Natural gas automobile tail gas purification catalyst and preparation method thereof

A technology for purifying catalysts and automobile exhaust gas, which is applied in the directions of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of increasing production costs, ammonia emissions, etc., and achieves a reduction in content, a concise preparation method, and economical The effect of preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

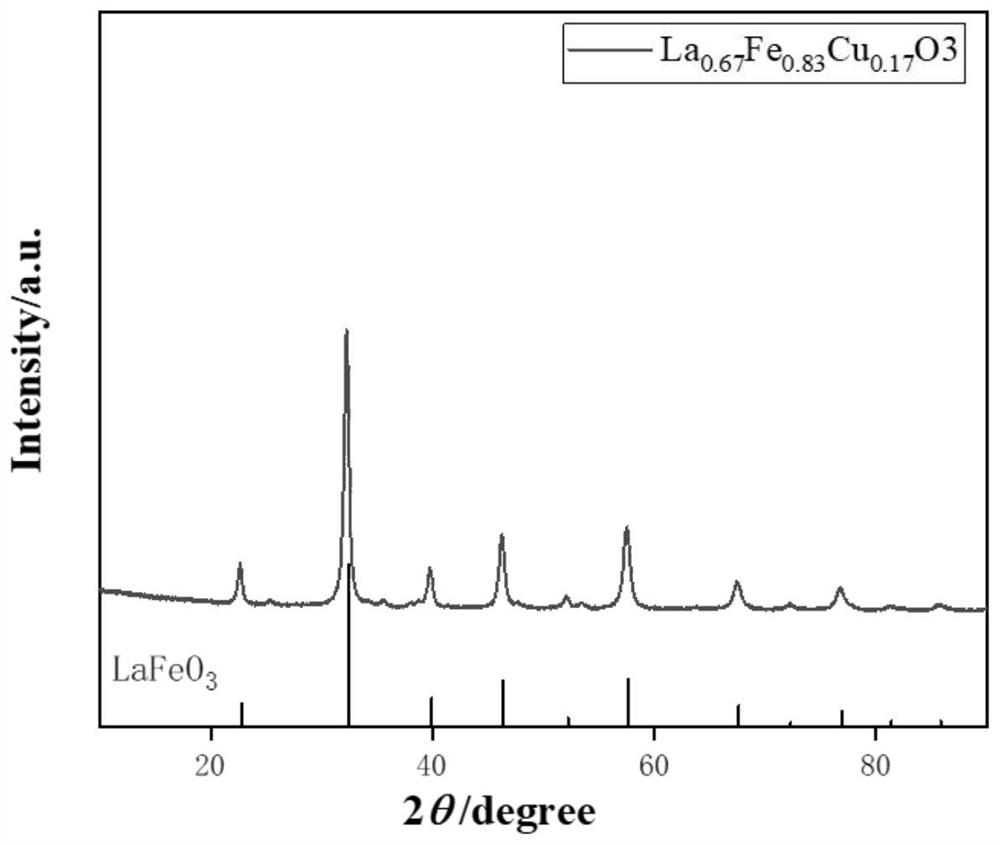

[0025] La 0.67 Fe 0.83 Cu 0.17 o 3 Preparation of perovskite:

[0026] (1) Weigh 29.012g (La(NO 3 ) 3 ·6H 2 O, 33.532g Fe(NO 3 )3 9H 2 O, 4.107Cu(NO 3 ) 2 2H 2 O was fully dissolved with 60ml deionized water.

[0027] (2) The solution obtained in step (1) was added into equimolar mass of citric acid, heated and stirred to dissolve, then stirred in a water bath at 98° C. for 12 h until the water was evaporated to dryness.

[0028] (3) The sample obtained in step (2) was calcined in a muffle furnace at 200°C for 1 h, and then calcined at 600°C for 8 h to obtain the perovskite compound La 0.67 Fe 0.83 Cu 0.17 o 3 .

[0029] Pd / Al 2 o 3 Preparation of materials:

[0030] (4) Properly dilute palladium nitrate solution (1.5wt% Pd), impregnate Al 2 o 3 powder, dried, and calcined at 550°C for 3h in a muffle furnace to obtain Pd / Al 2 o 3 powder catalyst.

[0031] Preparation of Monolithic Catalyst:

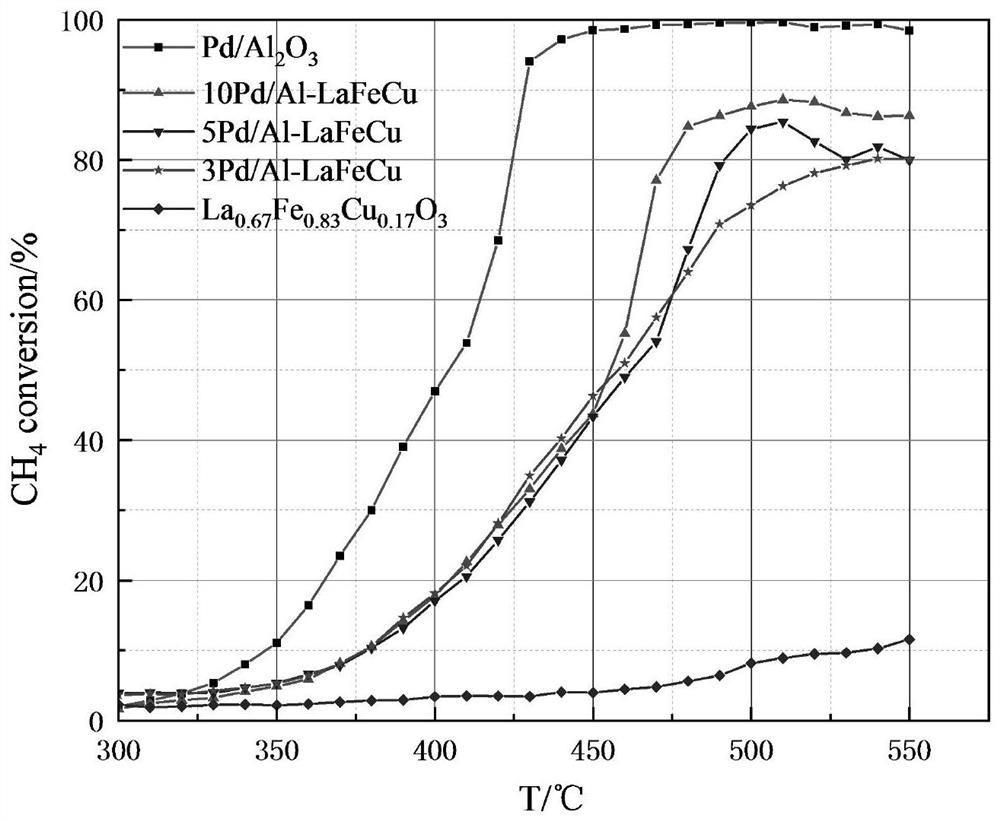

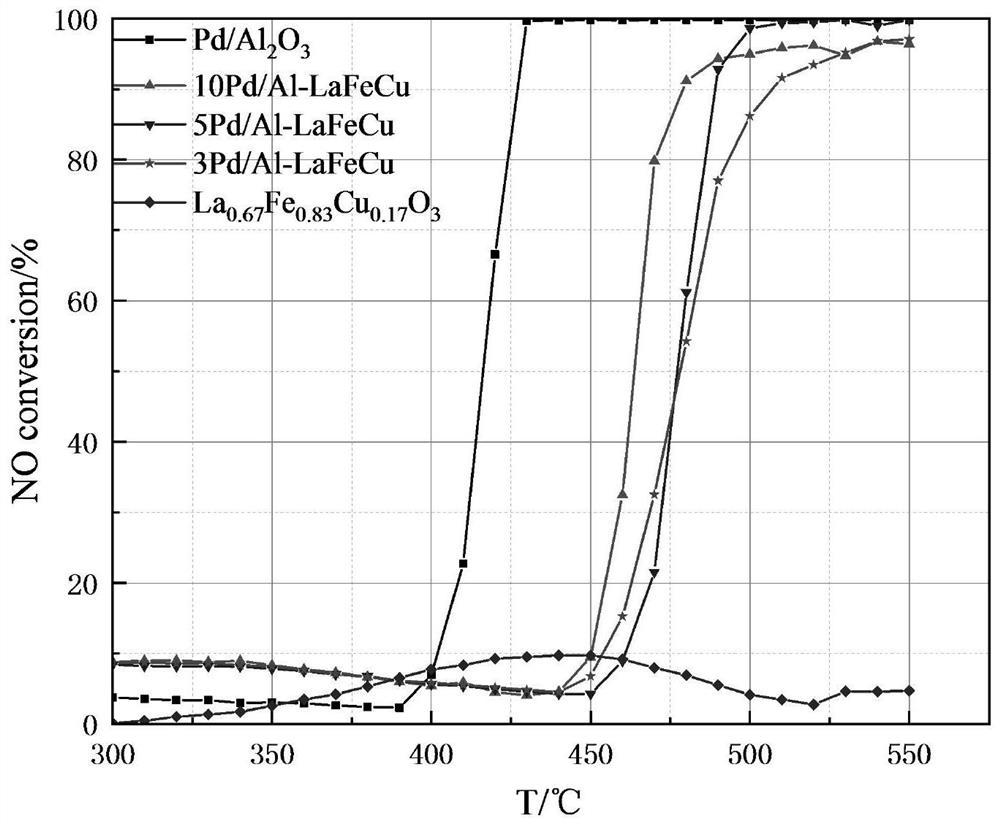

[0032] La 0.67 Fe 0.83 Cu 0.17 o 3 Powder and Pd / Al 2 o...

Embodiment 2

[0034] La prepared in the same steps as in Example 1 0.67 Fe 0.83 Cu 0.17 o 3 Perovskite and Pd / Al 2 o 3 Material.

[0035] Preparation of Monolithic Catalyst:

[0036] La 0.67 Fe 0.83 Cu 0.17 o 3 Powder and Pd / Al 2 o 3 The catalyst is mixed at a mass ratio of 5:1, and mixed with deionized water and binder to make a slurry, and the solid content of the slurry is controlled at 40%-45%, and evenly coated on Φ11mm*25mm / 400cpsi cordierite ceramic honeycomb On the substrate, control the loading amount of Pd to 1.7g / L, dry at 120°C for 8h, and bake in a muffle furnace at 550°C for 3h to obtain 5Pd / Al 2 o 3 -La 0.67 Fe 0.83 Cu 0.17 o 3 monolithic catalyst.

Embodiment 3

[0038] La prepared in the same steps as in Example 1 0.67 Fe 0.83 Cu 0.17 o 3 Perovskite and Pd / Al 2 o 3 Material.

[0039] Preparation of Monolithic Catalyst:

[0040] La 0.67 Fe 0.83 Cu 0.17 o 3 Powder and Pd / Al 2 o 3 The catalyst is mixed at a mass ratio of 3:1, and mixed with deionized water and binder to make a slurry, and the solid content of the slurry is controlled at 40%-45%, and evenly coated on Φ11mm*25mm / 400cpsi cordierite ceramic honeycomb On the substrate, control the loading amount of Pd to 1.7g / L, dry at 120°C for 8h, and bake in a muffle furnace at 550°C for 3h to obtain 3Pd / Al 2 o 3 -La 0.67 Fe 0.83 Cu 0.17 o 3 monolithic catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com