Preparation method of modified biaxially oriented polyethylene glycol terephthalate film

A technology of polyethylene terephthalate and biaxial stretching, which is applied in the field of plastic films, can solve the problems of cost increase, coating process increase, attenuation, etc., to reduce viscosity, improve printing performance, and good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

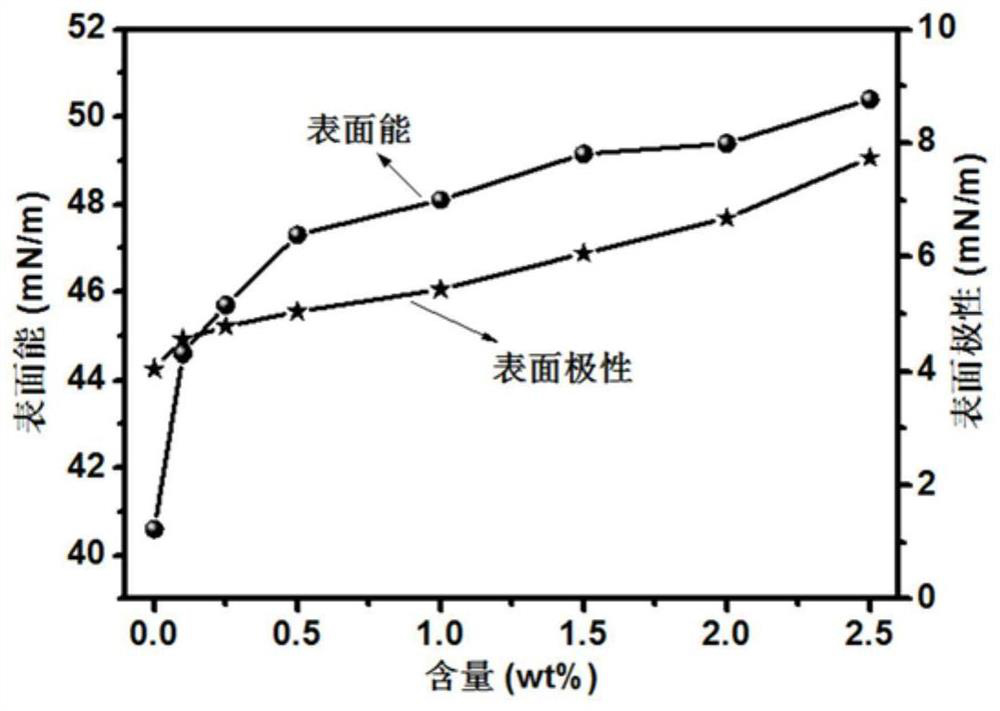

[0033] This example relates to the preparation of modified BOPET film. The specific preparation includes the following steps: adding PET and anti-blocking agent to the twin-screw extruder according to the ratio of 100:0.17 and blending uniformly; cooling the drum, longitudinal stretching, and transverse stretching , winding and other steps to prepare BOPET film. The temperature of the feeding section of the twin-screw extruder is 180°C, the temperature of the melting and plasticizing section is 260°C, the die opening temperature is 260°C, the transverse stretching temperature is 80°C, and the longitudinal stretching temperature is 100°C. Then the tensile properties of the film were tested for mechanical properties, and the test results are shown in Table 1. The optical properties are shown in Table 2. Surface properties such as figure 1 shown.

Embodiment 2

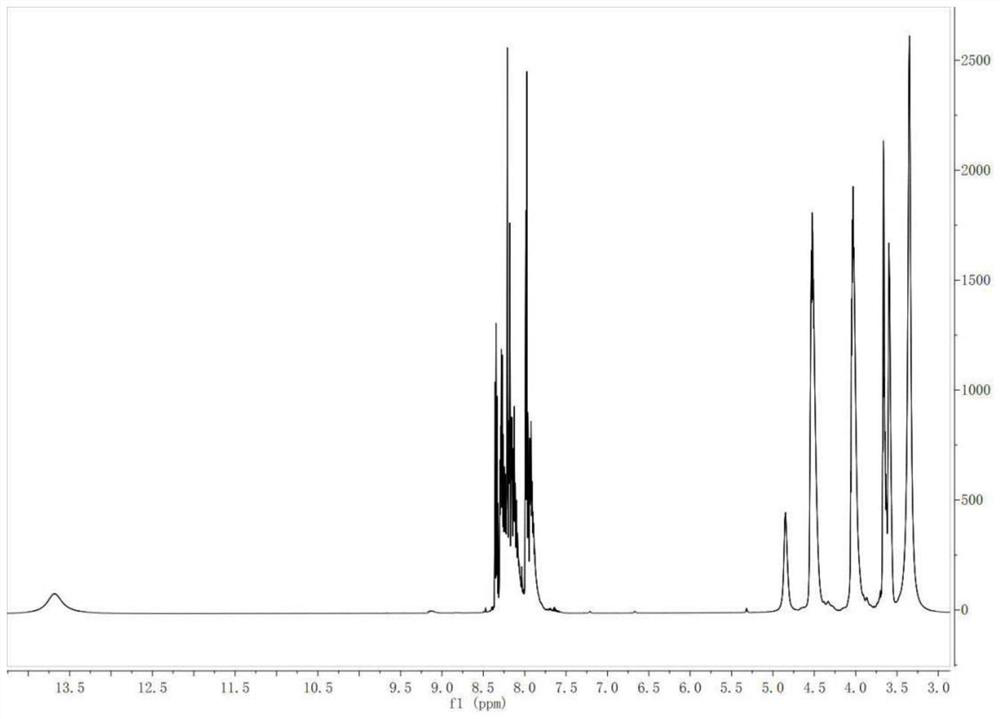

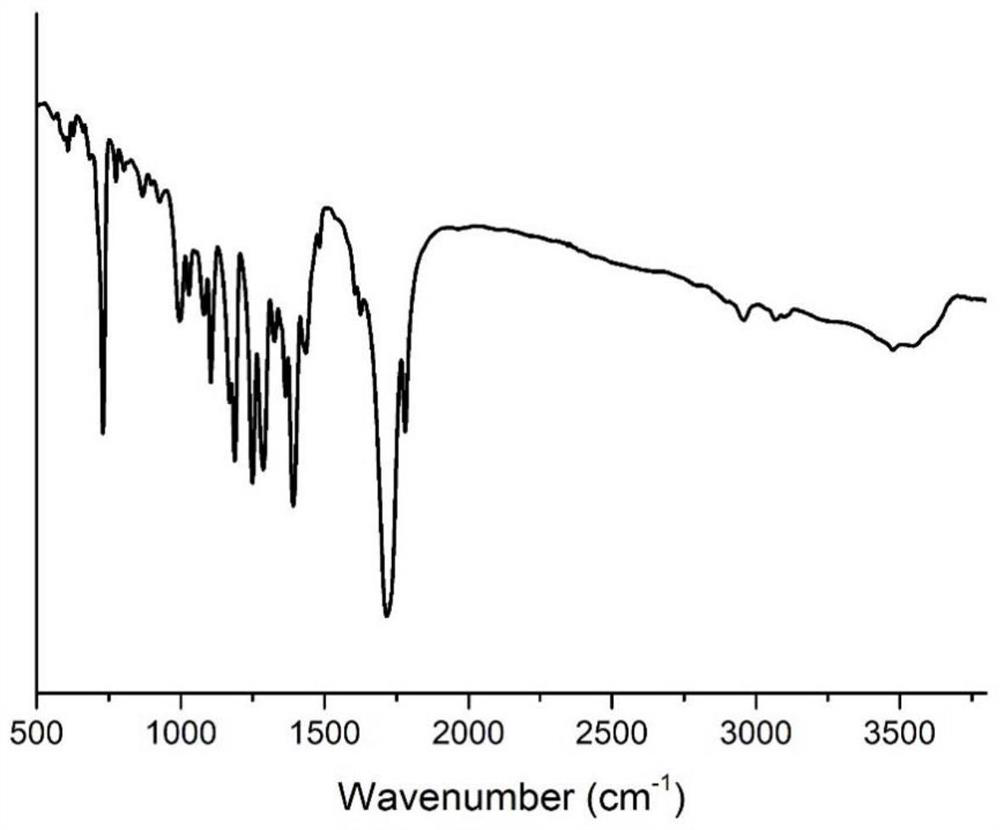

[0035] This example relates to the preparation of a modified BOPET film. The specific preparation includes the following steps: adding PET, an anti-blocking agent, and a polyester imide oligomer into a twin-screw extruder according to a ratio of 100:0.17:0.1 and blending uniformly; The BOPET film is prepared by cooling the drum, longitudinal stretching, transverse stretching, winding and other steps. The polyester imide oligomer selected in this embodiment has a molecular weight of 5000 g / mol, a decomposition temperature of 400° C., and the blocking agent is silica microspheres. The temperature of the feeding section of the twin-screw extruder is 180°C, the temperature of the melting and plasticizing section is 260°C, the die opening temperature is 260°C, the transverse stretching temperature is 80°C, and the longitudinal stretching temperature is 100°C. Then the tensile properties of the film were tested for mechanical properties, and the test results are shown in Table 1. T...

Embodiment 3

[0039]This example relates to the preparation of modified BOPET film. The specific preparation includes the following steps: adding PET, anti-blocking agent, polyesterimide oligomer) to the twin-screw extruder according to the ratio of 100:0.17:0.25 and blending evenly ; Cool the drum, longitudinal stretch, transverse stretch, winding and other steps to prepare BOPET film. The polyester imide oligomer selected in this embodiment has a molecular weight of 5000 g / mol, a decomposition temperature of 400° C., and the blocking agent is silica microspheres. The temperature of the feeding section of the twin-screw extruder is 180°C, the temperature of the melting and plasticizing section is 260°C, the die opening temperature is 260°C, the transverse stretching temperature is 80°C, and the longitudinal stretching temperature is 100°C. Then the tensile properties of the film were tested for mechanical properties, and the test results are shown in Table 1. The optical properties are sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transverse stretch temperature | aaaaa | aaaaa |

| Longitudinal stretch temperature | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com