Technology for preparing high-purity diborane in rectification and adsorption combined purifying mode

A process technology, the technology of diborane, is applied in the technical field of preparing high-purity diborane by means of rectification and adsorption combined purification, which can solve problems such as pollution, and achieve the effects of convenient use and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

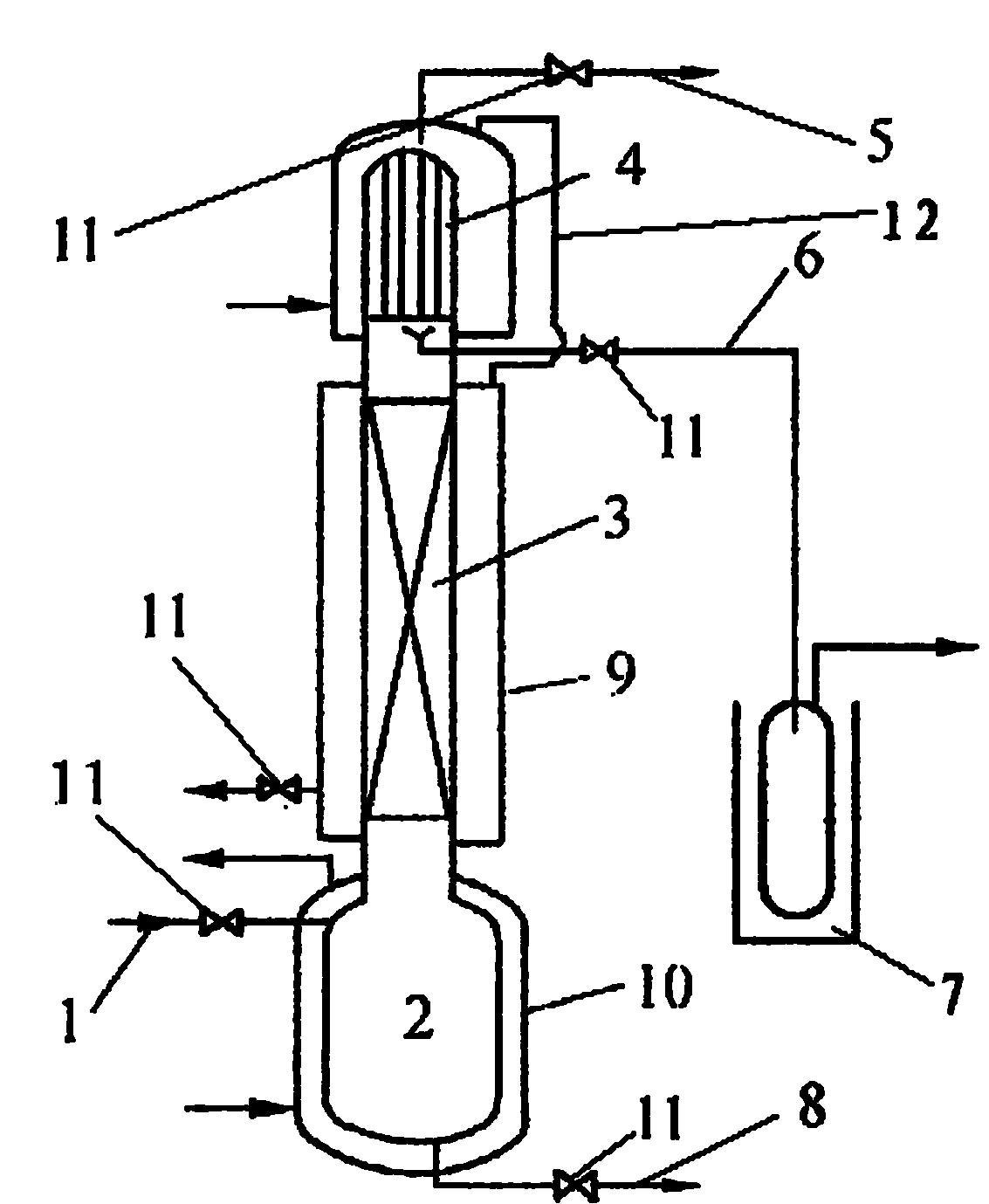

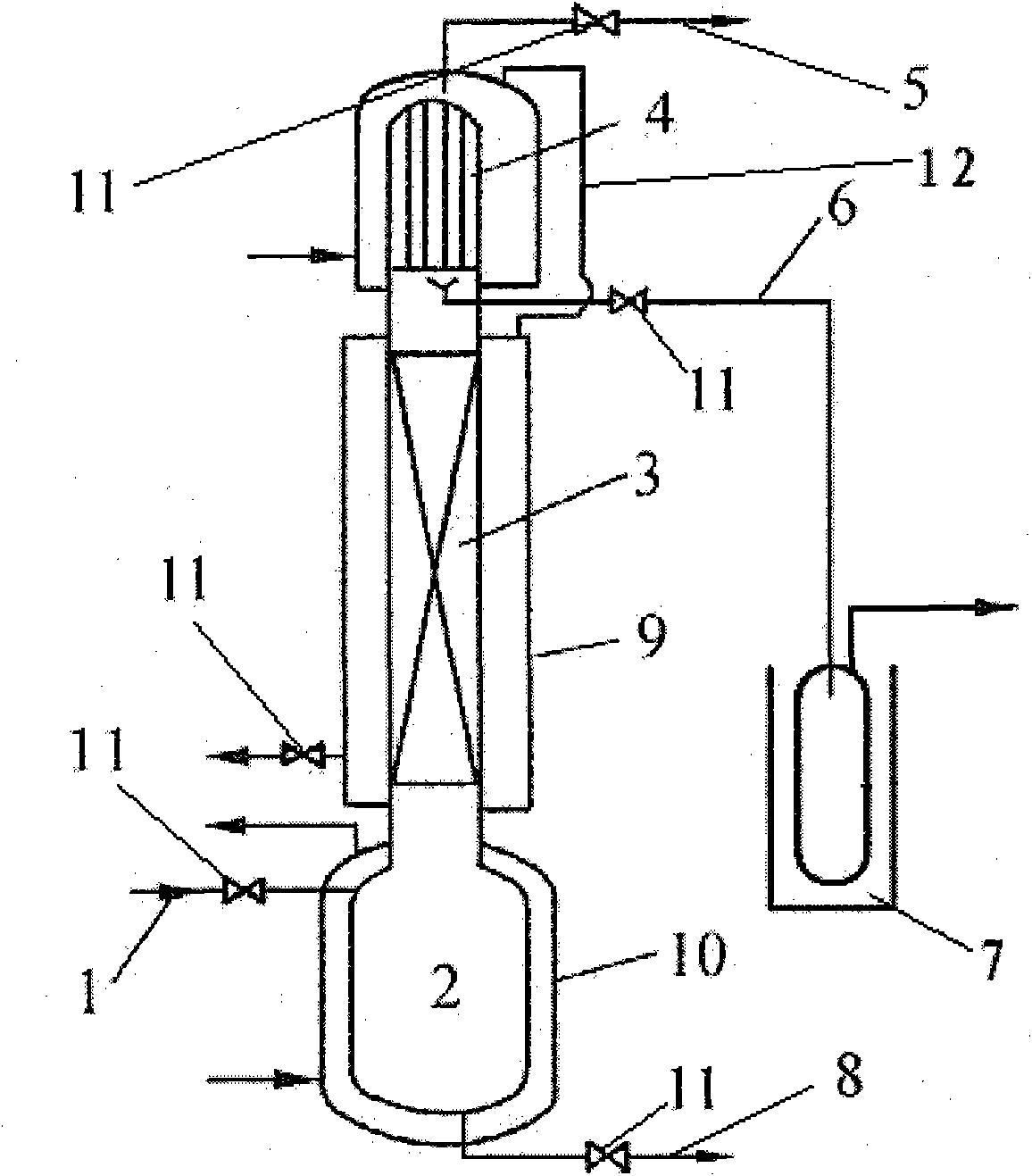

[0009] With reference to Fig. 1, feed gas inlet pipe (1), the reboiler (2) of external reboiler heating mantle (10), the packing tower (3) of external packing tower cooling jacket (9), condenser (4), Low boiling impurity discharge pipe (5), liquid product (high purity B 2 h 6 ) take-out pipe (6), product receiving tank (7), high-boiling impurity discharge pipe (8), and valve (11) are assembled into one body by connecting pipeline (12) according to their system functions.

[0010] The invention adopts a process method for preparing high-purity diborane by low-temperature adsorption, rectification, separation and purification with a filling agent.

[0011] (1) Source and composition of raw materials

[0012] This method is applicable to the thick B that described method prepares 2 h 6 . rough B 2 h 6 , containing ratio B 2 h 6 H with a low boiling point 2 , N 2 , O 2 , Ar, CH 4 and other impurities, and than B 2 h 6 High boiling point (C 2 h 5 )2O, CH 3 Cl, C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com