (produced by Changmao Biochemical Engineering Co., Ltd., content: 40%, molecular weight: 4000-5000) in a four-necked flask equipped with a stirrer, reflux condenser, constant pressure dropping funnel and thermometer 91.6g and 157ml of water, start stirring to fully dissolve polyaspartic acid. At room temperature (20°C), 26.6 g of aqueous formaldehyde solution was added (the active ingredient was 36%). A cold water bath was used to control the reaction temperature below 50°C, and 45.2 g of phosphorus trichloride (the effective ingredient was 97%) was added dropwise. After the dropwise addition of phosphorus trichloride is completed, the temperature is raised to 70±2°C and the temperature is kept for 2 hours, and the product is cooled down. The organic phosphine content of the product is 8.2%.

Embodiment 2

[0052] Add polyaspartic acid (produced by Changmao Biochemical Engineering Co., Ltd., content: 40%, molecular weight: 4000-5000) in a four-necked flask equipped with a stirrer, reflux condenser, constant pressure dropping funnel and thermometer 91.6g and 157ml of water, start stirring to fully dissolve polyaspartic acid. At room temperature (20°C), 26.6 g of aqueous formaldehyde solution was added (the active ingredient was 36%). A cold water bath was used to control the reaction temperature below 50°C, and 45.2 g of phosphorus trichloride (the effective ingredient was 97%) was added dropwise. After the dropwise addition of phosphorus trichloride is completed, the temperature is raised to 105±2°C and the temperature is kept for 2 hours, and the product is cooled down. The organic phosphine content of the product is 7.3%.

Embodiment 3

[0054] Add polyaspartic acid (produced by Changmao Biochemical Engineering Co., Ltd., content: 40%, molecular weight: 4000-5000) in a four-necked flask equipped with a stirrer, reflux condenser, constant pressure dropping funnel and thermometer 91.6g and 157ml of water, start stirring to fully dissolve polyaspartic acid. At room temperature (20°C), 26.6 g of aqueous formaldehyde solution was added (the active ingredient was 36%). A cold water bath was used to control the reaction temperature below 50°C, and 45.2 g of phosphorus trichloride (the effective ingredient was 97%) was added dropwise. After the dropwise addition of phosphorus trichloride is completed, the temperature is increased to 90±2° C. and the temperature is kept for 4 hours, and then cooled to obtain the product. The organic phosphine content of the product is 9.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com