A kind of method for preparing pyrite phase iron disulfide thin film

A technology of iron disulfide and pyrite, applied in the direction of coating and the like, can solve the problem of difficult to obtain a pyrite phase iron disulfide film, etc., and achieve the effect of solving the problem of sulfur vacancy and overcoming the vacancy of sulfur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

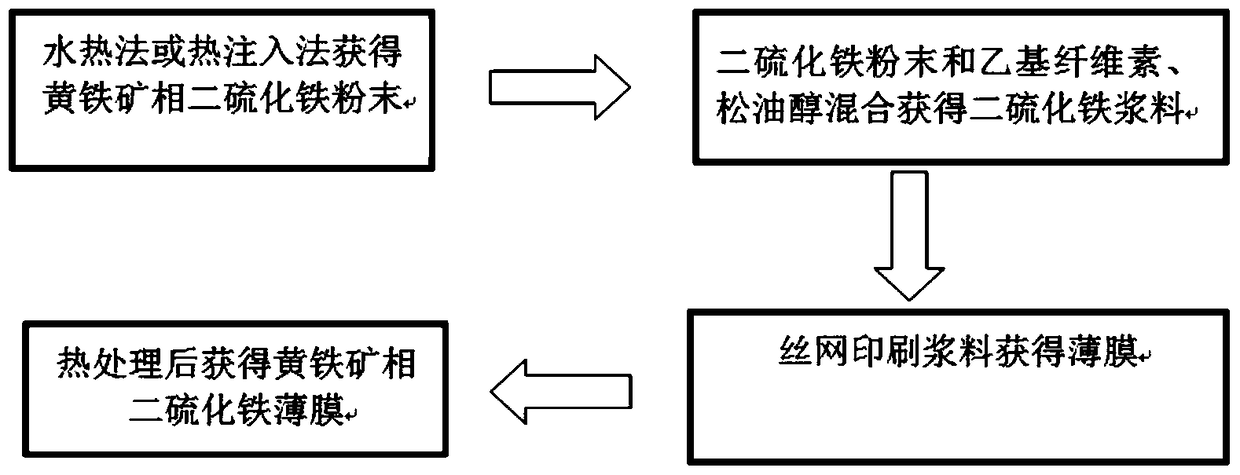

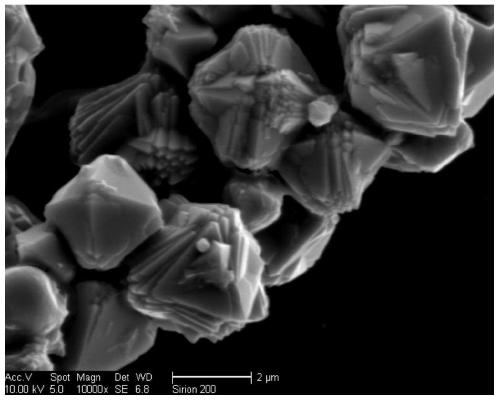

[0032] (1) Add 1.39g of ferrous sulfate heptahydrate and 0.83g of polyvinylpyrrolidone into 20ml of deionized water, stir for half an hour and add 0.76g of thiourea; transfer the above solution to the inner lining of the autoclave, and add 0.64g of sulfur powder , add an appropriate amount of ethanol to make the liquid volume reach about 80% of the volume of the autoclave lining. The autoclave was placed in a box furnace and heated at 200°C for 24 hours. After the temperature is cooled to room temperature, the liquid in the autoclave lining is poured out, washed with ethanol, deionized water, and carbon disulfide in sequence, and finally the powder is dried in an oven for use. figure 2 It is the scanning electron micrograph of this embodiment product; Figure 5 Be the X-ray diffraction result of this embodiment product; Figure 6 It is the Raman result of the product of this example.

[0033] (2) Add 0.1 g of iron disulfide powder to 5 ml of ethanol, add 0.1 g of terpineol...

Embodiment 2

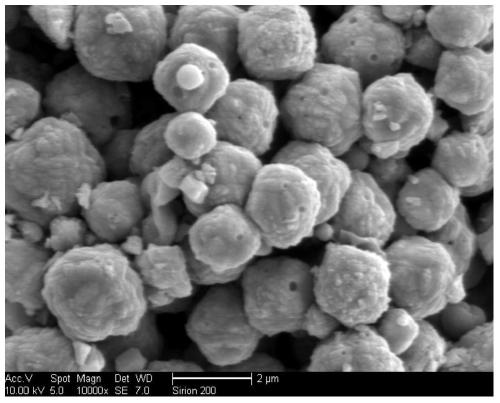

[0038] (1) Add 10ml of oleylamine to a three-necked bottle protected by nitrogen, add 0.20g of ferrous chloride tetrahydrate, and keep the temperature at 120°C for 1 hour to obtain solution A; in another container protected by nitrogen, add 0.19g Dissolve sulfur powder in 5ml of diphenyl ether, react at 70°C for 1 hour to obtain solution B; inject solution B into solution A through a needle, react at 220°C for 24 hours, then cool to room temperature. Rinse with absolute ethanol and chloroform several times, and finally dry the powder in an oven for use. image 3 It is the scanning electron micrograph of this embodiment product; Figure 5 Be the X-ray diffraction result of this embodiment product; Figure 6 It is the Raman result of the product of this example.

[0039] (2) Add 0.1 g of iron disulfide powder to 5 ml of ethanol, add 0.1 g of terpineol and 0.4 g of ethyl cellulose, and stir magnetically for one day.

[0040] (3) ultrasonically clean the FTO conductive glass an...

Embodiment 3

[0044] (1) Add 1.39g of ferrous sulfate heptahydrate and 0.83g of polyvinylpyrrolidone into 20ml of deionized water, stir for half an hour and add 0.76g of thiourea; transfer the above solution to the inner lining of the autoclave, and add 0.64g of sulfur powder , add an appropriate amount of ethanol to make the liquid volume reach about 80% of the volume of the autoclave lining. The autoclave was placed in a box furnace and heated at 200°C for 39 hours. After the temperature is cooled to room temperature, the liquid in the autoclave lining is poured out, washed with ethanol, deionized water, and carbon disulfide in sequence, and finally the powder is dried in an oven for use. Figure 4 It is the scanning electron micrograph of this embodiment product; Figure 5 Be the X-ray diffraction result of this embodiment product; Figure 6 It is the Raman result of the product of this example.

[0045] (2) Add 0.1 g of iron disulfide powder to 5 ml of ethanol, add 0.1 g of terpineol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com