Arsine phosphine special gas adsorbent and preparation method thereof

A technology of arsinephosphine and adsorbent, which is applied in the field of arsinephosphine special gas adsorbent and its preparation, can solve the problems of weak adsorption capacity, long adsorption time, large amount of arsinephosphine special gas adsorbent, etc. To achieve the effect of improving the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

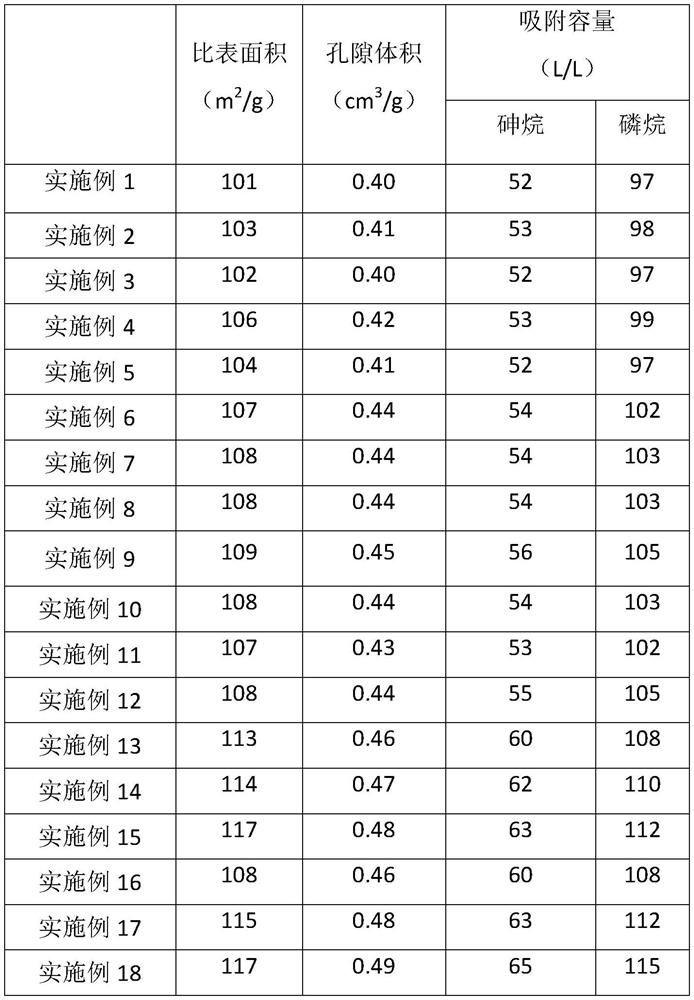

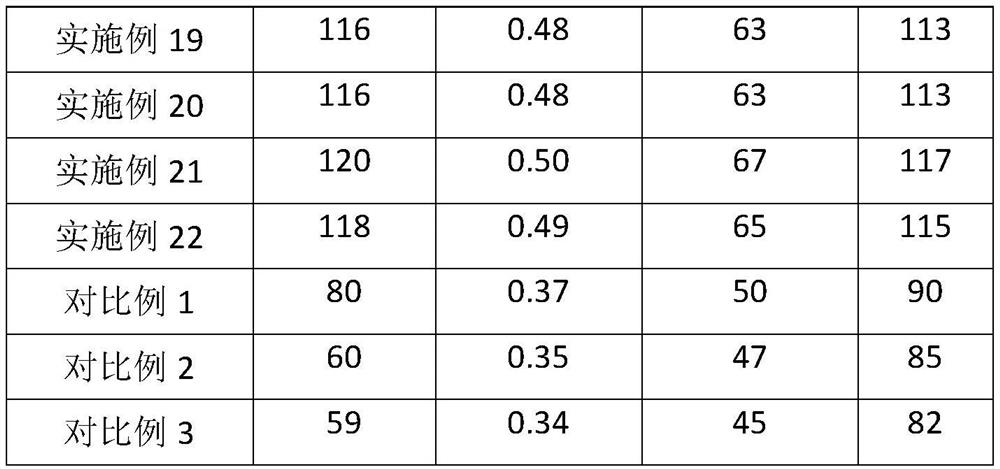

Examples

preparation example 1

[0040] The preparation of the stabilization aid in this application is prepared by the following operation steps: According to the dosage in Table 1, the sodium persulfate and sodium hypophosphite are pulverized to a particle size of 350 meshes, and mixed uniformly to obtain the stabilization aid.

preparation example 2-4

[0042] The preparation methods and types of raw materials of the preparation examples 2-4 are exactly the same as those of the preparation example 1, and the difference lies in the dosage of each raw material, as shown in Table 1 for details.

[0043] Table 1 The content of each raw material (unit: kg) of the arsine phosphine special gas adsorbents of preparation examples 1-4

[0044] raw material Preparation Example 1 Preparation Example 2 Preparation Example 3 Preparation Example 4 Sodium Persulfate 20 10 10 20 Sodium hypochlorite 20 20 30 10

Embodiment 1

[0046] The arsine phosphine special gas adsorbent of embodiment 1 is prepared by the following operation steps:

[0047] According to the dosage in Table 2, set the specific surface area to 100m 2 / g nanometer active copper oxide, active aluminum oxide and silicon dioxide are ground to a particle size of 350 meshes, and mixed uniformly to obtain mixture A;

[0048] Mix the mixture A and the aluminum sol in a volume ratio of 1:0.2, stir evenly, extrude, and granulate to obtain particles with a length of 3 mm and a particle size of 3 mm, and dry to obtain arsine phosphine special gas adsorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com