Antioxidation method of light rare earth metal hydride

A light rare earth and hydride technology, applied in the field of materials, can solve the problems of unsafe use, high cost of storage devices, and easy automatic combustion, etc., and achieve the effect of wide application range and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

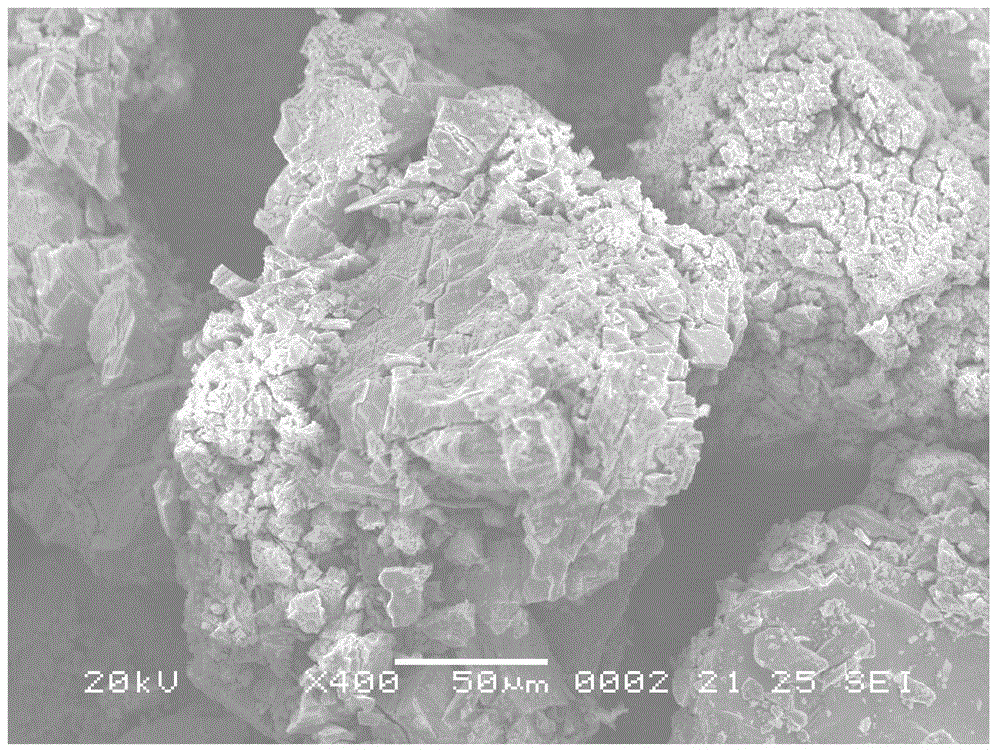

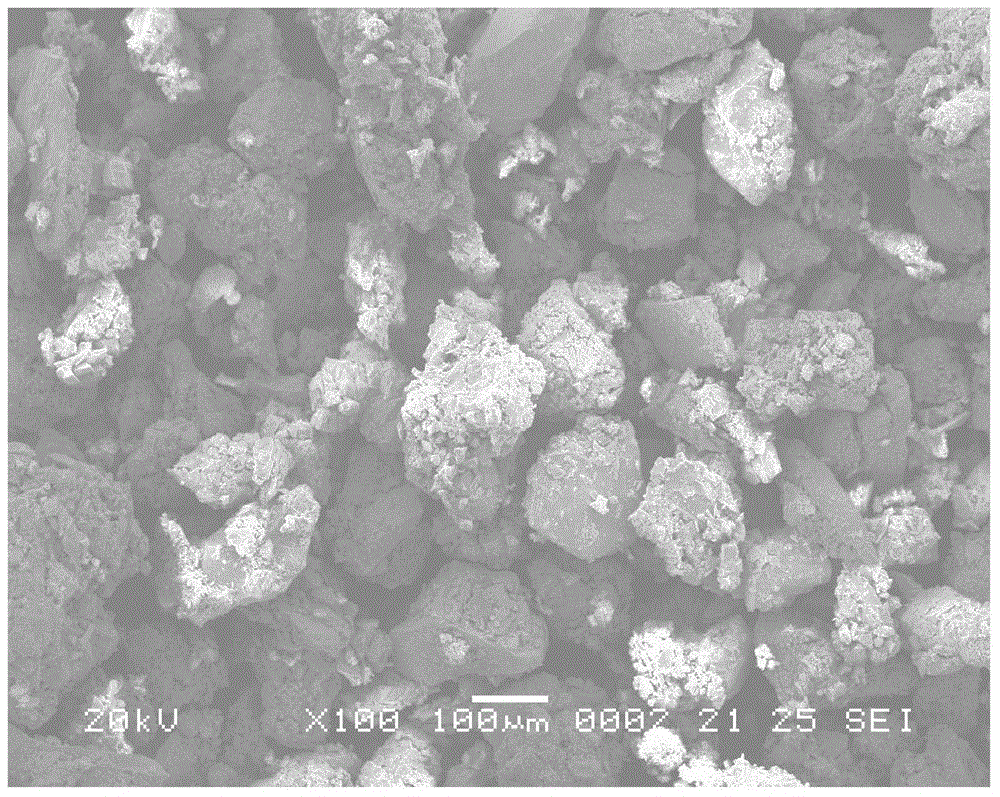

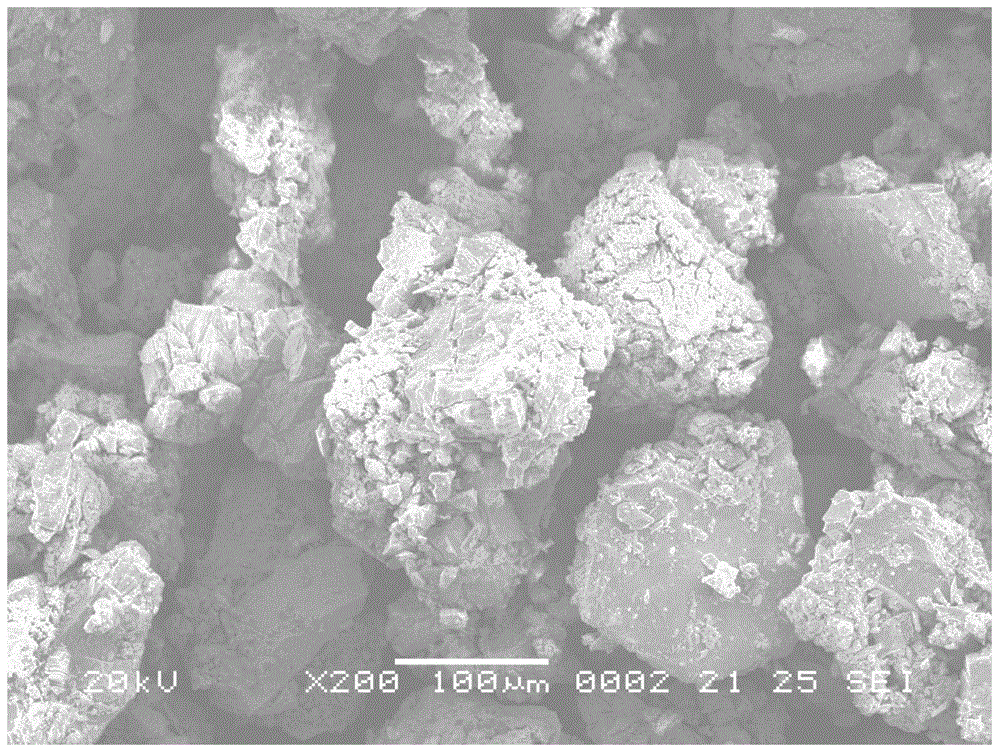

Image

Examples

Embodiment 1

[0029] (1) Add 800ml of butyl acetate into a dry 1000ml three-necked flask, install a condenser reflux tube, a thermometer, and introduce nitrogen; take the metal sodium, scrape off the surface oxides with a knife, and then cut into small slices about 0.5mm thick , Add 8g flake sodium metal to butyl acetate and heat to 128°C; after refluxing for 8h, add benzophenone reagent, the solution turns blue, and the blue becomes deeper and deeper with time, indicating that the water is clean; Finally, the butyl acetate distillate at 126°C was collected by distillation for use; ethyl acetate, aviation kerosene, toluene, n-heptane, and carbon tetrachloride have the same water removal method as above, and the distillation temperature is different;

[0030] (2) Take 3 g of granular methyl methacrylate and add it to a three-necked flask containing 100 mL of anhydrous butyl acetate, and heat to 60°C in a water bath until the methyl methacrylate is completely dissolved and a transparent glue is f...

Embodiment 2

[0034] (1) Add 6 g of polystyrene to 100 mL of anhydrous ethyl acetate, stir, and heat to 50°C until the polystyrene is completely transparent and form a glue solution for use;

[0035] (2) Put 20gCeH 3 Put it into a 500mL three-necked flask and add 220mL of anhydrous n-heptane, stir and heat to 50℃, and then drop 15mL of the glue prepared in step (1) into the reaction flask, the dropping rate is 40 drops per minute, and the stirring speed is 320r / min, continue stirring for 25min after the dripping is completed, and cool to normal temperature to obtain the coated CeH 3 ;

[0036] (3) CeH to be coated 3 Pour into a funnel and filter, and place the filtered solid material in an oven with a temperature of 35°C and a vacuum of 0.06 for 8 hours to obtain anti-oxidant CeH. 3 . CeH with antioxidant treatment 3 Its initial decomposition temperature is 264℃, and it will not ignite spontaneously when stored in air.

Embodiment 3

[0038] (1) Add 10g of fluororubber to 200mL of anhydrous butyl acetate, stir, and heat to 50°C until the fluororubber is completely transparent and form a glue solution for use;

[0039] (2) Put 22gCeH 3 Add to a 300mL three-necked flask and 200mL of anhydrous aviation kerosene. Install a stirring and a thermometer. When the temperature is raised to 58℃, add 20mL of the glue prepared in step (1) to the reaction flask; the dropping rate is 42 per minute. Drop, stirring speed is 300r / min, continue to stir for 15min after dropwise addition, cool to normal temperature;

[0040] (3) CeH to be coated 3 Pour into the funnel and filter; place the filtered solid material in an oven with a temperature of 35°C and a vacuum of 0.029 for 12 hours to obtain anti-oxidation CeH 3 . CeH of the antioxidant treatment 3 The initial decomposition temperature is 390℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com