Manganese-based denitration catalyst containing tourmaline and preparation method of manganese-based denitration catalyst

The technology of denitration catalyst and tourmaline is applied in the field of low temperature flue gas denitration, which can solve the problems of large specific surface area, low sulfur resistance and water resistance, and achieves simple preparation process, reduced catalyst cost, and high resistance to SO2 and H2O poisoning performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

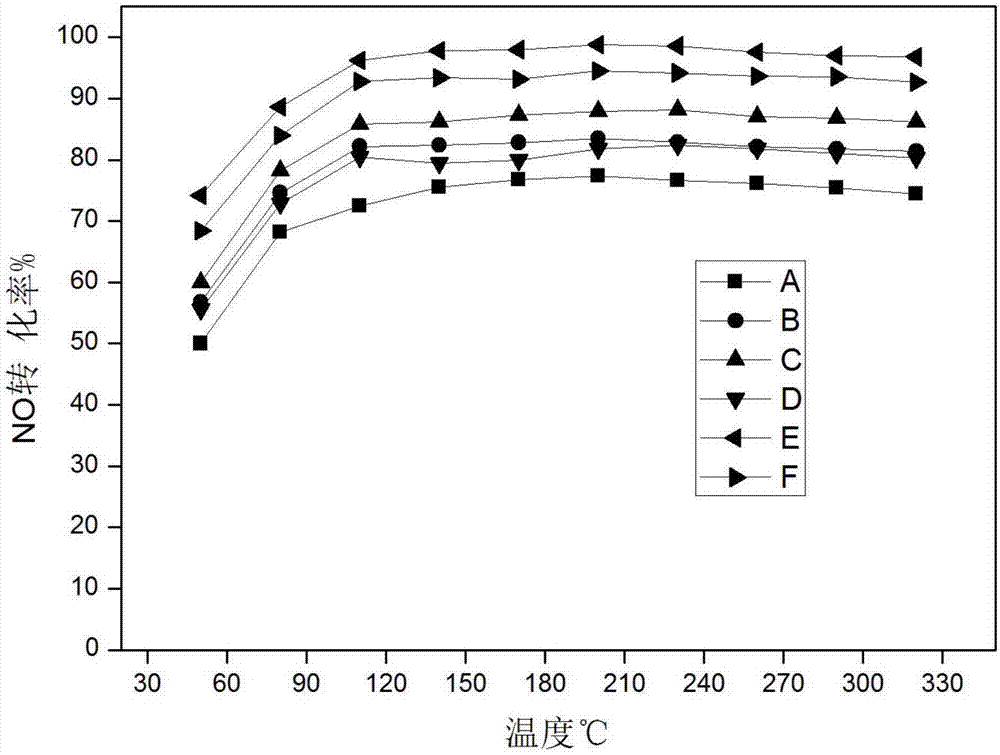

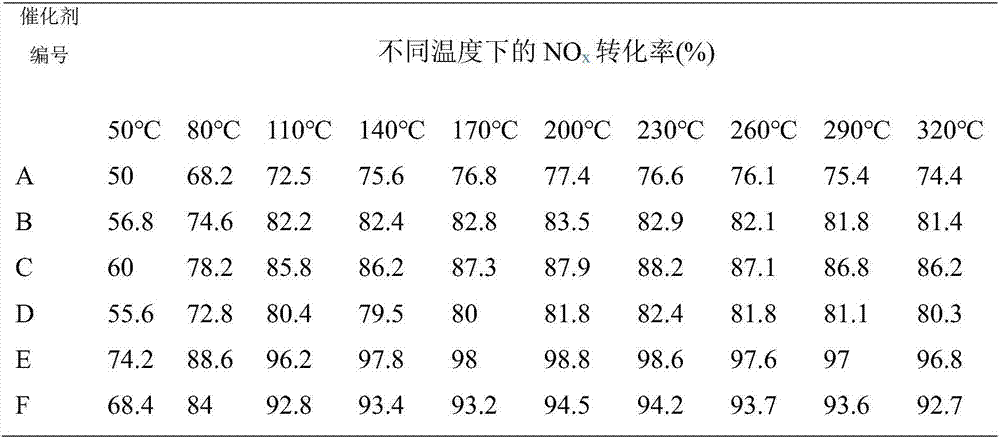

Embodiment 1

[0034]Manganese acetate (Mn(CH 3 COO) 2 4H 2 O) 2.451g and cobalt nitrate (Co(NO 3 ) 2 ·6H 2 (O) 2.911g is dissolved in 25ml deionized water to obtain a mixed solution, the mol ratio of Mn and Co is 1:1, the molar concentration of manganese acetate is 0.4mol / L, and the molar concentration of cobalt nitrate is 0.4mol / L, at room temperature Magnetically stir for 2 hours to mix the solution evenly, then drop the mixed salt solution into the beaker with 10g of dry KIT-6 (after testing, the saturated water absorption of 10g carrier is 25ml) while stirring the mixed solution, so that the manganese element The loading amount of cobalt element is 5.5%, and the loading amount of cobalt element is 5.9%. Place the beaker in an ultrasonic generator and ultrasonically impregnate it for 2 hours until the mixed salt solution is completely impregnated into the carrier, place the impregnated sample in a drying oven at 105°C for 12 hours, and finally pass through a muffle furnace in the T...

Embodiment 2

[0036] Dissolve 2.451g of manganese acetate, 2.911g of cobalt nitrate and 0.032g of tourmaline in 25ml of deionized water to obtain a mixed solution, so that the loading capacity of tourmaline is 0.32%, magnetically stir at room temperature for 2h to make the solution evenly mixed, while stirring Drop the mixed salt solution into a beaker with 10g of dry KIT-6, place the beaker in an ultrasonic generator, and ultrasonically impregnate for 2 hours until the mixed salt solution is completely impregnated into the carrier, and place the impregnated sample in an oven. The catalyst was obtained by drying in a dry box at 105°C for 12 hours, and finally calcining and activating at 500°C in air for 5 hours in a muffle furnace. The prepared catalyst was ground and sieved, and the particle size was 40-60 mesh for later use to prepare catalyst B.

Embodiment 3

[0038] Dissolve 2.451g of manganese acetate, 2.911g of cobalt nitrate and 0.064g of tourmaline in 25ml of deionized water to obtain a mixed solution, so that the loading capacity of tourmaline is 0.64%, stir magnetically at room temperature for 2 hours to mix the solution evenly, and mix the solution while stirring. Drop the mixed salt solution into a beaker with 10g of dry KIT-6, place the beaker in an ultrasonic generator, and ultrasonically immerse it for 2 hours until the mixed salt solution is completely impregnated into the carrier, and place the beaker in an ultrasonic generator , ultrasonically impregnated for 2 h, placed the impregnated sample in a drying oven at 105 °C for 12 h, and finally activated the catalyst by calcining in a muffle furnace at 500 °C for 5 h in air. The prepared catalyst was ground and sieved, and the particle size was 40-60 mesh for later use to obtain catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com