Purification adsorption agent for silicone hydride, phosphorane, arsine or borane gases and preparation method thereof

A borane gas and adsorbent technology, applied in the field of gas purification adsorbent and its preparation, can solve the problems of low impurity gas removal rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

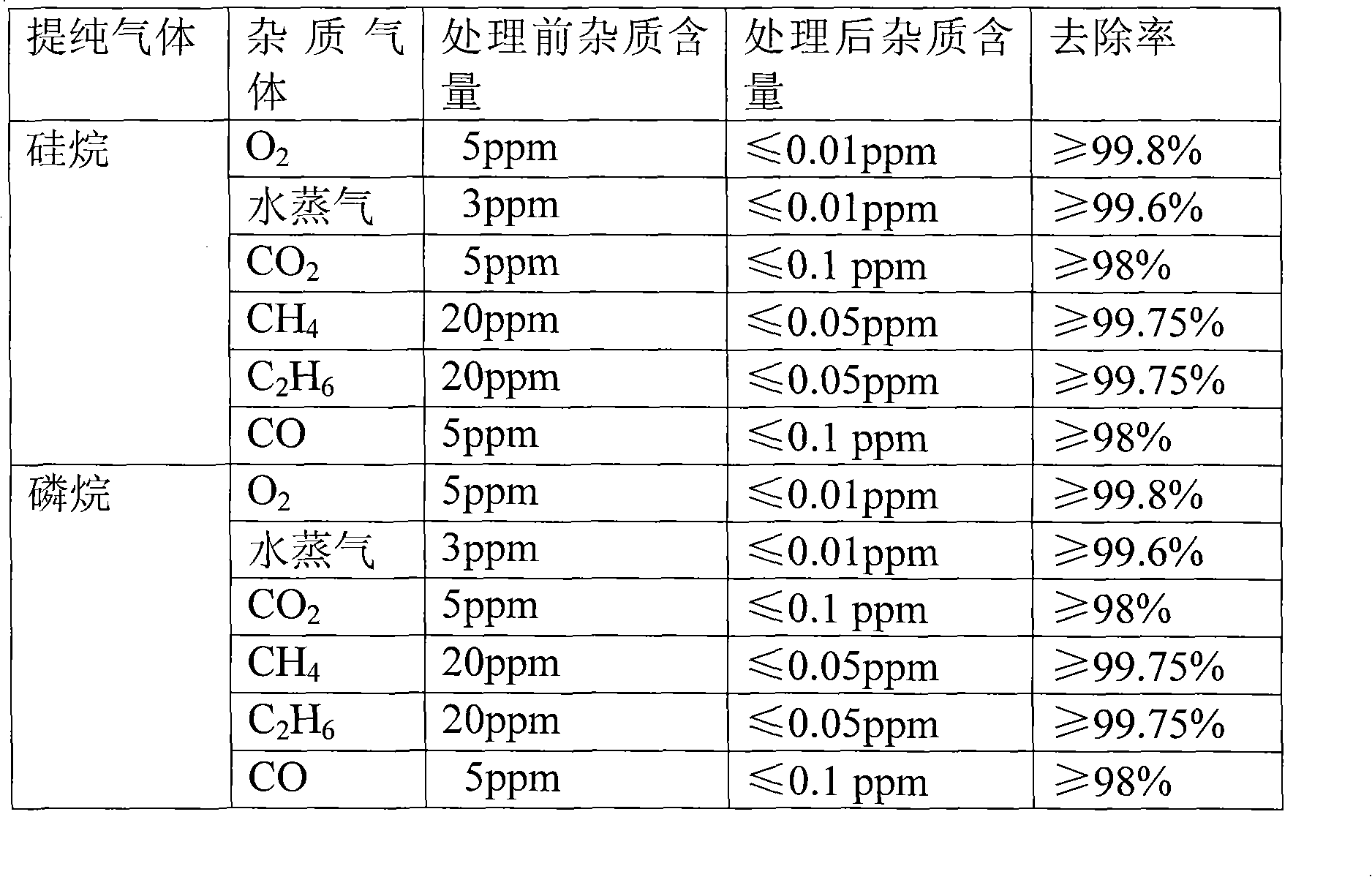

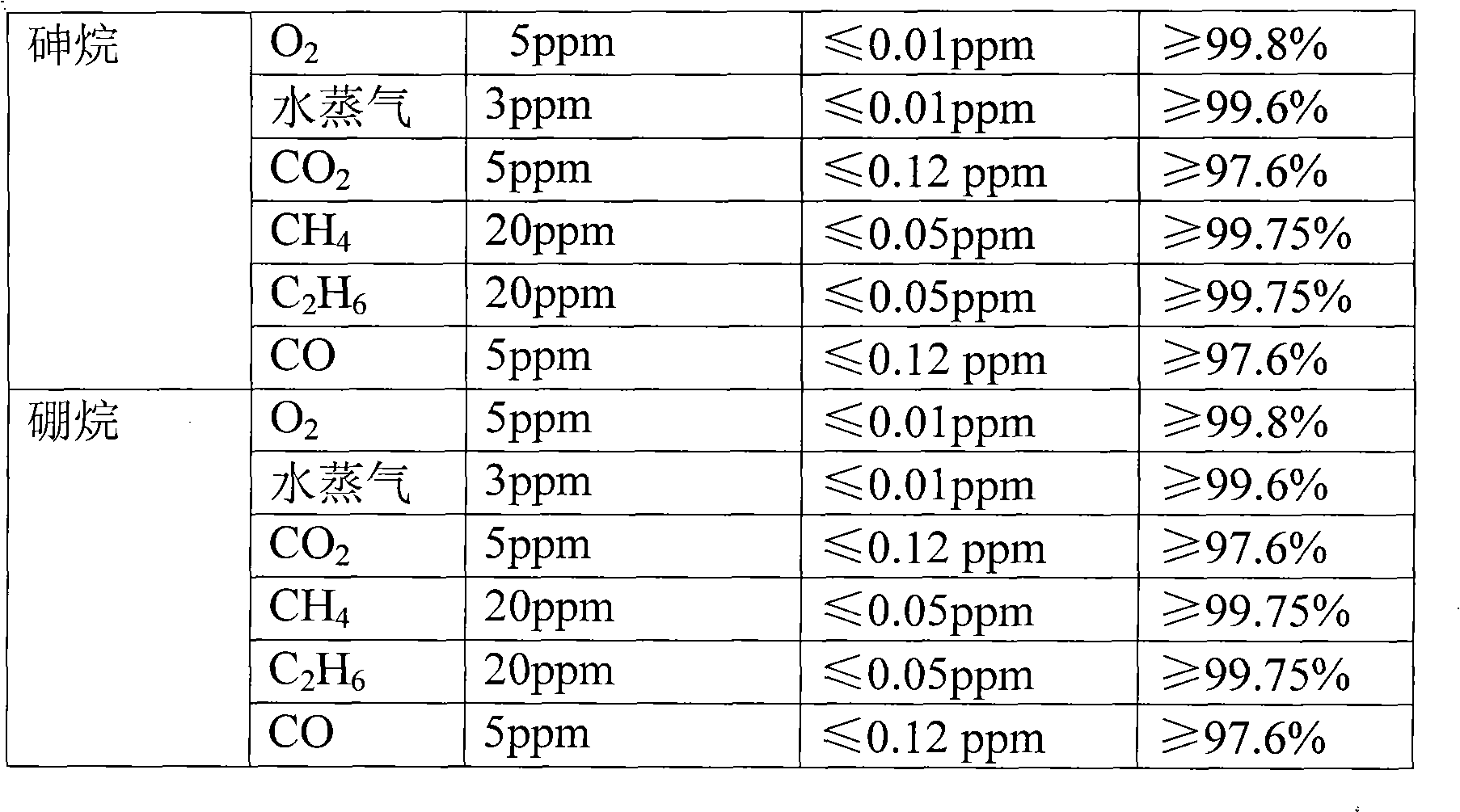

[0012] Embodiment 1: In this embodiment, the silane, phosphine, arsine or borane gas purification adsorbent consists of a carrier and a metal aluminum layer on the surface of the carrier.

specific Embodiment approach 2

[0013] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the carrier is activated carbon, zeolite or ceramsite. Others are the same as the first embodiment.

specific Embodiment approach 3

[0014] Specific embodiment three: In this embodiment, the silane, phosphine, arsine or borane gas purification adsorbent is prepared according to the following steps: spray the mixed gas of hydrogen and trimethylaluminum at a temperature of 600-650°C under a hydrogen atmosphere The surface of the carrier, that is to obtain silane, phosphine, arsine or borane gas purification adsorbent; wherein the molar ratio of hydrogen and trimethylaluminum in the mixed gas of hydrogen and trimethylaluminum is 1:5-10.

[0015] The hydrogen in this embodiment is high-purity hydrogen, and the trimethylaluminum is pure trimethylaluminum vapor.

[0016] In this embodiment, the thickness of the metal aluminum layer on the surface of the silane, phosphine, arsine or borane gas purification adsorbent can be determined according to needs, and is controlled by the spraying time and the spraying amount per unit time.

[0017] The preparation process of this embodiment is simple and easy to operate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com