Technology of method for preparing high purity diborane by way of adsorption, separation and purification

A technology of adsorption separation and process technology, which is applied in the technical field of adsorption separation and purification to prepare high-purity diborane, can solve problems such as pollution, and achieve the effects of convenient use, convenient operation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

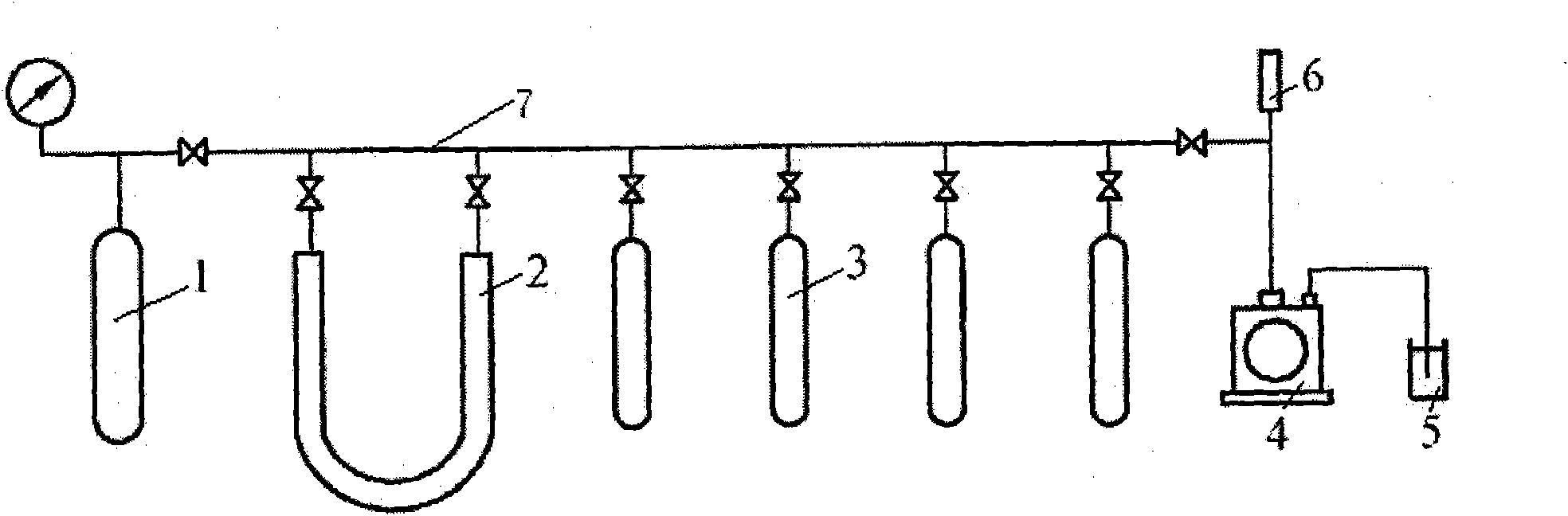

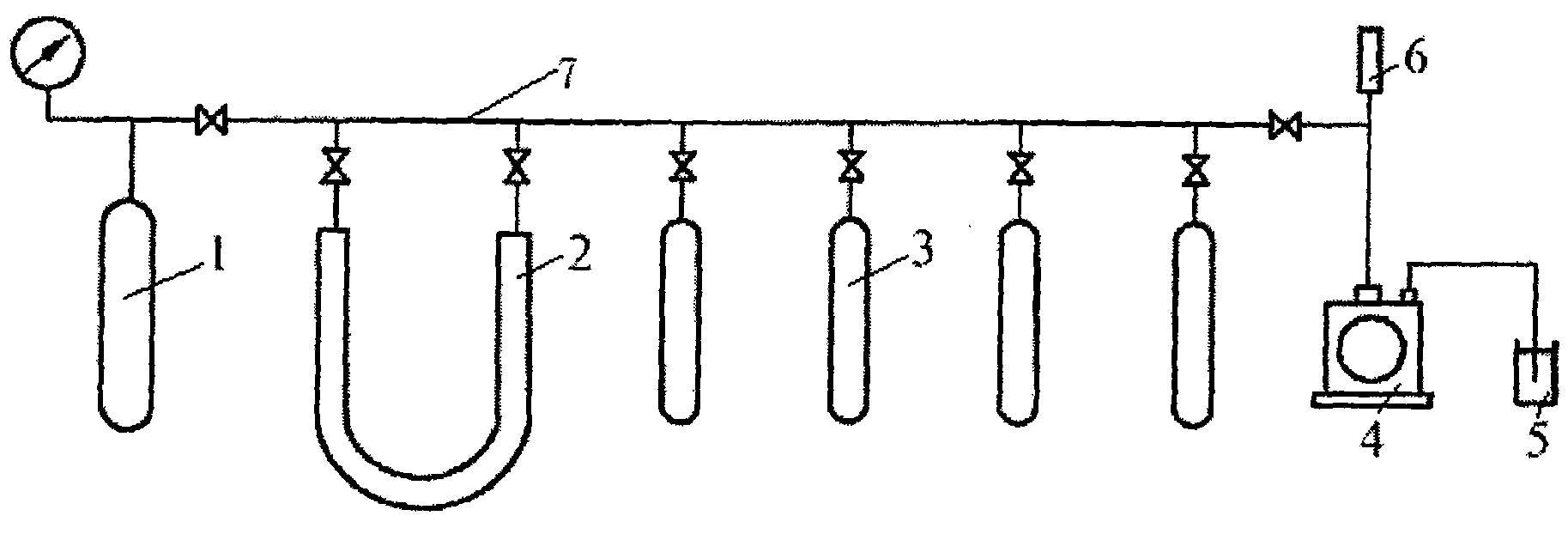

[0012] refer to figure 1 , rough B 2 h 6 (Diborane) gas cylinder (1), drier (2), adsorber (3), vacuum pump (4), tail gas absorber (5), product collector (6) according to their system functions through connecting pipelines (7) ) assembled into one body.

[0013] The invention adopts the process method for preparing high-purity diborane by means of adsorption, separation and purification.

[0014] Mainly, the crude diborane is continuously supplied by the device of the present invention that produces diborane, and according to the impurity content of the crude diborane, the B 2 h 6 CH in 4 , CO 2 etc., to prepare high-purity diborane, which is liquefied and vaporized to form a finished product.

[0015] Its advantages are high product yield, high purity (99.0%-99.9%), less impurities and easy separation. Except for the product itself, there are no other harmful and toxic by-products, and the operation is more convenient. It is the preparation of high-purity diborane idea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com