Anti-freezing super-sulfur cement concrete and preparation method thereof

A technology of supersulfur cement and concrete, which is applied in the field of material chemistry, can solve the problems of poor frost resistance, and achieve the effects of improved salt freeze resistance, obvious salt freeze resistance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Prepare 20kg of ground supersulfur cement mixture: take 15kg of slag, 4kg of desulfurized gypsum, and 1kg of Portland cement, mix and grind to get final product;

[0023] (2) Prepare 3kg of composite additives: add 2124g of water, 195g of water reducing agent and 225g of nano silicon dioxide in proportion, stir at 1300rpm for 3min; add 450g of sodium lactate, stir at 7000rpm for 10min; add 6g of air-entraining agent, stir at 200rpm for 5min to obtain the composite additive;

[0024] (3) Ultrasonic disperse the composite additive first, then mix the finely ground supersulfur cement mixture and composite additive, and finally add 27.6kg of sand, 41.4kg of stone and 4.598kg of water to prepare frost-resistant supersulfur cement concrete.

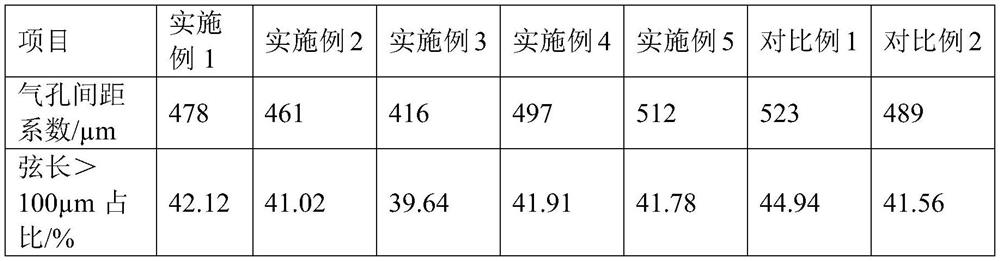

[0025] After the mixing is completed, the concrete is formed. After 1 day, the formwork is removed and moved into the standard curing room for curing until 28 days. The concrete strength test, single-sided freeze-thaw test, etc. are c...

Embodiment 2

[0027] (1) Prepare 20kg of ground supersulfur cement mixture: take 15kg of slag, 4kg of desulfurized gypsum, and 1kg of Portland cement, mix and grind to get final product;

[0028] (2) Prepare 4kg of composite additives: add 2832g of water, 260g of water reducing agent and 300g of nano silicon dioxide in proportion, stir at 1500rpm for 3min; add 600g of sodium lactate, stir at 7500rpm for 10min; add 8g of air-entraining agent, stir at 300rpm for 5min to obtain the composite additive;

[0029] (3) Ultrasonic dispersion of composite additives, mixing finely ground supersulfur cement mixture and composite additives, adding 27.6kg of sand, 41.4kg of stone and 3.798kg of water to prepare frost-resistant supersulfur cement concrete.

[0030] After the mixing is completed, the concrete is formed. After 1 day, the formwork is removed and moved into the standard curing room for curing until 28 days. The concrete strength test, single-sided freeze-thaw test, etc. are carried out. The e...

Embodiment 3

[0032] (1) Prepare 20kg of ground supersulfur cement mixture: take 15kg of slag, 4kg of desulfurized gypsum, and 1kg of Portland cement, mix and grind to get final product;

[0033] (2) Prepare 5kg of composite additives: add water 3540g, water reducer 325g and nano silicon dioxide 375g in proportion, and stir at 1000rpm for 3min; add 750g of sodium lactate, stir at 6000rpm for 9min; add air-entraining agent 10g, stir at 200rpm for 4min to obtain the composite additive;

[0034] (3) Ultrasonic dispersion of composite additives, mixing finely ground supersulfur cement mixture and composite additives, adding 27.6kg of sand, 41.4kg of stone and 2.997kg of water to prepare frost-resistant supersulfur cement concrete.

[0035] After the mixing is completed, the concrete is formed. After 1 day, the formwork is removed and moved into the standard curing room for curing until 28 days. The concrete strength test, single-sided freeze-thaw test, etc. are carried out. The experimental res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com