A kind of method for preparing chlorinated polyvinyl chloride resin based on tubular reactor

A chlorinated polyvinyl chloride, tubular reactor technology, applied in the field of new polymer materials and new processes, can solve the problems of high production cost, low production efficiency, poor chlorination uniformity, etc. The effect of reducing production cost and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

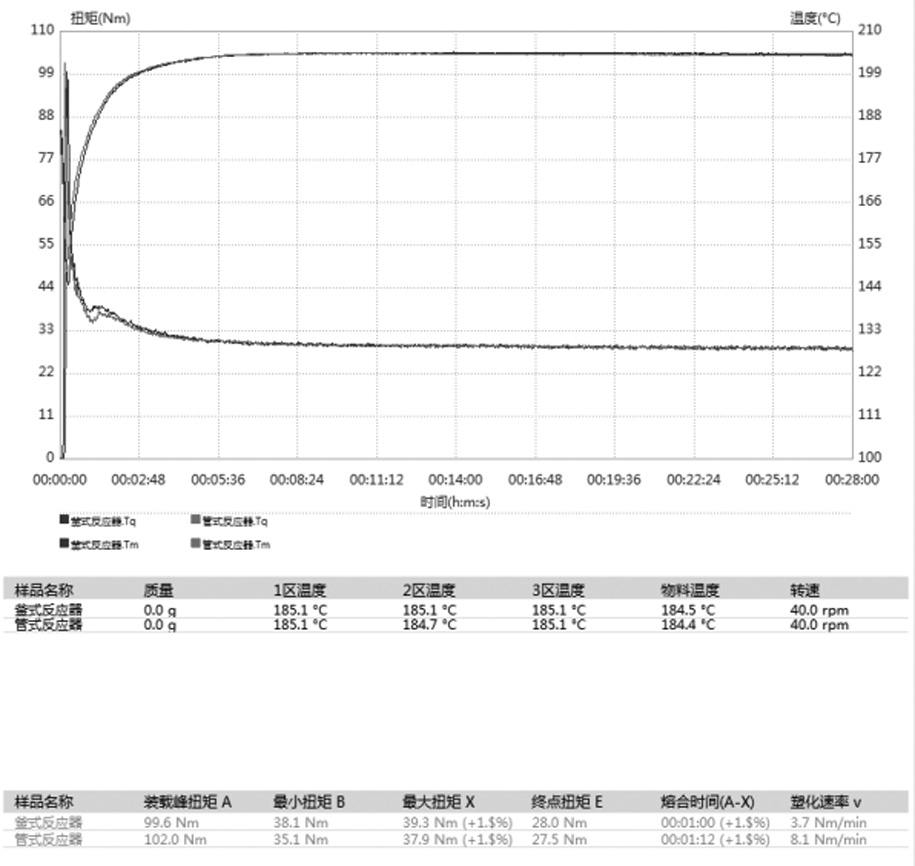

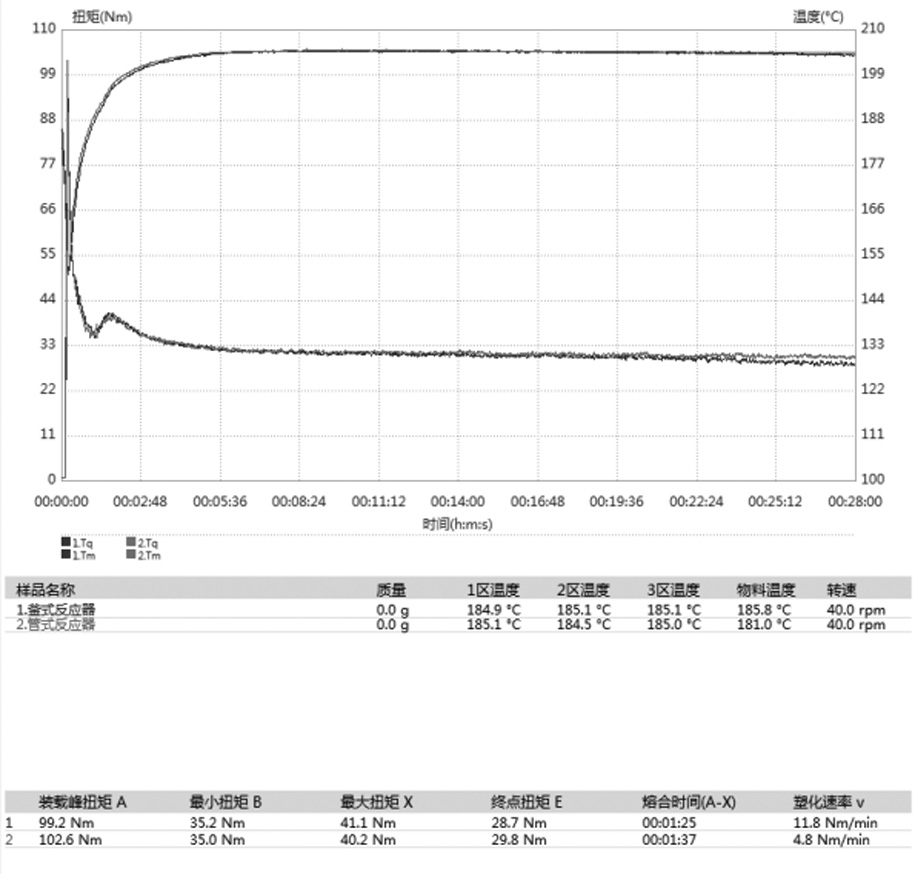

Image

Examples

Embodiment 1

[0048] (1), ingredients

[0049] Put the material into the batching kettle, stir evenly, and wait for the material to be transferred.

[0050] Materials include 1600kg PVC resin, 8000kg medium, 0.8kg dispersant, 2.4kg initiator.

[0051] Among them, PVC resin is selected with an apparent density of 0.60g / ml, a particle size of 100-130μm, and a porosity of 20-30%;

[0052] The reaction medium is deionized water or dilute hydrochloric acid water, and the concentration of hydrochloric acid water is 1%-3%;

[0053] The dispersant is one of polyvinyl alcohol, sodium polymethacrylate and sodium polystyrene sulfonate.

[0054] Initiators include low-temperature initiators and medium-temperature initiators;

[0055] The dosage ratio of low-temperature and medium-temperature initiators is 3:1;

[0056] The low-temperature initiator is one or more of diisopropyl peroxydicarbonate, dicyclohexyl peroxydicarbonate or tert-butyl peroxy tert-valerate;

[0057] The medium-temperature ini...

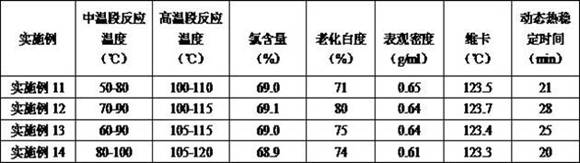

Embodiment 2

[0065] Embodiment 2 adopts the batching method identical with embodiment 1, has changed material feeding speed, reaction time, chlorine feeding speed.

[0066] Medium temperature reaction stage: press the material to 0.09m 3 / min, that is, 14.4kg / min speed is pressed into the first reactor, the liquid chlorine feed rate is 4.5kg / min, the reaction time is 3min, the temperature is 60-100°C, and the temperature is controlled from the inlet to the outlet according to 1.33°C / dm regular increase.

[0067] High-temperature reaction stage: After the reaction in the medium-temperature reactor is completed, it is directly transferred to the second reactor. The reaction time in the high-temperature reactor is 3 minutes, the feeding rate of liquid chlorine is 6.2kg / min, and the temperature is 100-120°C. The temperature is controlled by the feed From the outlet to the discharge outlet, it increases gradually according to the law of 0.67°C / dm.

[0068] Chlorine passage time in the middle ...

Embodiment 3

[0070] Embodiment 3 adopts the batching method identical with embodiment 1, has changed material feeding speed, reaction time, chlorine feeding speed.

[0071] Medium temperature reaction stage: press the material to 0.07m 3 / min, that is, the speed of 11.2kg / min is pressed into the first reactor, the feeding speed of liquid chlorine is 3.5kg / min, the reaction time is 4min, the temperature is 60-100°C, and the temperature is controlled from the inlet to the outlet according to 1.33°C / dm regular increase.

[0072] High-temperature reaction stage: After the reaction in the medium-temperature reactor is completed, it is directly transferred to the second reactor. The reaction time in the high-temperature reactor is 4 minutes, the feeding rate of liquid chlorine is 4.7kg / min, and the temperature is 100-120°C. The temperature is controlled by the feed From the outlet to the discharge outlet, it increases gradually according to the law of 0.67°C / dm.

[0073] Chlorine passage time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com