Preparation method of modified graphene oxide and preparation method of composite material containing modified graphene oxide

A technology of composite materials and stone oxide, which is applied in the preparation of composite materials and the preparation of modified graphene oxide, can solve the problems of uneven dispersion and affecting the flame retardancy of composite materials, and achieve uniform dispersion and good flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a preparation method of modified graphene oxide, comprising the following steps:

[0038] a) phosphorous oxychloride compound, cyanuric chloride or diisocyanate react with glycidol to obtain an intermediate product;

[0039] b) dispersing graphite oxide in an organic solvent, adding dropwise to the intermediate product, and obtaining modified graphene oxide after the reaction.

[0040] N and P are flame retardant elements. Adding N and / or P to the polymer can improve the flame retardant performance of the polymer. Therefore, after modifying graphene oxide with N and / or P, the resistance of graphene oxide can be improved. The flame retardancy of the polymer can also be improved after the modified graphene oxide is blended into the polymer. However, when the modified graphene oxide is added to the polymer by blending, the flame retardant performance of the polymer is limited due to uneven dispersion. Therefore, the inventors used a compound contain...

Embodiment 1

[0085] Add 46mL of concentrated sulfuric acid and 1g of sodium nitrate to a 250mL three-neck flask equipped with a mechanical stirrer, reflux condenser, constant pressure dropping funnel, and nitrogen inlet, and mix evenly under pressure, then add 2g of expandable graphite with a particle size of 325 mesh , Stir the reaction in an ice bath for 15 minutes, keep the temperature of the reaction solution below 5°C, slowly add 15g of potassium permanganate within 10 minutes, keep the temperature of the reaction solution below 10°C during the addition of potassium permanganate, and finish adding the potassium permanganate dropwise Finally, react in an ice bath for 30 minutes, then transfer to an oil bath, the temperature of the oil bath is 35°C, and react for 1 hour, then add 92 mL of deionized water dropwise to the reaction solution, and raise the temperature of the reaction solution to 98°C, and react for 15 minutes. , pour the obtained reaction solution into a beaker, dilute with ...

Embodiment 2

[0089] Add 6.33g (0.03mol) of phenyl phosphate dichloride and 6.06g (0.06mol) of trichloride into a 250mL three-necked flask equipped with a mechanical stirrer, a reflux condenser, a constant pressure dropping funnel, and a nitrogen inlet under stirring in an ice bath. Ethylamine; 3.48g (0.03mol) glycidol was dissolved in 20mL acetone, and slowly added dropwise to a three-necked flask within 2 hours, and after 4 hours of reaction, glycidyl alcohol-chlorinated phenyl phosphate was obtained; 0.5g was implemented The graphite oxide prepared in Example 1 was dispersed in 100 mL of acetone. After ultrasonication for 1 h, it was added dropwise to the glycidyl alcohol-chlorinated phenyl phosphate through a constant pressure dropping funnel within 1 h, stirred at room temperature for 12 h, and the obtained reaction Liquid was filtered, and the filter cake was washed three times with deionized water to obtain a yellow-brown product.

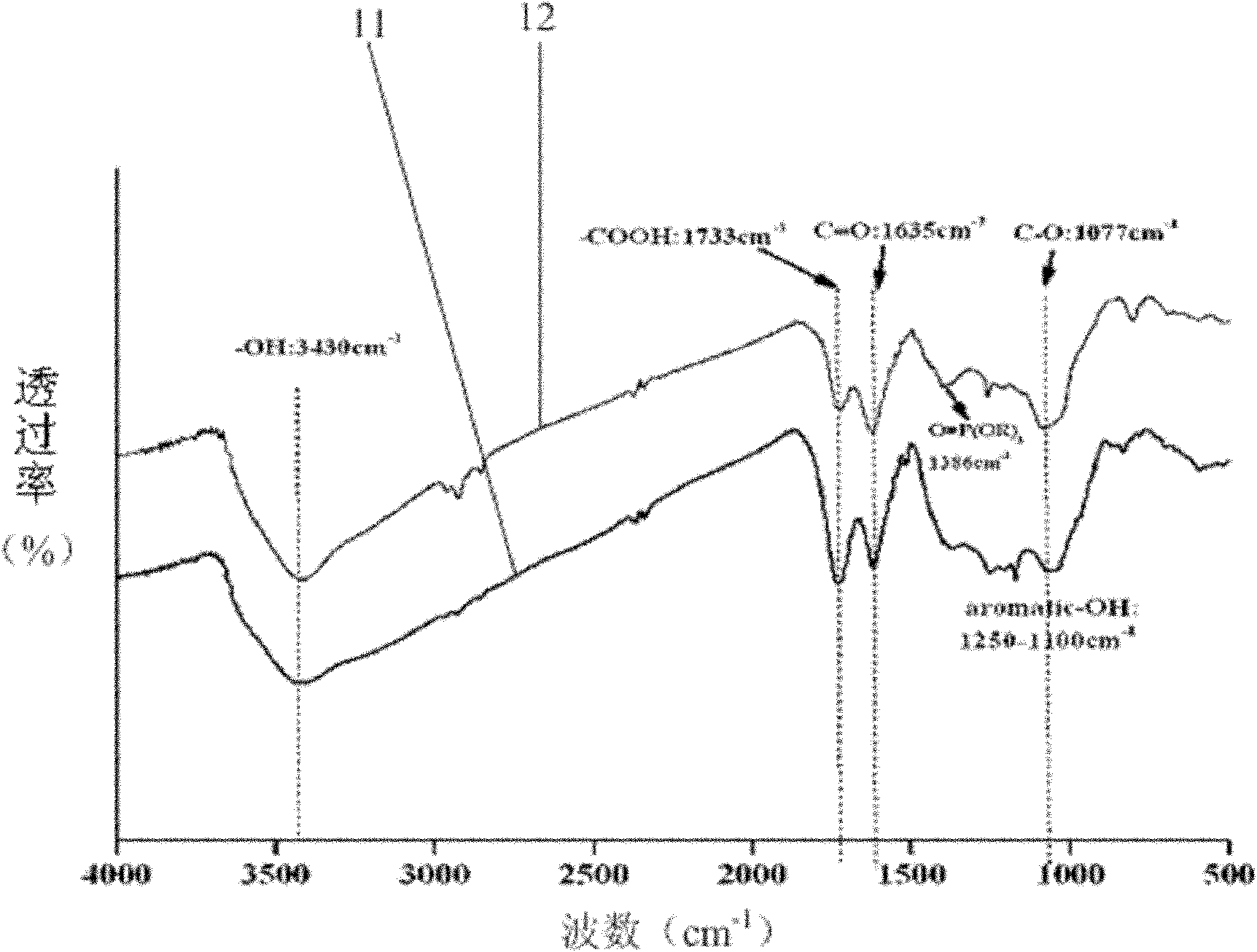

[0090] Infrared analysis is carried out to describe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com