Catalyst for purifying natural gas vehicle exhaust and preparation method thereof

A technology for purifying catalysts and automobile exhaust, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of increased production costs, ammonia emissions, etc., to achieve reduced content, simple and economical preparation methods The effect of preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

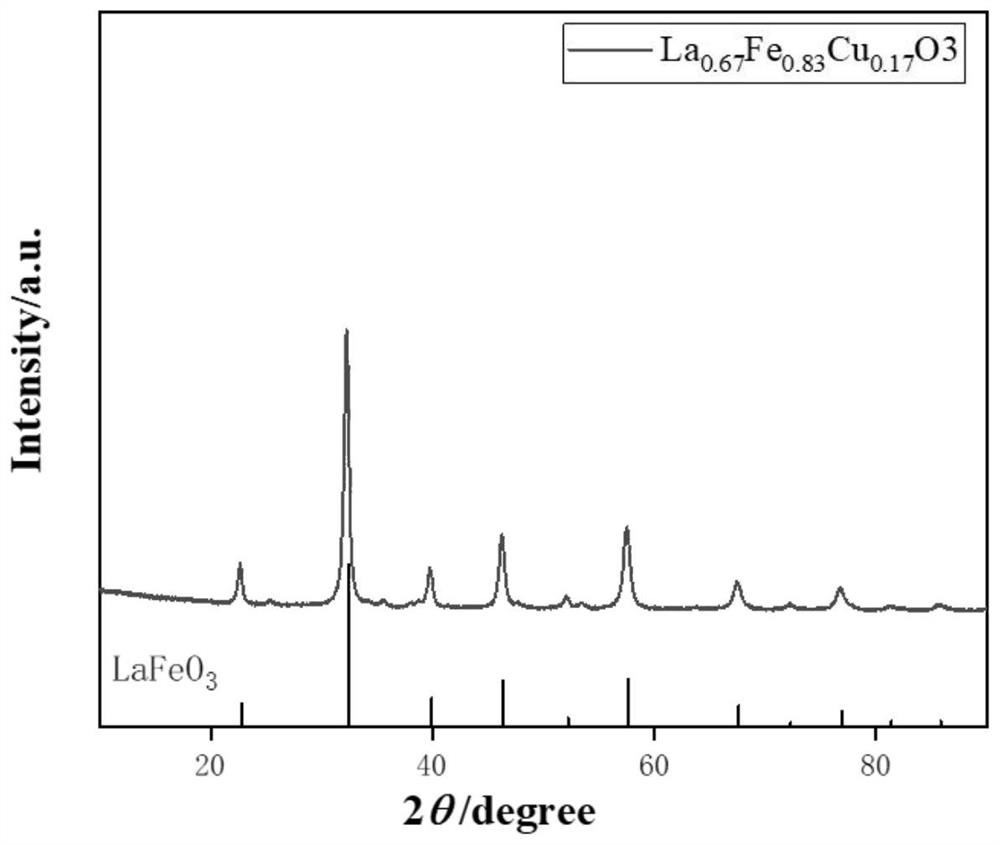

[0025] La 0.67 Fe 0.83 Cu 0.17 o 3 Preparation of perovskite:

[0026] (1) Weigh 29.012g (La(NO 3 ) 3 ·6H 2 O, 33.532g Fe(NO 3 )3 9H 2 O, 4.107Cu(NO 3 ) 2 2H 2 O was fully dissolved with 60ml deionized water.

[0027] (2) The solution obtained in step (1) was added into equimolar mass of citric acid, heated and stirred to dissolve, then stirred in a water bath at 98° C. for 12 h until the water was evaporated to dryness.

[0028] (3) The sample obtained in step (2) was calcined in a muffle furnace at 200°C for 1 h, and then calcined at 600°C for 8 h to obtain the perovskite compound La 0.67 Fe 0.83 Cu 0.17 o 3 .

[0029] Pd / Al 2 o 3 Preparation of materials:

[0030] (4) Properly dilute palladium nitrate solution (1.5wt% Pd), impregnate Al 2 o 3 powder, dried, and calcined at 550°C for 3h in a muffle furnace to obtain Pd / Al 2 o 3 powder catalyst.

[0031] Preparation of Monolithic Catalyst:

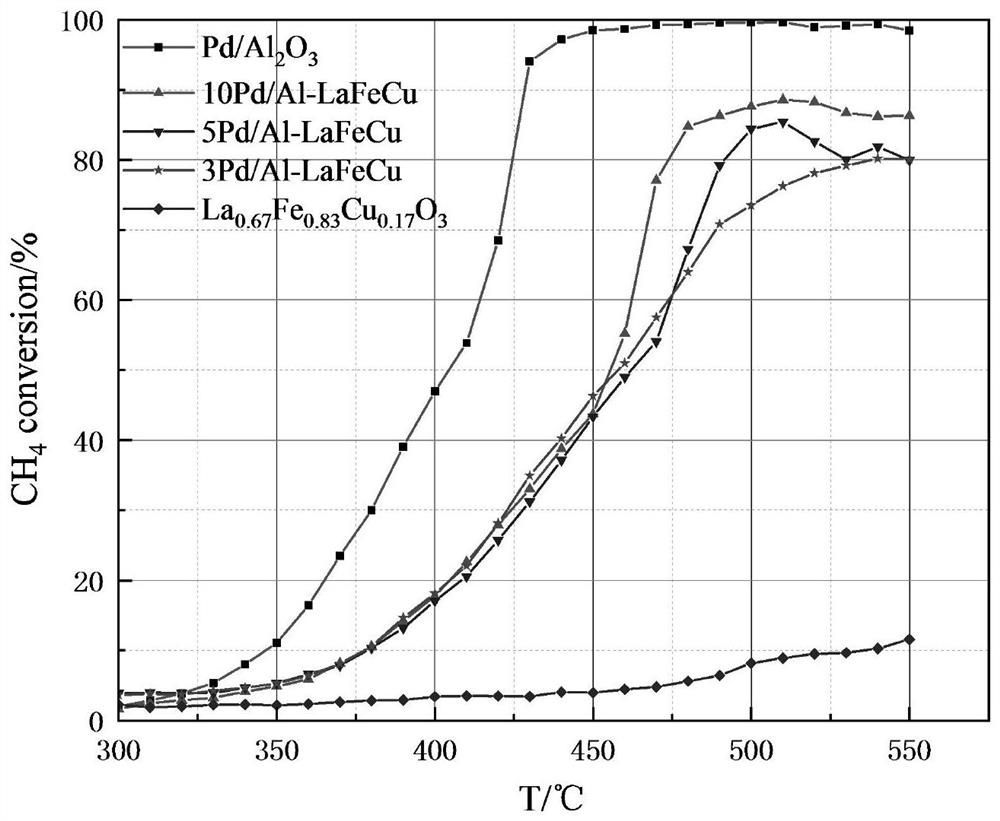

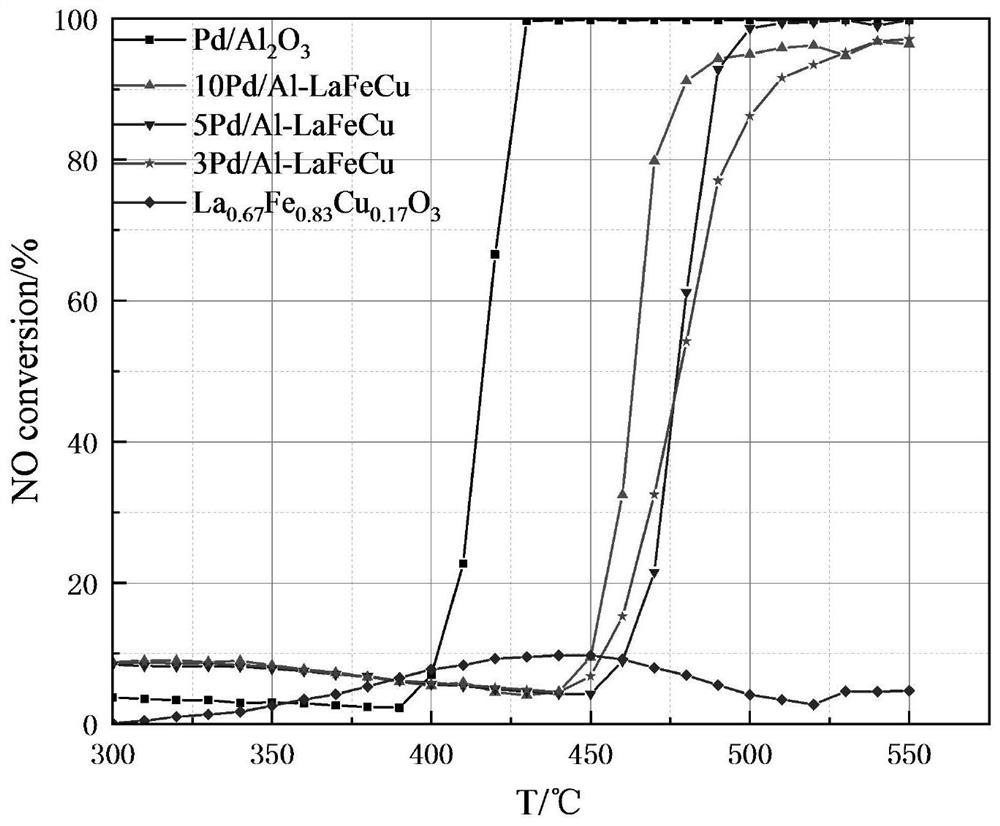

[0032] La 0.67 Fe 0.83 Cu 0.17 o 3 Powder and Pd / Al 2 o...

Embodiment 2

[0034] La prepared in the same steps as in Example 1 0.67 Fe 0.83 Cu 0.17 o 3 Perovskite and Pd / Al 2 o 3 Material.

[0035] Preparation of Monolithic Catalyst:

[0036] La 0.67 Fe 0.83 Cu 0.17 o 3 Powder and Pd / Al 2 o 3 The catalyst is mixed at a mass ratio of 5:1, and mixed with deionized water and binder to make a slurry, and the solid content of the slurry is controlled at 40%-45%, and evenly coated on Φ11mm*25mm / 400cpsi cordierite ceramic honeycomb On the substrate, control the loading amount of Pd to 1.7g / L, dry at 120°C for 8h, and bake in a muffle furnace at 550°C for 3h to obtain 5Pd / Al 2 o 3 -La 0.67 Fe 0.83 Cu 0.17 o 3 monolithic catalyst.

Embodiment 3

[0038] La prepared in the same steps as in Example 1 0.67 Fe 0.83 Cu 0.17 o 3 Perovskite and Pd / Al 2 o 3 Material.

[0039] Preparation of Monolithic Catalyst:

[0040] La 0.67 Fe 0.83 Cu 0.17 o 3 Powder and Pd / Al 2 o 3 The catalyst is mixed at a mass ratio of 3:1, and mixed with deionized water and binder to make a slurry, and the solid content of the slurry is controlled at 40%-45%, and evenly coated on Φ11mm*25mm / 400cpsi cordierite ceramic honeycomb On the substrate, control the loading amount of Pd to 1.7g / L, dry at 120°C for 8h, and bake in a muffle furnace at 550°C for 3h to obtain 3Pd / Al 2 o 3 -La 0.67 Fe 0.83 Cu 0.17 o 3 monolithic catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com