20000-ton-annual-yield production technique of trimethylolpropane by calcium method

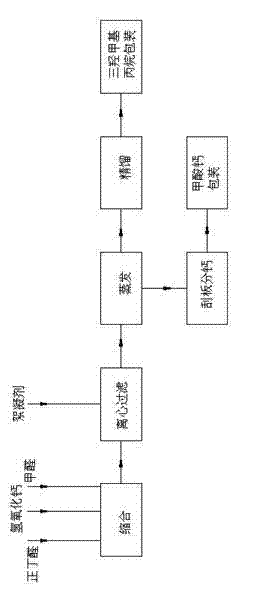

A trimethylolpropane and production process technology, which is applied in the chemical industry, can solve the problems that the high vacuum of trimethylolpropane cannot be guaranteed, the distribution of rectification towers is uneven, and the production capacity has not been improved, so as to eliminate washing sewage and save Settling time, effect of land area reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

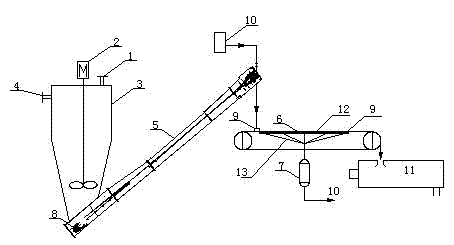

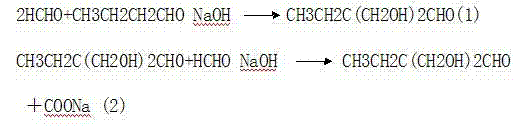

[0043] (1) Condensation: two condensation reactors are used, and the effective volume of each condensation reactor is designed to be 30 cubic meters. Increase the stirring to above 150 rev / min; n-butyraldehyde: formaldehyde: calcium hydroxide is 1: 3.0:0.6, stir and heat up to 50-70°C for condensation reaction, and 2,2-dimethylol butyraldehyde is obtained during the reaction , then formaldehyde is carried out Cannizzaro reaction, and 0.2 mole of formaldehyde is added per mole of the above-mentioned n-butyraldehyde; then, formic acid is added to the reaction kettle for neutralization to reach a pH value of 5-7, that is, to obtain a compound containing ditrimethylolpropane The crude trimethylolpropane reaction solution with calcium formate by-product; the trimethylolpropane in the crude trimethylolpropane reaction solution accounts for about 12%-12.5%.

[0044] in:

[0045] The condensation reaction kettle adopts multi-layer and various stirring, the first layer adopts three-bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com