Water volatile oil distilling and extracting device and method

A technology of water distillation and volatile oil, which is applied in the direction of essential oil/fragrance, fat production, etc., can solve the problem of incomplete condensation, achieve high cooling efficiency, improve oil-water separation efficiency, and reduce the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The device for extracting volatile oil by distillation on water and the method for extracting volatile oil with the device will be further described below.

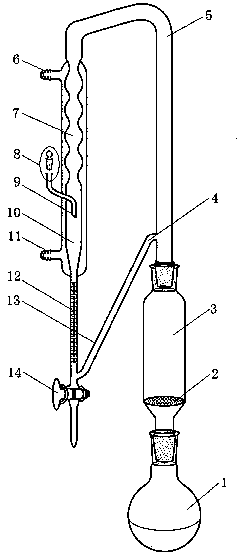

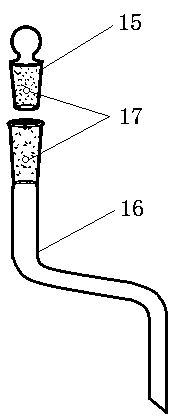

[0019] The above-water distillation extracting volatile oil device described in the present invention has a structure such as figure 1 , figure 2 , image 3 As shown, it includes a round bottom flask 1, a steaming tube 3, and a closed and condensed integrated volatile oil extractor (4-14); , separation collection pipe 10, scale pipe 12, return branch pipe 13, cock 14; Described spherical condenser pipe 7 is provided with water inlet 11 and water outlet 6; Described tool plug branch pipe 8 comprises branch pipe hollow plug 15 and ventilation branch pipe 16 ( Both are 5# standard grinding mouth), the branch pipe hollow plug 15 is a bottomless hollow plug, the branch pipe hollow plug 15 and the side wall of the ventilation branch pipe 16 have ventilation holes 17 corresponding to each other, and the diameter of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com