1,1,2-trichloroethane reactor and method thereof

A technology of trichloroethane and reactor, which is applied in the field of 1,1,2-trichloroethane reactor, can solve the problems of high production cost, decreased reaction selectivity and yield, and many by-products, etc. The effects of production efficiency and safety, enhanced reaction stability control, and improved product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

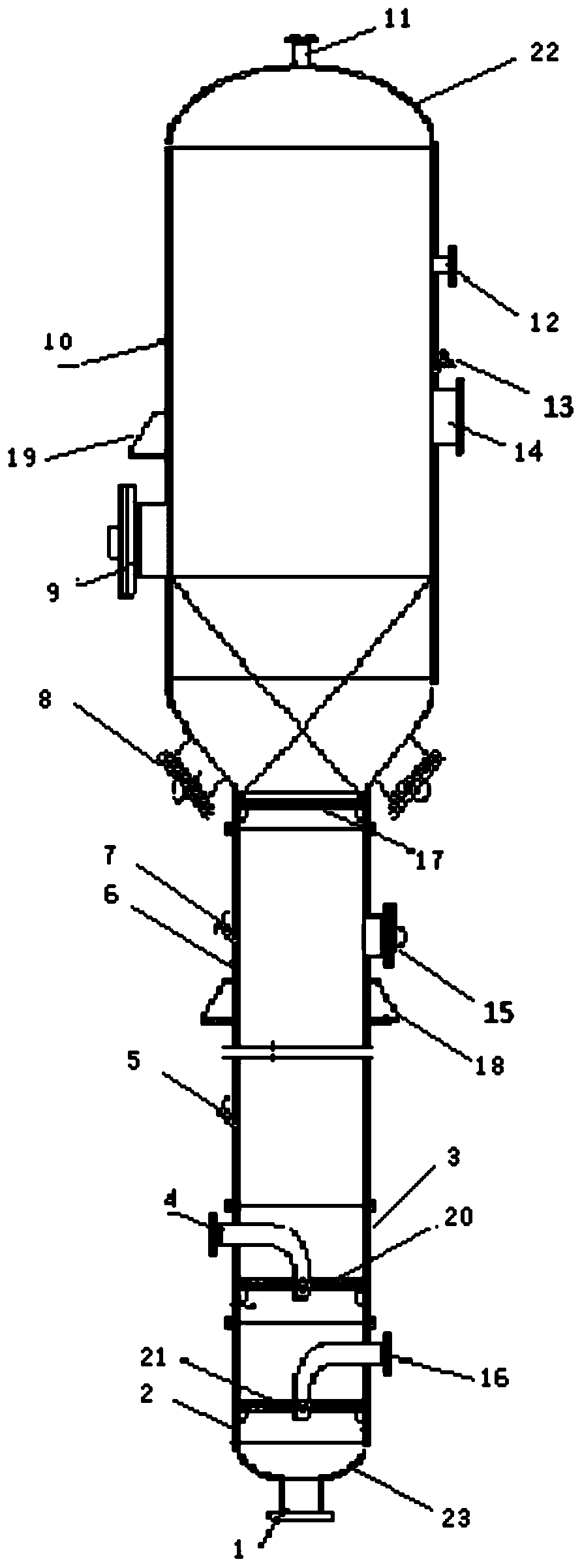

[0043] A 1,1,2-trichloroethane reactor, comprising a vertically installed cylinder, the cylinder consists of a lower head 23 connected sequentially from bottom to top, a first section cylinder 2 (made of carbon steel, with an inner diameter of 600mm), the second cylinder body 3 (made of carbon steel, with an inner diameter of 600mm), the third cylinder body 6 (made of carbon steel, with an inner diameter of 600mm), the fourth cylinder body 10 and the upper head 22, and the lower seal The bottom of the head 23 is provided with a circulating fluid inlet 1, a vinyl chloride distributor 21 (the number of vent holes is 360, and the diameter of the vent hole is 5 mm) is provided in the first section of the cylinder body 2, and the first section of the cylinder body 2 is provided with Vinyl chloride inlet 16, vinyl chloride inlet 16 is connected with vinyl chloride distributor 21, chlorine gas distributor 20 is arranged in cylinder body 3 of the second section (the number of exhaust h...

Embodiment 2

[0048]A 1,1,2-trichloroethane reactor, comprising a vertically installed cylinder, the cylinder consists of a lower head 23 connected sequentially from bottom to top, a first section cylinder 2 (made of carbon steel, with an inner diameter of 800mm), the second cylinder 3 (made of carbon steel, with an inner diameter of 800mm), the third cylinder 6 (made of carbon steel, with an inner diameter of 800mm), the fourth cylinder 10 and the upper head 22, and the lower seal The bottom of the head 23 is provided with a circulating fluid inlet 1, a vinyl chloride distributor 21 is provided in the first section of the cylinder body 2 (the number of vent holes is 400, and the diameter of the vent hole is 4.5mm), and the first section of the cylinder body 2 is provided with There is a vinyl chloride inlet 16, and the vinyl chloride inlet 16 is connected to the vinyl chloride distributor 21, and the second cylinder body 3 is provided with a chlorine gas distributor 20 (the number of exhaus...

Embodiment 3

[0053] A 1,1,2-trichloroethane reactor, comprising a vertically installed cylinder, the cylinder consists of a lower head 23 connected sequentially from bottom to top, a first section cylinder 2 (made of carbon steel, with an inner diameter of 1000mm), the second cylinder body 3 (made of carbon steel, with an inner diameter of 1000mm), the third cylinder body 6 (made of carbon steel, with an inner diameter of 1000mm), the fourth cylinder body 10 and the upper head 22, and the lower seal The bottom of the head 23 is provided with a circulating fluid inlet 1, a vinyl chloride distributor 21 is provided in the first section of the cylinder body 2 (the number of vent holes is 500, and the diameter of the vent hole is 4mm), and the first section of the cylinder body 2 is provided with There is a vinyl chloride inlet 16, and the vinyl chloride inlet 16 is connected with the vinyl chloride distributor 21, and a chlorine gas distributor 20 is arranged in the cylinder body 3 of the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com