Cable-type welding wire double-twisting stranding machine

A cable-type welding wire and stranding machine technology, which is applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems such as stepless adjustment of lay length, complicated transmission mechanism and low production efficiency, etc. Achieve the effect of improving labor efficiency, improving economic benefits, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

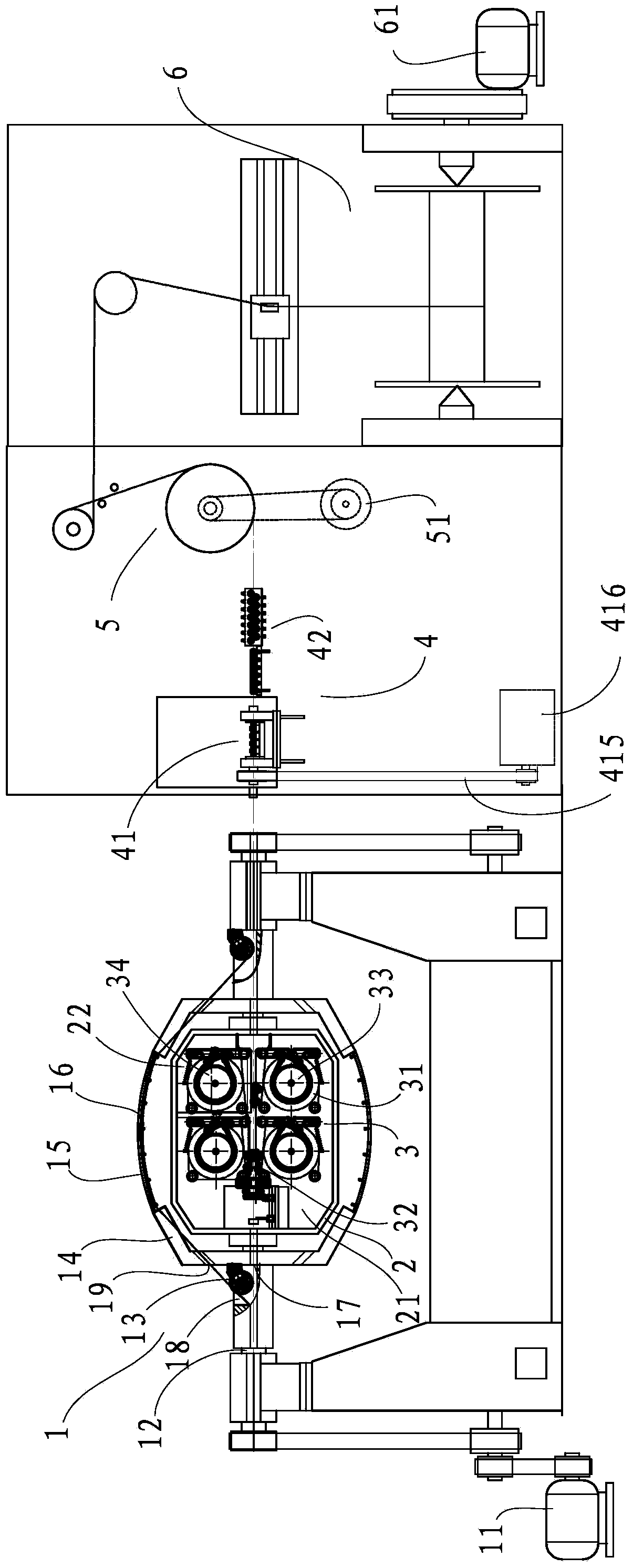

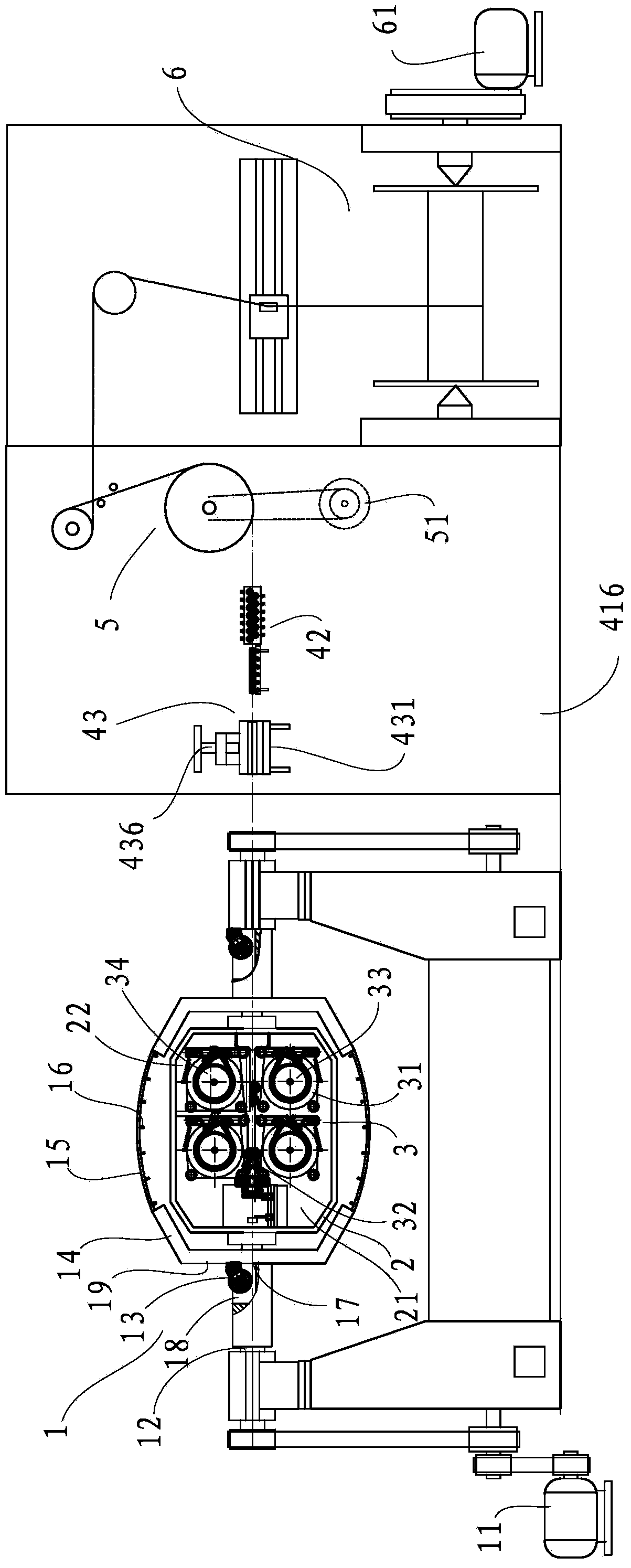

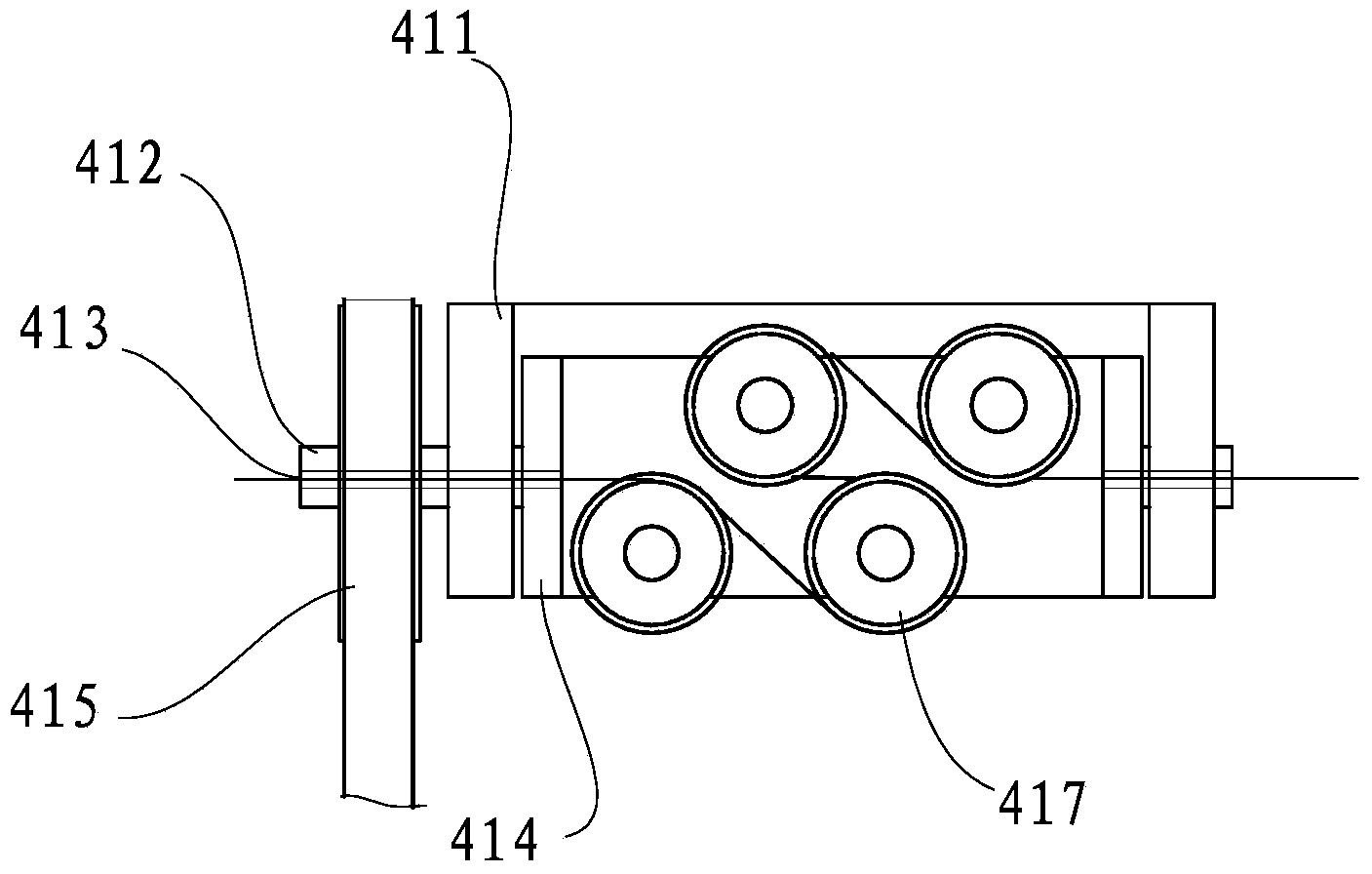

[0031] see figure 1 , figure 2Shown, the cable-type welding wire double-twisting stranding machine of preferred embodiment of the present invention, comprises two main shafts 12 and the pulley 13 that are on the same axis that are driven by stranding motor 11 and have central hole 17 and side hole 18 and constitute Stranding device 1, a wire-releasing device 3 with a plurality of wire-releasing I-shaped wheels 31 and a wire-passing wheel 32 arranged in the cradle 2, a shaping stress-relief device 4 arranged on the extension of the axis of the main shaft, a traction device 5 and a take-up device Line device 6, described cradle 2 is suspended on the shaft end of two main shafts 12; Above-mentioned each device all belongs to the basic structure of existing steel cord strand twisting machine. In order to adapt to the high-speed twisting needs of the cable-type welding wire, the two main shafts 12 of the twisting device 1 are fixedly provided with two oppositely arranged arcuate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com