Catalyst of mixed conductor film reactor for hydrogen production from coke oven gas and preparation method thereof

A technology of mixed conductor film and coke oven gas, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of lack of scale and economy , to achieve the effect of low product cost, excellent CH4 conversion rate and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

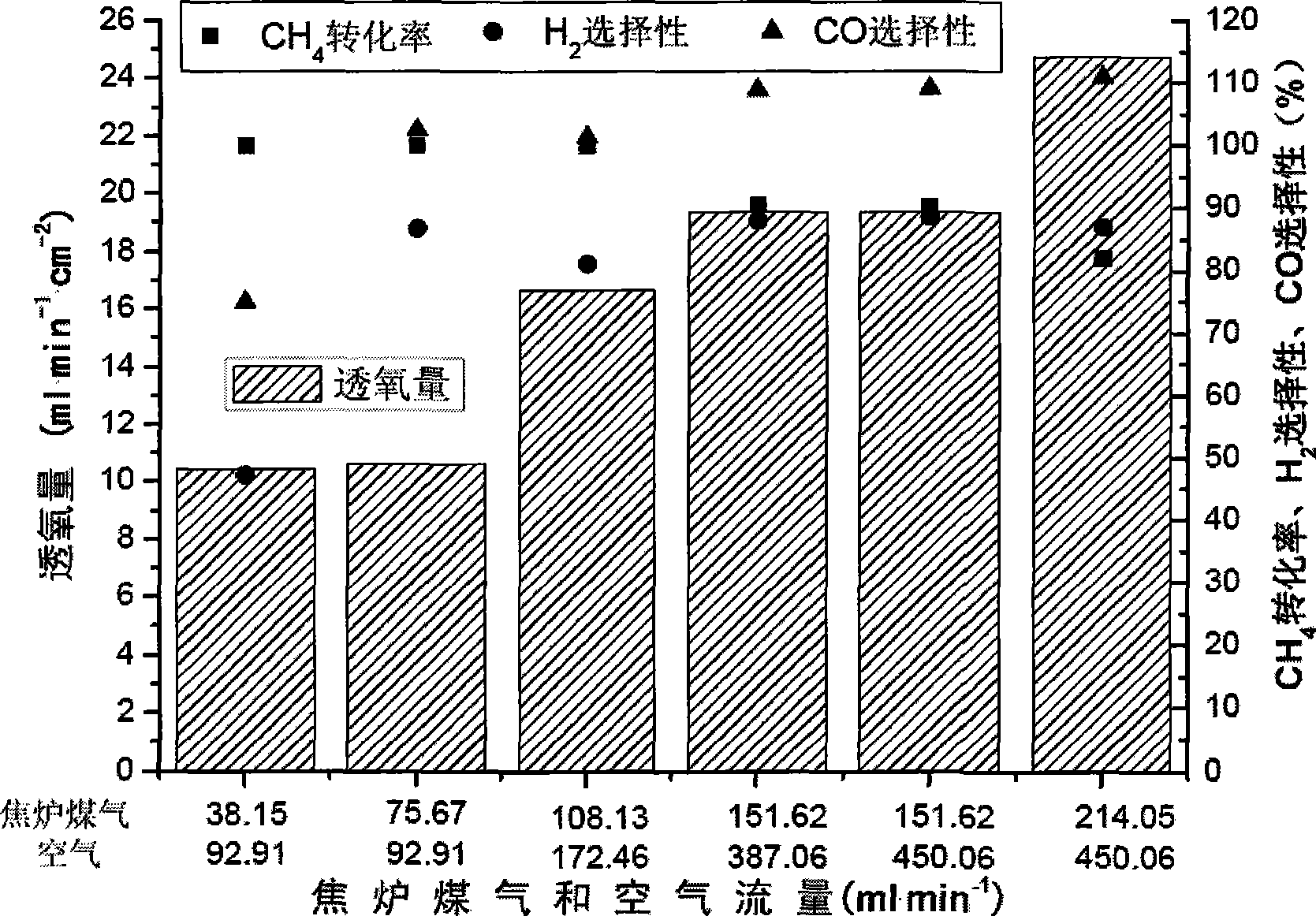

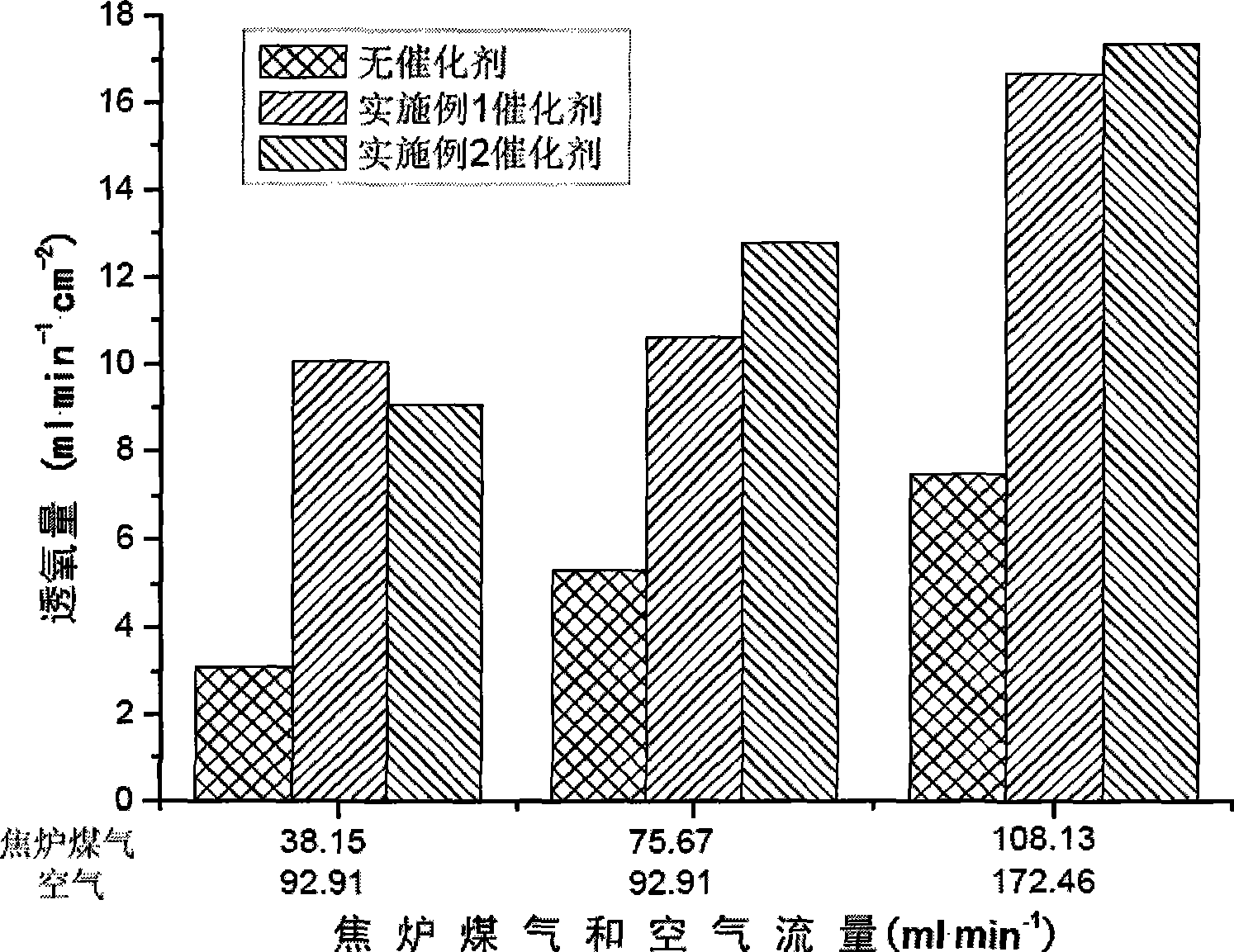

[0026] Take 2.9915g Ni(NO 3 ) 2 ·6H 2 O, 2.7086g Ce(NO 3 ) 3 ·6H 2 O and 0.1549g LiNO 3 Make a solution with deionized water. 5 g of gamma alumina support was added to the solution, stirred thoroughly and impregnated for 24 hours, stirring once an hour during this period. The impregnated catalyst was dried at 100° C. for 15 hours in a blast drying oven. The dried raw materials were placed in a muffle furnace and calcined at 800 °C for 8 hours in an air atmosphere. Sieve the sintered particles to obtain particles with a diameter of 0.6-0.9 mm, which is the desired catalyst. The catalyst is Ni-Li 2 O-CeO 2 / γAl 2 o 3 , where Ni, Li 2 O and CeO 2 The weight percentages are 9%, 0.5% and 16%. The effect of the catalyst obtained in this example as a mixed conductor membrane reactor catalyst for hydrogen production from coke oven gas can be seen in figure 1 .

Embodiment 2

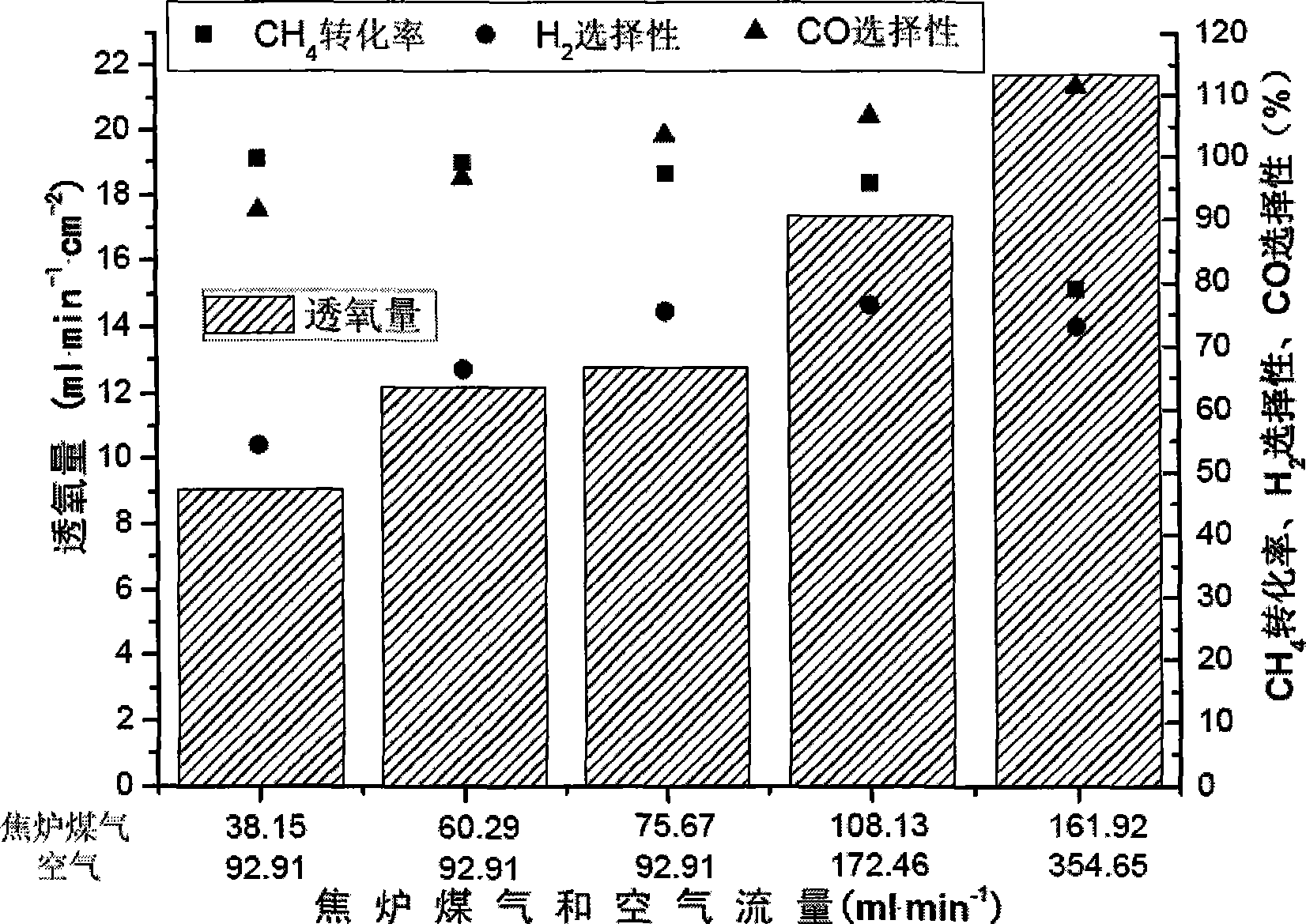

[0028] Take 2.9723g Ni(NO 3 ) 2 ·6H 2 O, 0.1482g LiNO 3 , 1.2109g Ce(NO 3 ) 3 ·6H 2 O and 0.1481gZr(NO 3 ) 4 ·5H 2 O was made into a solution with deionized water. 5 g of gamma alumina support was added to the solution, stirred thoroughly and impregnated for 24 hours, stirring once an hour during this period. The impregnated catalyst was dried at 100° C. for 15 hours in a blast drying oven. The dried raw materials were placed in a muffle furnace and calcined at 800 °C for 8 hours in an air atmosphere. Sieve the sintered particles to obtain particles with a diameter of 0.6-0.9 mm, which is the desired catalyst. The catalyst is Ni-Li 2 O-ZrO 2 -CeO 2 / γAl 2 o 3 , where Ni, Li 2 O, ZrO 2 and CeO 2 The weight percentages are 10%, 0.5%, 2% and 8%. The effect of the catalyst obtained in this example as a mixed conductor membrane reactor catalyst for hydrogen production from coke oven gas can be seen in figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com