Powder material multistage dry-method modification system

A powder material, dry modification technology, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc. , the processing process is difficult to control and other problems, to achieve the effect of being beneficial to health, saving labor costs, and evenly distributed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

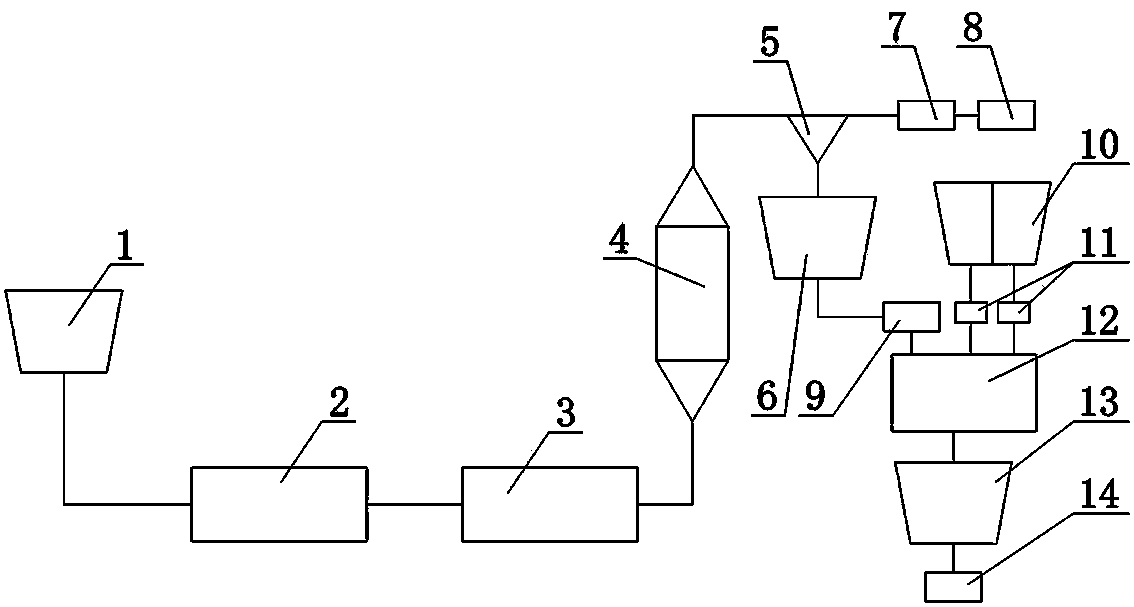

[0015] Such as figure 1 As shown, the powder material multi-stage dry modification system includes a powder material storage tank 1, a high-pressure fan 2, a heater 3, a boiling drying tower 4, a cyclone separator 5, a negative pressure fan 7, and a collector 8 , dry powder storage tank 6, powder material metering feeder 9, modifier storage tank 10, modifier metering feeder 11, modifier machine 12 and finished product storage tank 13, powder material storage tank 1 through The pipeline is connected to the air inlet of the high-pressure blower 2, and the air outlet of the high-pressure blower 2 is connected to the feed port of the boiling drying tower 4 through the heater 3 through the pipeline, and the discharge port of the boiling drying tower 4 is connected to the inlet of the cyclone separator 5 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com