Technique for preparing phosphine by heating white phosphorous placed into potassium hydroxide solution

A technology of potassium hydroxide and solution, which is applied in the field of chemical synthesis of phosphine, can solve problems such as pollution, and achieve the effect of convenient use and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

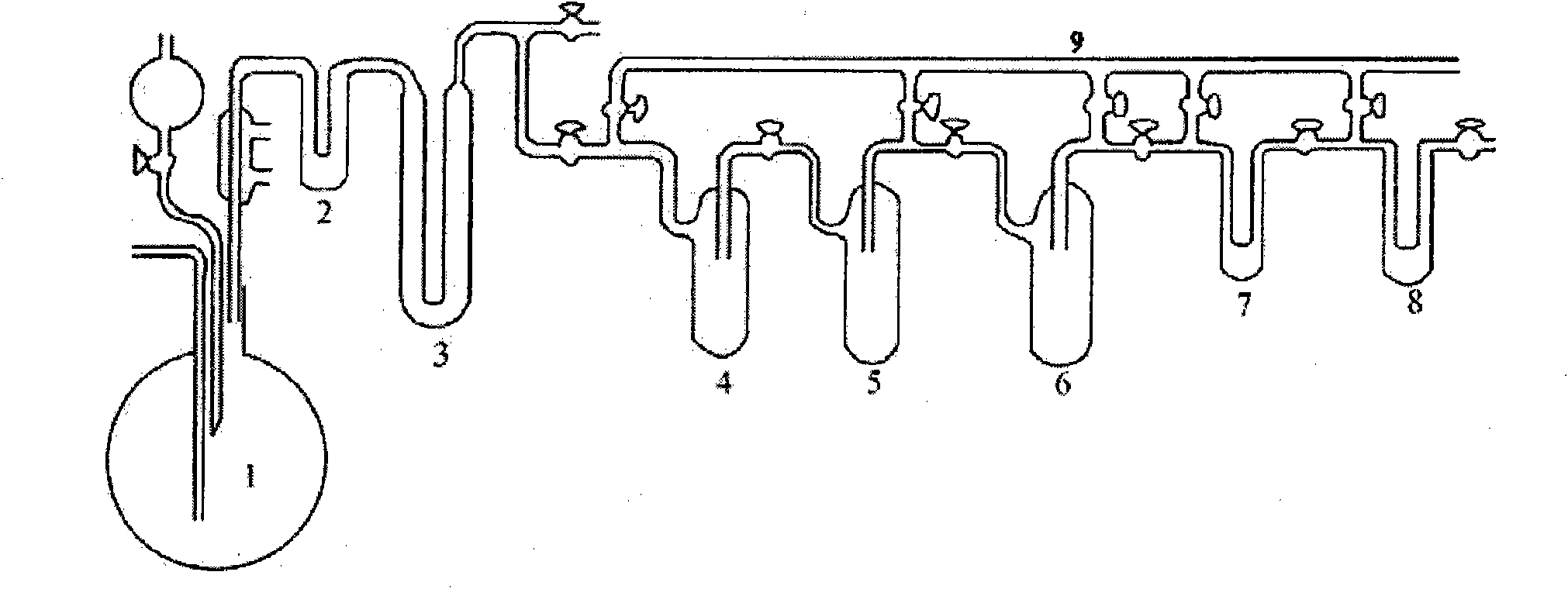

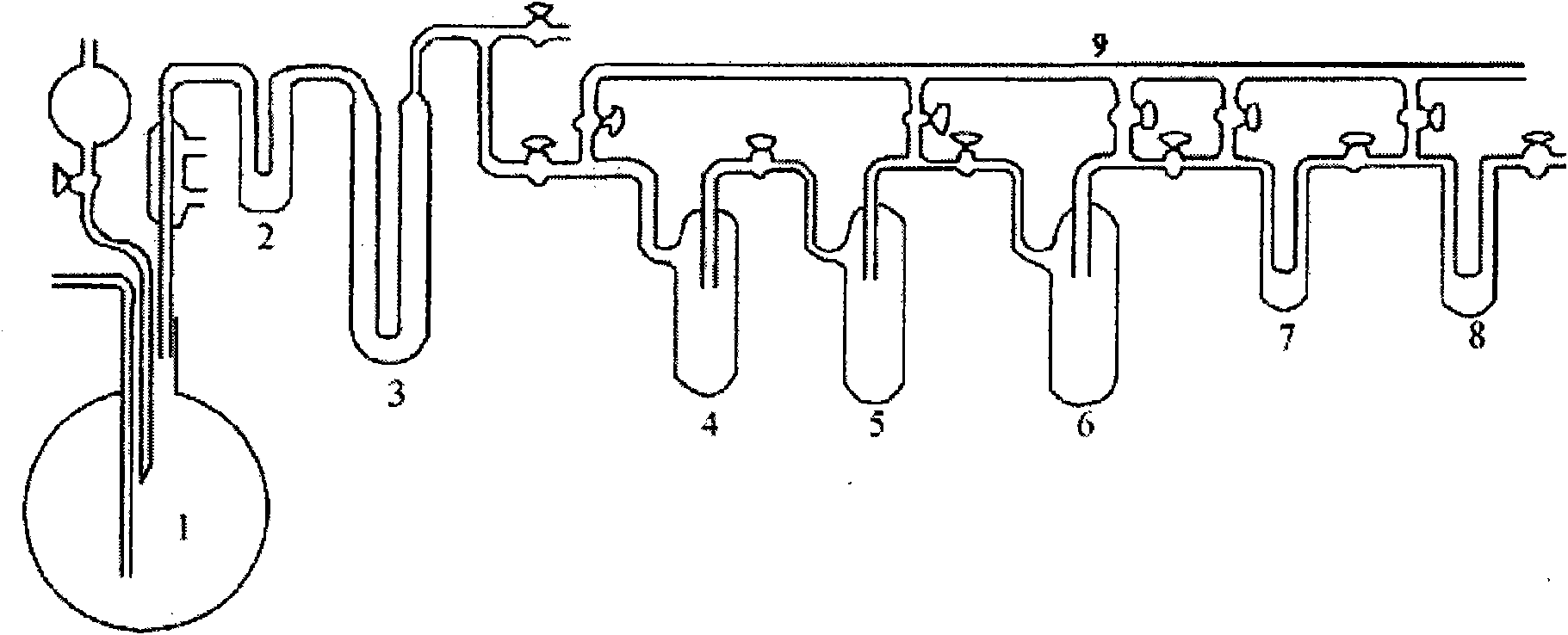

[0010] refer to figure 1 , generating bottle (1), 1# cold trap (2), drying tube (3), 2# cold trap (4), 3# cold trap (5), 4# cold trap (6), 5# cold trap ( 7), 6# cold trap (8) is formed by assembling the connecting pipeline (9) according to its system function.

[0011] When in use, a certain amount of white phosphorus is added to the generating bottle (1), and then a stoichiometric potassium hydroxide dilute solution is added through a separatory funnel. Then, after blowing off the air in the preparation device with deoxygenated hydrogen, the generator bottle was heated to 60°C. The phosphine generated by the reaction, the hydrogen generated by the side reaction and the large amount of water it carries pass through the drying pipe (3) and its multiple cold traps (-90°C, -100°C, -180°C). In the cold trap, What is condensed is mainly diphosphine (P 2 h 4 ), and in the cold trap, phosphine is condensed. The phosphine is then carefully distilled into the next cold trap. Phos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com