A kind of α-alh3 flotation method and its application

A technology of flotation liquid and suspension liquid, applied in flotation, chemical instruments and methods, offensive equipment, etc., can solve the problems of reducing the energy of energetic materials, impact sensitivity of propellant slurry, increased friction sensitivity, poor stability, etc. problems, to achieve the effect of simple and efficient separation technology, low slurry sensitivity and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

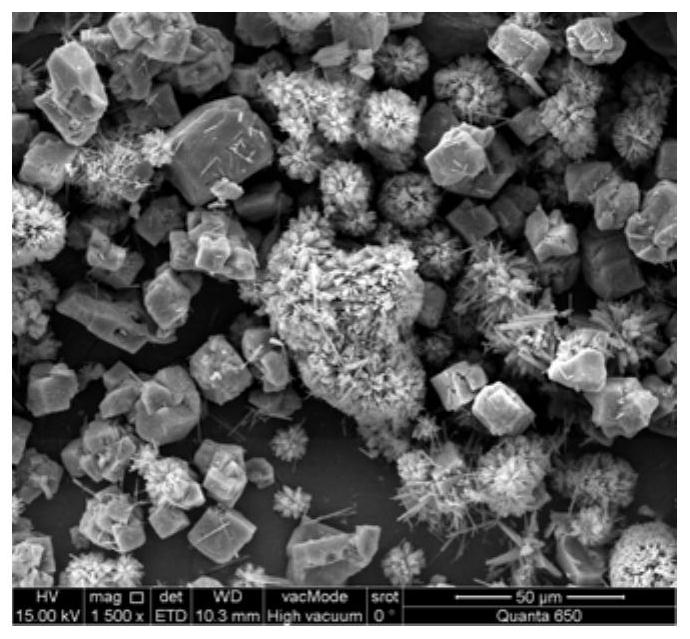

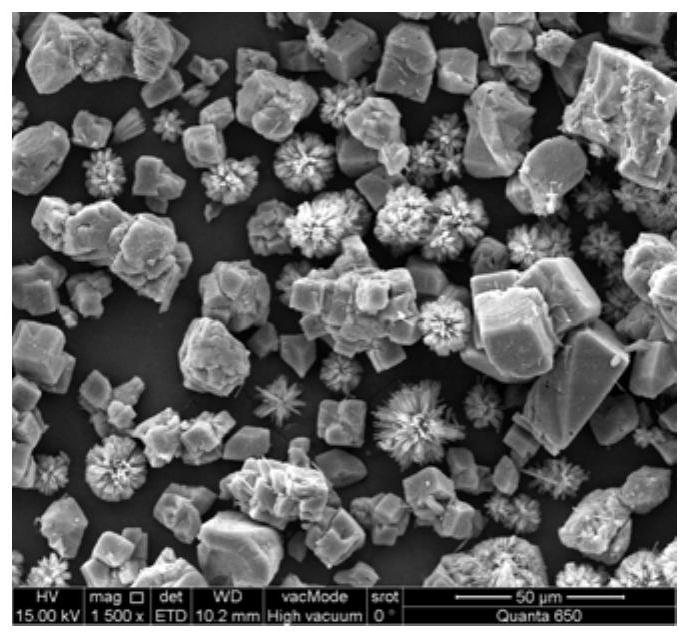

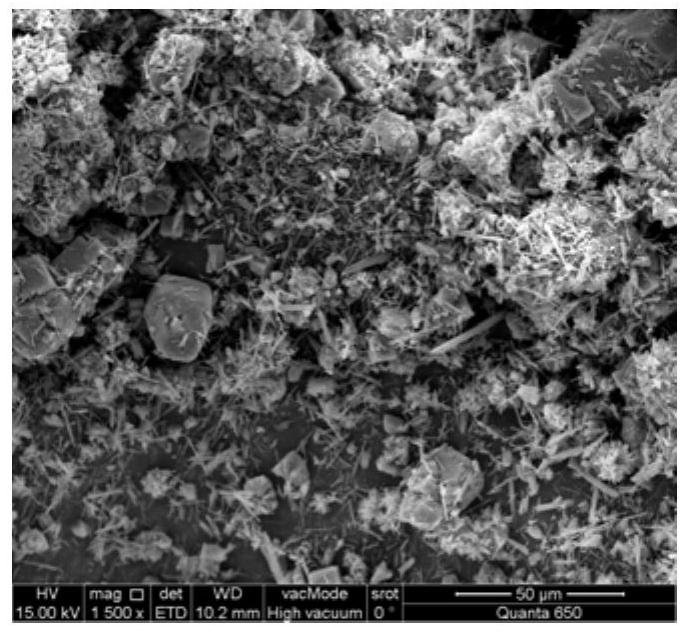

Image

Examples

Embodiment 1

[0046] an α-AlH 3 The flotation method, the steps are:

[0047] Step 1: Weigh 5gAlH 3 The crude product was placed in a 500mL beaker, and 250mL oleic acid was accurately measured, and after 60min magnetic stirring at 400r / min, the AlH 3 The crude product was completely wetted with oleic acid to give suspension A.

[0048] Step 2: Ultrasonicate the suspension A with an ultrasonic pulverizer for 120s with 600W ultrasonic power, and then stir at a stirring speed of 800rmp / min for 240min to obtain the suspension B;

[0049] Step 3: Put the suspension B in a separatory funnel and let it stand for 24 hours to separate layers. Suction filter the lower layer solid C and the upper layer suspension D respectively, wash with n-hexane several times, and store in a vacuum oven at 50°C In, after 24 hours of heat preservation, the off-white powder AlH 3 -C3.78g and AlH 3 -D1.13g.

[0050] AlH 3 Crude, AlH obtained 3 -C and AlH 3 -D Test the H content separately, and test the basic f...

Embodiment 2

[0052] an α-AlH 3 The flotation method, the steps are:

[0053] Step 1: Weigh 5gAlH 3 Put the crude product in a 500mL beaker, accurately measure 500mL of linoleic acid, and stir for 360min under magnetic stirring at 200r / min to make AlH 3 The crude product was completely wetted with linoleic acid to obtain suspension A.

[0054] Step 2: Suspension A was sonicated with an ultrasonic pulverizer at 2000W ultrasonic power for 30s, and then stirred at a speed of 200rmp / min for 360min to obtain suspension B.

[0055] Step 3: Put the suspension B in a separatory funnel and let it stand for 72 hours to separate layers. Suction filter the lower layer solid C and the upper layer suspension D respectively, wash with n-hexane for several times, and store in a vacuum oven at 30°C In, after 72h of heat preservation, the off-white powder AlH 3 -C4.12g and AlH 3 -D0.86g.

[0056] Step 4: As-is AlH 3 , AlH 3 -C and AlH 3 -D Test the H content separately, and test the basic formula Al...

Embodiment 3

[0058] an α-AlH 3 The flotation method, the steps are:

[0059] Step 1: Weigh 5gAlH 3 Put the crude product in a 500mL beaker, accurately measure 100mL of linolenic acid, and stir the AlH with 1500r / min magnetic force for 30min 3 The crude product was completely wetted by linolenic acid to obtain suspension A.

[0060] Step 2: Ultrasonicate the suspension A with an ultrasonic pulverizer at 400W ultrasonic power for 1200s, then stir at 600rmp / min for 180min to obtain the suspension B.

[0061] Step 3: Put the above suspension B in a separatory funnel and let it stand for 8 hours to separate the layers. Suction filter the lower layer solid C and the upper layer suspension D respectively, wash with cyclohexane several times, and then vacuum at 40°C In the drying oven, after 24 hours of heat preservation, the off-white powder AlH 3 -C4.28g and AlH 3 -D0.68g.

[0062] Step 4: As-is AlH 3 , AlH 3 -C and AlH 3 -D Test the H content separately, and test the basic formula AlH 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact sensitivity | aaaaa | aaaaa |

| impact sensitivity | aaaaa | aaaaa |

| impact sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com