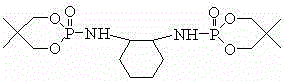

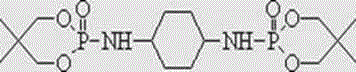

Phosphorus-nitrogen intumescent flame retardant and preparation method thereof

A technology of intumescent flame retardants and flame retardants, applied in the field of phosphorus-nitrogen-containing flame retardants and their synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

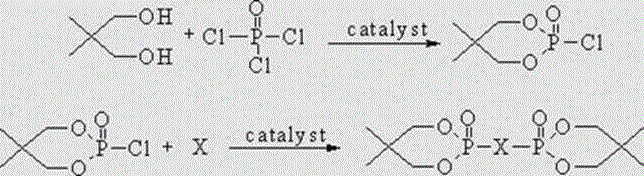

Method used

Image

Examples

Embodiment 1

[0030] Add 83.2g of neopentyl glycol and 500mL of chloroform in a 2000mL four-necked bottle equipped with a reflux condenser, a thermometer, an agitator, and a constant pressure dropping funnel, then add 8g of anhydrous aluminum trichloride, stir fully to dissolve the raw materials, and then Put the four-necked flask into an ice-water bath, and slowly add 128.8 g of phosphorus oxychloride into the four-necked flask through a constant pressure dropping funnel under the condition of stirring at 5°C. The reaction temperature is controlled at 0-10°C. The time was 2 hours. After the phosphorus oxychloride was added dropwise, the temperature was raised to 50° C., and the reaction was carried out at this temperature for 6 hours. After the reaction was over, the solvent was recovered by distillation under reduced pressure, the residual solid was washed twice with deionized water, and dried in vacuum at 60° C. for 10 hours to obtain 137.9 g of cyclic phosphorus oxychloride, 2-chloro-2-o...

Embodiment 2

[0035]Add 83.2g of neopentyl glycol and 500mL of chloroform into a 2000mL four-necked bottle equipped with a reflux condenser, a thermometer, an agitator, and a constant pressure dropping funnel, then add 8g of anhydrous magnesium chloride, stir fully to dissolve the raw materials, and then put the four-necked Put the bottle in an ice-water bath, and slowly add 128.8g of phosphorus oxychloride into the four-necked flask through a constant pressure dropping funnel under the condition of stirring at 5°C. The reaction temperature is controlled at 0-10°C, and the dropping time is 2h. , After the phosphorus oxychloride was added dropwise, the temperature was raised to 50°C, and the reaction was carried out at this temperature for 6h. After the reaction was over, the solvent was recovered by distillation under reduced pressure, the residual solid was washed twice with deionized water, and dried in vacuum at 60° C. for 10 hours to obtain 136.9 g of cyclic phosphorus oxychloride, 2-chl...

Embodiment 3

[0040] Add 83.2g of neopentyl glycol and 500mL of chloroform into a 2000mL four-necked bottle equipped with a reflux condenser, a thermometer, a stirrer, and a constant pressure dropping funnel, then add 8g of triethylamine, stir well to dissolve the raw materials, and then put the four-necked Put the bottle into an ice-water bath, and slowly add 128.8 g of phosphorus oxychloride into the four-necked flask through a constant pressure dropping funnel under stirring at 5°C, and the reaction temperature is controlled at 0 to 10 o C, the dropping time is 2h. After the phosphorus oxychloride was added dropwise, the temperature was raised to 50°C, and the reaction was carried out at this temperature for 6h. After the reaction was over, the solvent was recovered by distillation under reduced pressure, the residual solid was washed twice with deionized water, and dried in vacuum at 60° C. for 10 hours to obtain 132.9 g of cyclic phosphorus oxychloride, 2-chloro-2-oxo-5, 5-Dimethyl-1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com