Technology for producing chloroethane by ethane hydrochlorination method

A technology of ethyl chloride and hydrochlorination, which is applied in the fields of producing ethyl chloride by ethylene hydrochlorination and chemically synthesizing ethyl chloride, can solve the problems of complex production technology, poor product quality, and high cost, and achieve convenient use, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

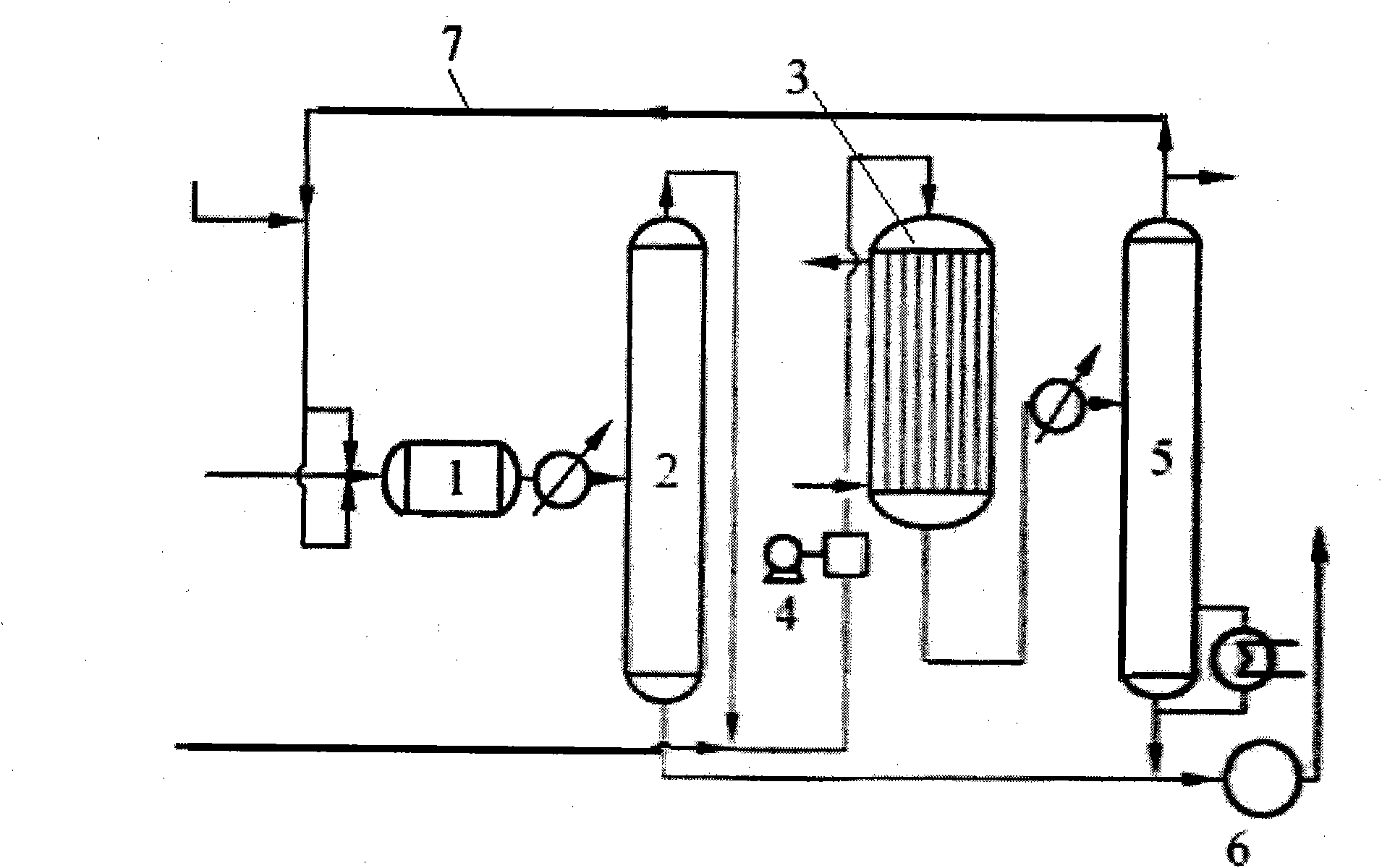

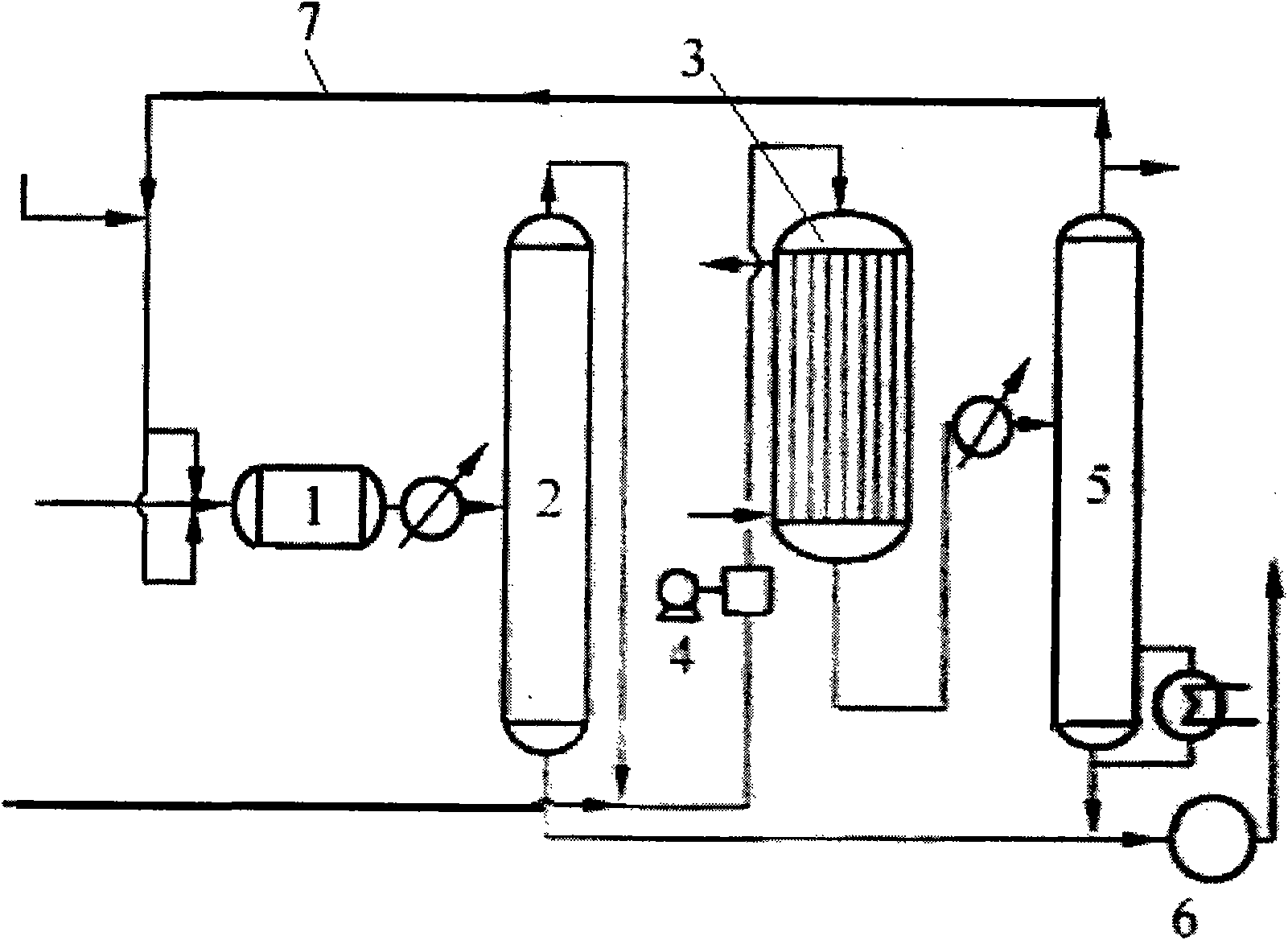

[0010] Reference figure 1 , Chlorination reactor (1), first ethyl chloride tower (2), HCI addition reactor (3), compressor (4), second ethyl chloride tower (5), crude ethyl chloride storage tank (6) According to its system function, it is constituted by assembling one piece by connecting pipeline (7).

[0011] When used, ethyl chloride is produced by liquid phase hydrochlorination of ethylene. Ethylene and hydrogen chloride are added to the device of the present invention at a pressure of 0.1~0.3MPa (or 0.1~0.9MPa) and room temperature (or -5~55℃), and then a chloroethane solution containing 2% aluminum trichloride is passed through to react to produce When the chloroethane overflows, flash evaporation, water washing, alkali washing, drying, and distillation obtain a chloroethane product with a purity of more than 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com