Patents

Literature

31results about How to "Skill improved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

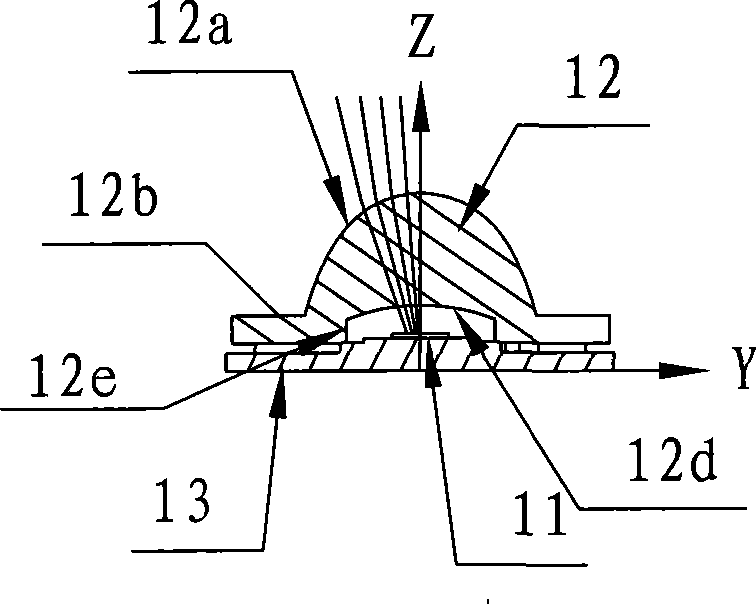

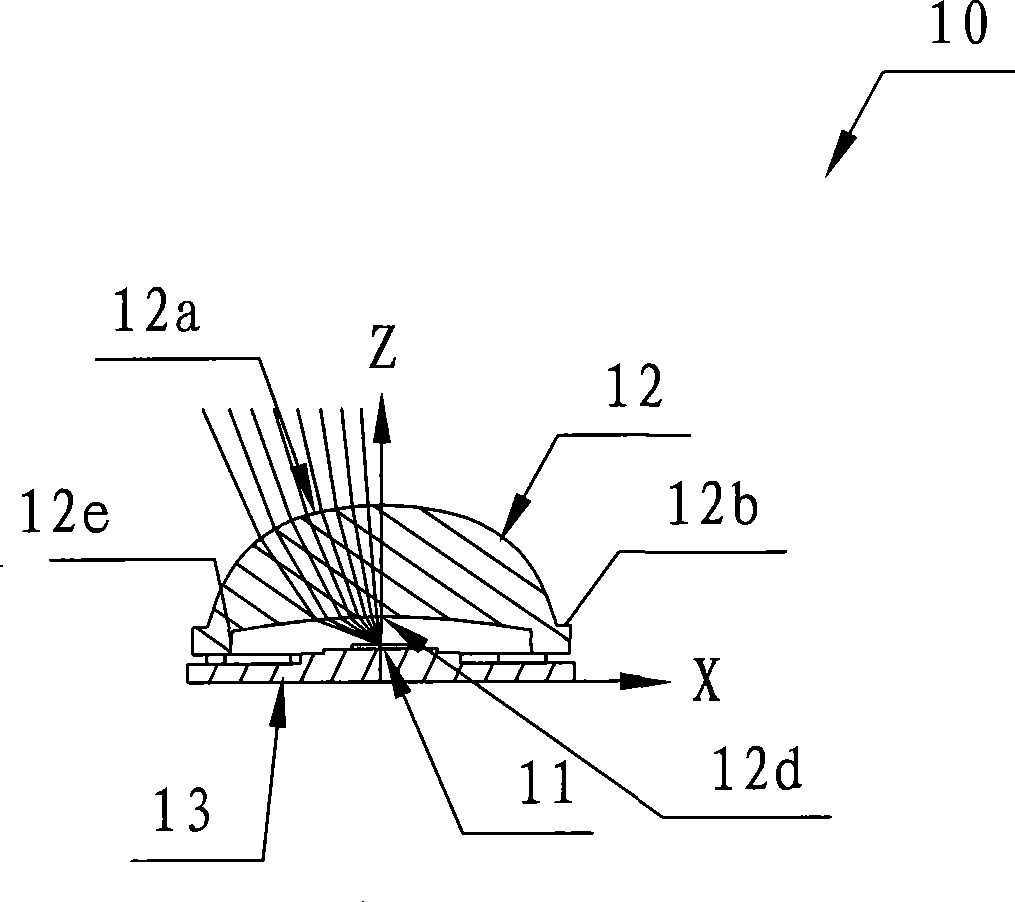

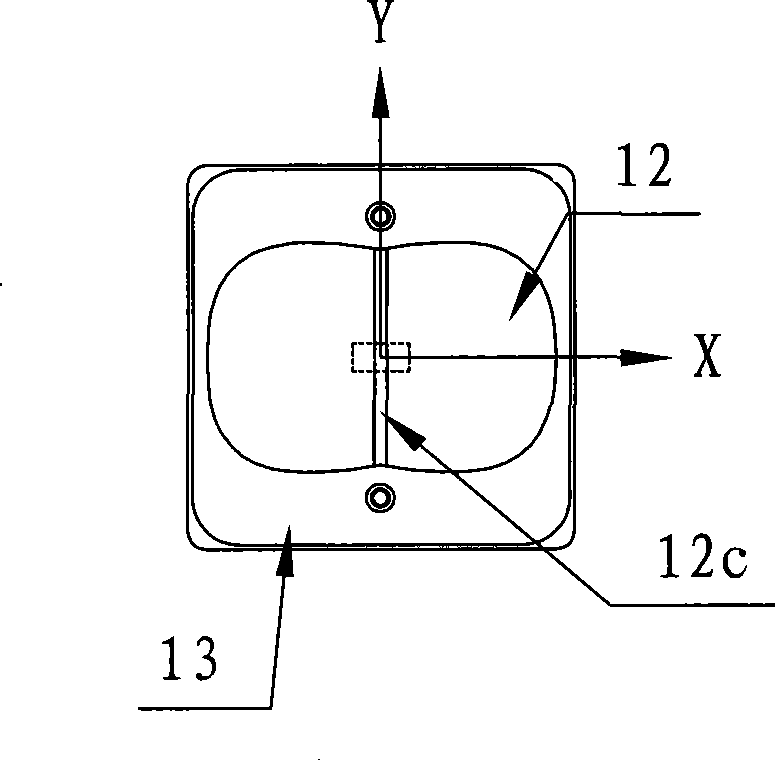

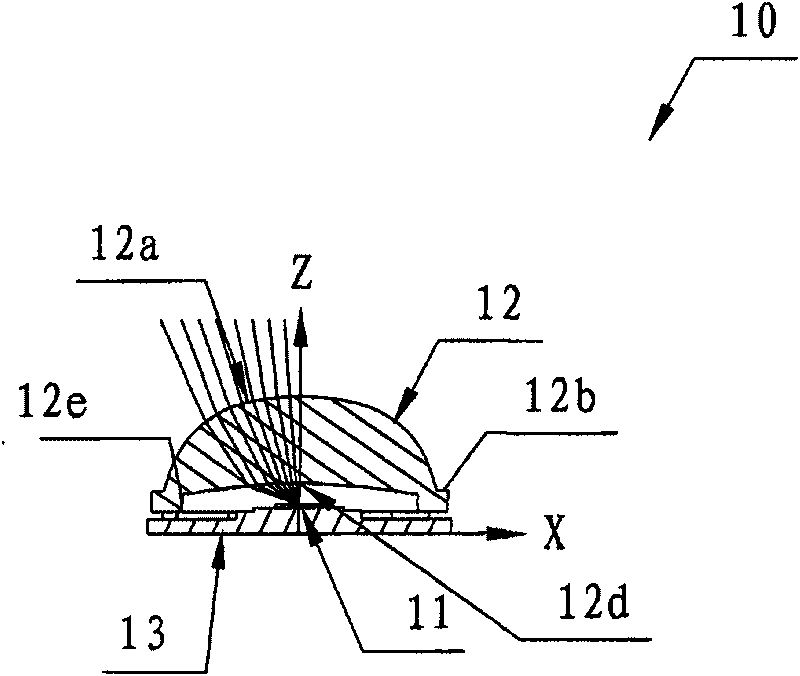

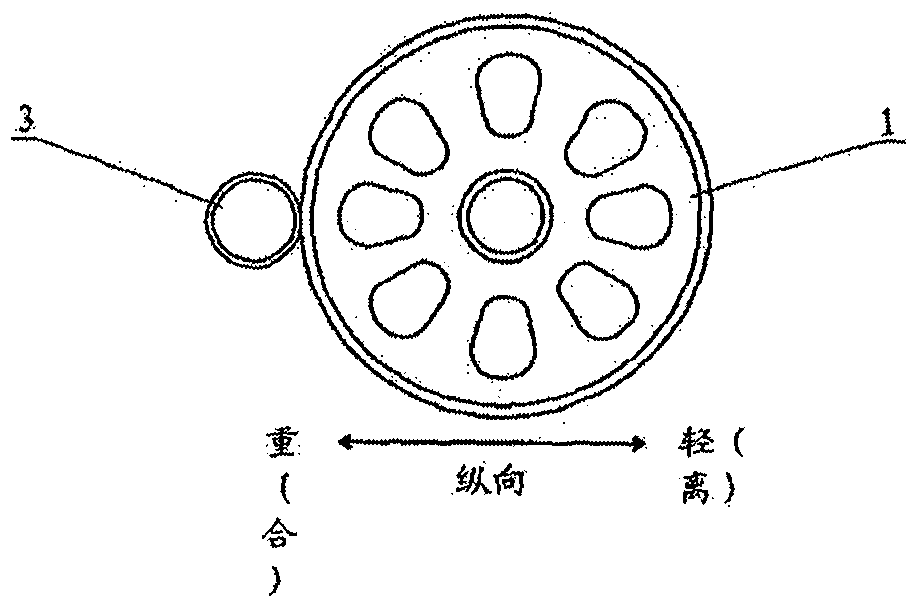

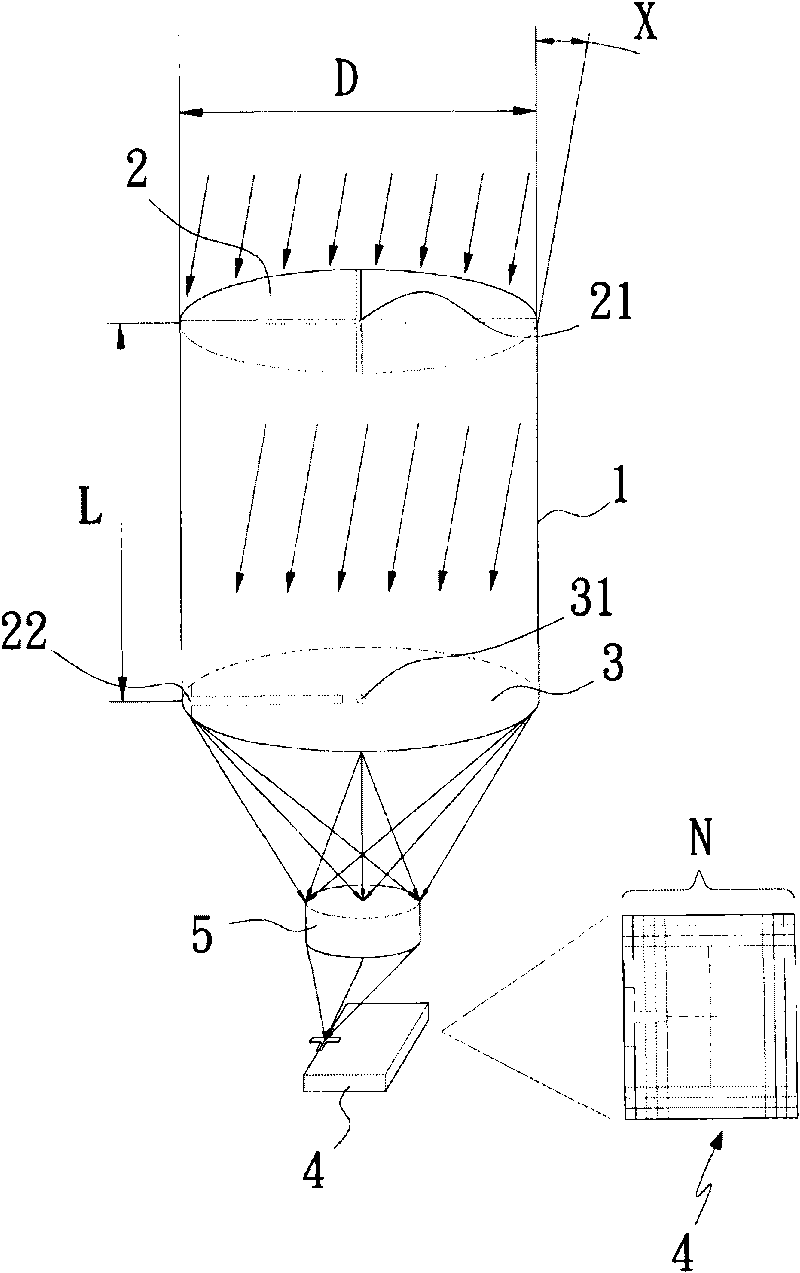

Lens system suitable for LED road lamp

ActiveCN101487579AConvergence requirements are lowCentral light intensity value is smallMechanical apparatusPoint-like light sourceIlluminanceCurve shape

The invention relates to a lens system which is applicable to an LED street lamp and is matched with an LED illuminant for use to form light distribution with multiple Light beam angles and light intensities. A plane of light incidence of a lens in the system being close to the LED illuminant is a compound curved surface of an aspherical concave surface, and a light-emitting surface is a compound curved surface of an aspherical convex surface; the shapes of the incident surface and the emitting surface are determined by the luminescent properties of the LED illuminant and the requirement of the emergent ray; after the light ray emitted by the LED illuminant is refracted by the lens, facula formed on the irradiation surface within a certain distance has the characteristics of being comparatively long in the distance covered by the facula along one direction being vertical to the axes of the LED illuminant, being comparatively shorter in the distance covered by the facula along another direction being vertical to the direction, being symmetrical in the shapes of the faculas correspondingly to the axes of the LED illuminant, and taking on the distribution which is similar to rectangle. Similar plane isolux distribution curve shape as well as completely different maximum light intensity values of the light beam and half peak value light intensity light beam wrap angles can be obtained by the LED illuminant through different lenses, so that the lens system is especially suitable for the LED light fittings having the requirement of rectangle illumination scope.

Owner:NINGBO LIAOYUAN IND

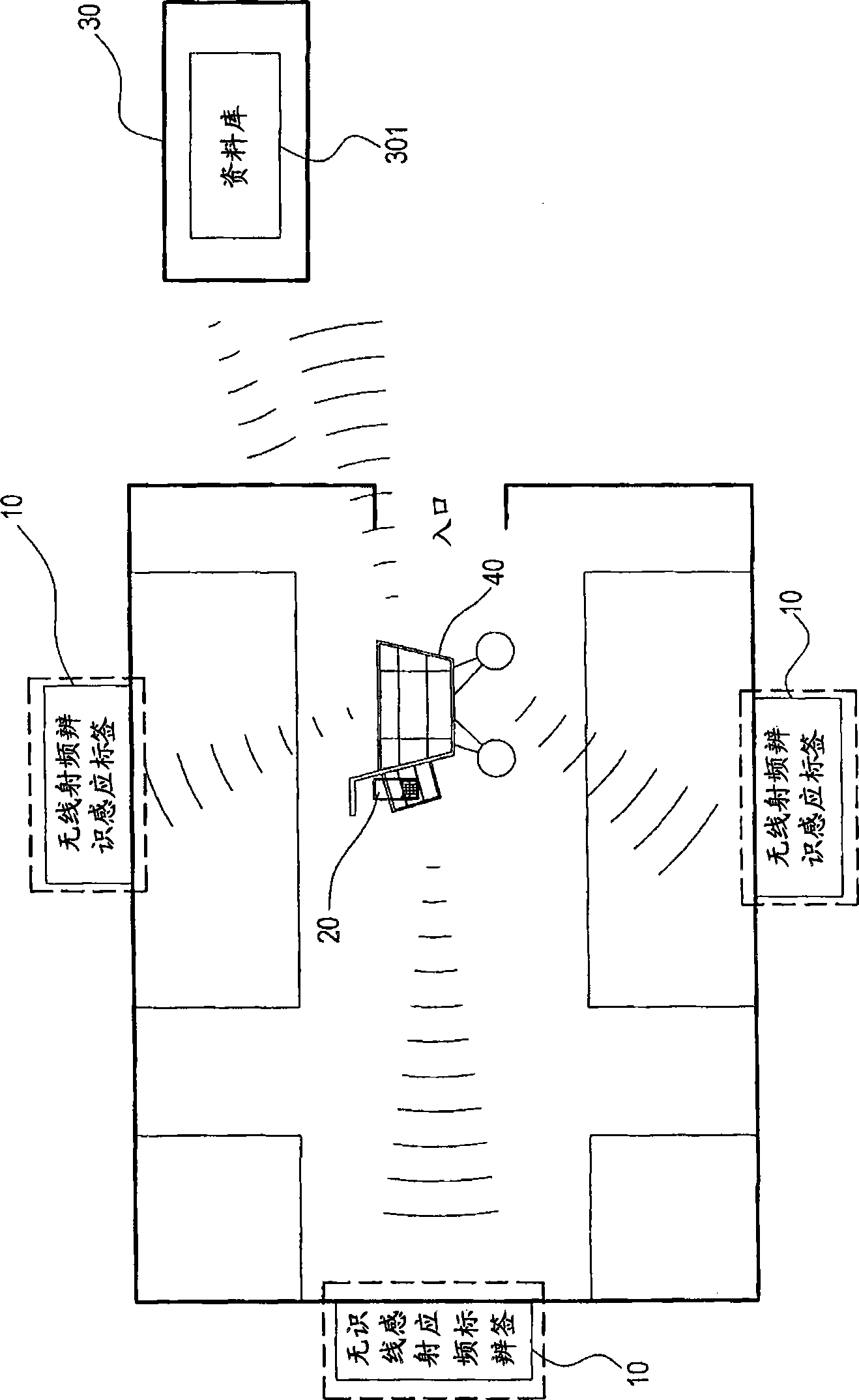

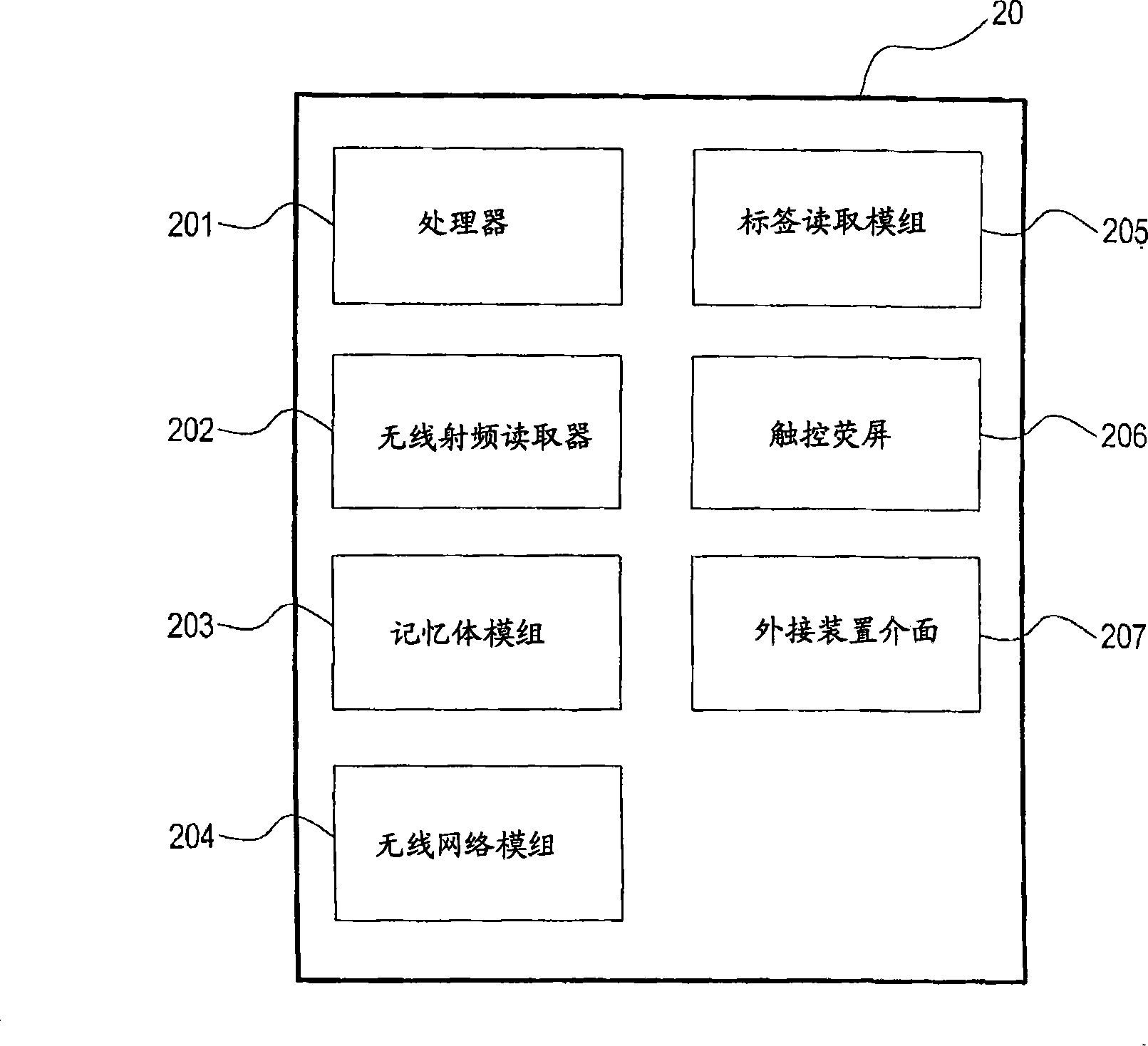

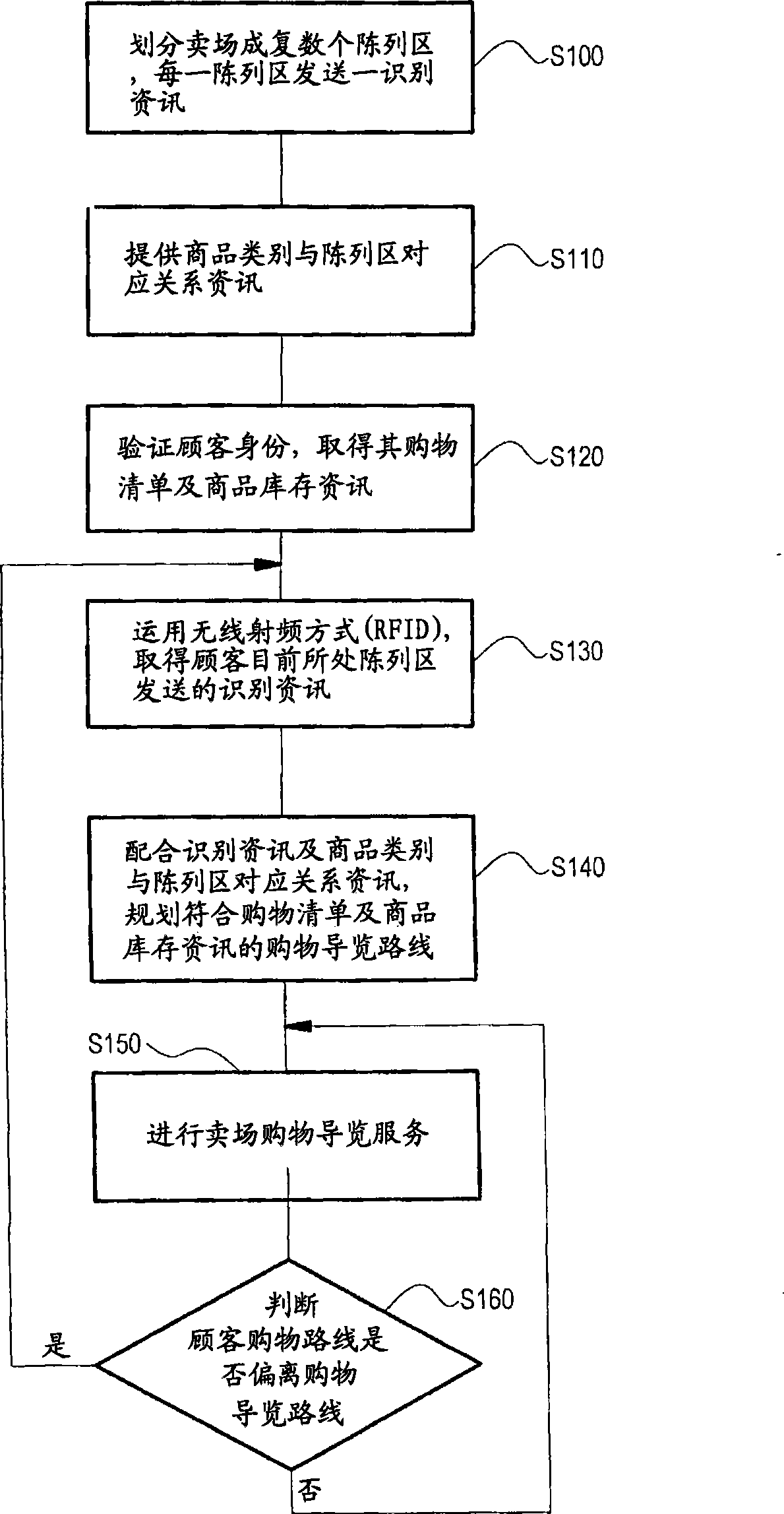

Shopping guide service method and system for sales field

InactiveCN101499154AOptimize system structureSkill improvedCo-operative working arrangementsCommerceService systemPersonal identification number

The invention provides a method for providing market shopping guide service and a system thereof. The method includes steps as follows: firstly, reading a client personal identification number in a membership card by a guide device and transmitting to a market servo for identifying by wireless method; secondly, obtaining commodity information and client information relative to the client identification number; finally, layouting the market shopping route for providing shopping guide service. The guide device can layout a new shopping route according with present client position when client deviates away the shopping route. The shopping guide service provides a sales promotion information, commodity price, inventory status and rapid payment on the shopping guide route. The market shopping guide service system includes: a plurality of wireless RF identifying induction labels, at least one guide device containing a wireless RF reader and a processor, and a servo. The method and the system can help customer finding commodity needed to buy rapidly or obtaining the commodity sales promotion information in shopping, and can help market increasing profit which cause win-win situation between the customer and the market.

Owner:INVENTEC APPLIANCES CORP

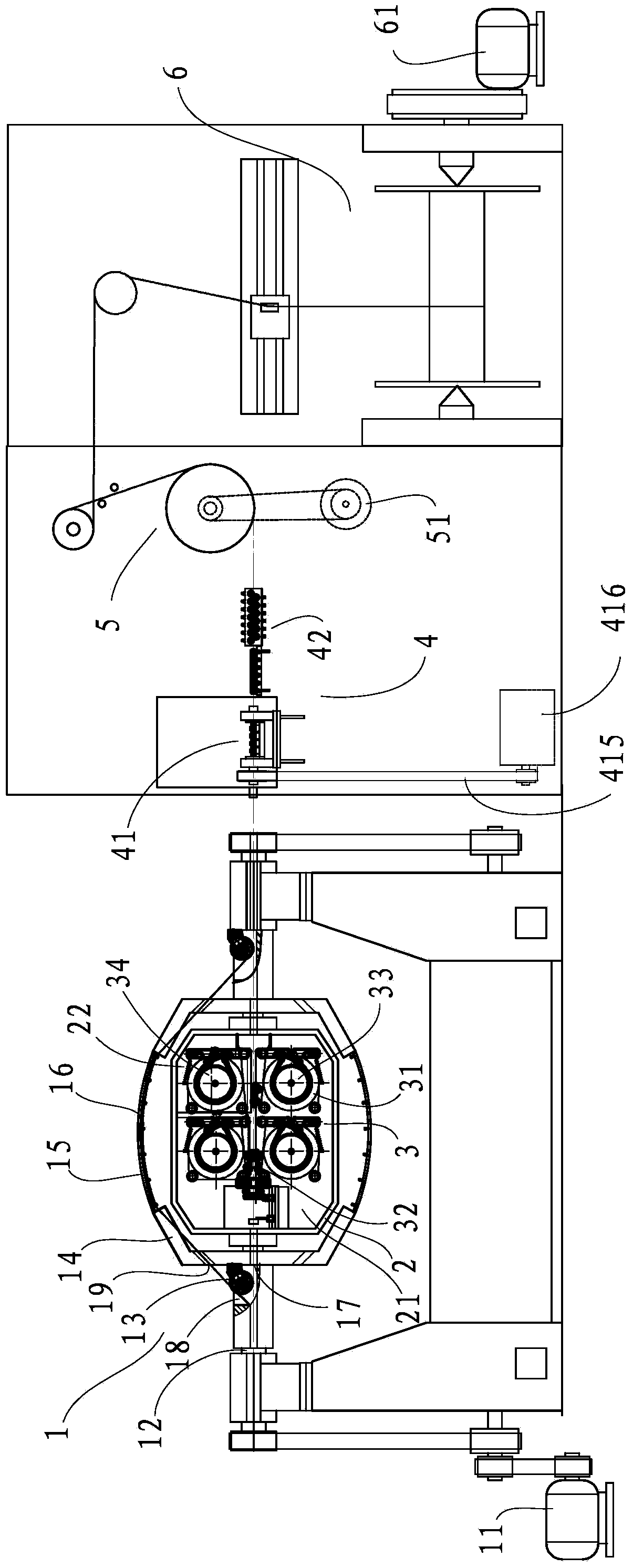

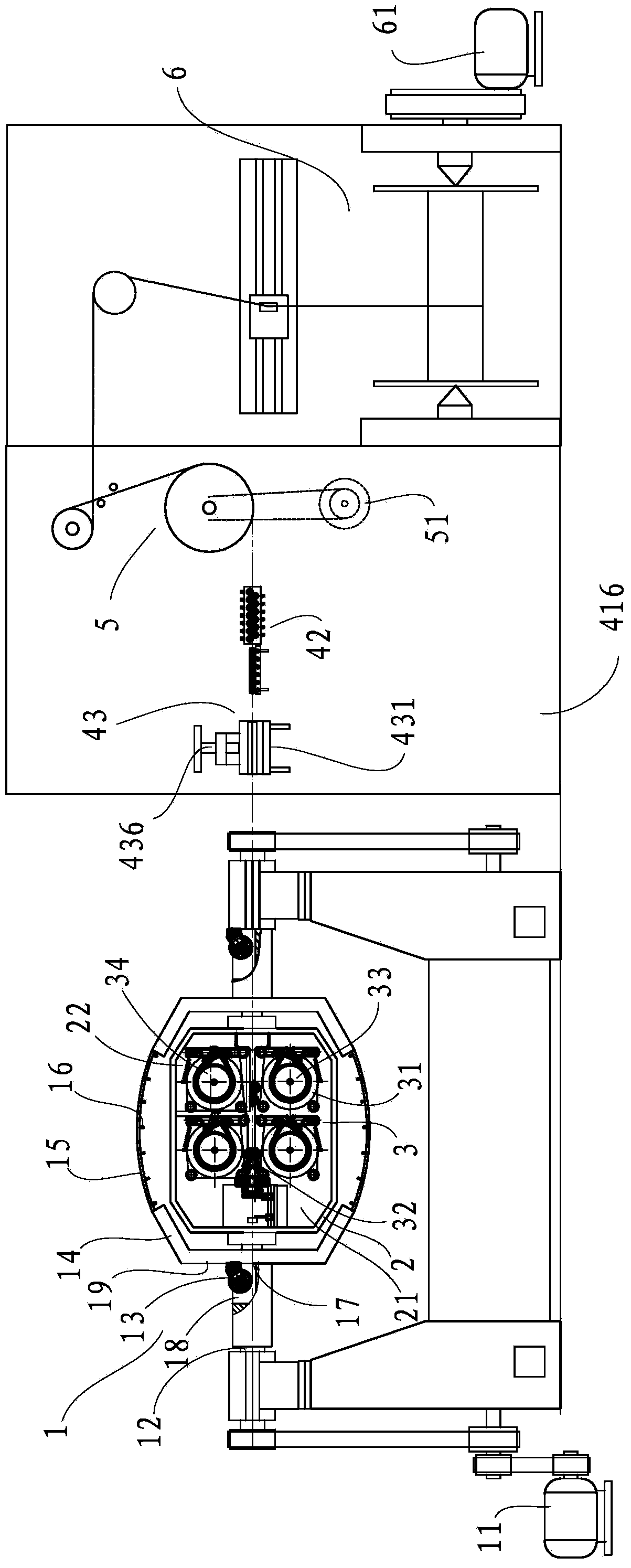

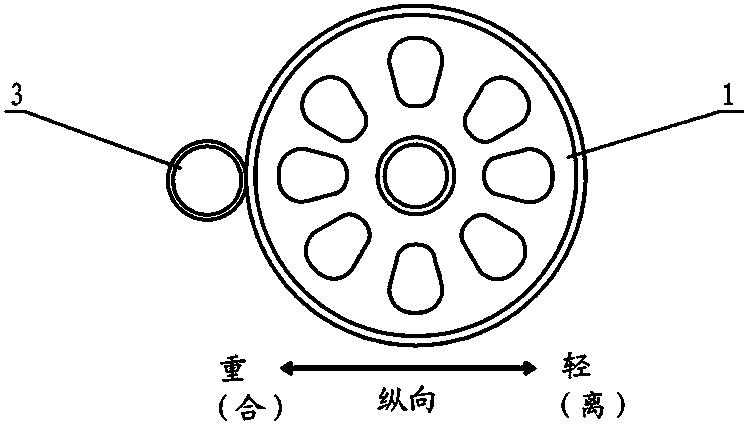

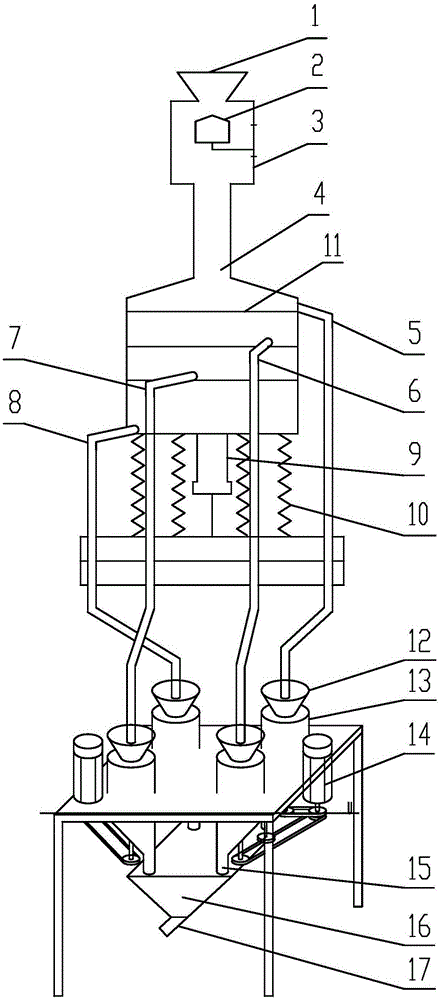

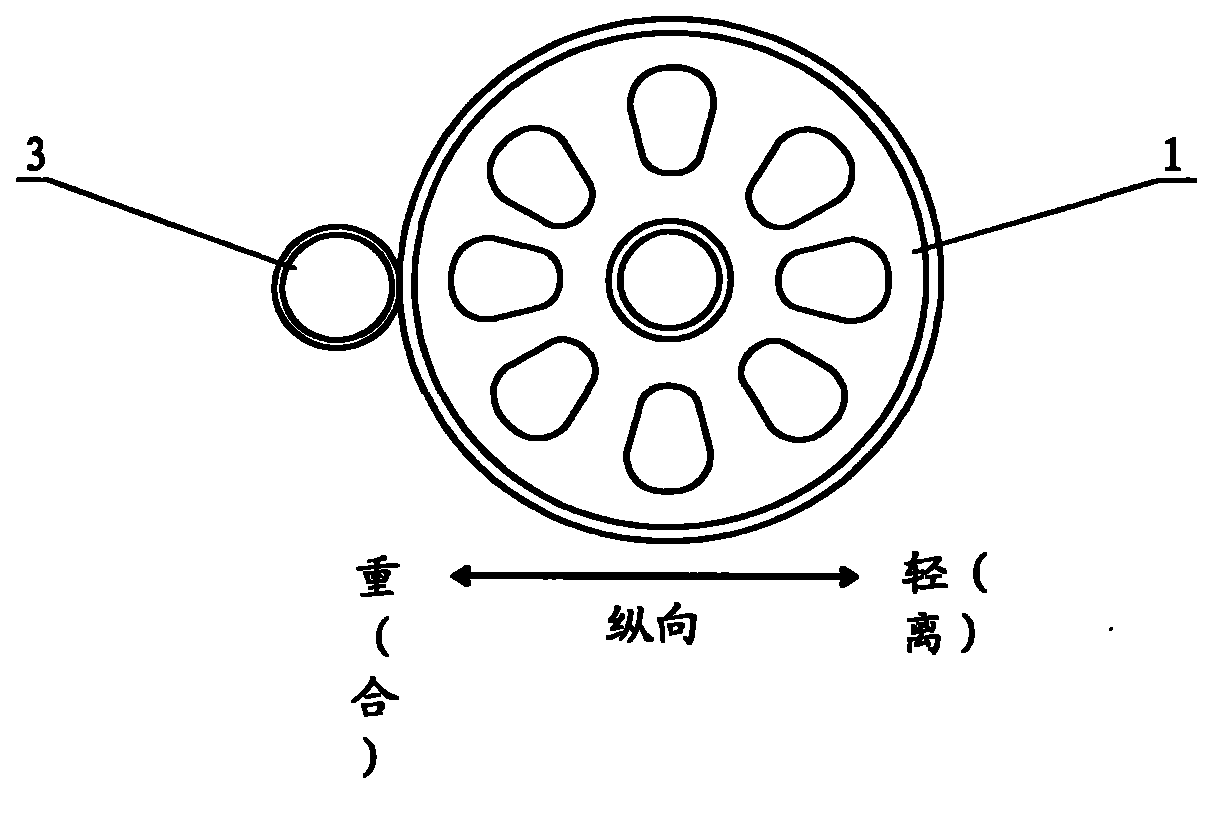

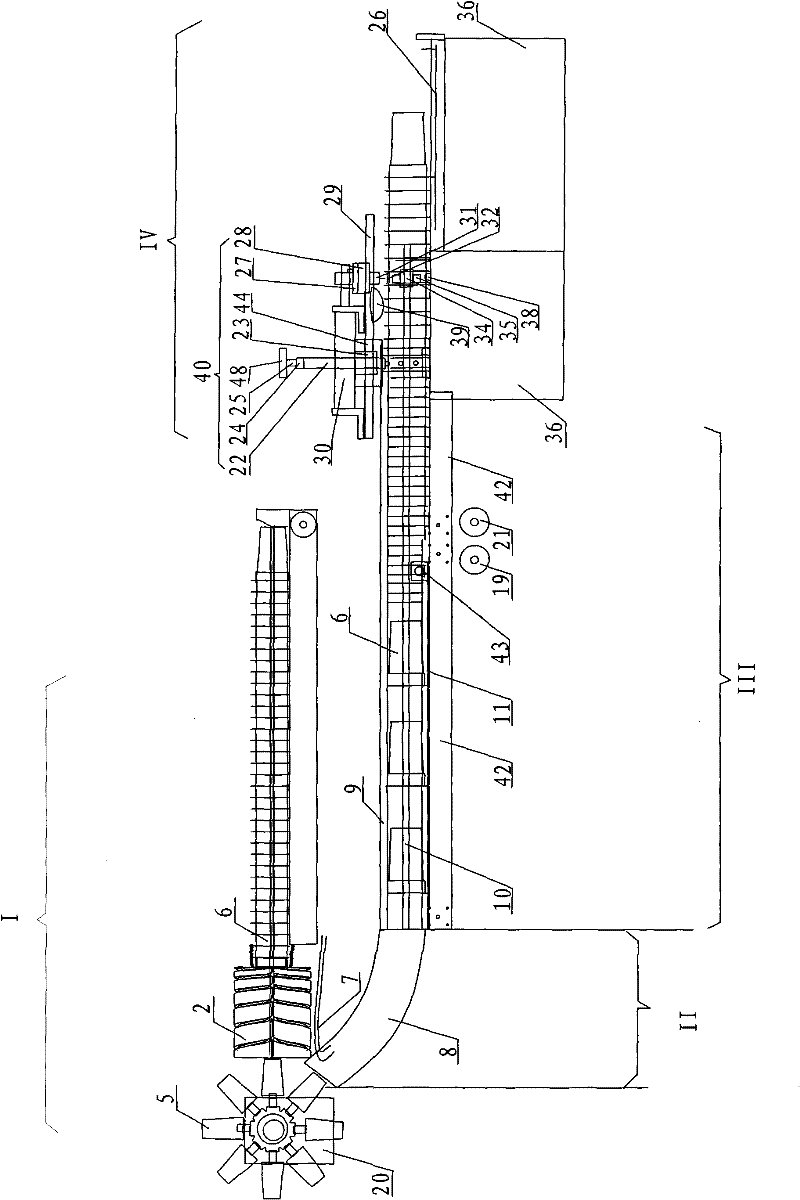

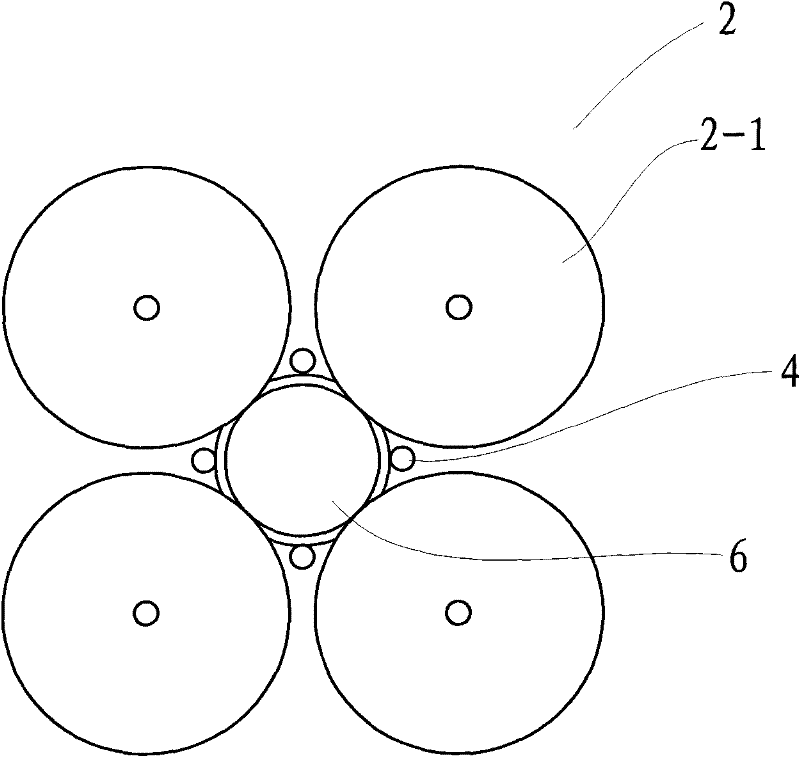

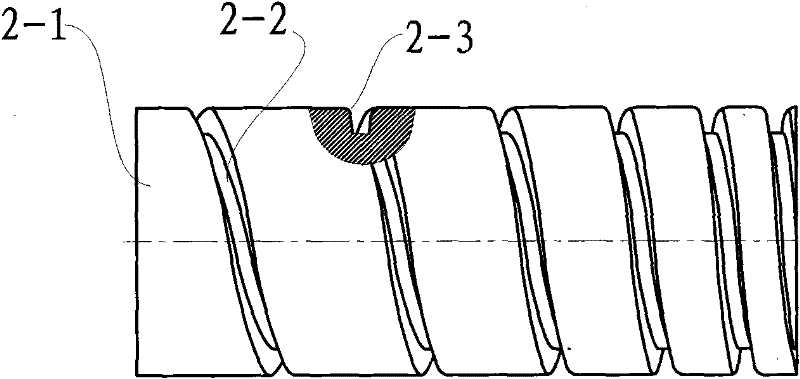

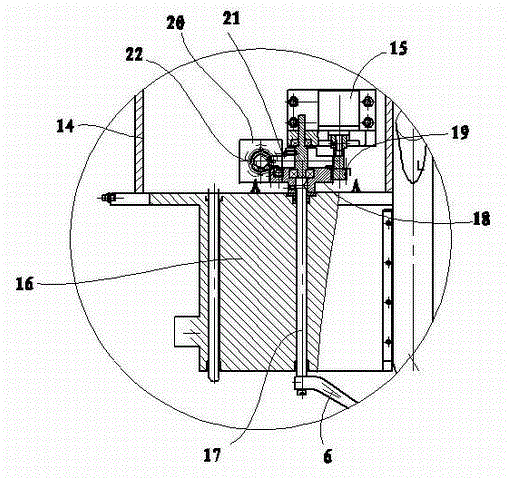

Cable-type welding wire double-twisting stranding machine

InactiveCN103464934ASmall moment of inertiaLow powerWelding/cutting media/materialsSoldering mediaTraction motorRocker arm

The invention relates to a welding wire processing device, particularly to a cable-type welding wire double-twisting stranding machine. The cable-type welding wire double-twisting stranding machine comprises a stranding unit, an unwinding unit, a sizing and stress relieving unit, a traction unit and a winding unit, wherein two main shafts with center holes and side holes of the stranding unit are fixedly provided with two arched rocker arms which are arranged oppositely, the arm ends of the two arched rocker arms which are arranged oppositely are provided with arched belts which are connected with the two arched rocker arms in which threading inclined holes are formed, the inner sides of the arched belts are provided with a plurality of wire through holes, and the stranding unit, the traction unit and the winding unit are respectively driven by a standing motor, a traction motor and a winding motor. The cable-type welding wire double-twisting stranding machine has the advantages of being high in production efficiency and small in vibration noise.

Owner:江苏科为焊业有限公司 +1

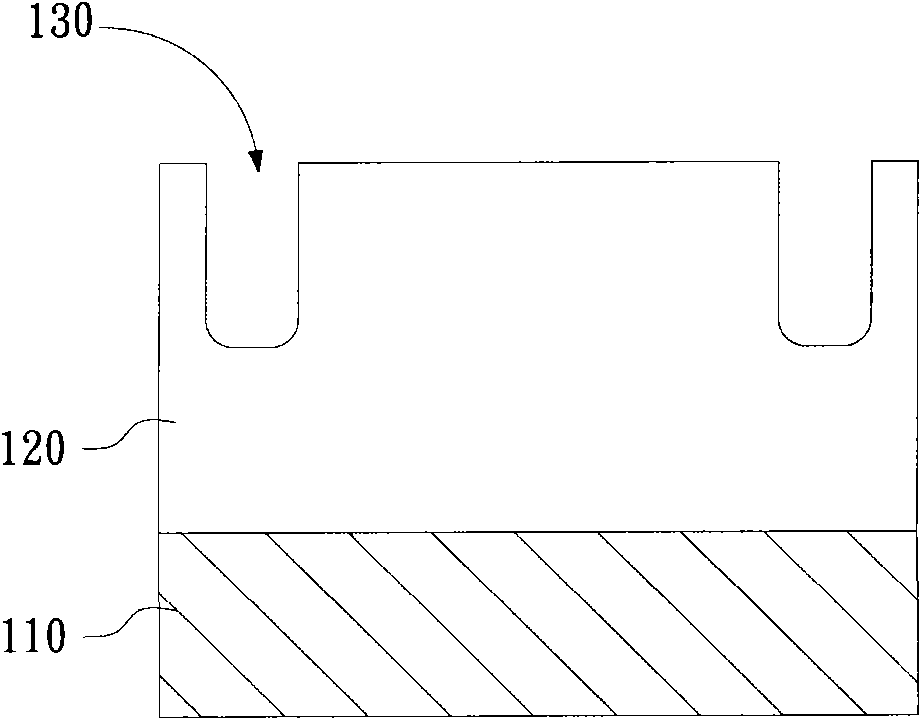

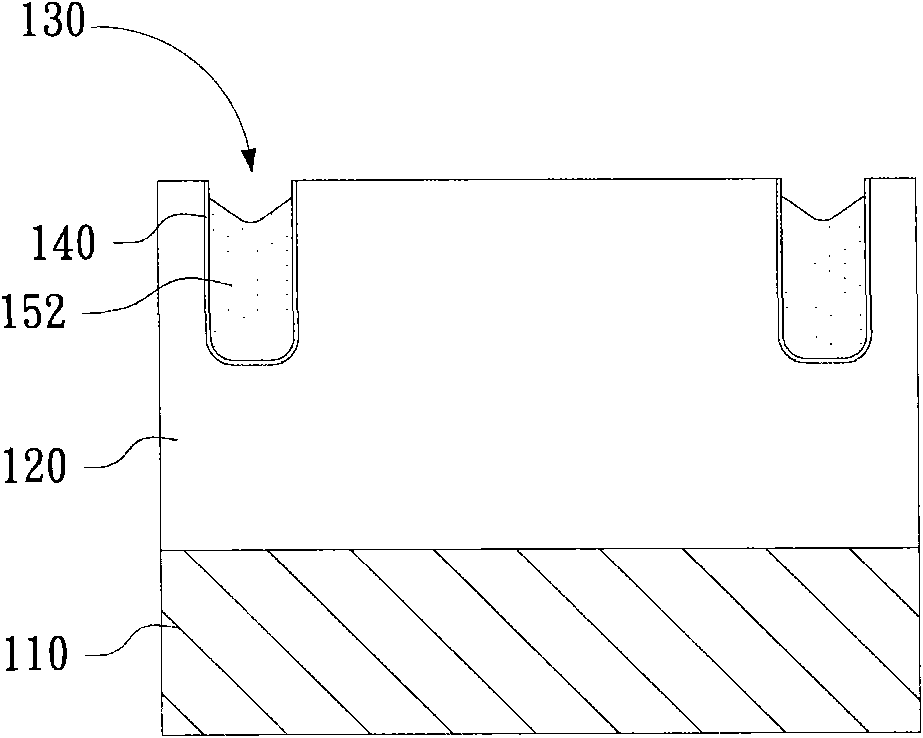

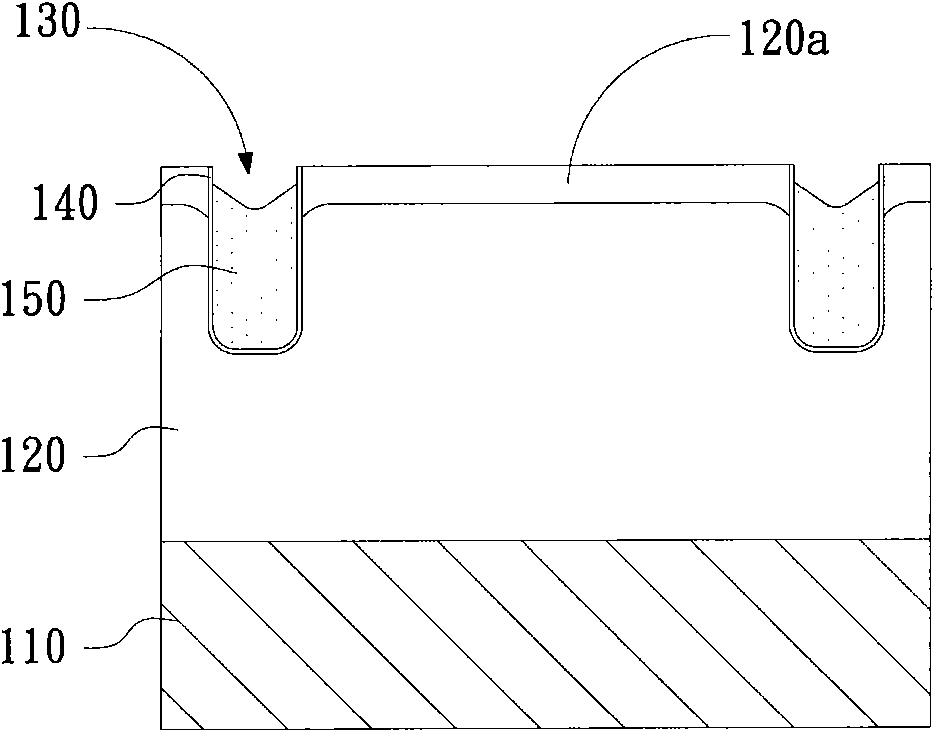

Trench gate metal oxide semiconductor field effect transistor and manufacturing method thereof

InactiveCN101656213ASimple structureEnhance the outstanding effectSemiconductor/solid-state device manufacturingSemiconductor devicesField-effect transistorPolysilicon gate

The invention relates to a trench gate metal oxide semiconductor field effect transistor and a manufacturing method thereof. The method comprises the following steps: manufacturing a first conductiveepitaxial layer on a silicon substrate; manufacturing a plurality of trenches on the epitaxial layer; performing overall ion implantation of a first conductive doping material on the epitaxial layer;manufacturing a polysilicon pattern layer covering the trenches and the epitaxial layer in a preset range around the trenches; implanting a second conductive doping material on the epitaxial layer through the polysilicon pattern layer; importing a doping material to form a well area having the second conductive doping material; implanting the first conductive doping material in the well area through the polysilicon pattern layer to form a plurality of first doped areas; implanting the doping material of the first doped areas to form source electrode doped areas close to the trenches; and removing the polysilicon pattern layer above the epitaxial layer to form a polysilicon gate. The method can improve the depth distribution of the sell area of the trench gate metal oxide semiconductor field effect transistor and avoiding the effectiveness loss caused by the coverage of the gate trenches by the well area.

Owner:NIKO SEMICON

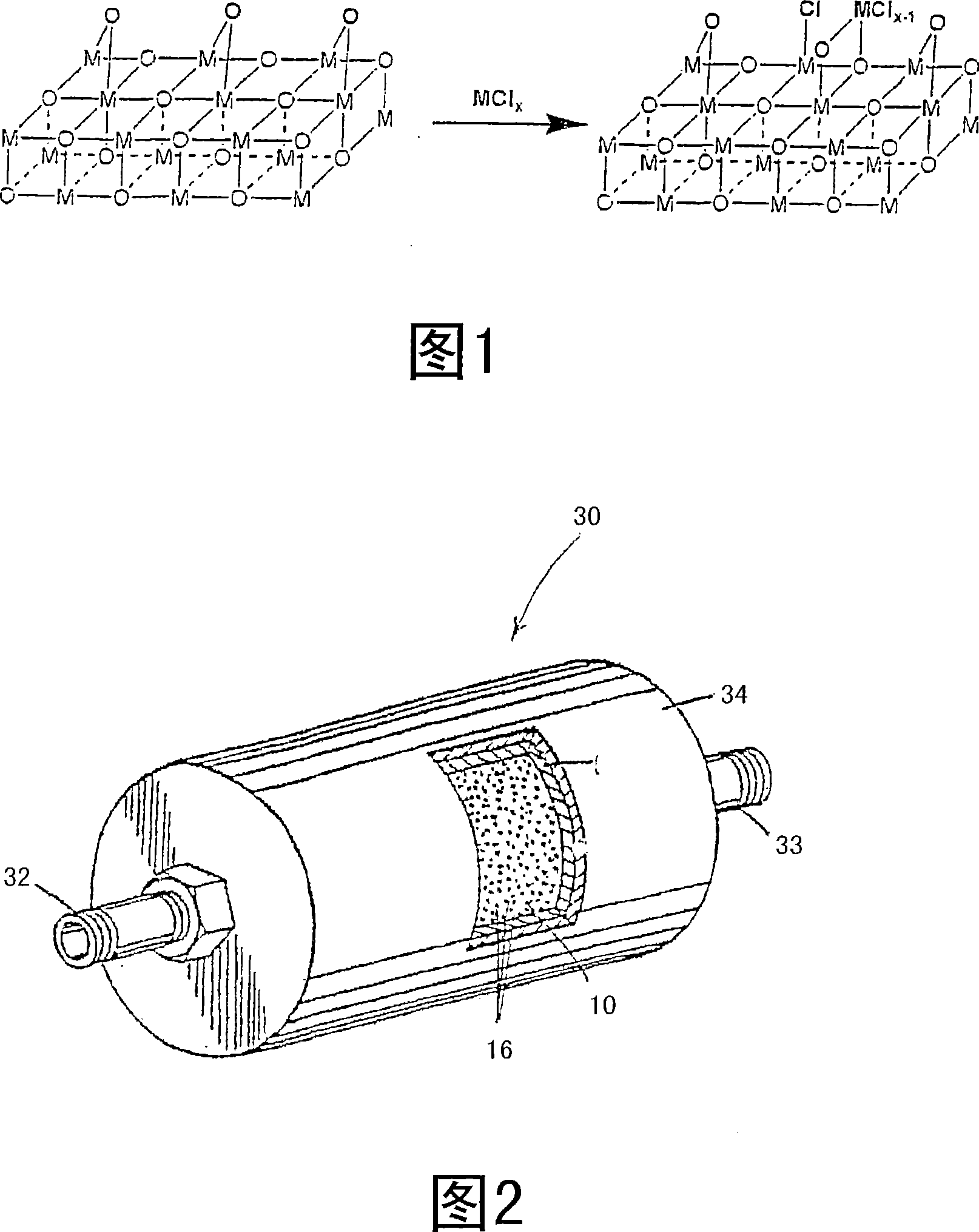

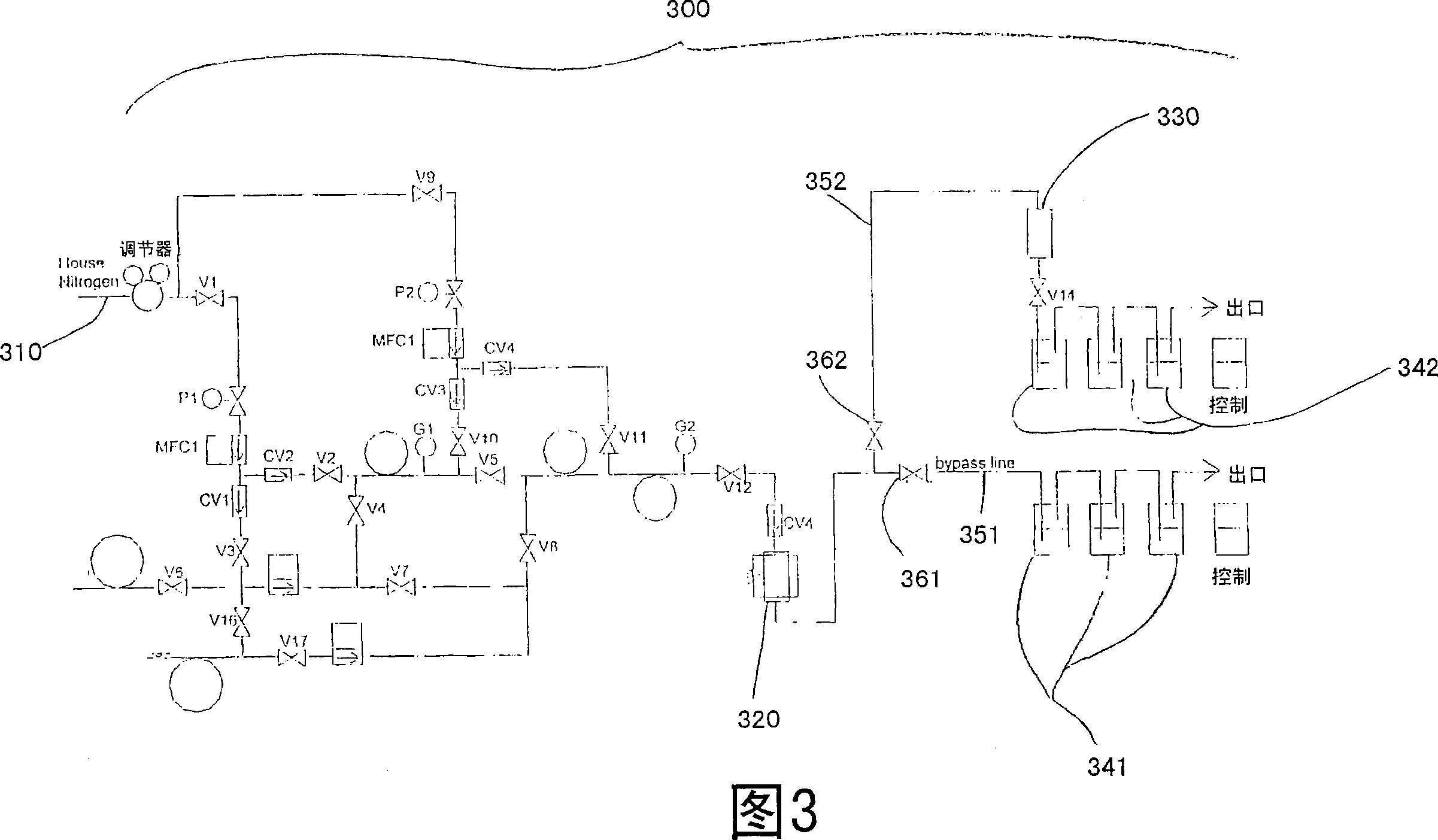

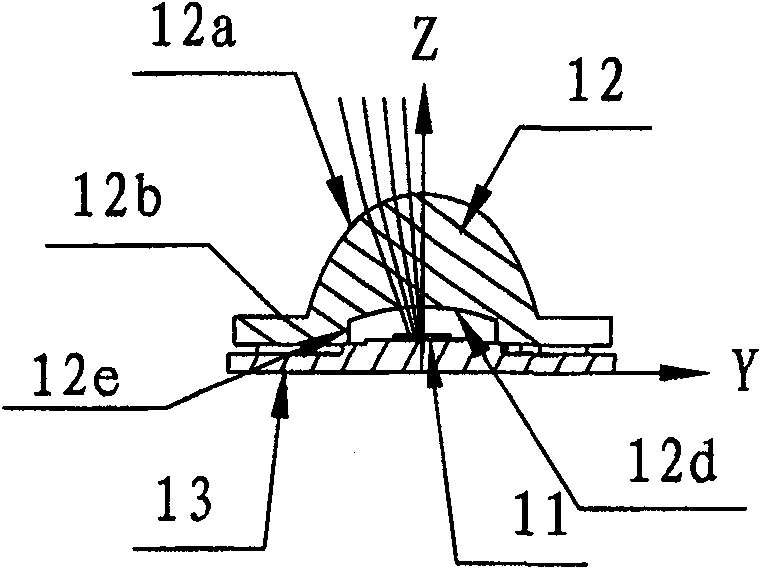

Removal of metal contaminants from ultra-high purity gases

InactiveCN1988948ASkill improvedImprove stabilityHydrogen bromideNitrogen compoundsUltra high purityDevice failure

The invention is a method and apparatus for removing metal compounds from ultra-high purity gases using a purifier material comprising a high surface area inorganic oxide, so that the metals do not deposit on a sensitive device and cause device failure.

Owner:ENTEGRIS INC

Lens system suitable for LED road lamp

ActiveCN101487579BWidely used valueConvergence requirements are lowMechanical apparatusPoint-like light sourceIlluminanceCurve shape

Owner:NINGBO LIAOYUAN IND

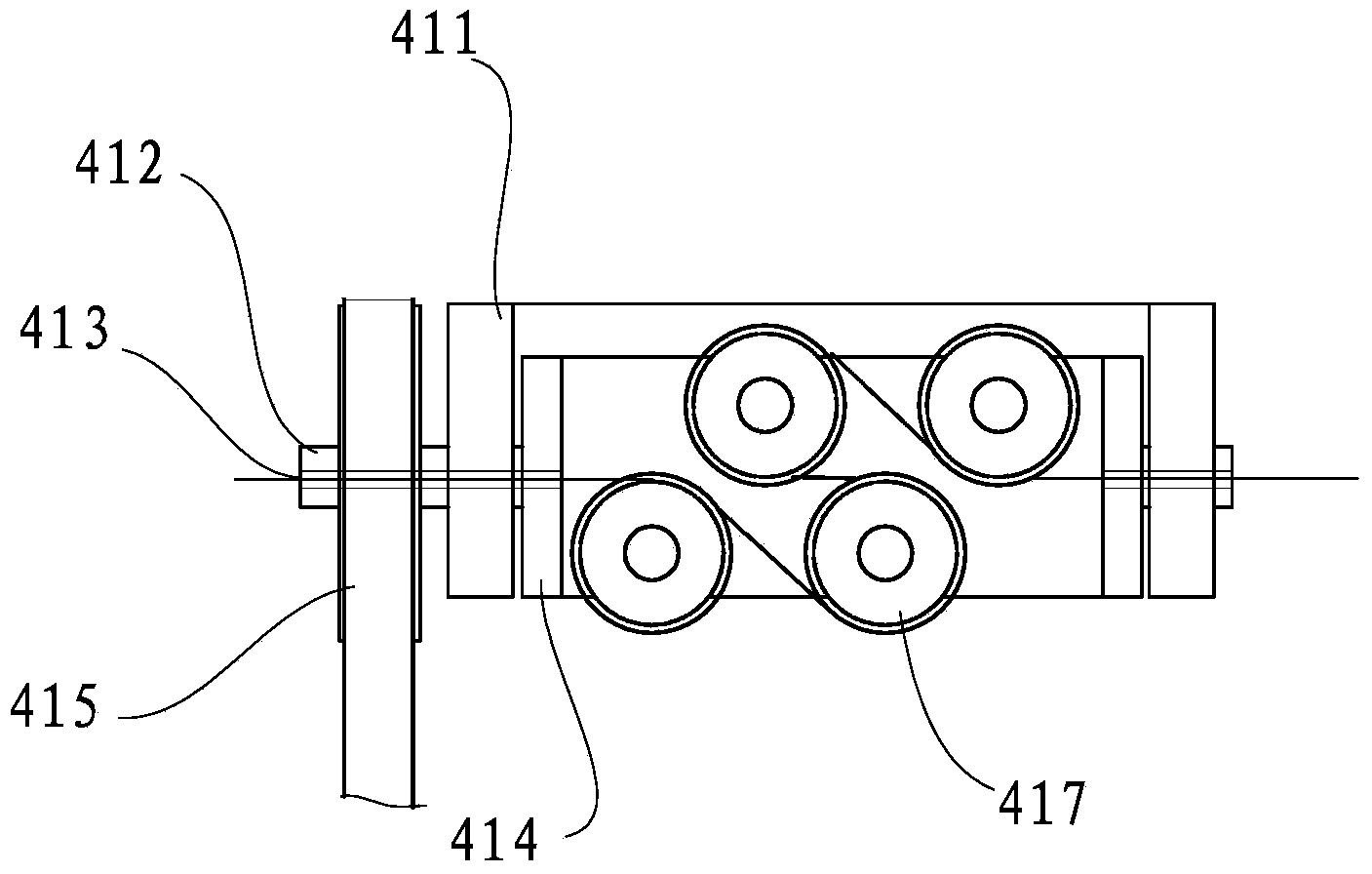

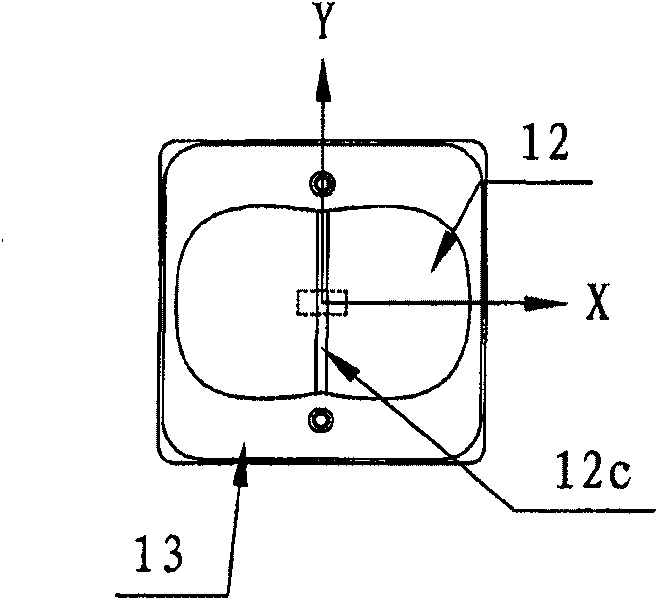

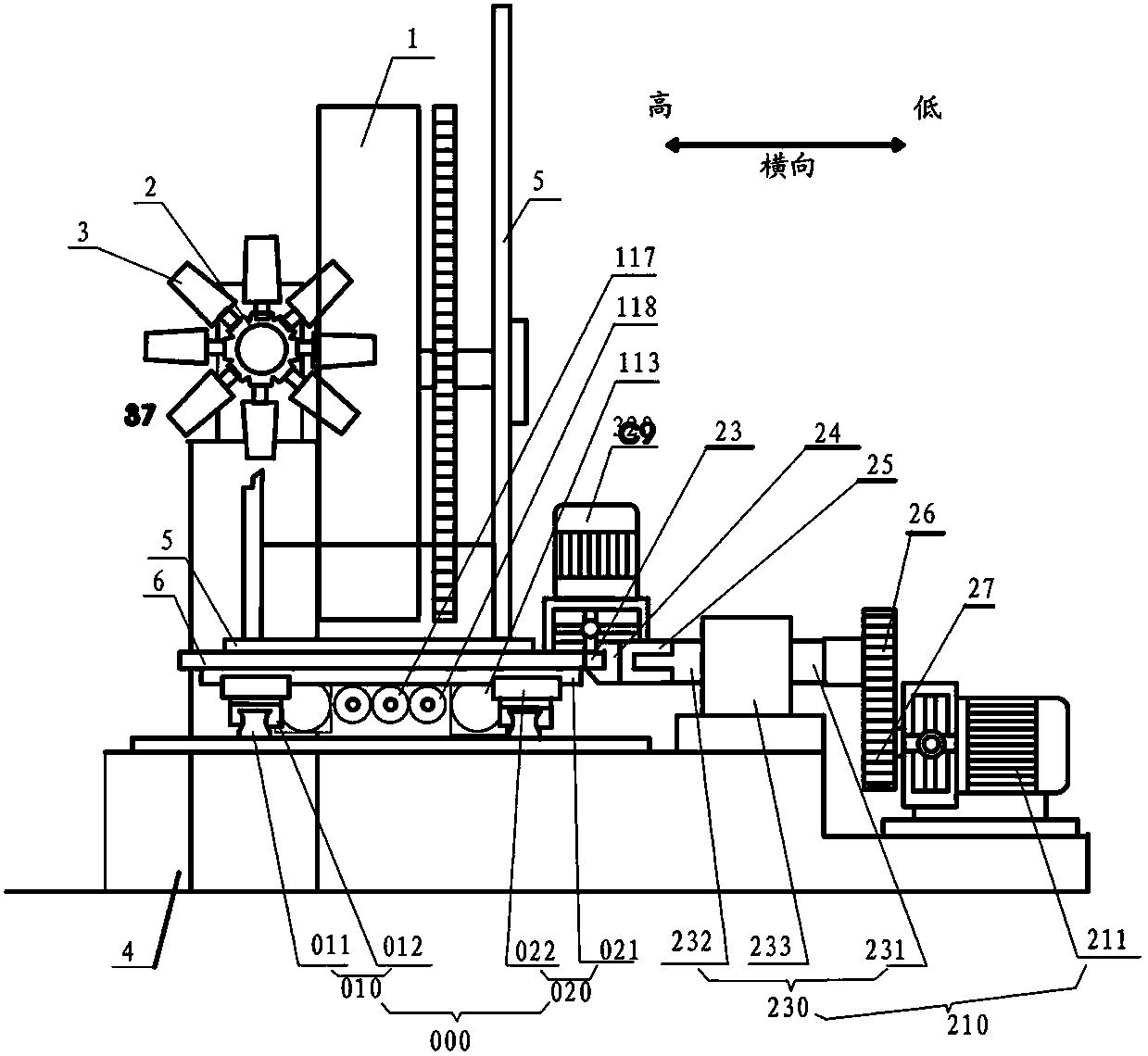

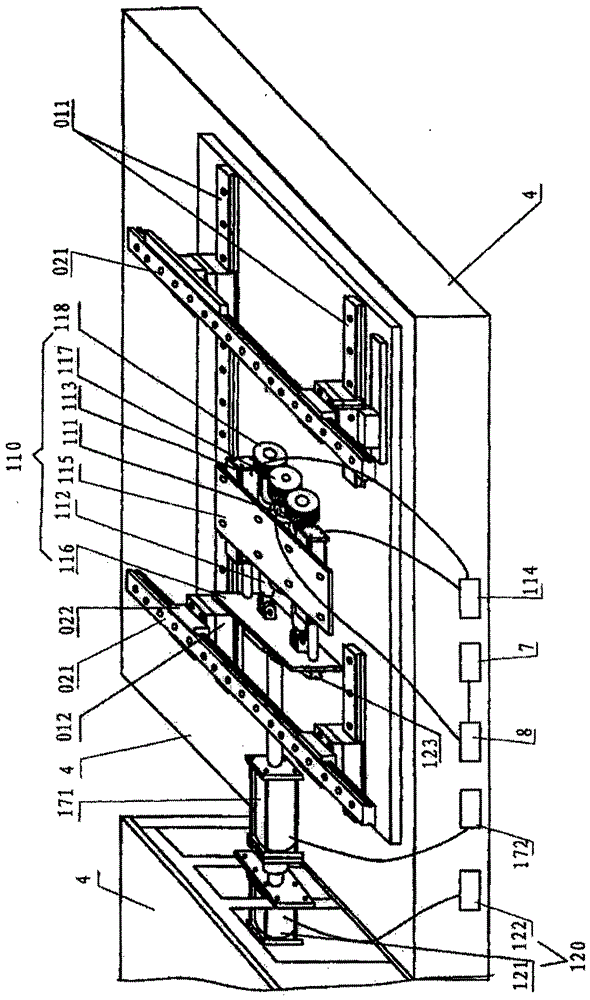

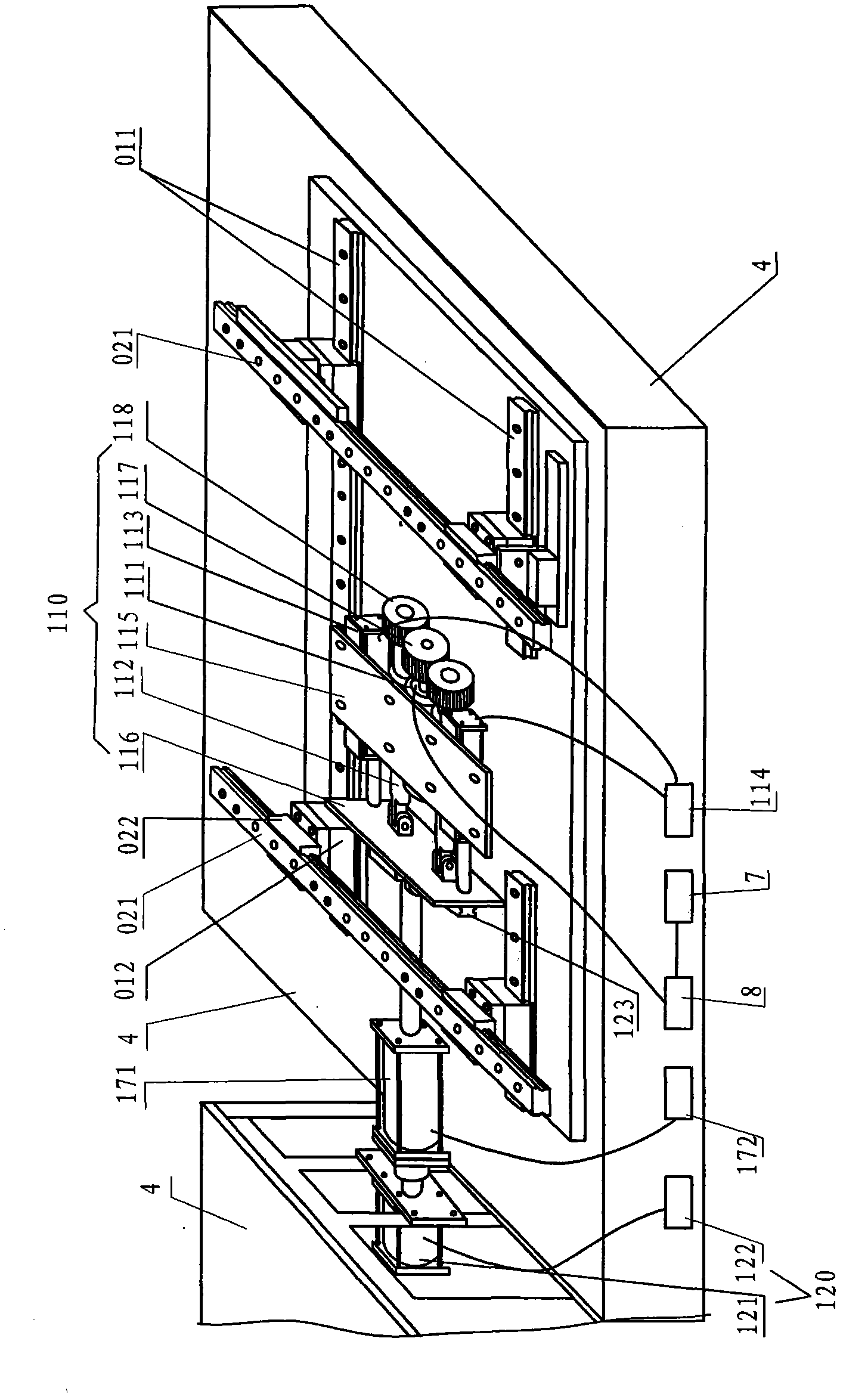

Embedded numerical-control printing pressing force adjustment and clearance tolerance elimination device

InactiveCN104339828ASmall vibrationEasy to replace rubber and maintenanceRotary pressesPrinting press partsEngineeringEmbedded controller

The invention relates to printing machinery, in particular to an embedded numerical-control printing pressing force adjustment and clearance tolerance elimination device which comprises a printing device and a printing main unit, wherein the printing device is arranged on a base and provided with a multi-station stepping indexing turntable and a die handle, and the printing main unit is arranged on a main unit support and provided with a transfer print large drum wheel. The device is characterized in that a two-dimensional orthogonal sliding seat is arranged on the base, the main unit support is arranged on the two-dimensional orthogonal sliding seat through a main unit seat plate, an embedded controller is provided with a longitudinal moving device for eliminating a clearance and a touch screen and controls the longitudinal moving device for eliminating the clearance, and the longitudinal moving device for eliminating the clearance is arranged between the base and the main unit seat plate, controls the main unit seat plate to move along the direction perpendicular to the axis of the die handle, and eliminates the tolerance clearance. The embedded numerical-control printing pressing force adjustment and clearance tolerance elimination device is convenient to operate and small in vibration and meets the accuracy requirement of high-speed running of a cup printing machine, the cup printing machine prints 450-650 cups per minute, and the cup printing speed is doubled as compared with that of an existing device.

Owner:GUANGDONG LONGXING PACKAGING IND

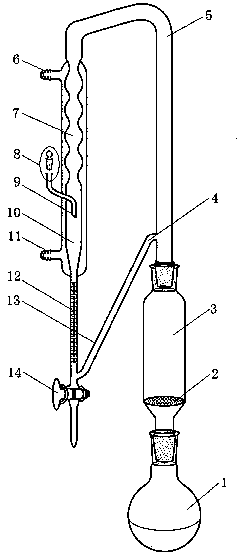

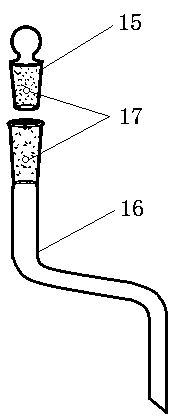

Water volatile oil distilling and extracting device and method

InactiveCN110093209AFacilitate the study of extraction processSolve the absence problemEssential-oils/perfumesWater vaporDistillation

The invention discloses a water volatile oil distilling and extracting device and method. Compared with conventional distillation extraction methods, both the extraction rate and sensory quality of volatile oil can be enhanced, and the extraction rate can be enhanced by 3-4 times. The device is characterized in that the device includes a round bottom flask, a material steaming pipe and an enclosing and condensation integrated volatile oil extractor; water is put in the flask, and a material is put in the material steaming pipe; water vapor passes through the material and carries volatile oil;condensation is performed in an Allihn condenser from top to bottom; oil and water separation is performed in a separating and collecting pipe under a low temperature environment to perform full cooling; and the precision of a scale pipe reaches 0.01 mL, so that the volume of the volatile oil can be read more accurately. Therefore, the vacancy problem of water volatile oil distilling and extracting devices in laboratories can be solved; the problems of hydrolysis and pyrolysis of volatile oil components caused by long-time soaking of the materials in boiling water can be solved; enclosed condensation and cooling systems can prevent the natural dissipation of the volatile oil during extraction; and accurate scales provide reliable data for the scientific research of the laboratories.

Owner:QIQIHAR UNIVERSITY

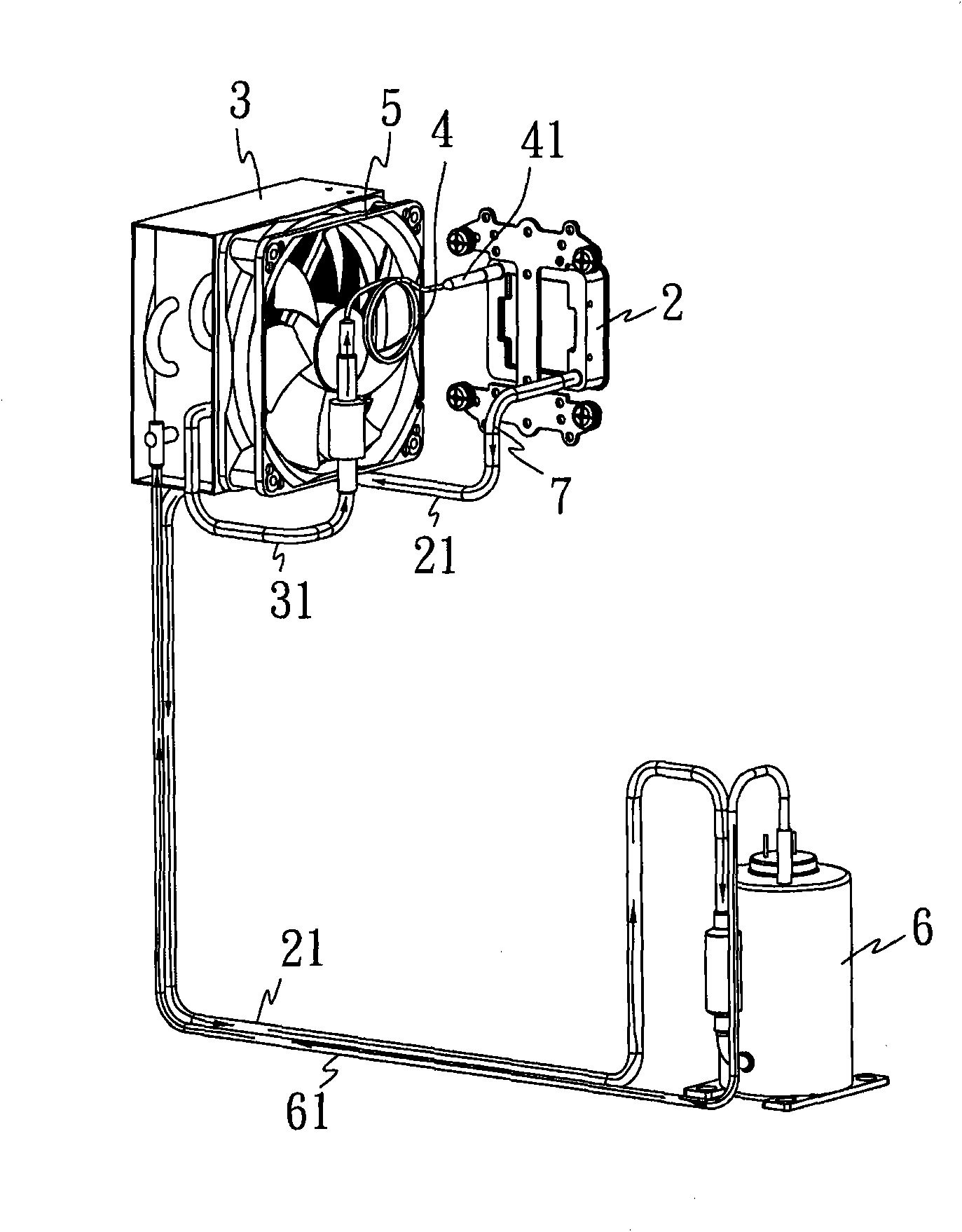

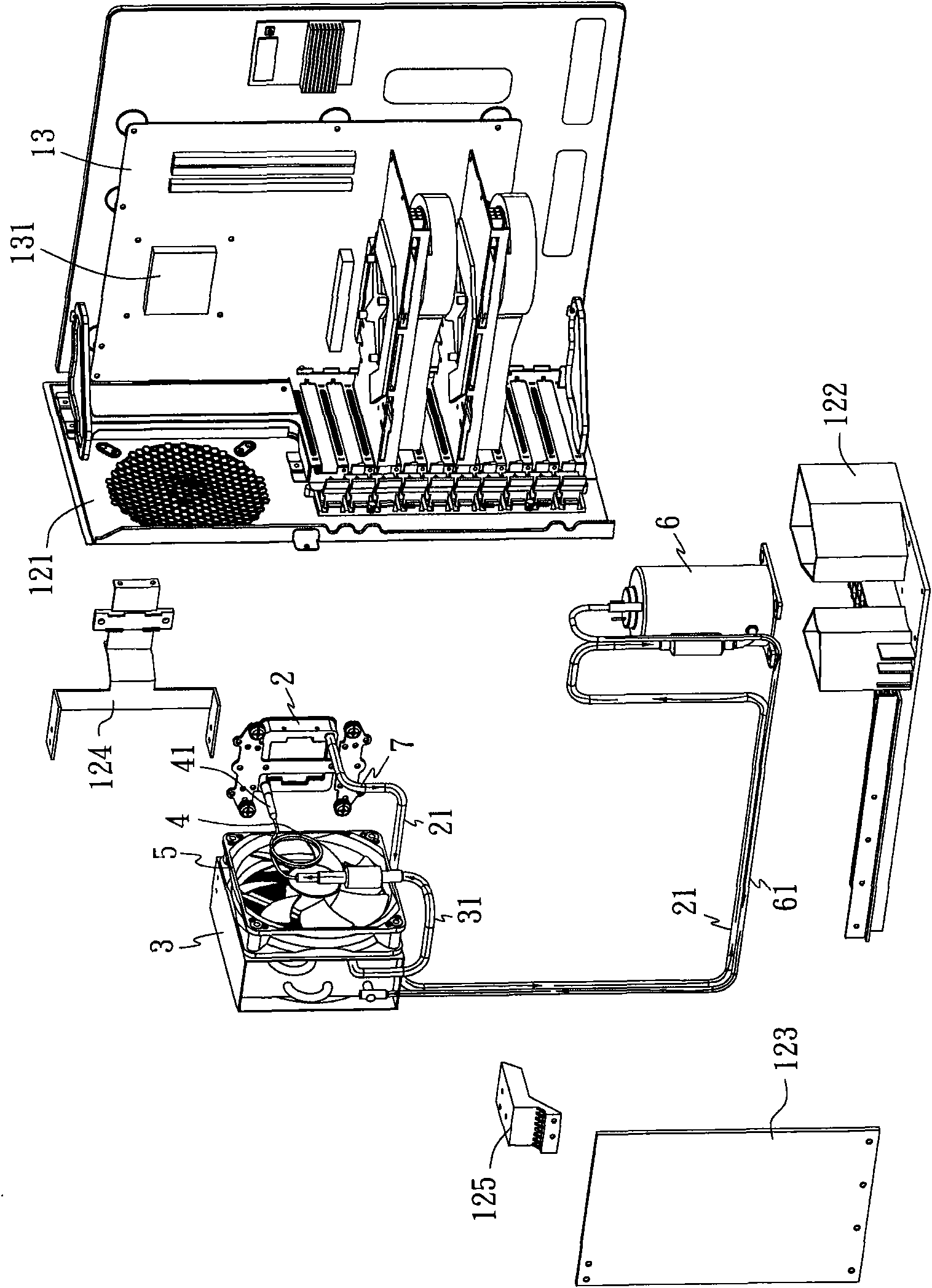

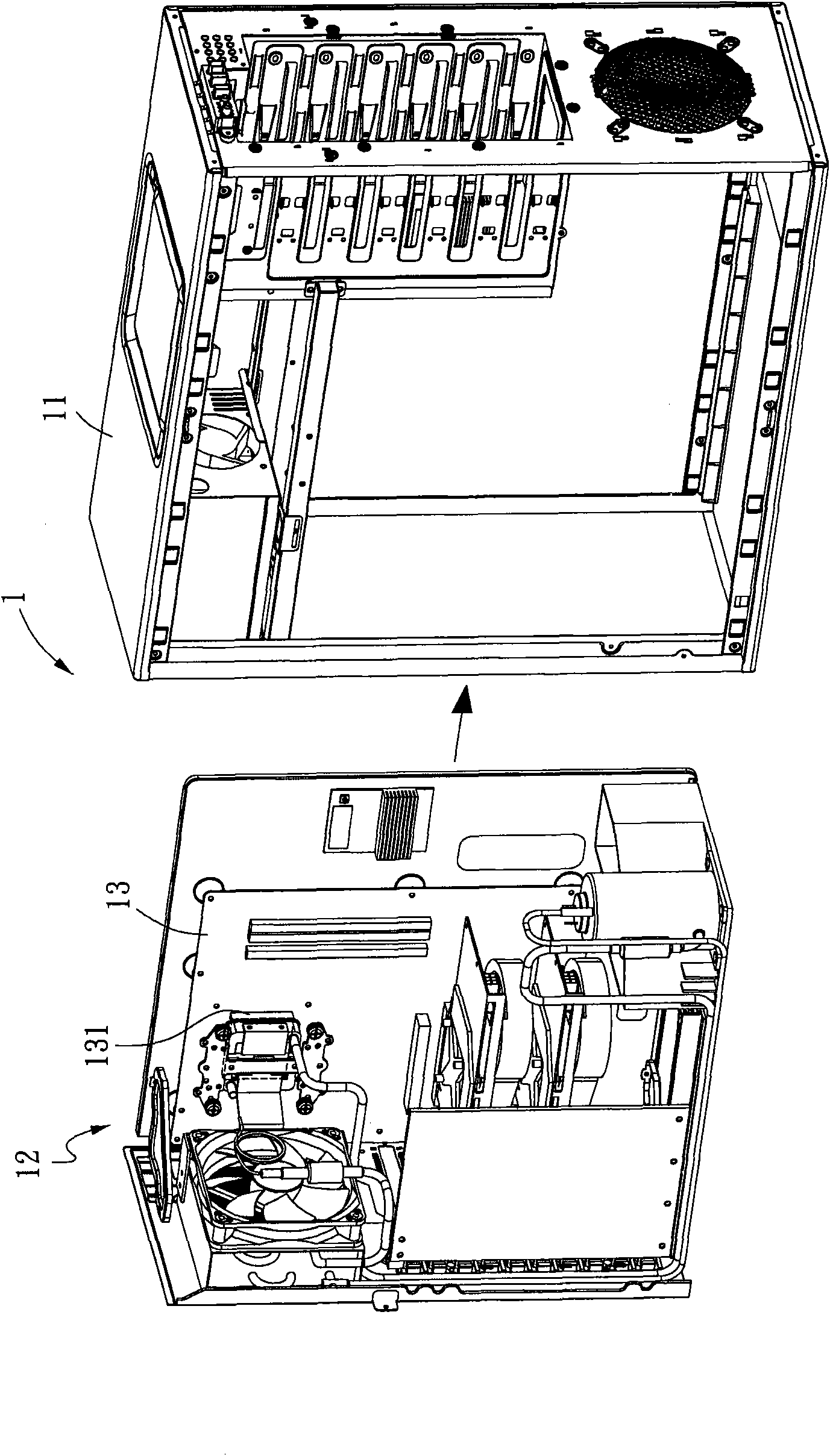

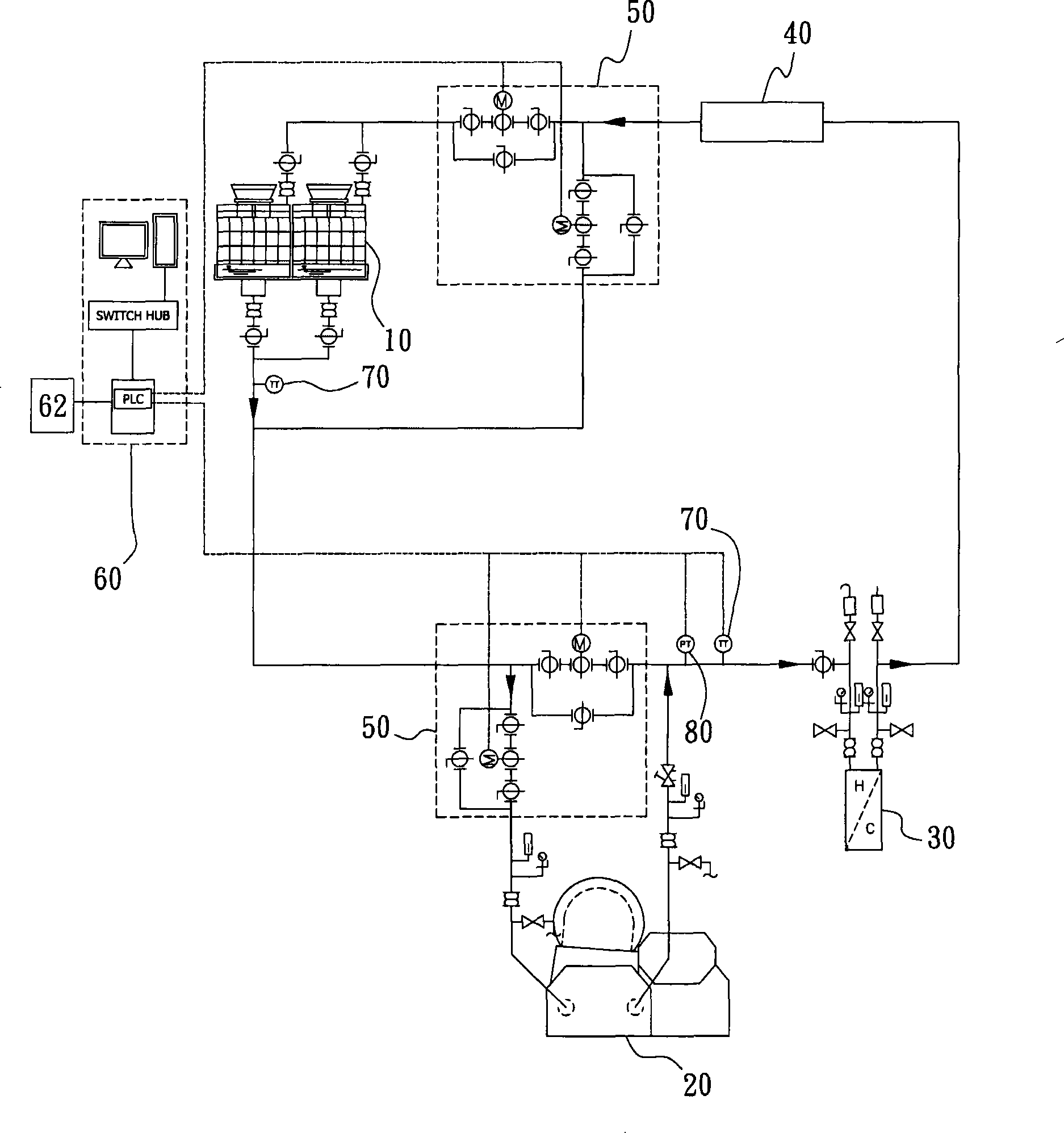

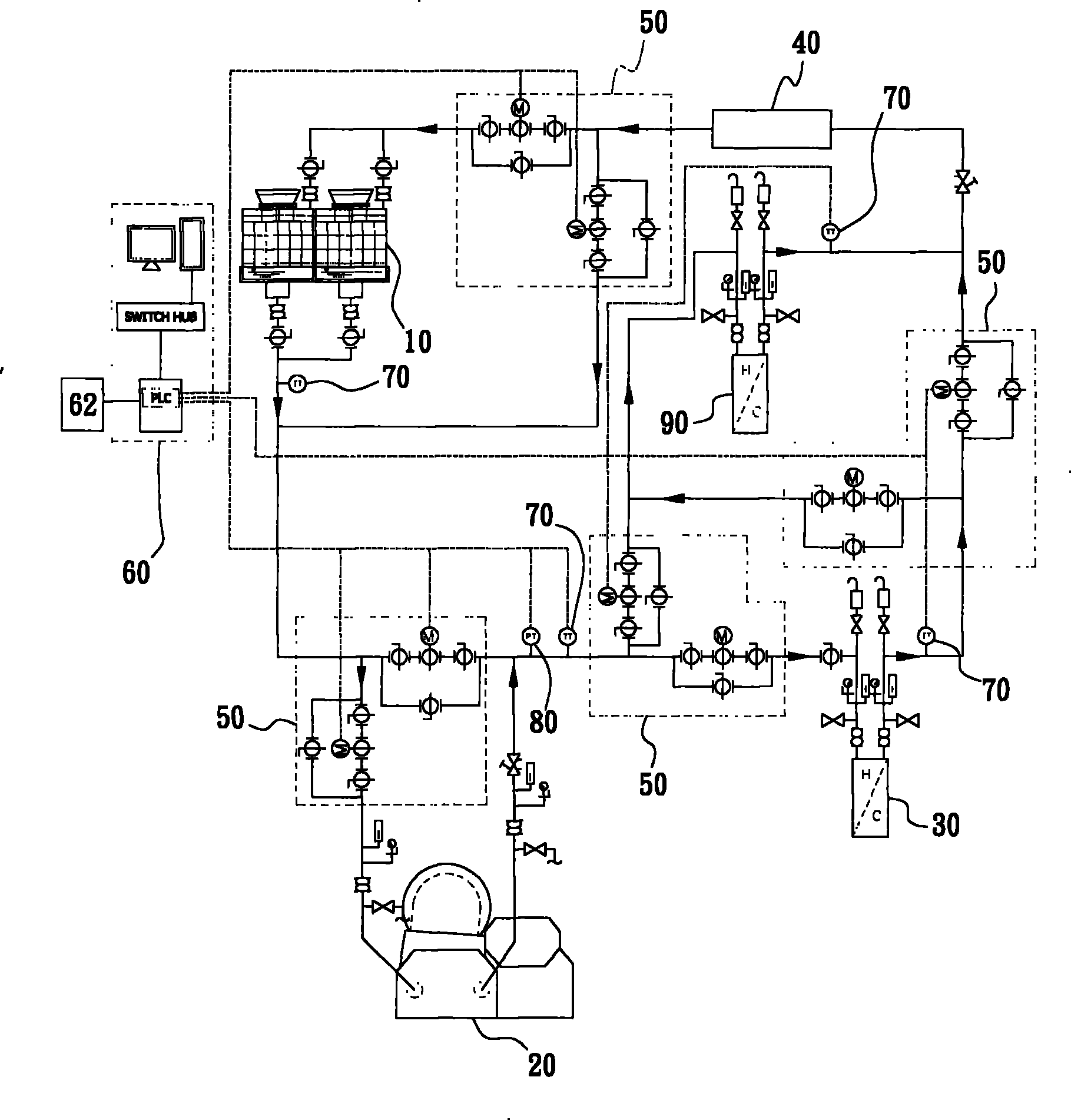

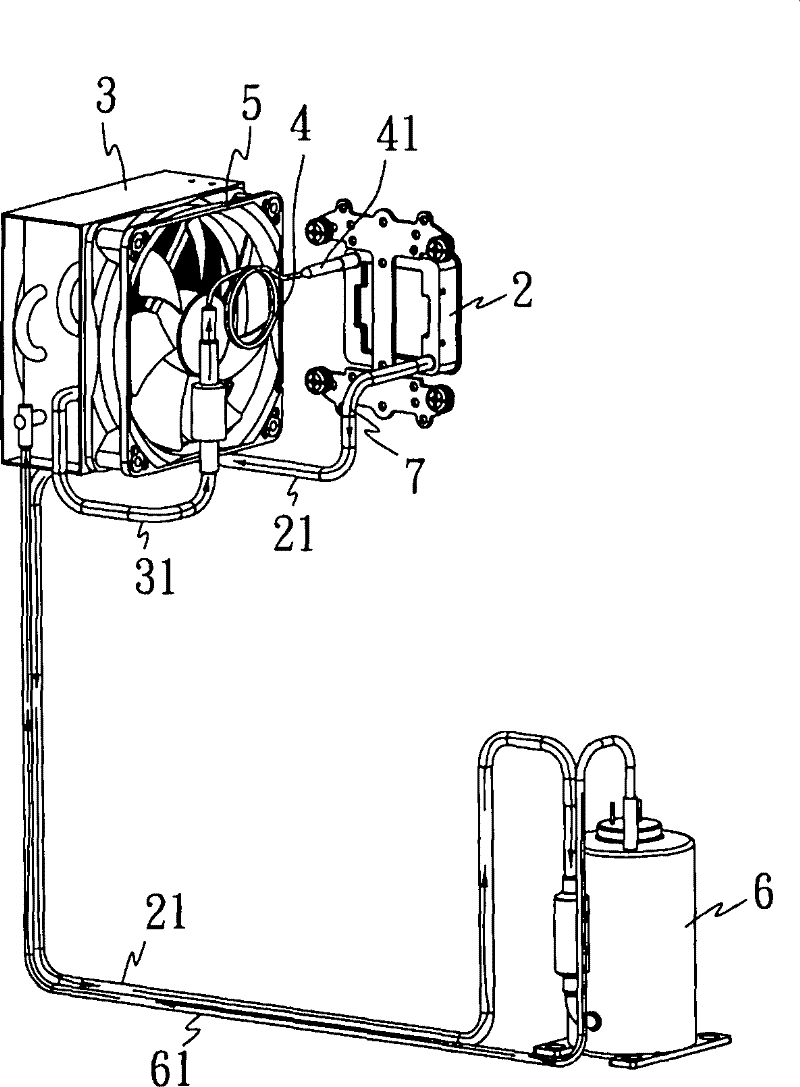

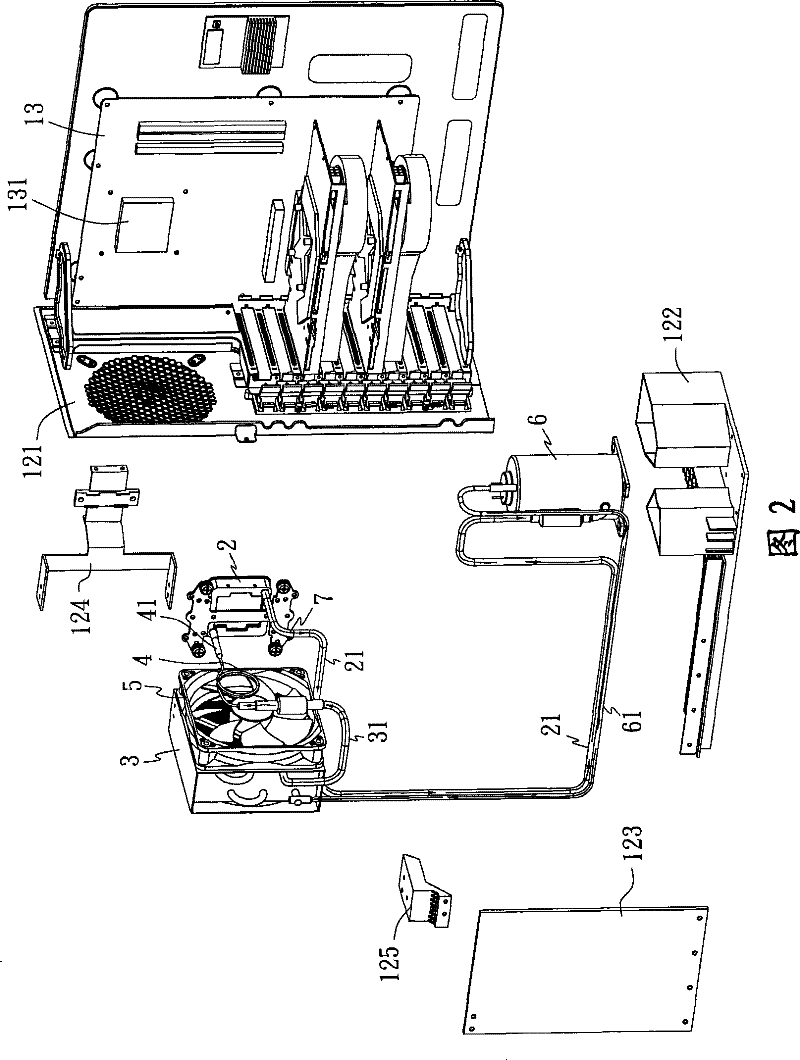

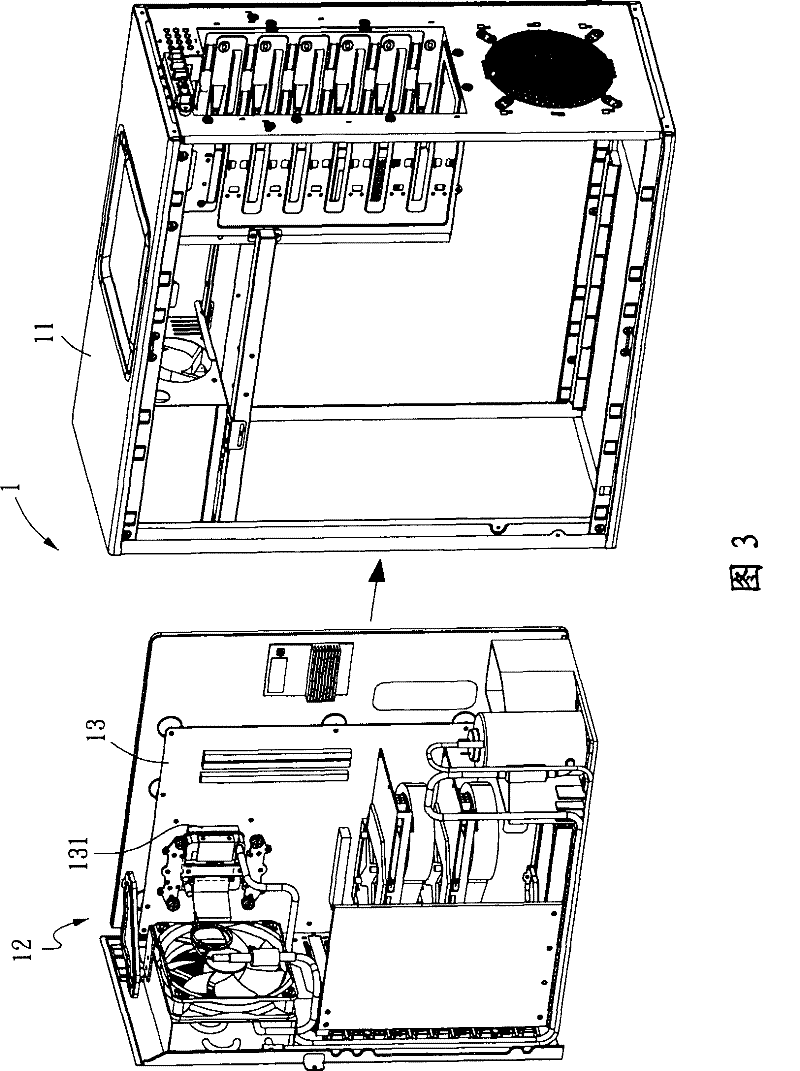

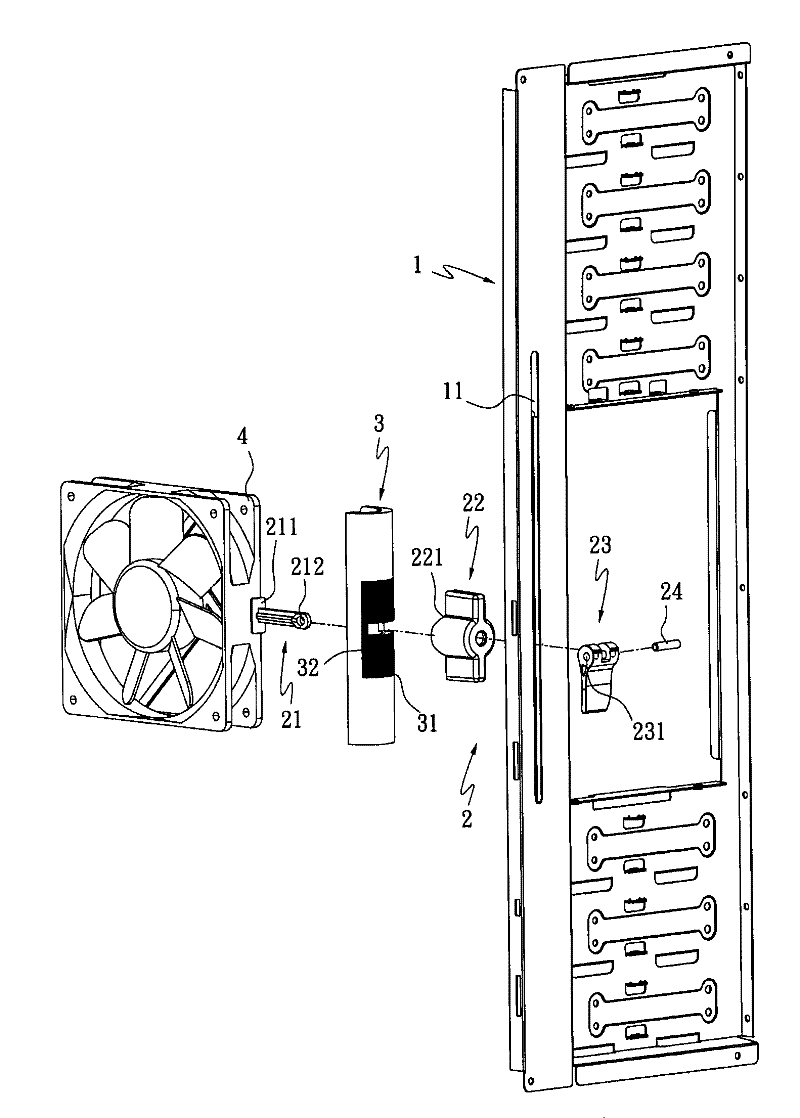

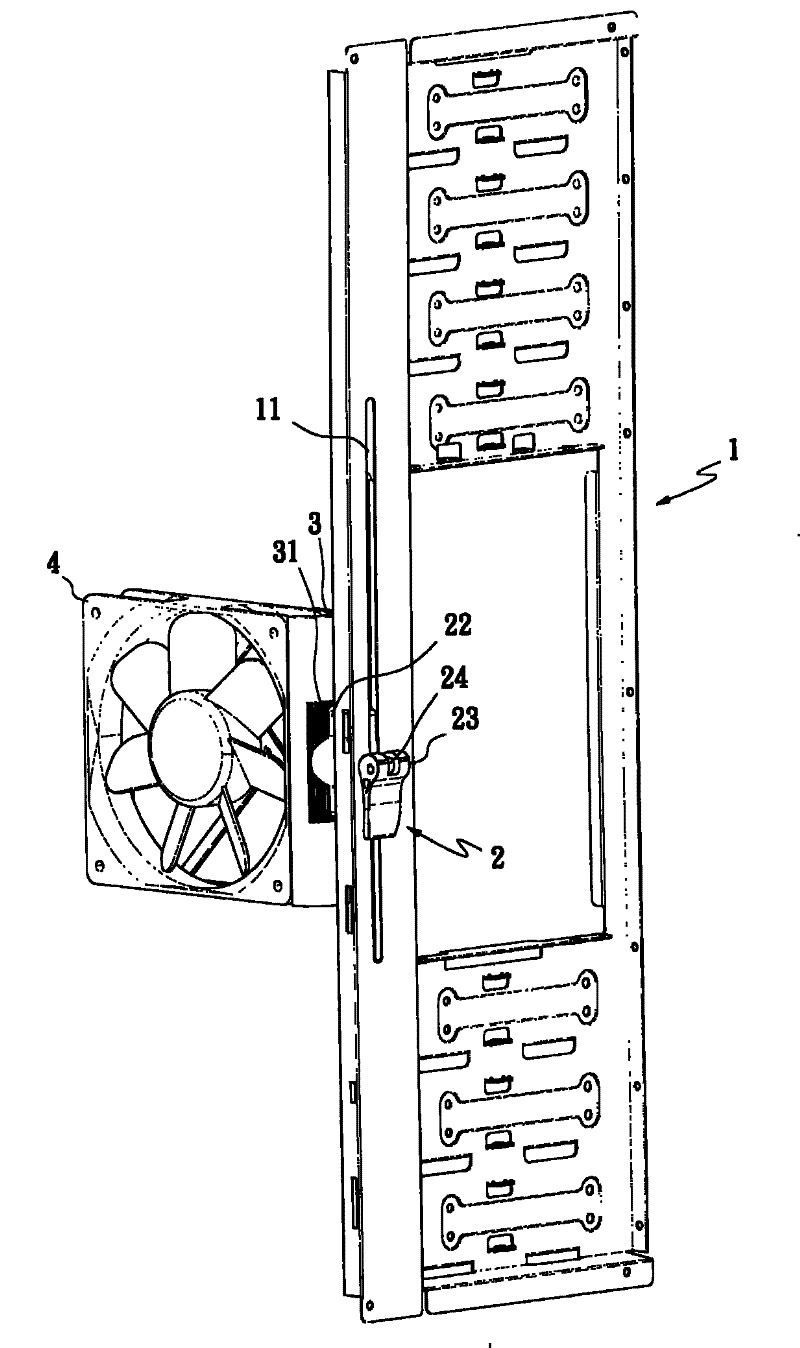

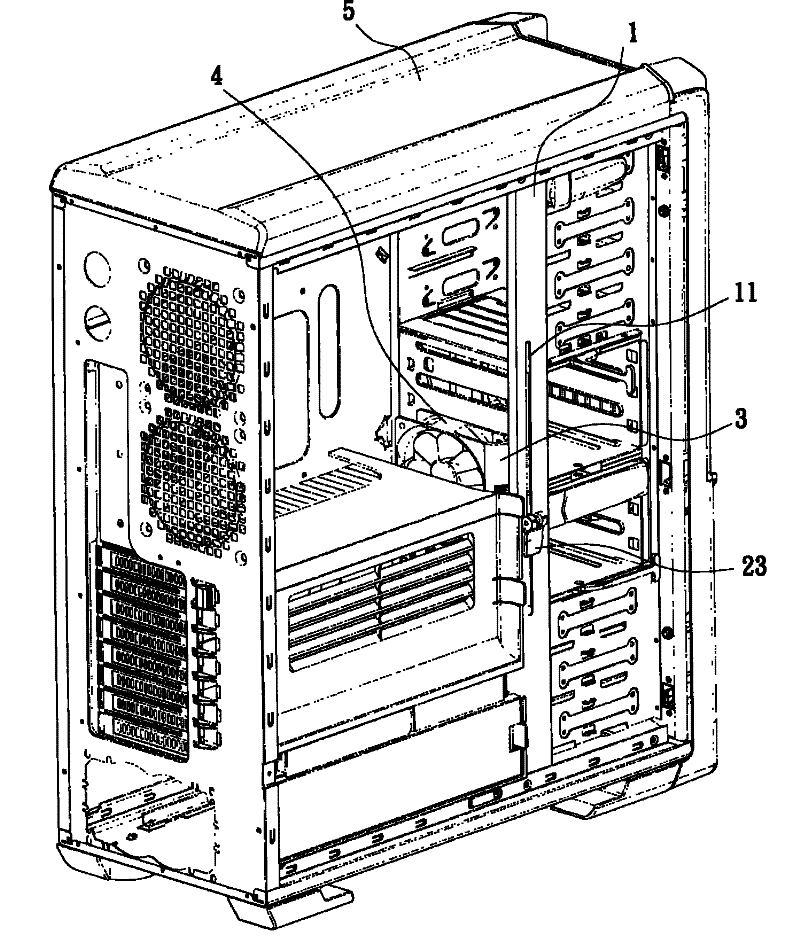

Improved computer cooling device

ActiveCN101561702AImprove shortcomingsFast dissipationDigital data processing detailsCompression machines with non-reversible cycleComputer coolingComputer engineering

The invention discloses an improved computer cooling device which comprises at least one evaporator, a compressor, a condenser, an expanding valve, a fan and a cooling medium. The evaporator is arranged on one side of at least one heating source which is arranged in a computer host unit and can be a central processing unit; the compressor is connected with the evaporator; the condenser is connected with the compressor; the expanding valve is connected between the condenser and the evaporator; the fan is arranged on one side of the condenser; and the cooling medium is circulated among the evaporator, the compressor, the condenser and the expanding valve. Therefore, the invention enables the heating source in the computer host unit to achieve the efficacy of rapid heating source dissipation by utilizing the cooperation of the evaporator, the compressor, the condenser, the fan, the expanding valve and the cooling medium.

Owner:THERMALTAKE

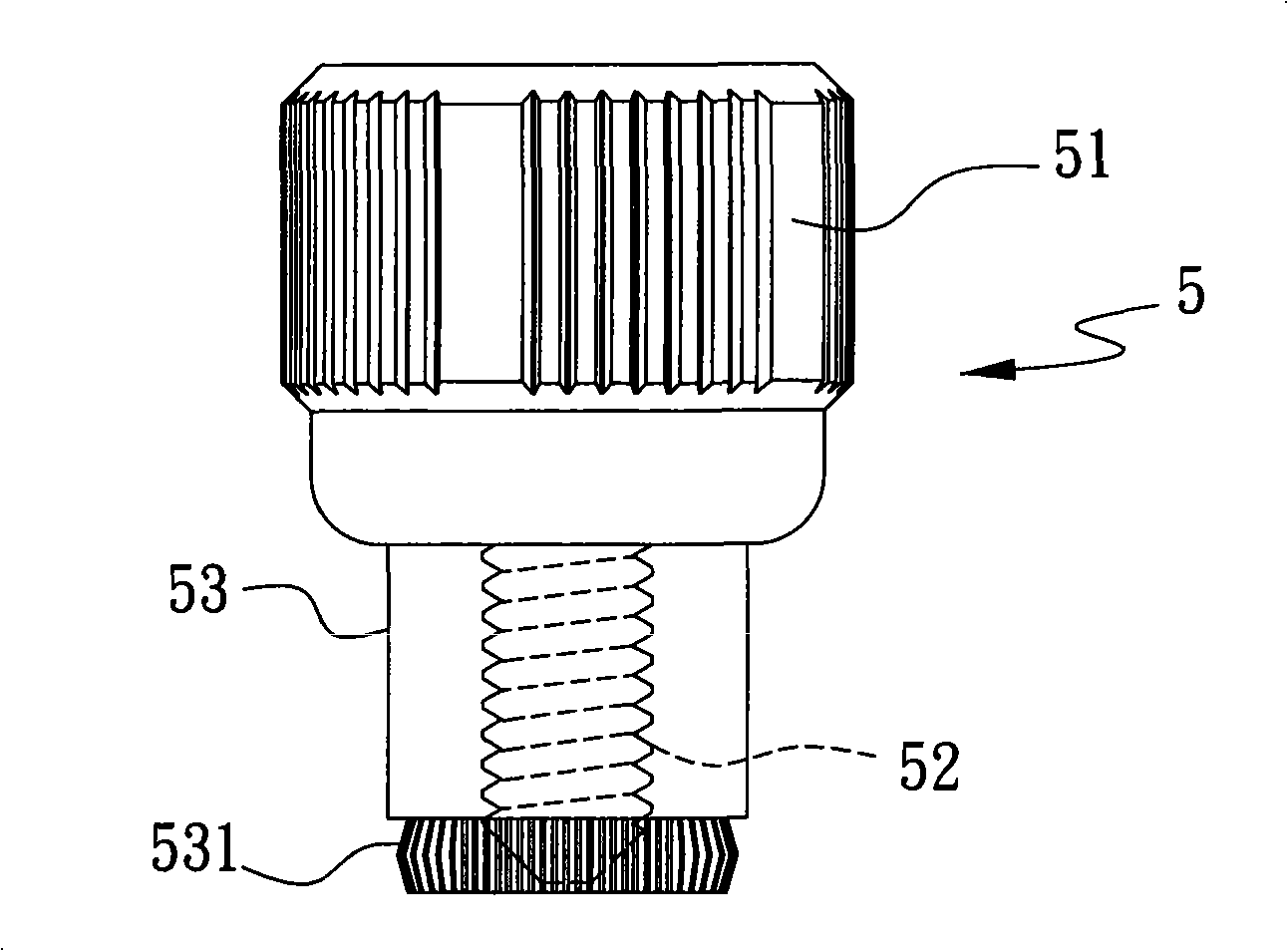

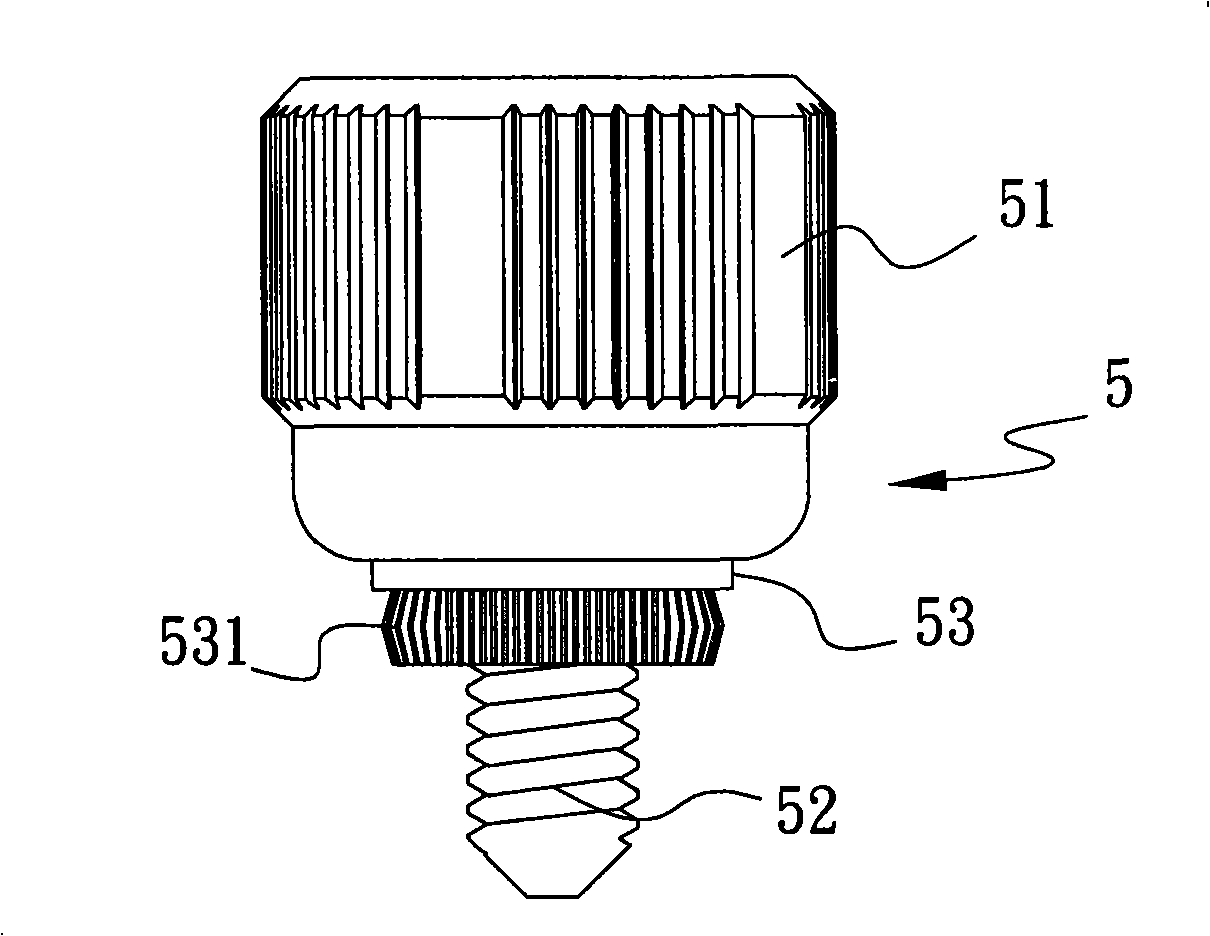

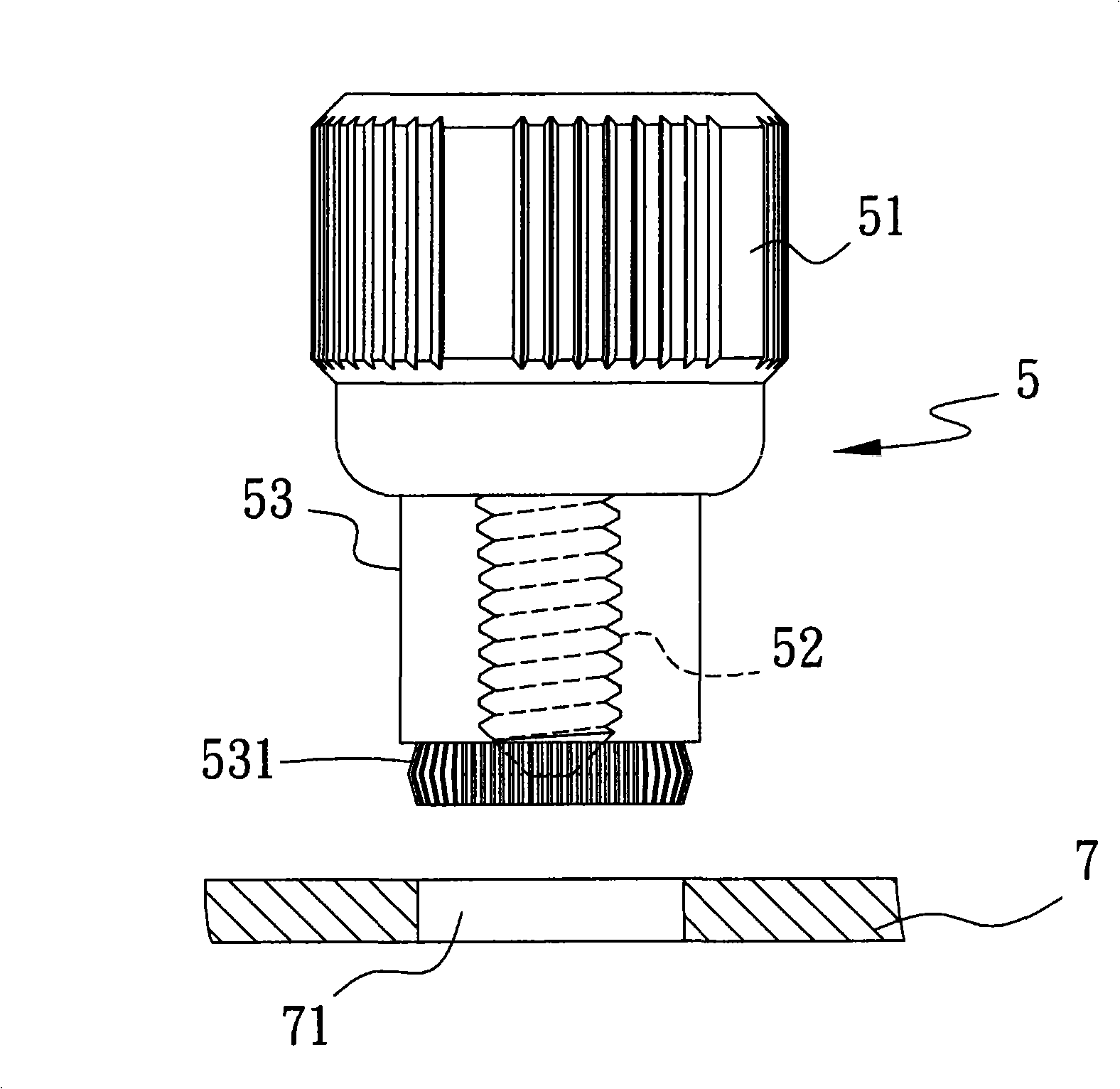

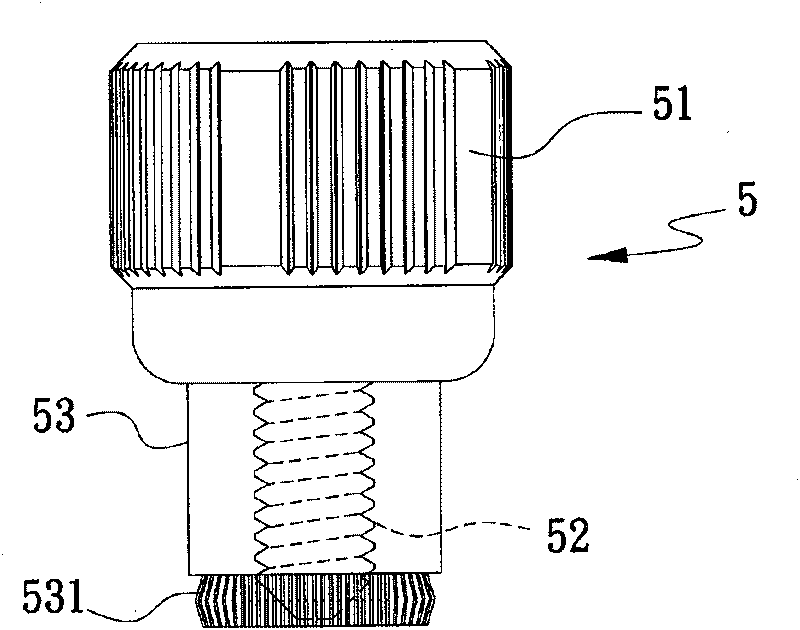

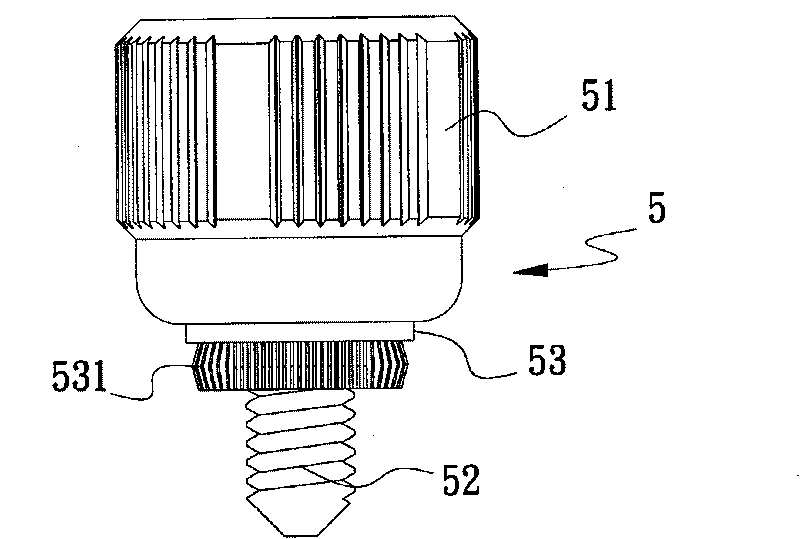

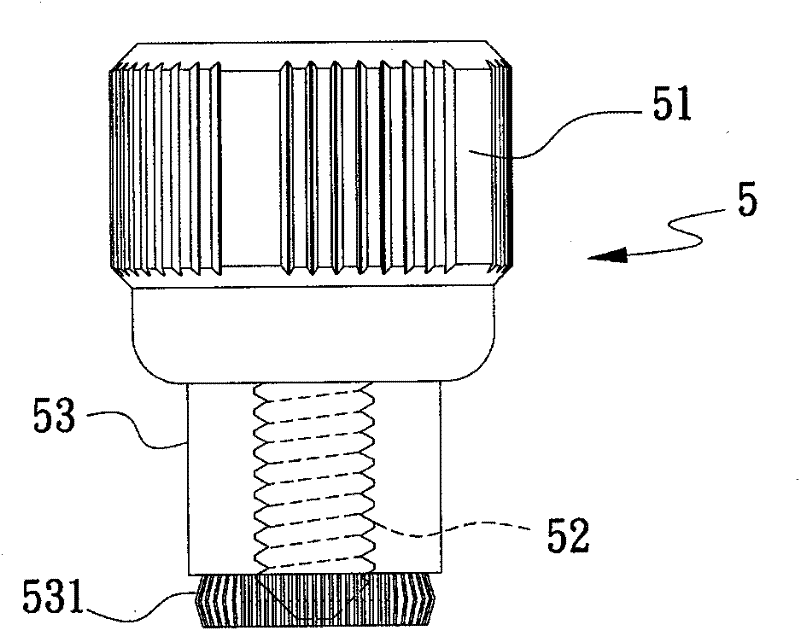

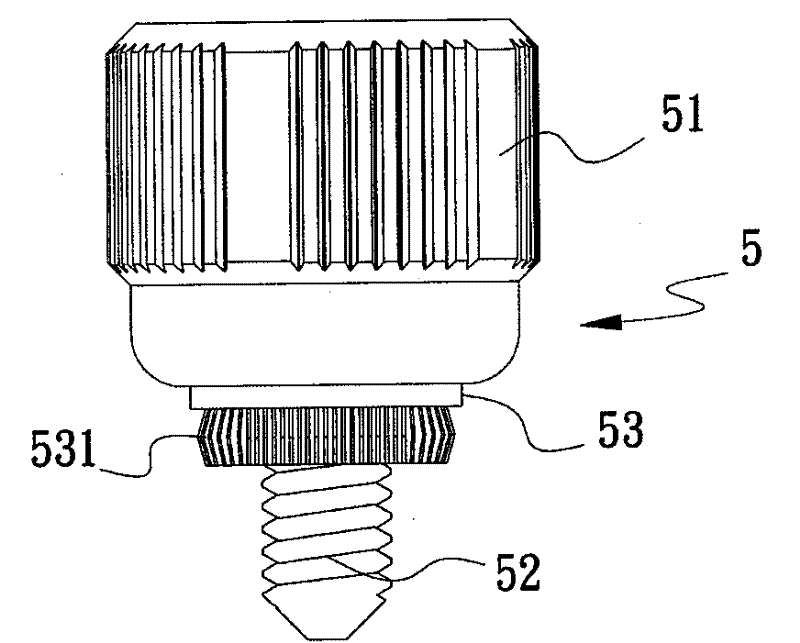

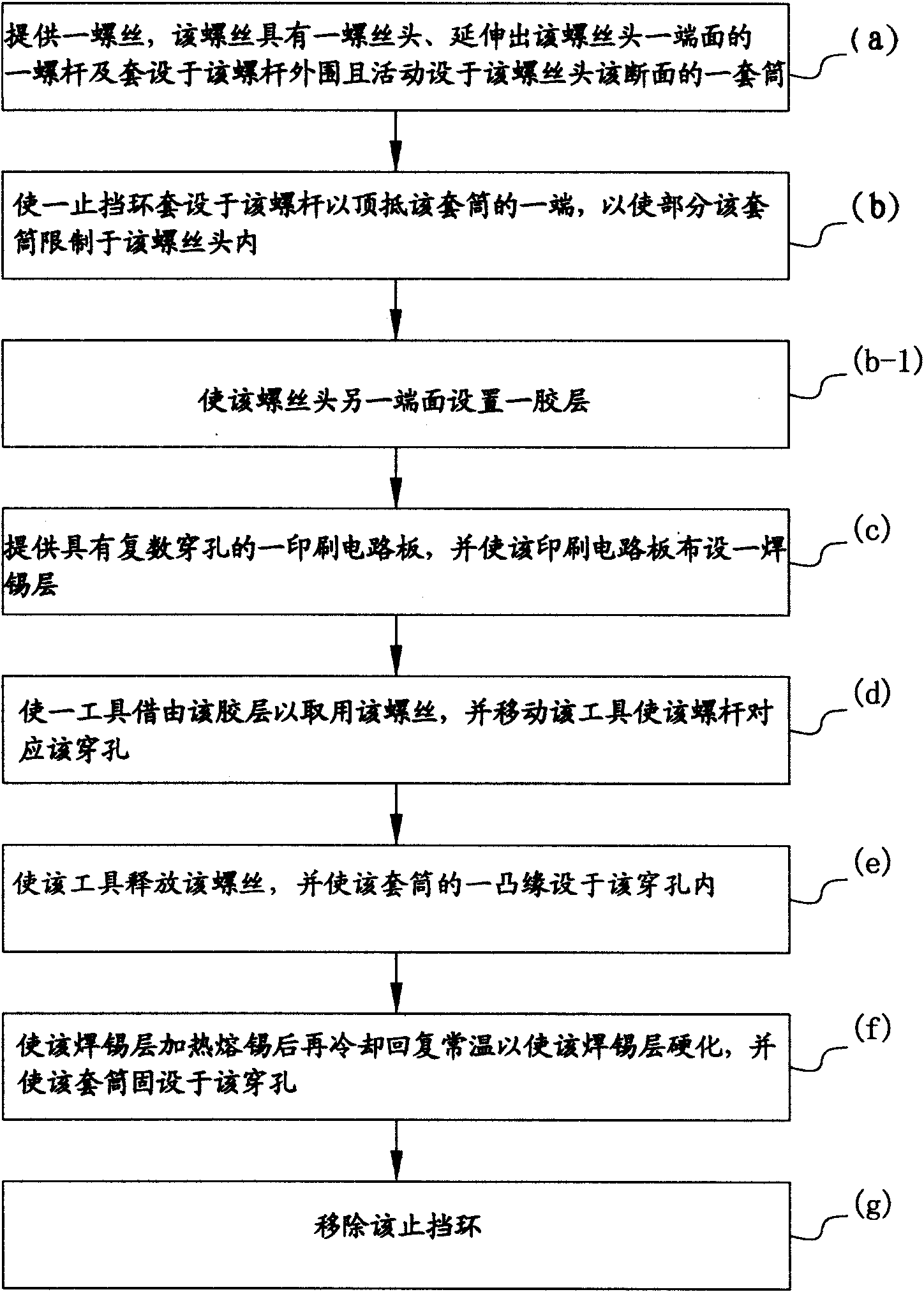

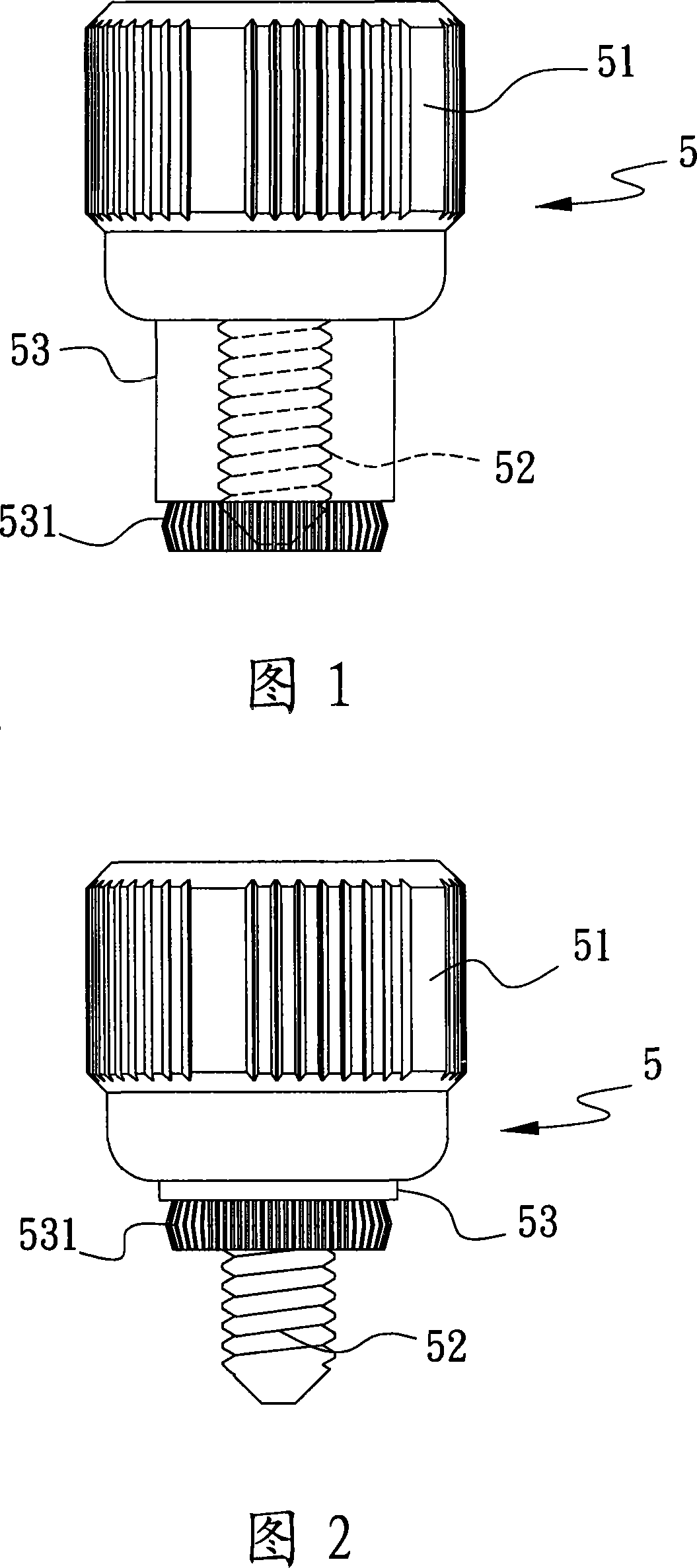

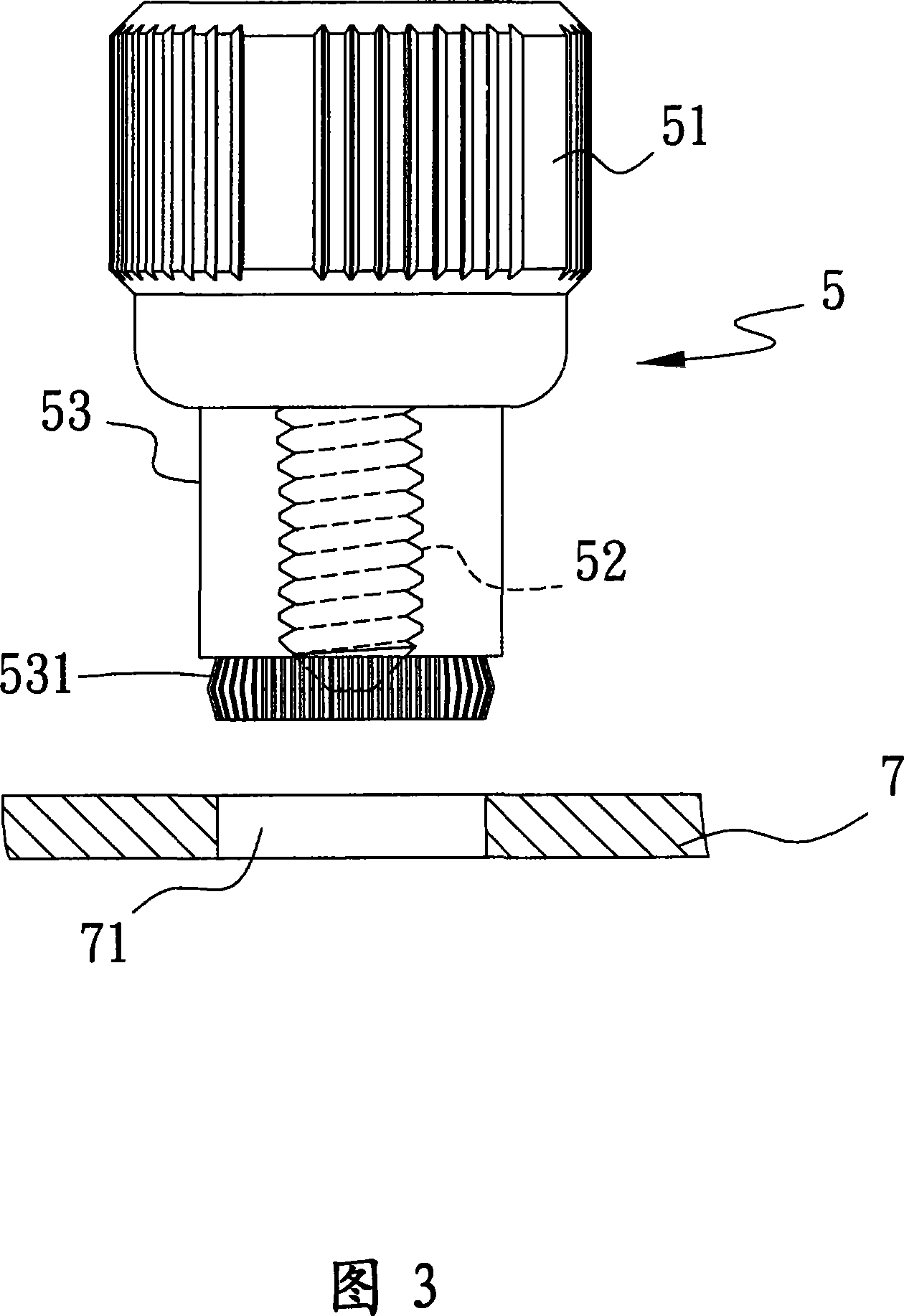

Packaging method for combining screw to printed circuit board

ActiveCN101516163AImprove the various shortcomingsMeet needsPrinted circuit manufacturePrinted circuit non-printed electric components associationPrinted circuit boardScrew head

The invention relates to a packaging method for combining a screw to a printed circuit board, which is a method for combining the screw to the printed circuit board by a surface adhesion technique and comprises the following steps: providing a screw having a screw head, a screw rod extending out of one end of the screw head, and a sleeve sleeved on the periphery of the screw rod and movably arranged on one end face of the screw head; sleeving a limit ring on the screw rod to lean against one end of the sleeve so that part of the sleeve is limited in the screw head; arranging an adhesive layer on the other end face of the screw head; providing the printed circuit board with a plurality of through holes and arranging a soldering tin layer; making a tool use the screw through the adhesive layer and moving the tool so that the screw rod corresponds to the through holes; making the tool release the screw to drop the screw, and arranging a flange of the sleeve in the through holes; heating the soldering tin layer to melt tin, and cooling the soldering tin layer to the normal temperature so as to harden the soldering tin layer; fixedly arranging the sleeve in the through holes; and removing the limit ring. The method has the efficacy of achieving precise, non-offset, non-deflective and easy arrangement in the process of arranging a screw sleeve.

Owner:DTECH PRECISION INDS

All-in-one machine for shelling peony seeds

The present invention relates to an all-in-one machine for shelling peony seeds. The all-in-one machine comprises a magnetic separation system, a grading system and a shelling system; wherein the magnetic separation system comprises a feed inlet 1, a strong magnet 2 and a magnet support rod 3; the grading system comprises a grading sieve feed port 4, a large seed discharge port 5, a medium seed discharge port 6, a medium and small seed discharge port 7, a small seed discharge port 8, a polarization motor 9, a support spring 10 and a grading sieve 11; the shelling system comprises a shelling feed port 12, shelling units 13, a motor 14, grading feed ports 15, a total storage bin 16 and a total discharge port 17; and wherein the number of the shelling units is the same with that of the grades after the peony seeds are divided, each grade of peony seeds correspond to a separate discharge port, the discharge port corresponding to each grade of peony seeds is connected to the shelling feed port of one shelling unit respectively, and each shelling unit 13 is provided with a separate grading feed port 15. The all-in-one machine for shelling peony seeds is simple in structure and convenient in use, so that the shelling efficiency is improved, the rate of kernel cracking is reduced, and the shelling rate can reach 96%.

Owner:洛阳臻萝服装有限公司

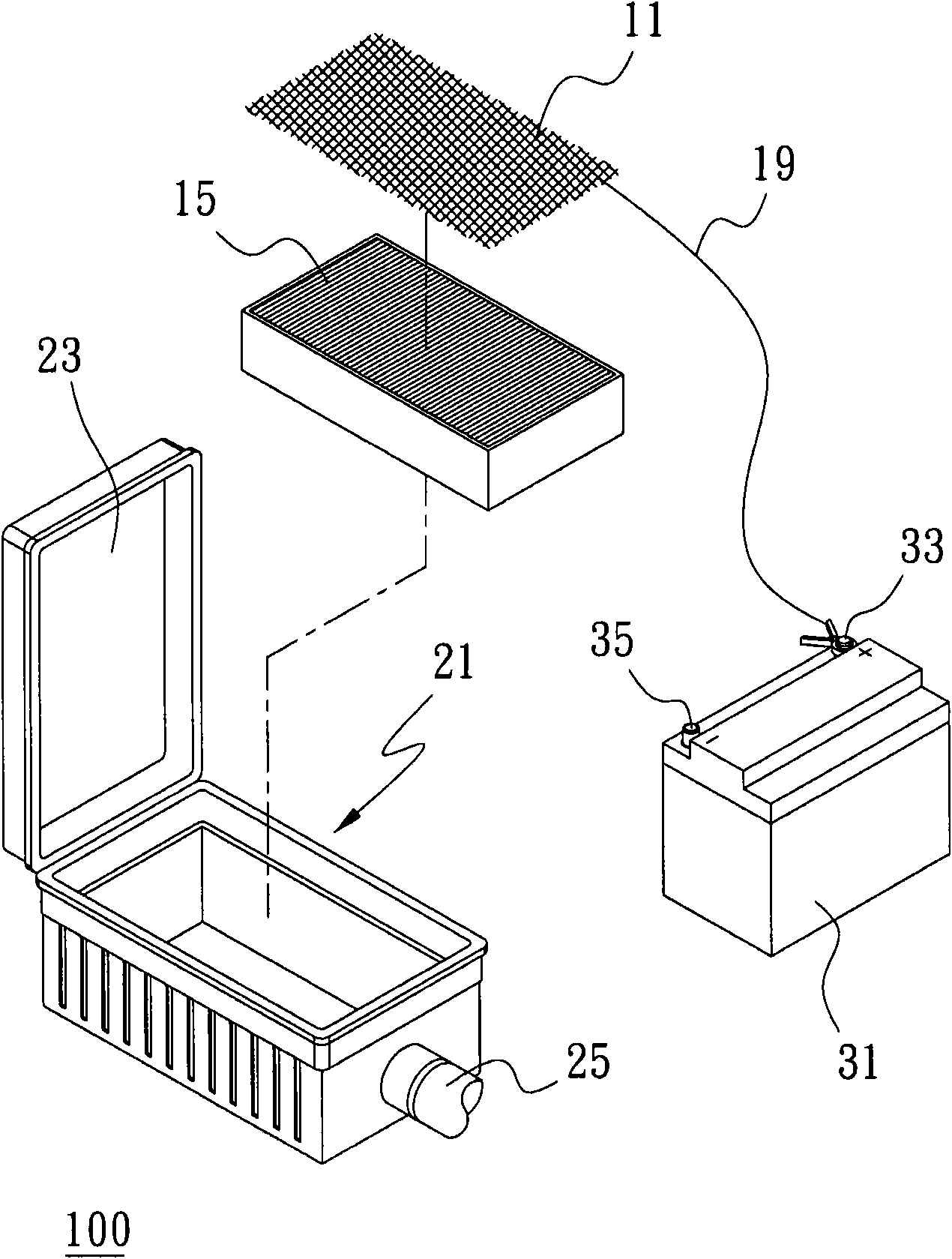

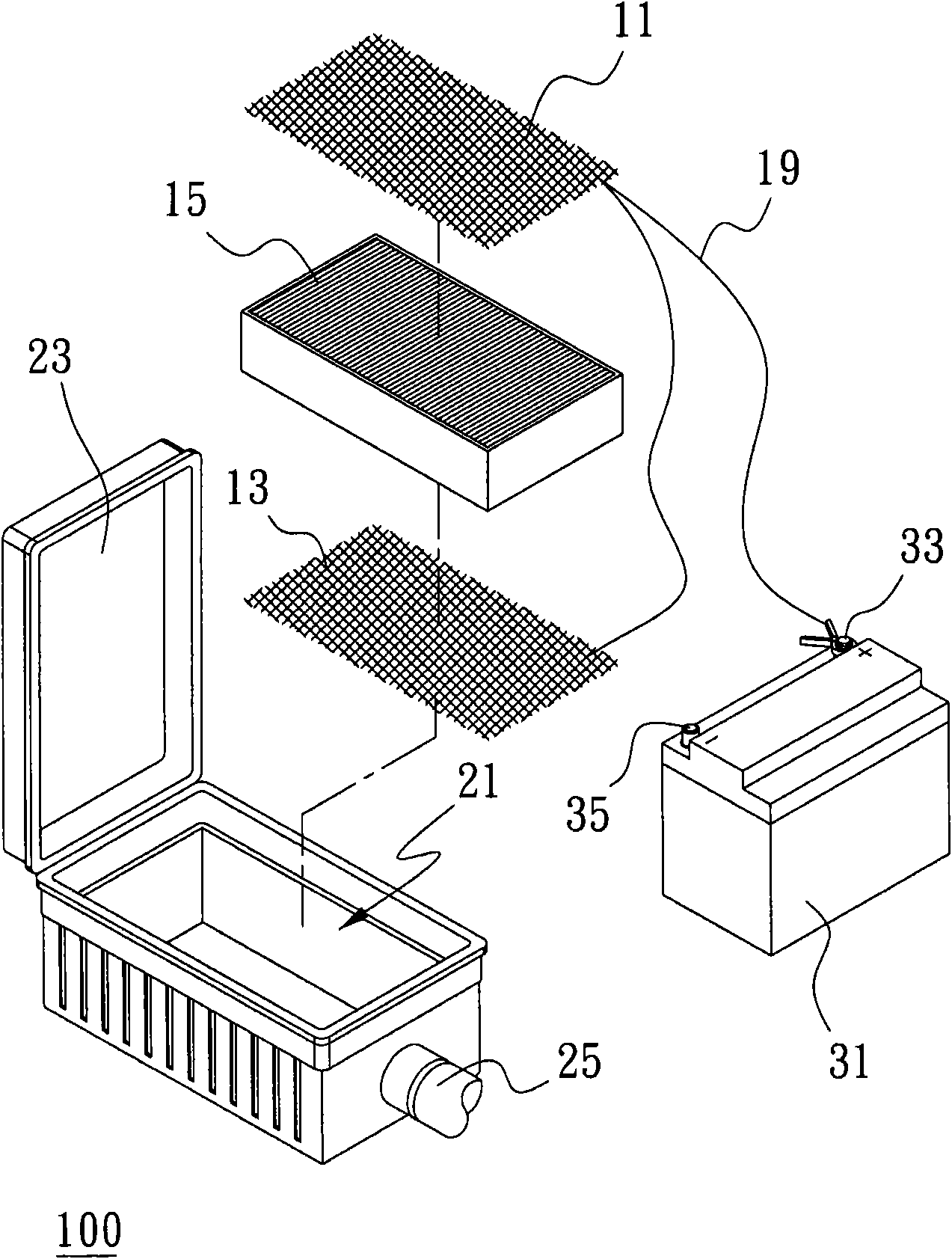

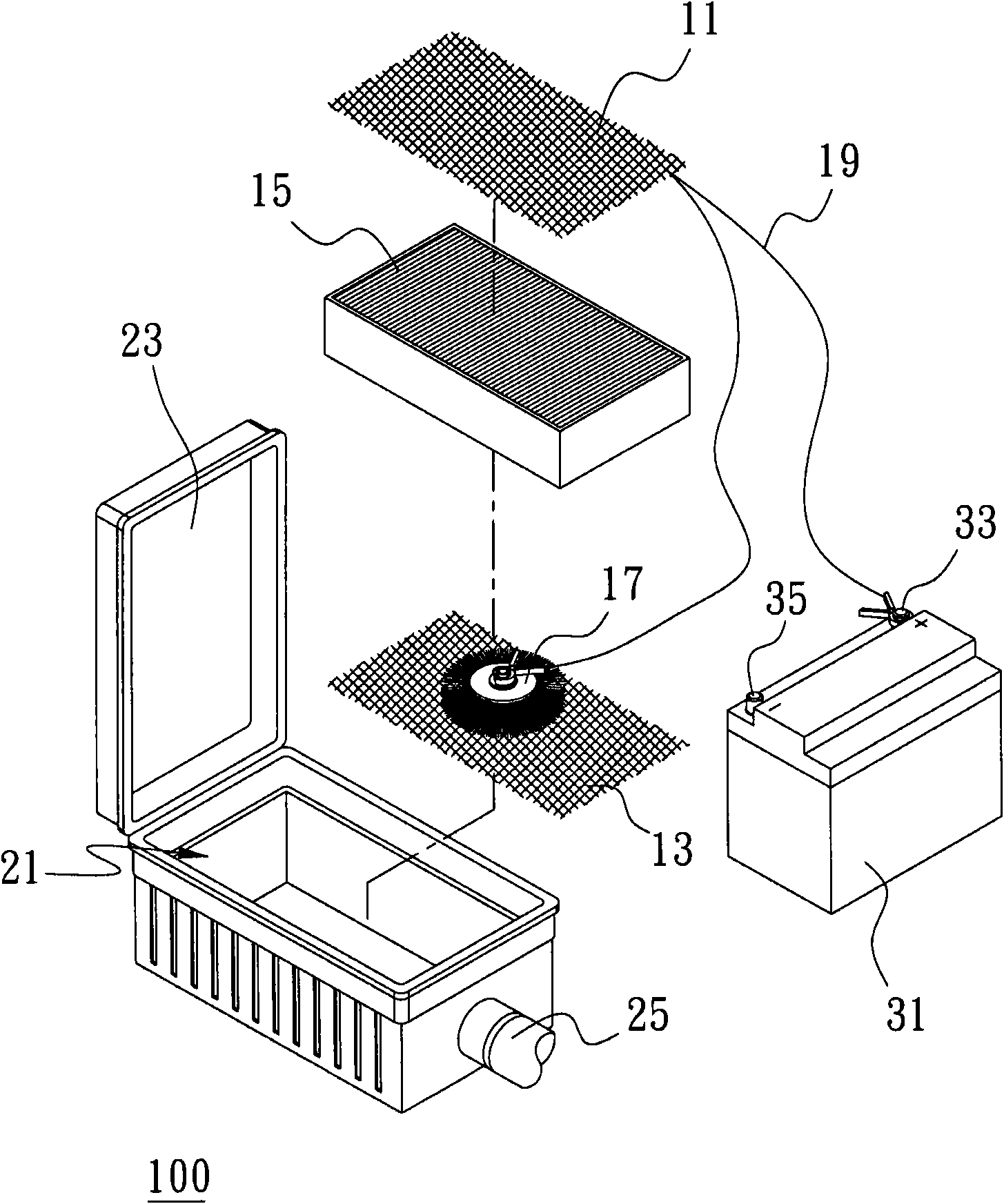

Air activation auxiliary device

InactiveCN101655055AImprove the activation effectMeet the efficacyInternal combustion piston enginesCombustion-air/fuel-air treatmentAir filtrationElectrical conductor

The invention relates to an air activation auxiliary device, which comprises a first far-infrared ray network layer, an air filtration layer, and a first electrical conductor, wherein the first far-infrared ray network layer is made of metal and is used for sending far-infrared rays to activate air molecules; the air filtration layer is used for filtering impurities in the air; the first electrical conductor is connected with a power supply device and the first far-infrared ray network layer; and the first far-infrared ray network layer is not contacted with the air filtration layer. Therefore, the air activation auxiliary device makes the far-infrared ray network layer which is made of the metal connect the power supply device through the first electrical conductor by using a simple component combination so as to generate a magnetic field to strengthen the activation efficiency of the far-infrared ray network layer, so that a user can simply add the air activation auxiliary device without changing the design of an original air inlet system to achieve the aims of low cost, convenient installation and high efficiency.

Owner:刘府广

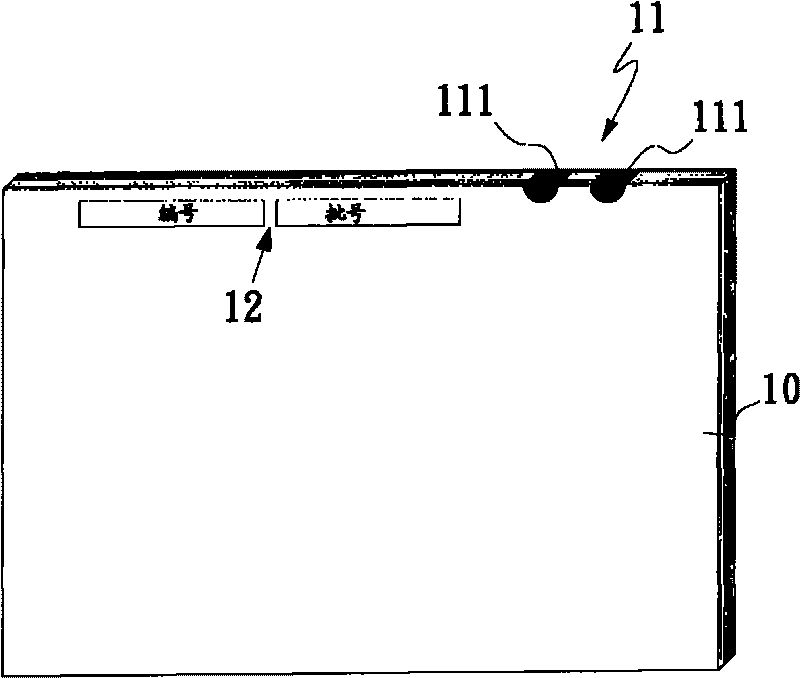

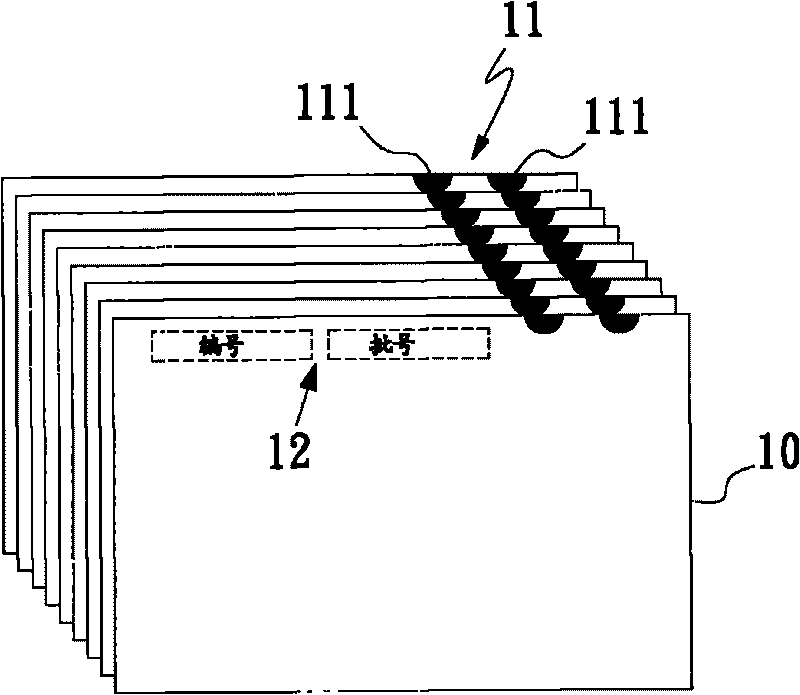

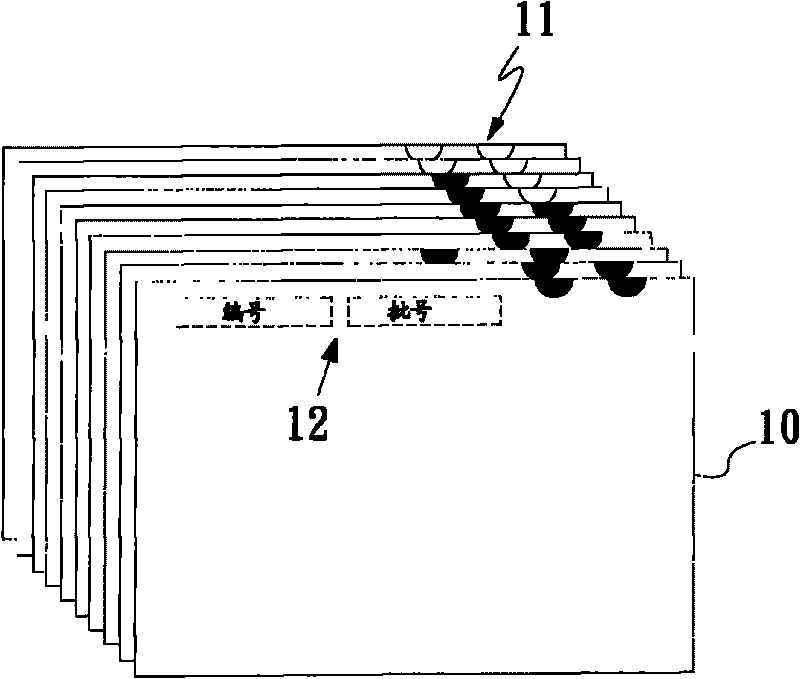

Method for identification management of flat panel objects

InactiveCN101723180AOrganize assignments quicklyOrganize work correctly and efficientlyStacking articlesComputer graphics (images)Computer vision

The invention relates to a method for identification management of flat panel objects. The edge and the proper position of at least one surface of the flat panel object are provided with a first identification area and a second identification area respectively; when a plurality of flat panel objects are orderly piled, the flat panel objects can be identified by the first identification areas on the edges of the flat panel objects, the flat panel objects different from the position of the first identification area are picked out and then the relative comparison confirmation is done by the second identification areas so as to correctly place the flat panel objects, so that the flat panel objects are sorted quickly, correctly and in high efficiency.

Owner:TENMARK AUTOMATION

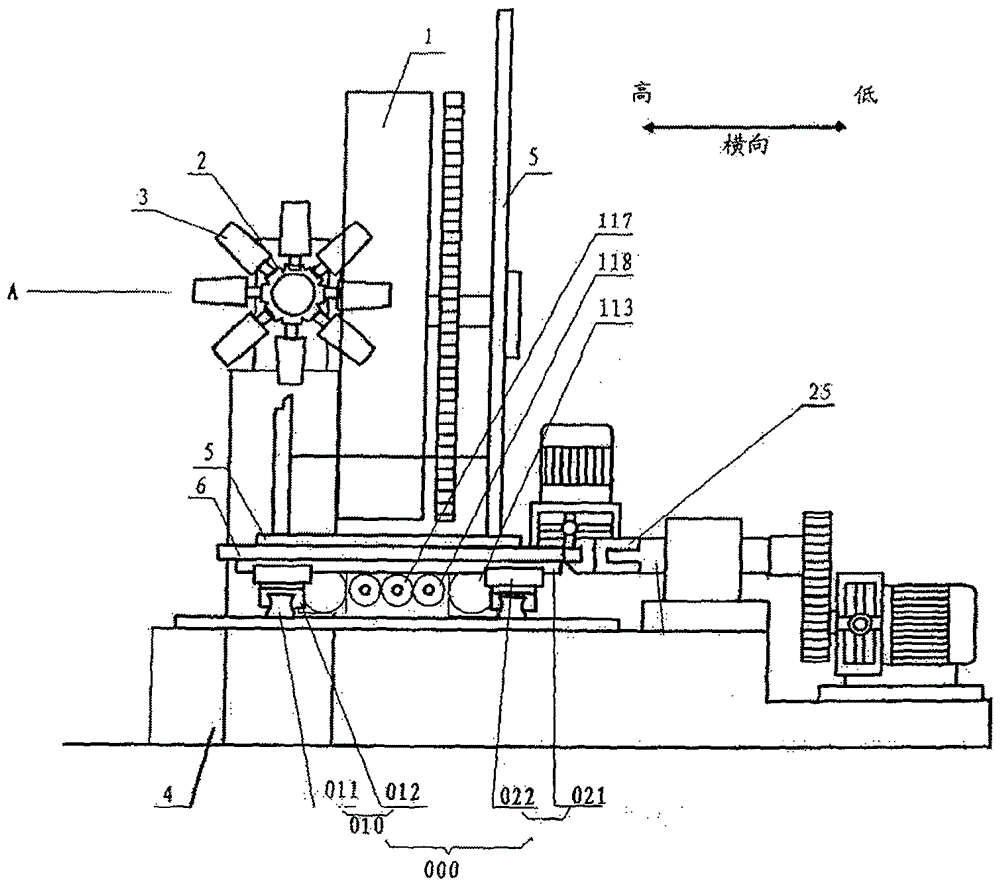

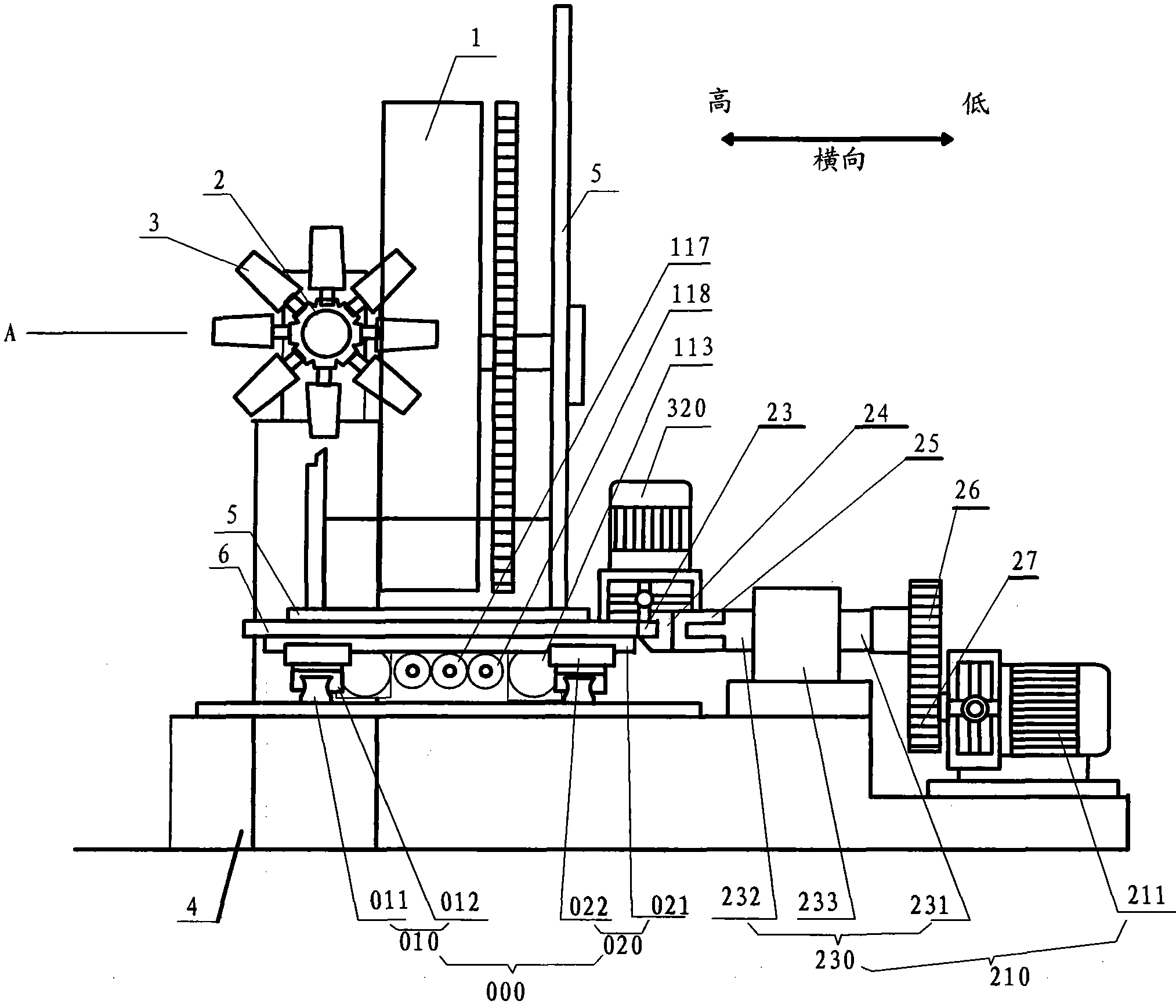

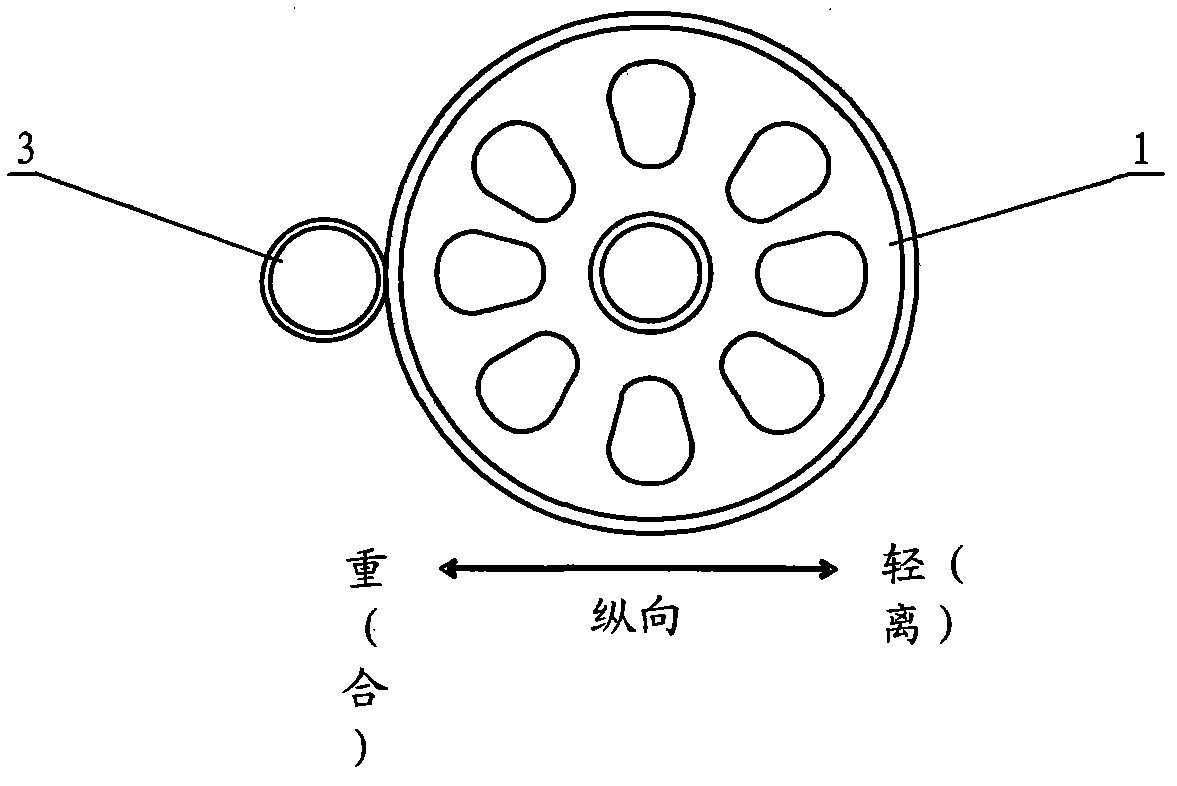

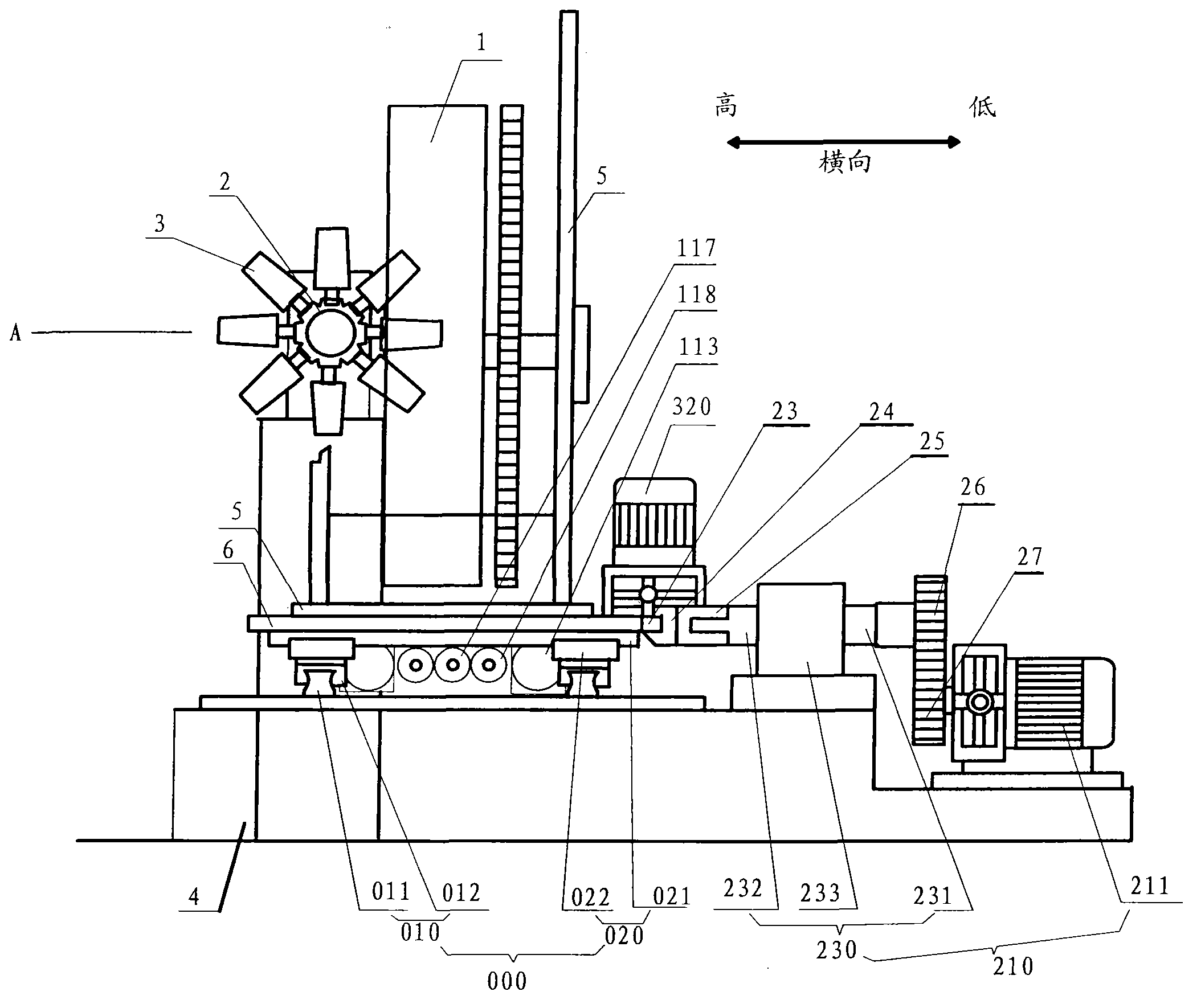

Displacement Printing Pressing Force and Clearance Tolerance Device of Curved Surface Printing Machine

ActiveCN103252987BWidely used valueEliminate natural tolerance gapsRotary pressesProgrammable logic controllerEngineering

The invention relates to a printing machine, in particular to a device for displacing printing pressing force and eliminating a tolerance clearance of a curved-surface printing machine. The device for displacing the printing pressing force and eliminating the tolerance clearance of the curved-surface printing machine comprises a printing device which is arranged on a base and is provided with a multi-work-position stepping indexing turntable and a mould handle, and a printing main machine which is arranged on a main machine supporting frame and provided with a transferring printing large drum, and is characterized in that a two-dimensional orthogonal sliding seat is arranged on the base, the main machine supporting frame is arranged on the two-dimensional orthogonal sliding seat through a main machine seat plate, the base is further provided with a longitudinal moving device used for eliminating the clearance, and a programmable logic controller (PLC) which is used for controlling the longitudinal moving device used for eliminating the clearance and is provided with a touch screen, and the longitudinal moving device used for eliminating the clearance is arranged between the base and the main machine seat plate, controls the main machine seat plate to move in the direction perpendicular to the axis of the mould handle, and eliminates the tolerance clearance. The device for displacing the printing pressing force and eliminating the tolerance clearance of the curved-surface printing machine is convenient to operate, is small in vibration, and meets the accuracy requirement for high-speed operation at the speed of 450-650 cups per minute in the cup printing process, and the speed of cup printing is improved by one time compared with existing equipment.

Owner:GUANGDONG LONGXING PACKAGING IND

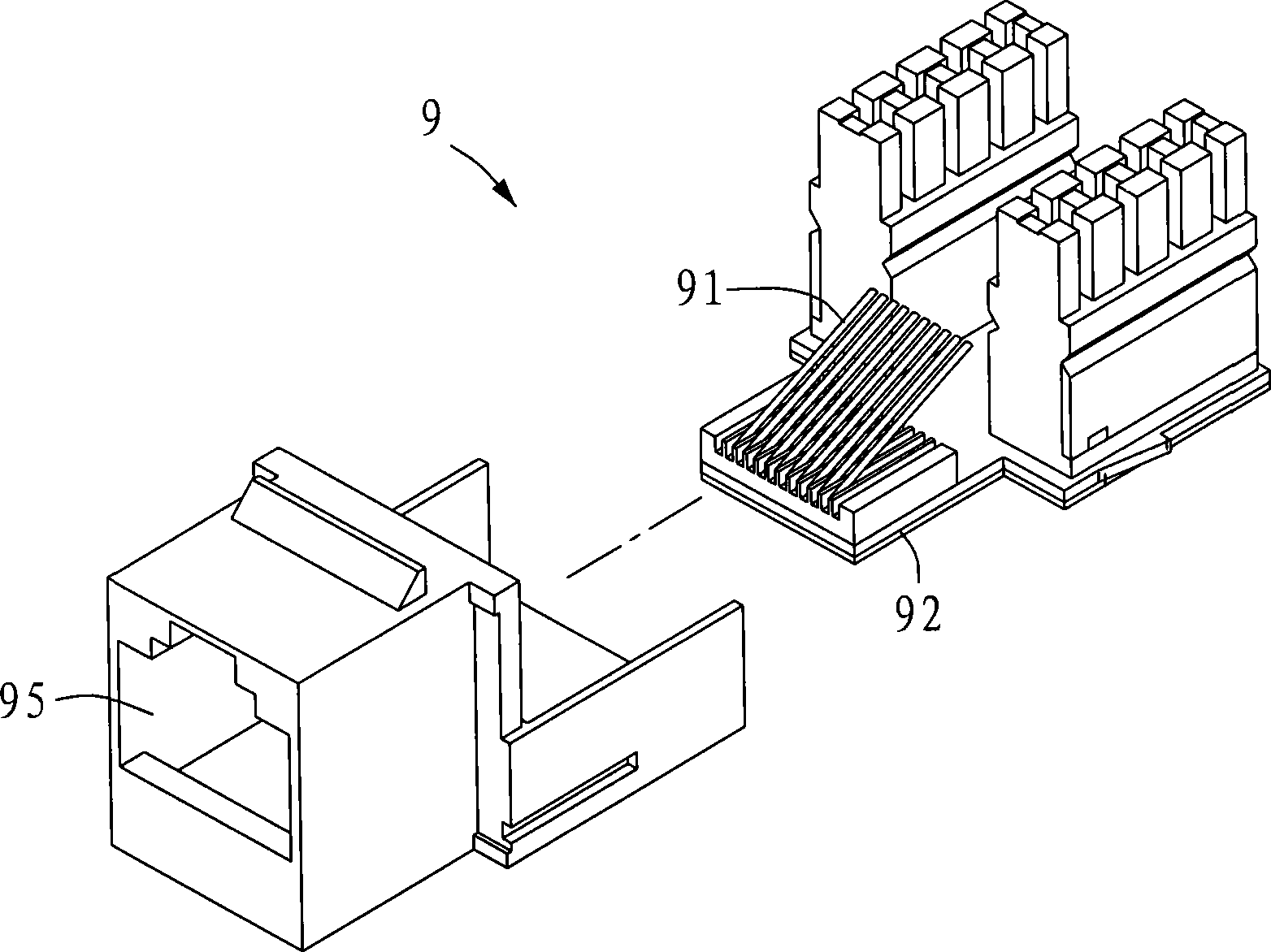

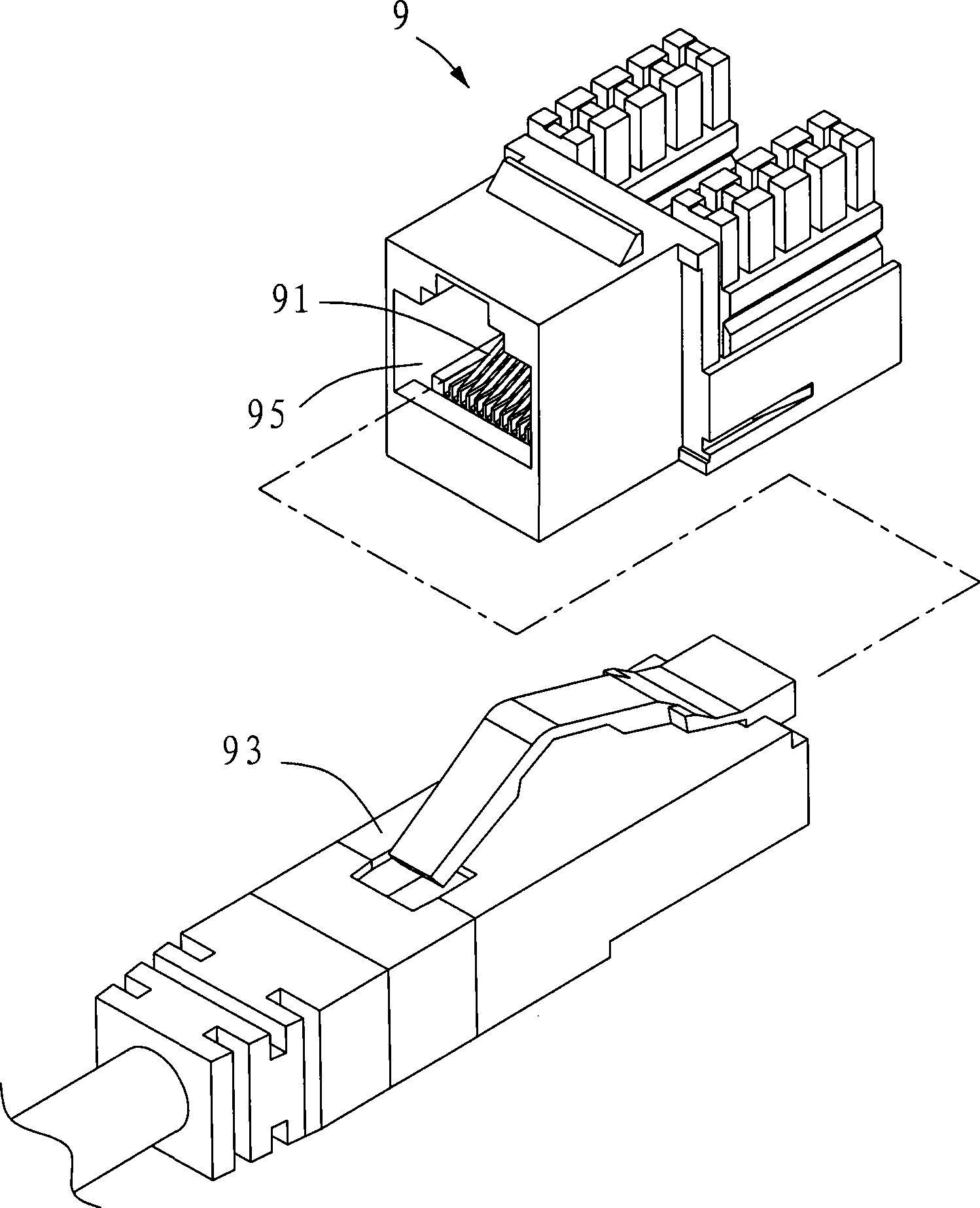

Improved structure of electrical connector

InactiveCN101521329AImprove and avoid various shortcomings caused by weldingQuality improvementSecuring/insulating coupling contact membersCoupling contact membersEngineeringJunction point

The invention relates to an improved structure of an electrical connector, which comprises the following components: a connector base, which comprises a connecting jack; an electrical conductive base, which comprises a plurality of electrical conductive shrapnels and is provided with a bent heave part; an electrical conductive module, which comprises complex electrical conductive elastic sheets and is provided with a bent protruded part; and a circuit board, which is provided with complex junction points and contact points, each junction point respectively corresponds to the heave part of the electrical conductive shrapnel, and each contact point respectively corresponds to the protruded part of the electrical conductive elastic sheet; the electrical conductive base, the electrical conductive module and the circuit board are respectively assembled on the connector base, a connecting part of the electrical conductive shrapnel is correspondingly exposed from the connecting jack, the heave part of the electrical conductive shrapnel is respectively and correspondingly butted against and contacted with each junction point of the circuit board with the elastic force, and each protruded part of the electrical conductive elastic sheet of the electrical conductive module is respectively and correspondingly butted against and contacted with each contact point of the circuit board with the elastic force. The improved structure of the electrical connector utilizes the connection way of elastic butting, thus avoiding various disadvantages which are caused by the welding way, simplifying manufacturing process and lowering cost, and simultaneously raising signal transmission quality.

Owner:MEGACEN INDAL

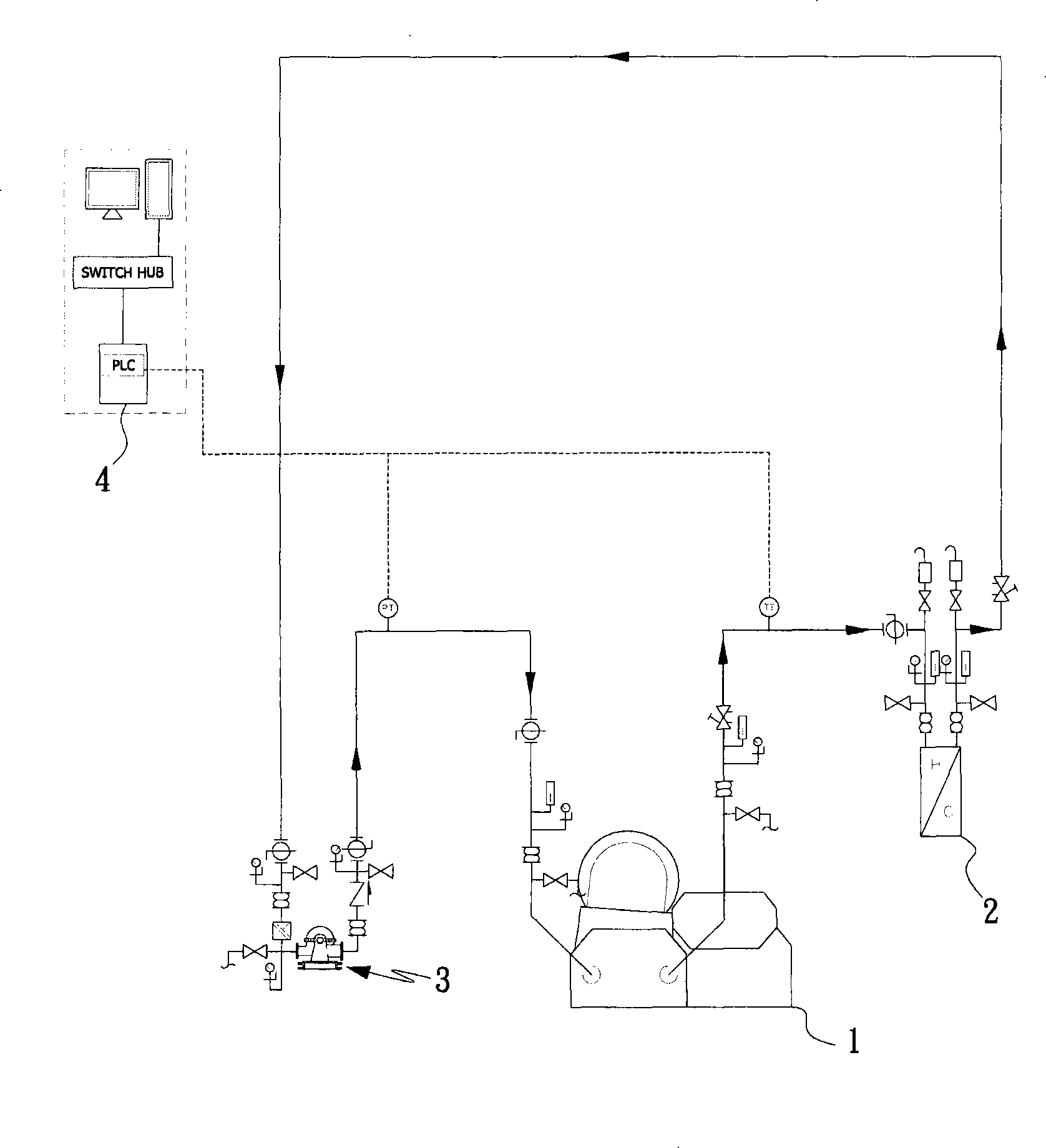

Energy-saving circulatory system utilizing external air to regulate temperature

InactiveCN101592413BImprove shortcomingsMeet the efficacyCompression machines with several condensersRefrigeration safety arrangementActive coolingCoolant temperature

Owner:曾德勋

Improved computer cooling device

ActiveCN101561702BImprove shortcomingsFast dissipationDigital data processing detailsCompression machines with non-reversible cycleEngineeringComputer cooling

The invention discloses an improved computer cooling device which comprises at least one evaporator, a compressor, a condenser, an expanding valve, a fan and a cooling medium. The evaporator is arranged on one side of at least one heating source which is arranged in a computer host unit and can be a central processing unit; the compressor is connected with the evaporator; the condenser is connected with the compressor; the expanding valve is connected between the condenser and the evaporator; the fan is arranged on one side of the condenser; and the cooling medium is circulated among the evaporator, the compressor, the condenser and the expanding valve. Therefore, the invention enables the heating source in the computer host unit to achieve the efficacy of rapid heating source dissipationby utilizing the cooperation of the evaporator, the compressor, the condenser, the fan, the expanding valve and the cooling medium.

Owner:THERMALTAKE

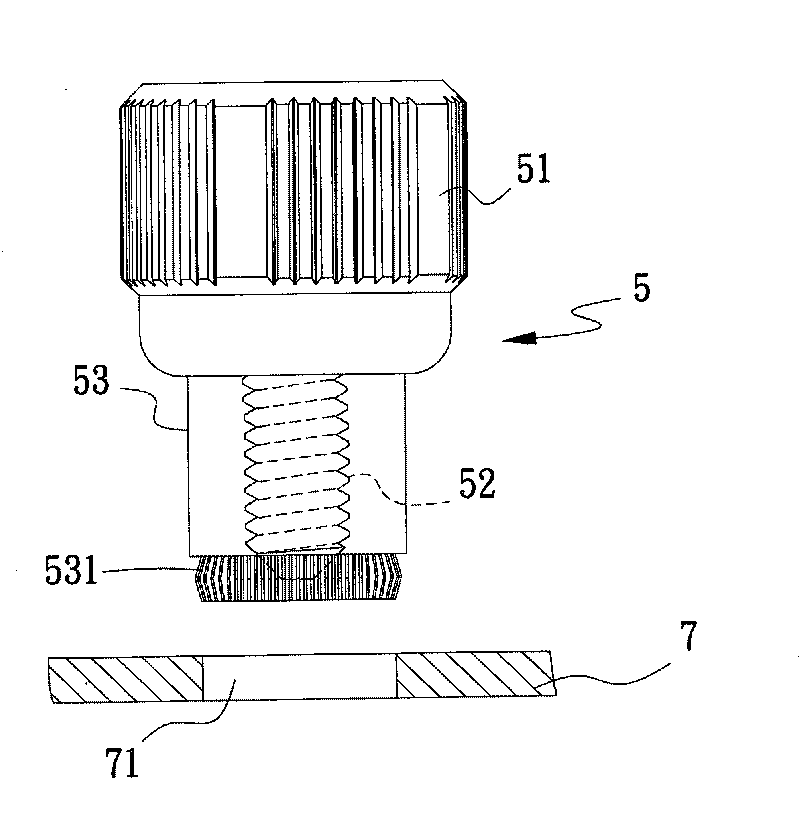

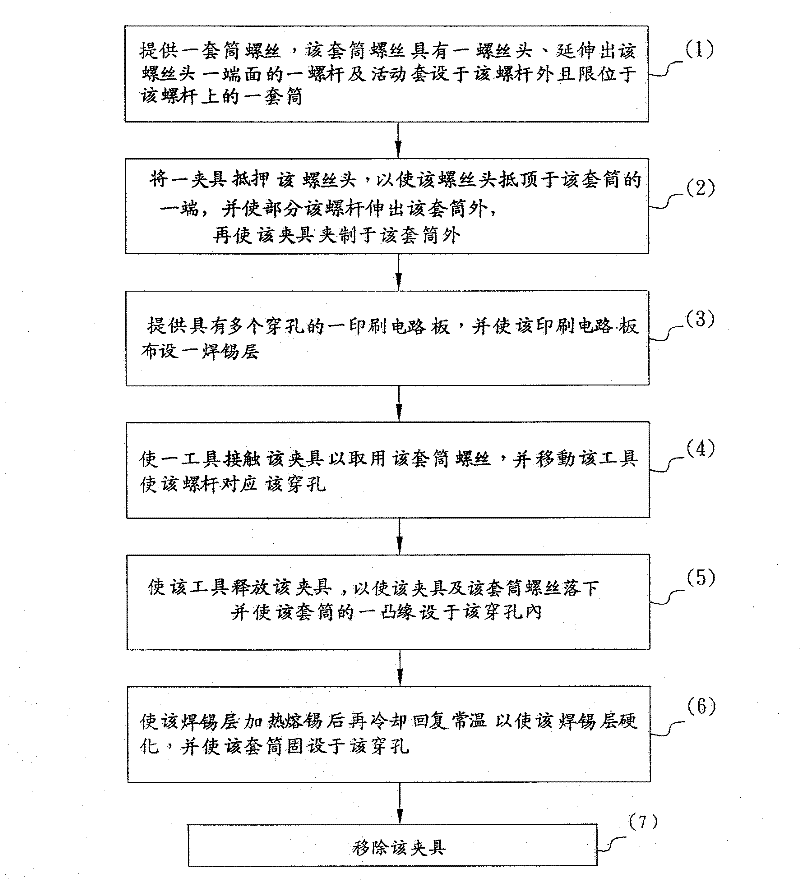

Packaging method for combining telescopic screw with printed circuit board

ActiveCN101742818AEasy to set upSkill improvedPrinted circuit manufacturePrinted circuit non-printed electric components associationEngineeringPrinted circuit board

The invention relates to a ppackaging method for combining a telescopic screw with a printed circuit board, which comprises the following steps: pressing a screw head of the telescopic screw comprising the screw head, a screw rod and a sleeve with a fixture to prop the screw head at one end of the sleeve, extend a part of the screw rod out of the sleeve and fix the fixture outside the sleeve, providing the printed circuit board provided with a plurality of perforations and a solder layer; contacting the fixture with a tool to take the telescopic screw to make the screw rod correspond to the perforations of the printed circuit board; allowing the tool to release the fixture to make the fixture and the telescopic screw fall down, and cooperating flanges of the sleeve with the solder layer to limit the flanges in the perforations; and after the solder layer is hardened to fix the sleeve, removing the fixture to combine the telescopic screw with the printed circuit board. The package method achieves the effect of precisely and easily arranging the sleeve of the telescopic screw without shift and deflection.

Owner:王鼎瑞

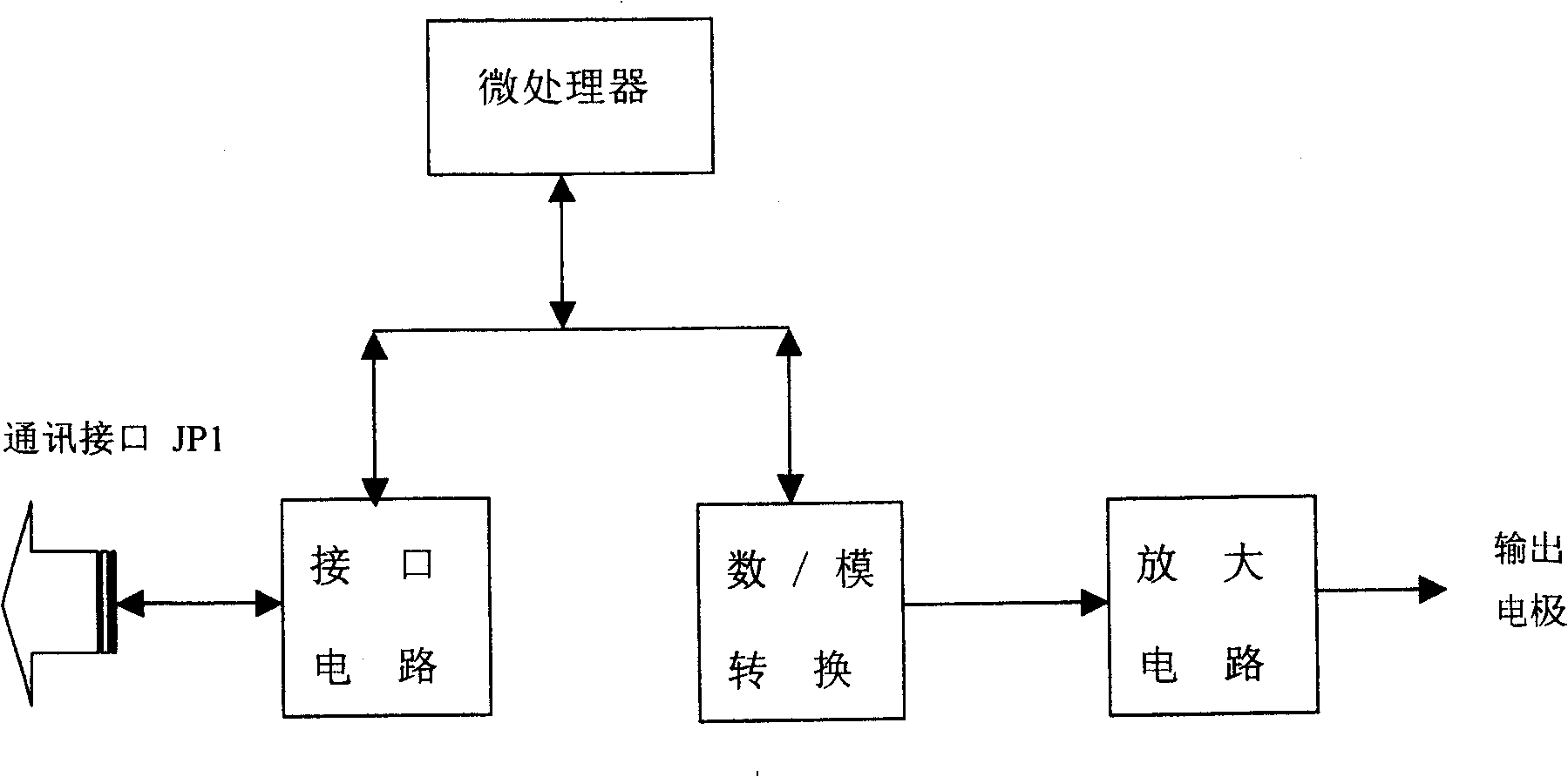

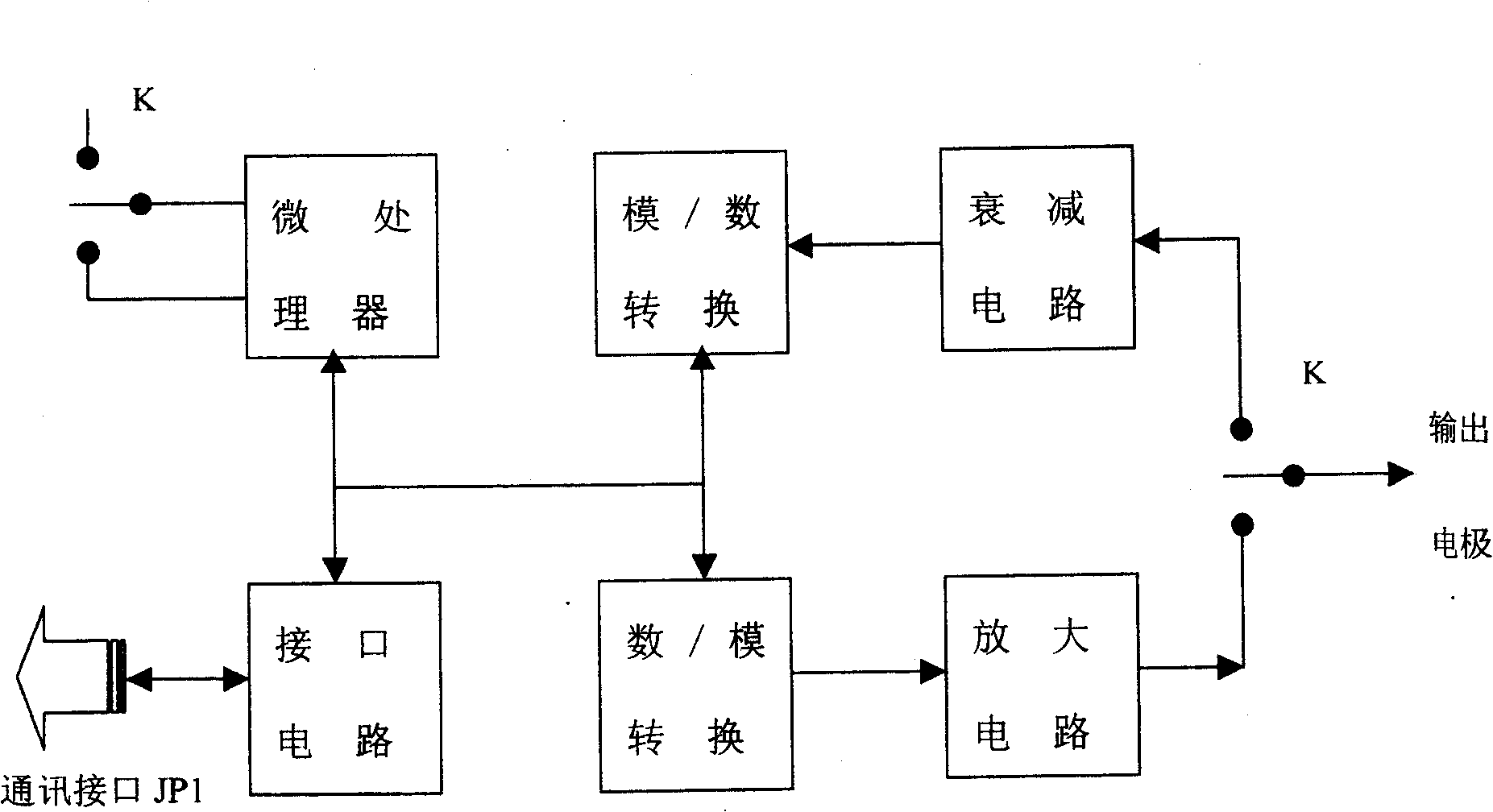

Electro-therapeutic apparatus matched with personal computer

InactiveCN100435883CWill not affect normal useFlexible and extensive useDigital computer detailsElectric digital data processingWeb siteCommunication interface

The electrotherapeutical instrument matching with PC includes output electrode, amplifier circuit, microprocessor, etc. and features its communication interface connected to PC, interface circuit and A / D converter circuit connected together. The present invention makes it possible for the user to select different treating waveform by means of the corollary software and to download new treating scheme from web sit for even wide use. In addition, the present invention uses the digital communication interface directly without occupying the sound card and affecting the normal operation of PC.

Owner:GUANGDONG TONZE ELECTRIC CO LTD

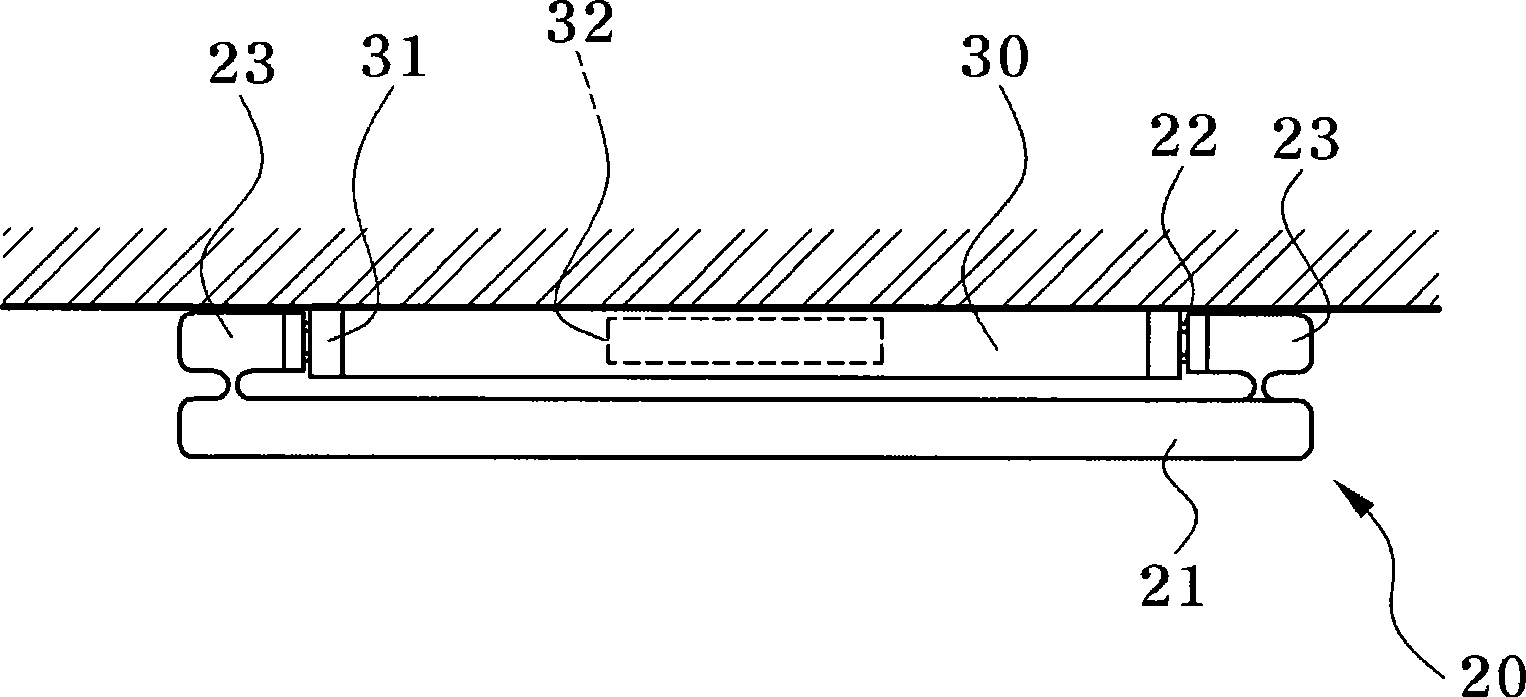

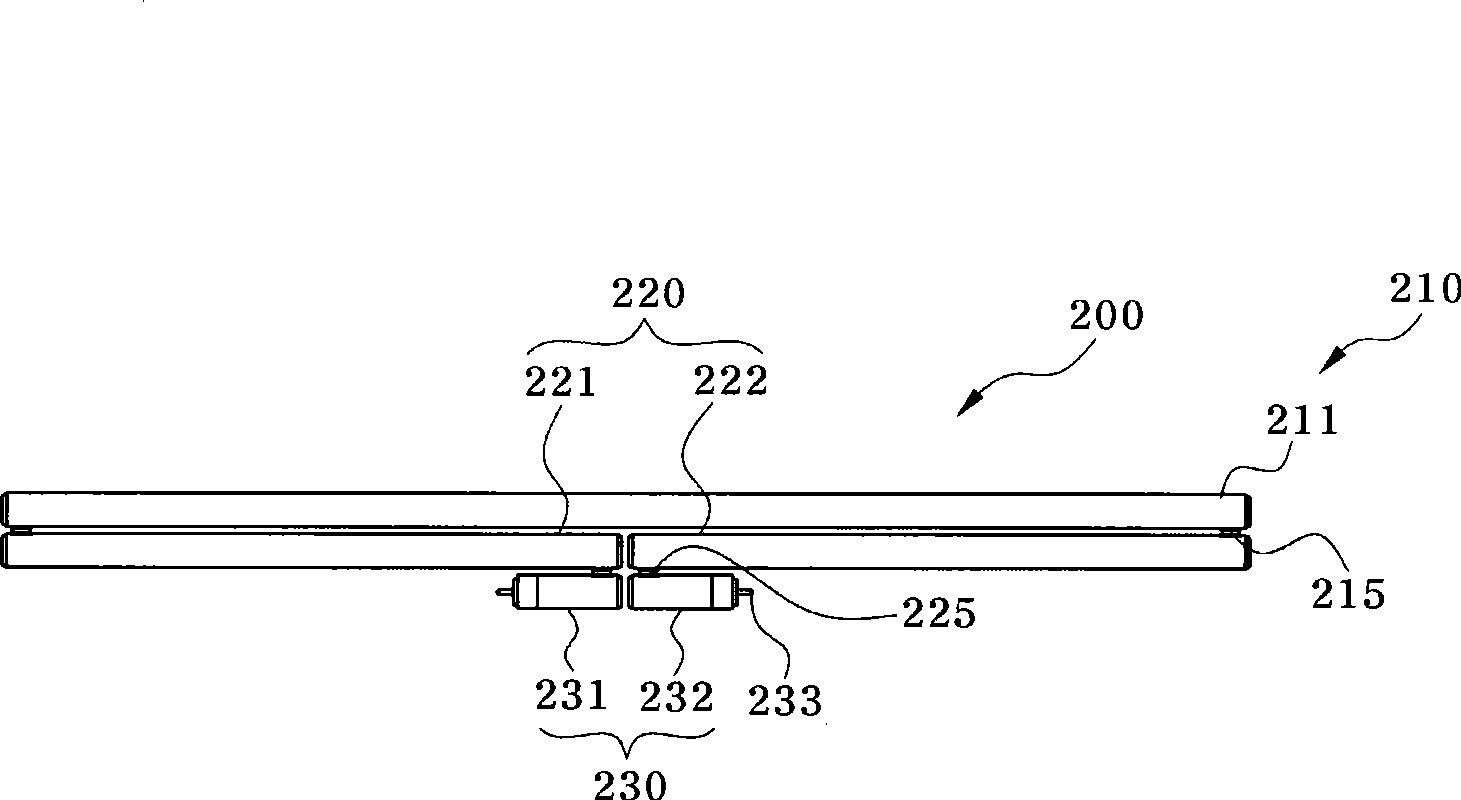

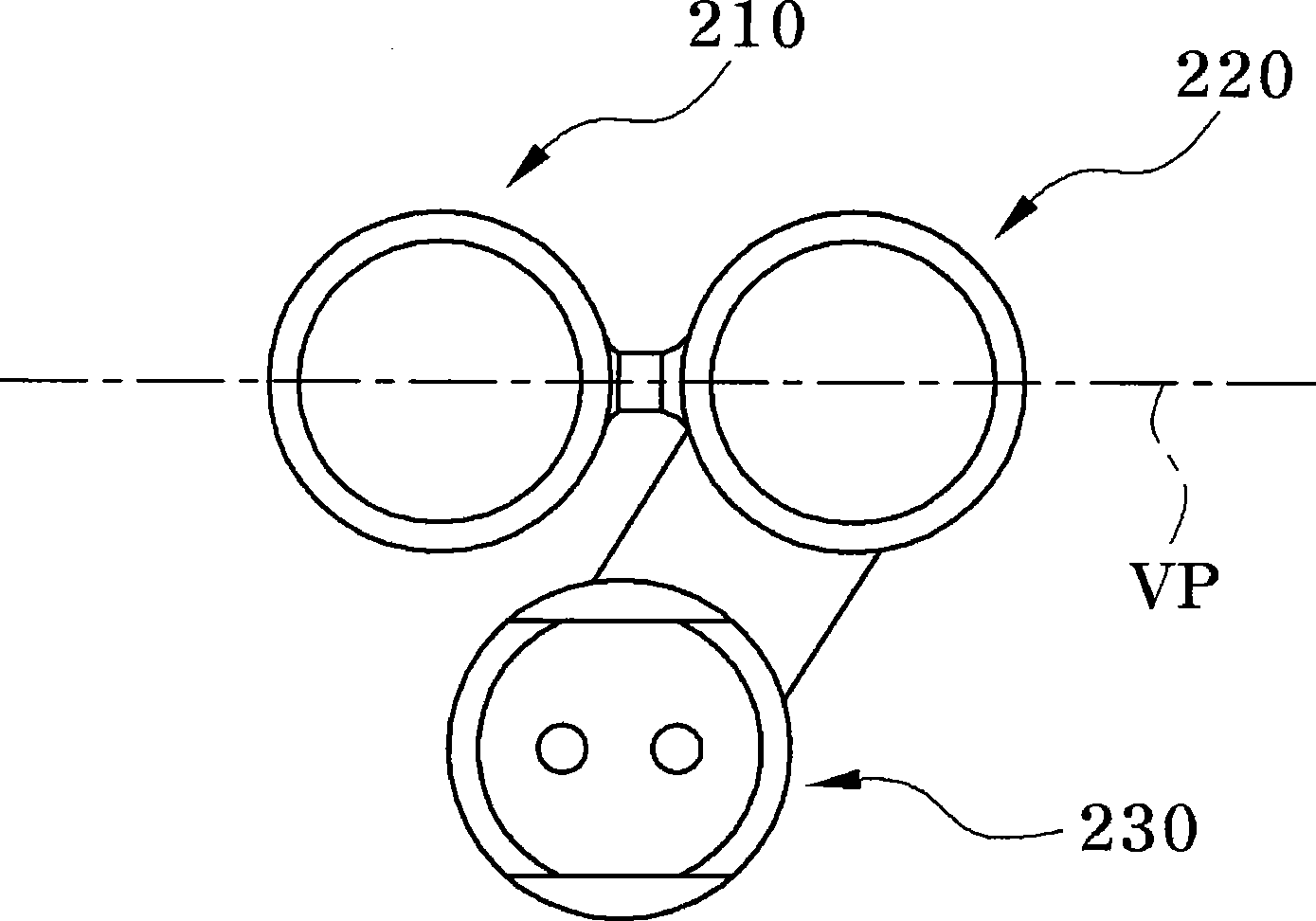

Fluorescent lamp

InactiveCN101368696AIncrease light intensityLower the altitudeElectric circuit arrangementsGas discharge lamp detailsEngineeringFluorescent lamp

The present invention relates to a fluorescent lamp, which is constituted by main tubes, subsidiary tubes having electrodes, and connection tubes each connecting the main tube to the subsidiary tube. Specifically, the fluorescent lamp includes a first stage main tube part having a first main tube, a second stage main tube part communicating with the first stage main tube part and having second and third main tubes, and a third stage subsidiary tube part communicating with the second stage main tube part and having first and second subsidiary tubes each having an electrode. Thereby, the present invention provides a florescent lamp capable of emitting different colors with two or more tubes integrated mutually for improving lighting strength of unit installation area when coupling to luminous equipment.

Owner:FEELUX CO LTD

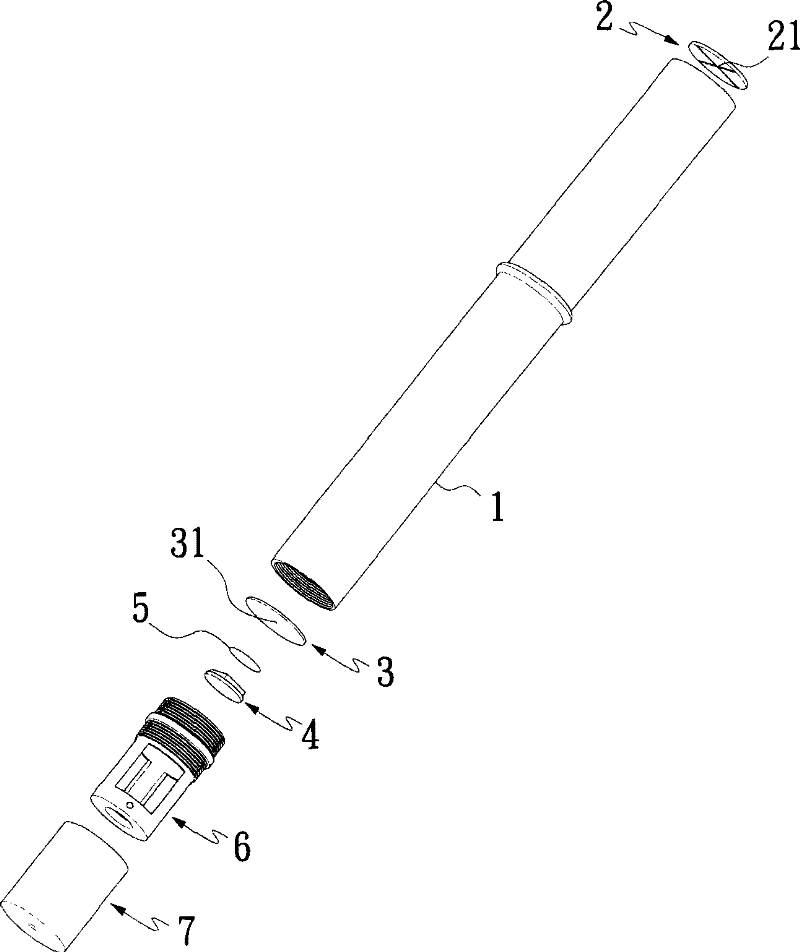

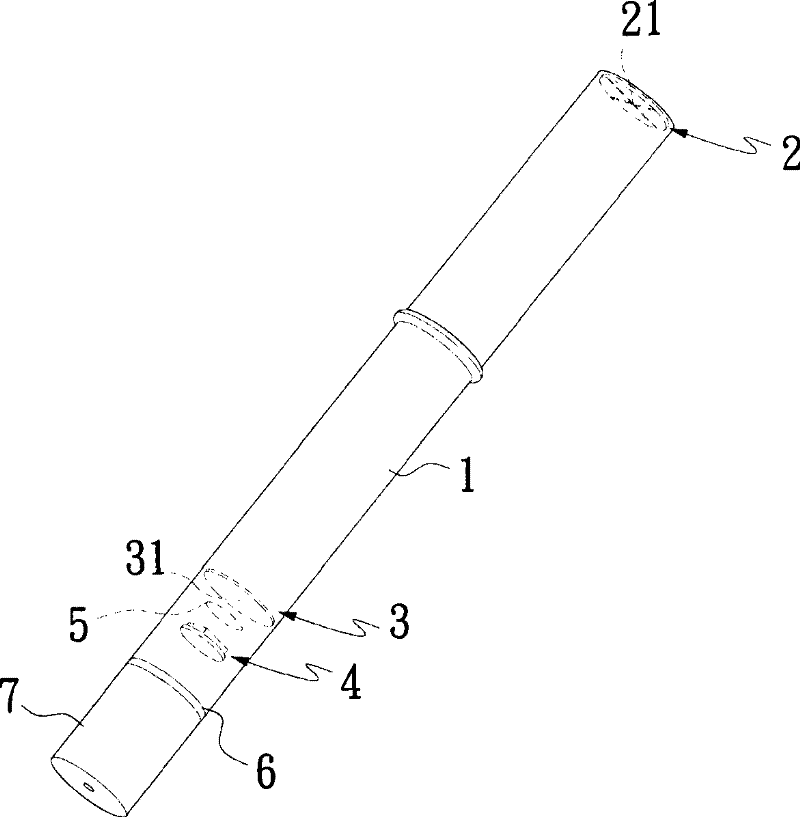

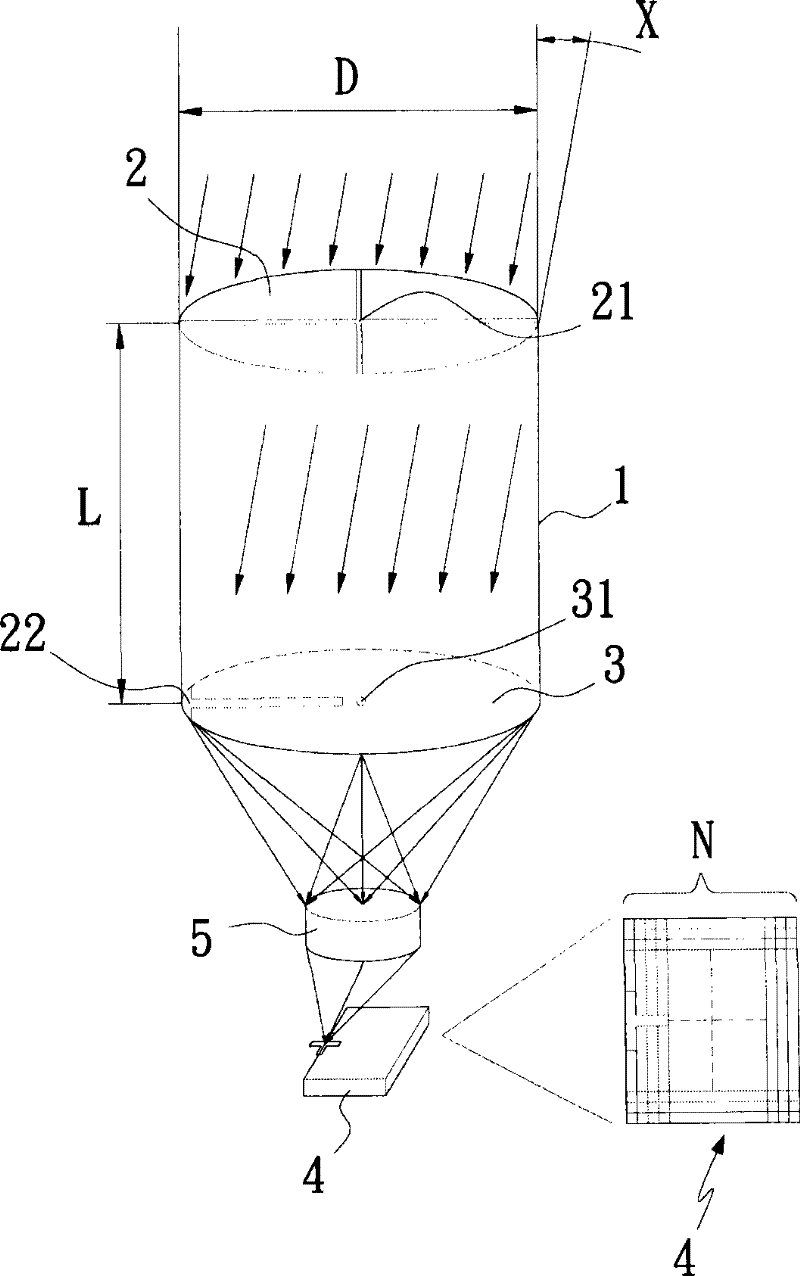

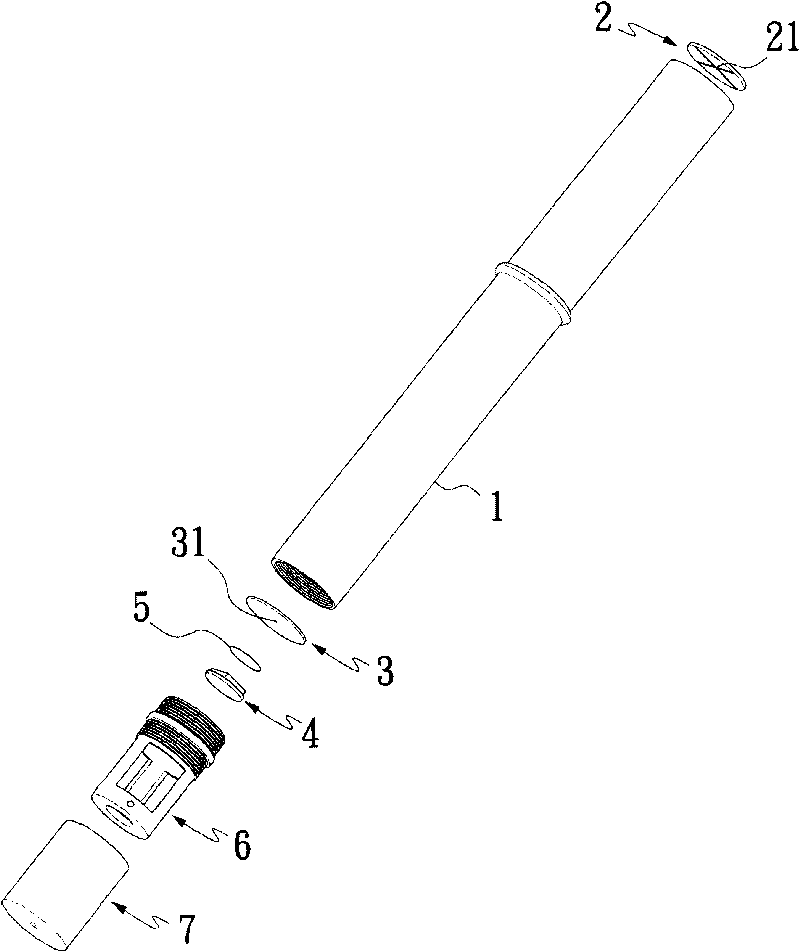

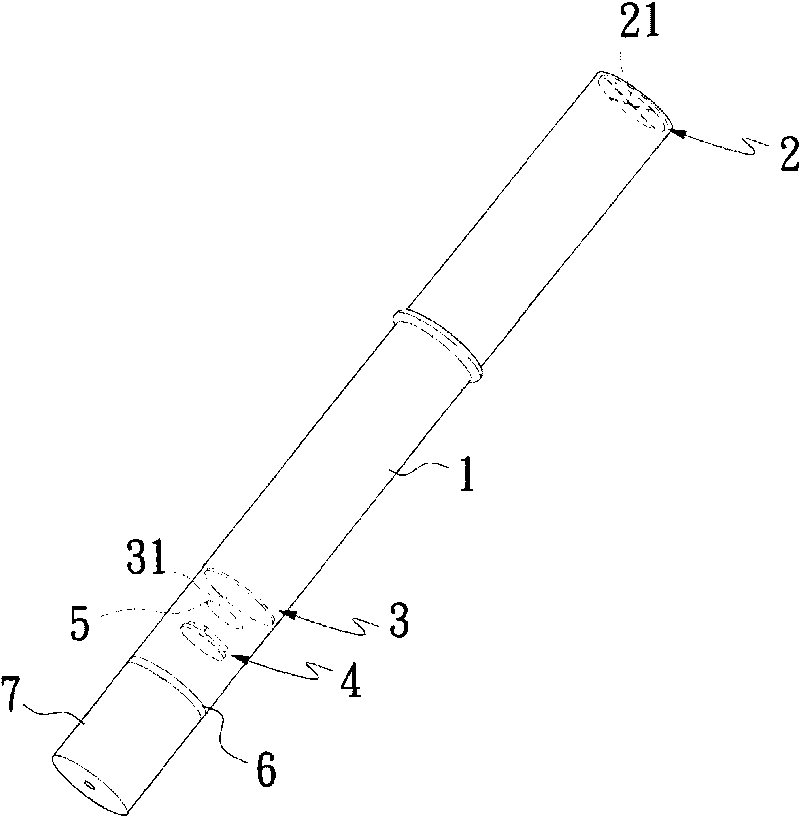

Solar panel tracking device

InactiveCN101726123BImprove shortcomingsHigh sensitivitySolar heating energySolar heat collector controllersEngineeringVisual angle

The invention relates to a solar panel tracking device which comprises a cylinder body, a transmission unit, a projection unit, a light sensitive unit and a lens, wherein the transmission unit is arranged at one end of the cylinder body facing the sun; the center of the transmission unit has a light-transmitting junction; the projection unit is arranged between two ends of the cylinder body and is a translucent body; the light sensitive unit is arranged at one side of the projection unit; the projection unit is positioned between the transmission unit and the light sensitive unit; the light sensitive unit is preinstalled with a positioning center at the center of the projection unit; and the lens is arranged between the projection unit and the light sensitive unit. Thus, the solar panel tracking device of the invention can improve the sensitivity and the accuracy of tracking the sun and has the function of switching the visual angle conveniently.

Owner:PACIFIC SPEED

Packaging method for combining telescopic screw with printed circuit board

ActiveCN101742818BEasy to set upSkill improvedPrinted circuit manufacturePrinted circuit non-printed electric components associationEngineeringMaterial Perforation

The invention relates to a packaging method for combining a telescopic screw with a printed circuit board, which comprises the following steps: pressing a screw head of the telescopic screw comprising the screw head, a screw rod and a sleeve with a fixture to prop the fixture at one end of the sleeve, providing the printed circuit board provided with a plurality of perforations and a solder layer; contacting the fixture with a tool to take the telescopic screw to make the screw rod correspond to the perforations of the printed circuit board; allowing the tool to release the fixture, and cooperating flanges of the sleeve with the solder layer to limit the flanges in the perforations; making the solder layer hardened to fix the sleeve. The package method achieves the effect of precisely and easily arranging the sleeve of the telescopic screw without shift and deflection.

Owner:王鼎瑞

Solar panel tracking device

InactiveCN101726123AImprove shortcomingsHigh sensitivitySolar heating energySolar heat collector controllersEngineeringVisual angle

The invention relates to a solar panel tracking device which comprises a cylinder body, a transmission unit, a projection unit, a light sensitive unit and a lens, wherein the transmission unit is arranged at one end of the cylinder body facing the sun; the center of the transmission unit has a light-transmitting junction; the projection unit is arranged between two ends of the cylinder body and is a translucent body; the light sensitive unit is arranged at one side of the projection unit; the projection unit is positioned between the transmission unit and the light sensitive unit; the light sensitive unit is preinstalled with a positioning center at the center of the projection unit; and the lens is arranged between the projection unit and the light sensitive unit. Thus, the solar panel tracking device of the invention can improve the sensitivity and the accuracy of tracking the sun and has the function of switching the visual angle conveniently.

Owner:PACIFIC SPEED

Packaging method for combining screw to printed circuit board

ActiveCN101516163BImprove the various shortcomingsMeet needsPrinted circuit manufacturePrinted circuit non-printed electric components associationEngineeringPrinted circuit board

The invention relates to a packaging method for combining a screw to a printed circuit board, which is a method for combining the screw to the printed circuit board by a surface adhesion technique and comprises the following steps: providing a screw having a screw head, a screw rod extending out of one end of the screw head, and a sleeve sleeved on the periphery of the screw rod and movably arranged on one end face of the screw head; sleeving a limit ring on the screw rod to lean against one end of the sleeve so that part of the sleeve is limited in the screw head; arranging an adhesive layeron the other end face of the screw head; providing the printed circuit board with a plurality of through holes and arranging a soldering tin layer; making a tool use the screw through the adhesive layer and moving the tool so that the screw rod corresponds to the through holes; making the tool release the screw to drop the screw, and arranging a flange of the sleeve in the through holes; heating the soldering tin layer to melt tin, and cooling the soldering tin layer to the normal temperature so as to harden the soldering tin layer; fixedly arranging the sleeve in the through holes; and removing the limit ring. The method has the efficacy of achieving precise, non-offset, non-deflective and easy arrangement in the process of arranging a screw sleeve.

Owner:DTECH PRECISION INDS

Bearing device for triaxial adjustment

InactiveCN101631442BImprove the various shortcomingsEfficacy meetsDigital processing power distributionSupport structure mountingMechanical engineeringEngineering

Owner:THERMALTAKE

Displacement printing pressing force and tolerance clearance removing device of curved surface printing machine

ActiveCN102259476BWidely used valueEliminate natural tolerance gapsRotary pressesPrinting pressMechanical engineering

Owner:GUANGDONG LONGXING PACKAGING IND

Device for displacing printing pressing force and eliminating tolerance clearance of curved-surface printing machine

ActiveCN103252987AWidely used valueEliminate natural tolerance gapsRotary pressesProgrammable logic controllerEngineering

The invention relates to a printing machine, in particular to a device for displacing printing pressing force and eliminating a tolerance clearance of a curved-surface printing machine. The device for displacing the printing pressing force and eliminating the tolerance clearance of the curved-surface printing machine comprises a printing device which is arranged on a base and is provided with a multi-work-position stepping indexing turntable and a mould handle, and a printing main machine which is arranged on a main machine supporting frame and provided with a transferring printing large drum, and is characterized in that a two-dimensional orthogonal sliding seat is arranged on the base, the main machine supporting frame is arranged on the two-dimensional orthogonal sliding seat through a main machine seat plate, the base is further provided with a longitudinal moving device used for eliminating the clearance, and a programmable logic controller (PLC) which is used for controlling the longitudinal moving device used for eliminating the clearance and is provided with a touch screen, and the longitudinal moving device used for eliminating the clearance is arranged between the base and the main machine seat plate, controls the main machine seat plate to move in the direction perpendicular to the axis of the mould handle, and eliminates the tolerance clearance. The device for displacing the printing pressing force and eliminating the tolerance clearance of the curved-surface printing machine is convenient to operate, is small in vibration, and meets the accuracy requirement for high-speed operation at the speed of 450-650 cups per minute in the cup printing process, and the speed of cup printing is improved by one time compared with existing equipment.

Owner:GUANGDONG LONGXING PACKAGING IND

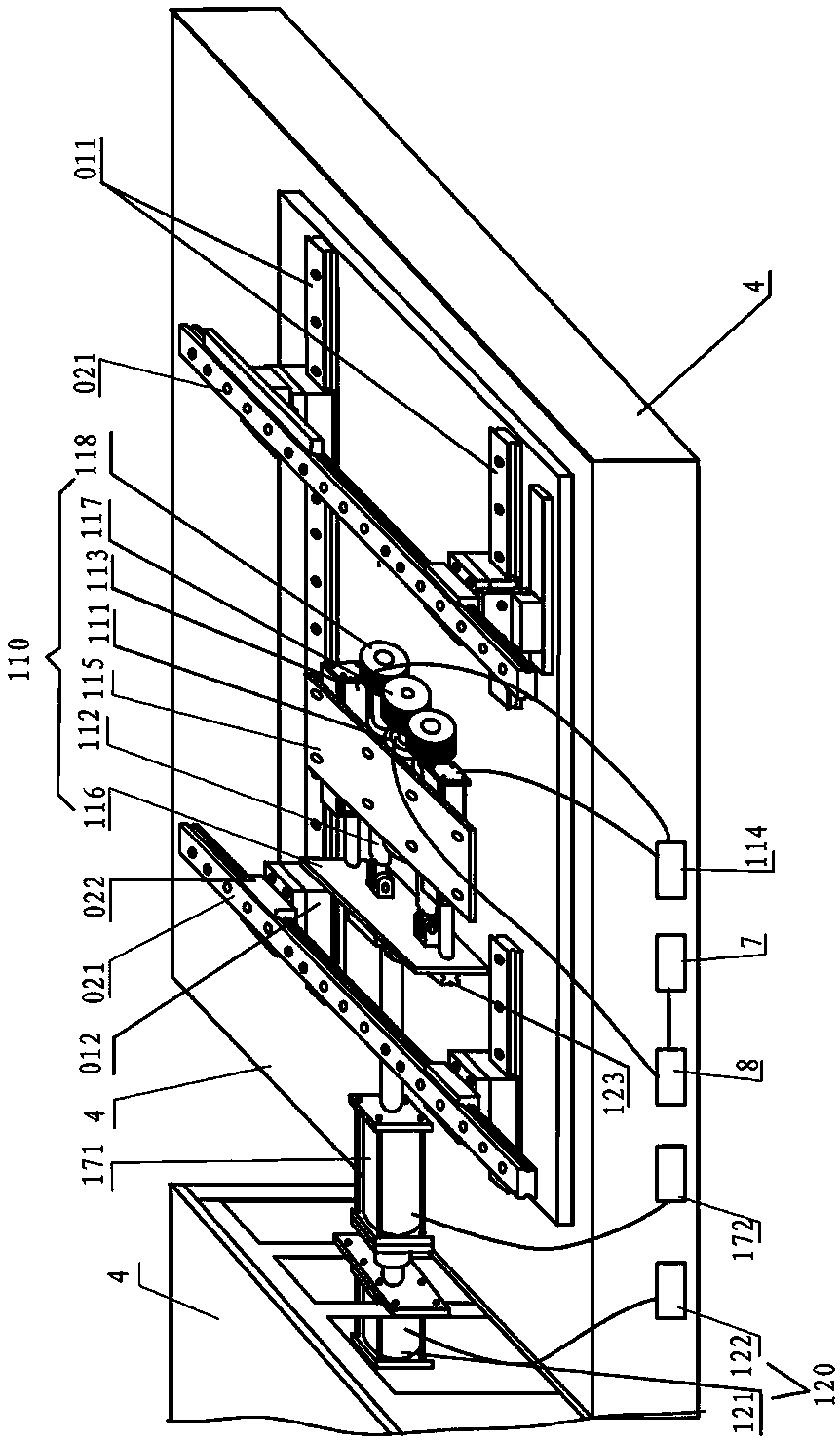

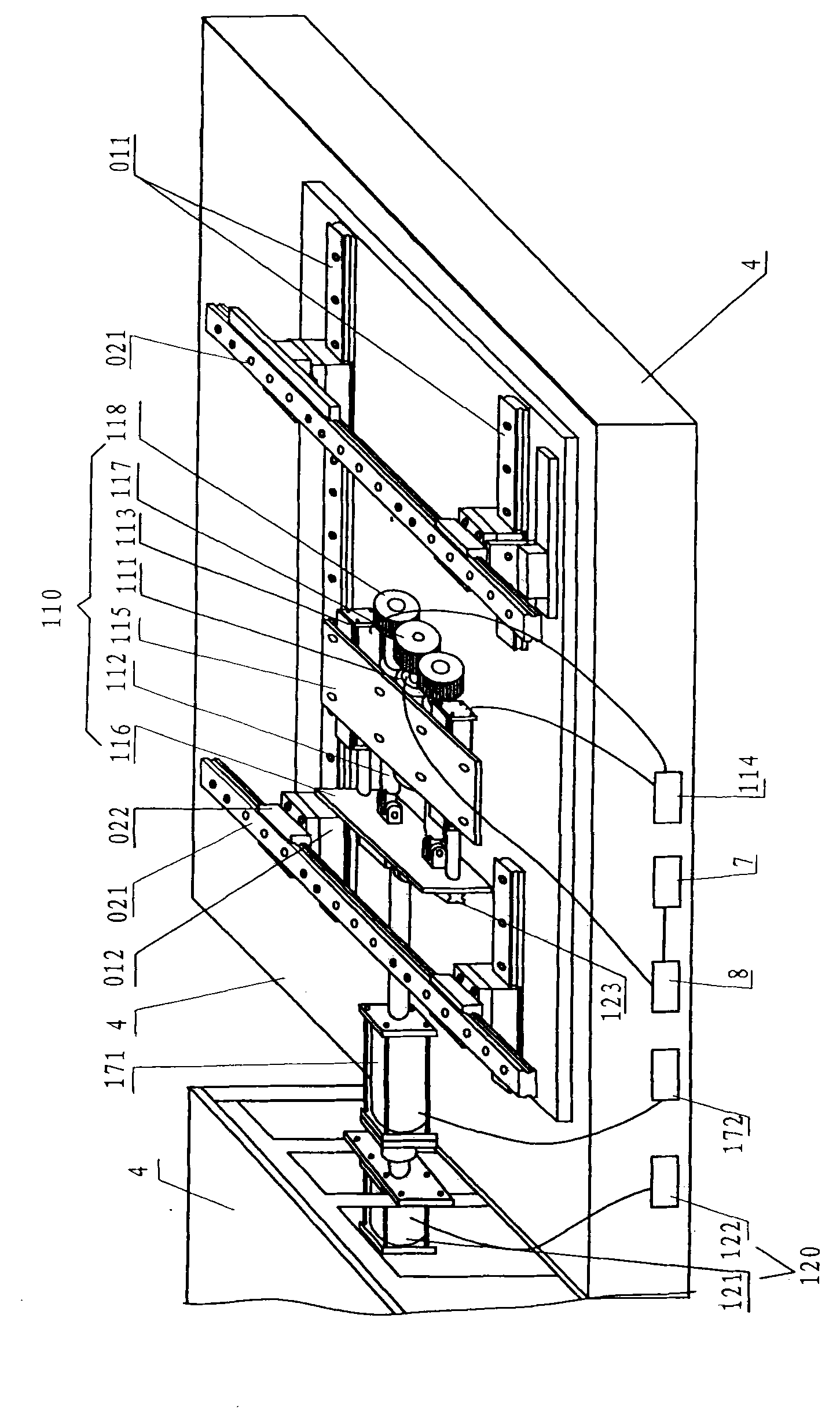

Automatic conveyer system of EPS (Expandable Polystyrene) cup printing machine

InactiveCN101823361BWidely used valueIncrease productivityRotary pressesProgrammable logic controllerPolystyrene

The invention relates to a cup and bowl printing machine, in particular to an automatic conveyer system of an EPS (Expandable Polystyrene) cup printing machine, mainly comprising an automatic cup separating device, an automatic cup receiving and sending device, an automatic cup stacking and conveying device, an automatic cup counting and pushing device and a PLC (Programmable Logic Controller) controller, wherein the automatic cup separating device separates conveyed cups to be printed, which are sleeved and stacked into a whole strip, into single cups and conveys the cups into a mould of a eight-graduation turntable of a stepper graduator for printing; the printed cups are conveyed to the automatic cup stacking device through the automatic cup receiving and sending device; the automatic cup stacking device sleeves and stacks the cups into a whole cup strip and pushes the cup strip to the automatic cup counting and pushing device; and after counting, the cups are pushed to a cup receiving groove. The whole process is controlled by the PLC controller to realize the automation of the whole printing process, and the production efficiency is greatly improved.

Owner:GUANGDONG LONGXING PACKAGING IND

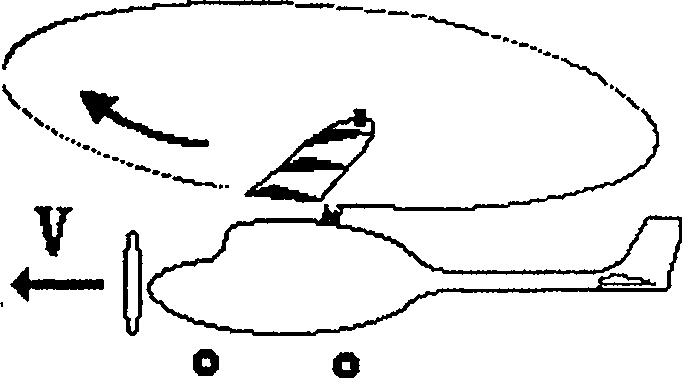

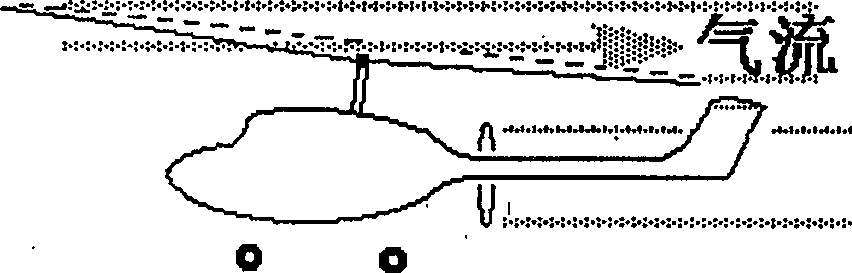

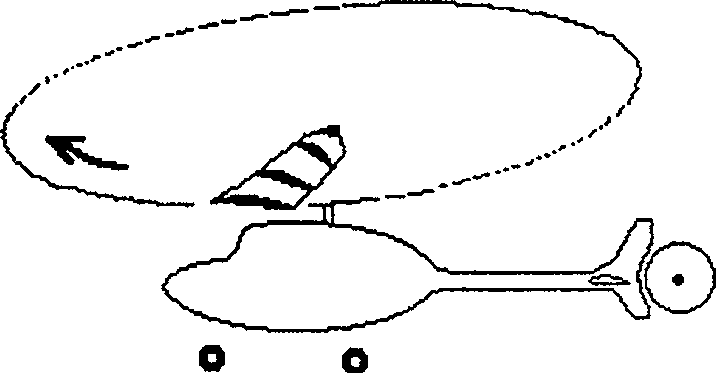

Helirota plane

InactiveCN100486867CGive full play to the advantages of workAvoid aerodynamic efficiencyPropellersRotocraftLow noiseRotary wing

Owner:章洪

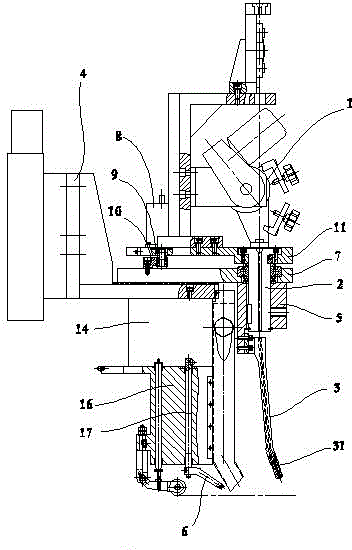

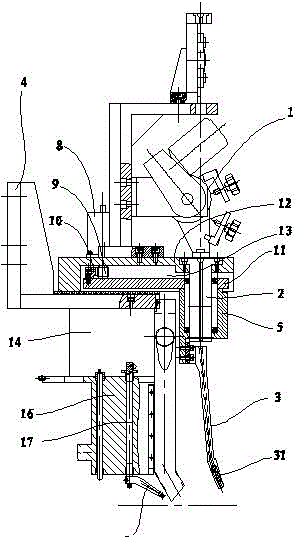

Narrow-gap welding nose with tilt angle device

ActiveCN103071898BWidely used valueUniform and stable penetrationElectrode supporting devicesElectrode accessoriesControl systemNose

The invention relates to a narrow-gap welding nose with a tilt angle device, which carries out narrow-gap welding. The narrow-gap welding nose with the tilt angle device comprises an electric conduction nozzle of a welding gun, a connecting plate for installing the welding gun, and a tilt angle device, wherein the lower end of the electric conduction nozzle is provided with a bent part; and the bent part is coaxially and fixedly arranged on the lower end of a wire guide rod by a corner sleeve. The narrow-gap welding nose with the tilt angle device is characterized in that the tilt angle device comprises a tilt angle mechanism for driving the electric conduction nozzle to carry out deflection, and a side wall tracking mechanism for keeping the distance between the electric conduction nozzle and the side wall, wherein the tilt angle mechanism for driving the electric conduction nozzle to carry out deflection is connected with the electric conduction nozzle; the side wall tracking mechanism comprises an oscillating rod, an angle sensor and a controller, wherein the oscillating rod is used for supporting the side wall of a groove; the angle sensor is connected with the oscillating rod and is connected with the controller; the controller controls the tilt angle mechanism; and the oscillating rod and the side wall of the groove are always in elastic contact. The lateral displacement moving amount of a workpiece is measured by a high-precision sensing assembly, and the distance between the electric conduction nozzle and the workpiece is controlled to be within a tracking precision of + / -0.5mm by the lateral regulation of the control system so as to guarantee the stable and even penetration of the side wall.

Owner:北京嘉克新兴科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com