Acetonitrile production reactor and preparing method thereof

A technology for reactors and acetonitrile, applied in chemical instruments and methods, chemical/physical/physical chemical fixed reactors, methods for chemically changing substances using atmospheric pressure, etc., can solve the problem of damage to stirring devices and easy clogging of feed materials Pipelines, troublesome handling, etc., to prevent the hazards caused by overpressure, facilitate the handling of pipeline blockages, and reduce the effect of connecting devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

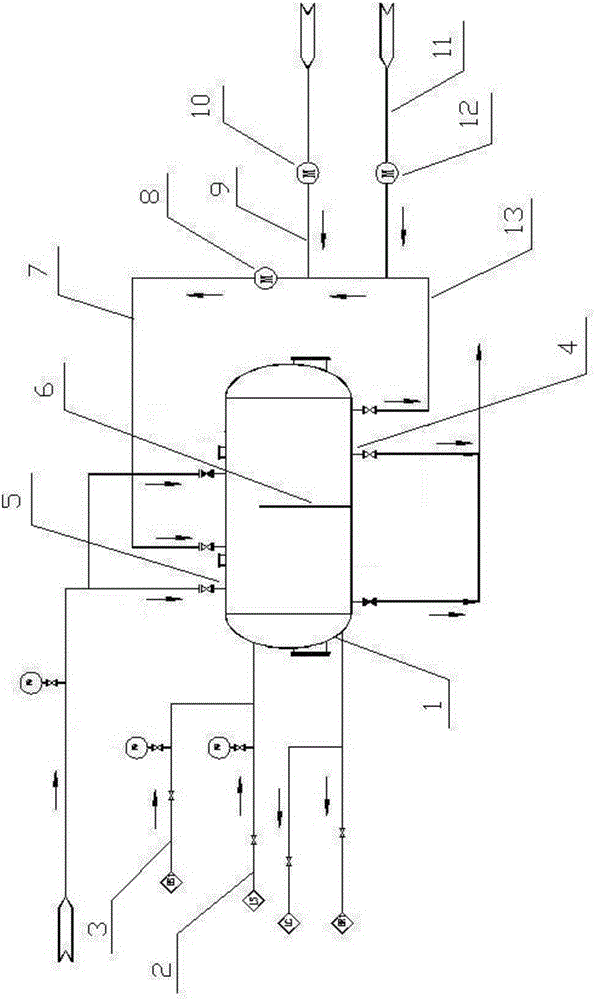

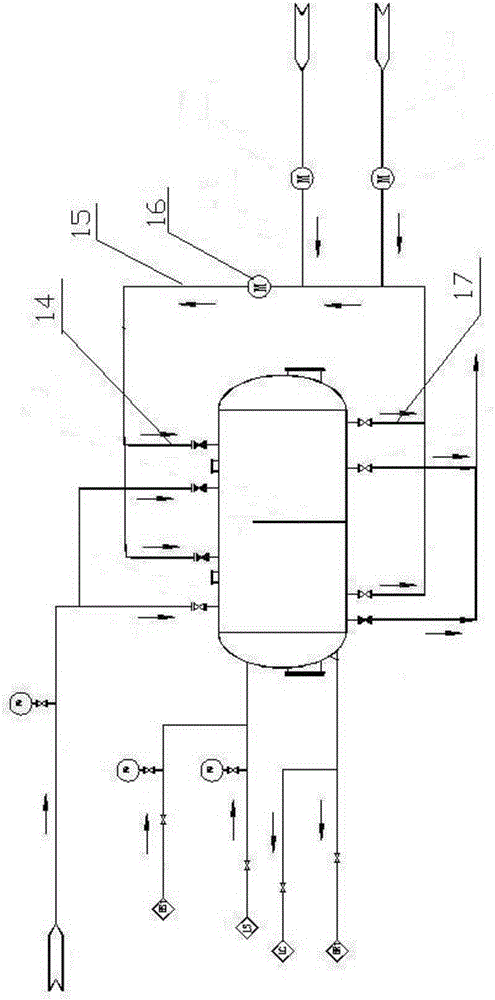

[0023] Embodiment 1, a kind of acetonitrile production reactor, is provided with the reactor 1 with jacket, is provided with the clapboard 6 that vertically is arranged in the reactor 1, and the reactor 1 is separated by the clapboard 6 and has two left and right sides that the upper part communicates with each other. The top of each chamber is provided with a feed port 5, and the bottom of each chamber is provided with a discharge port 4. The reactor 1 is provided with a material mixing pipeline connecting the two chambers, which can be connected Two different chambers can also be communicated with the same chamber, and the supply pipelines for supplying sodium hydroxide solution and formaldehyde solution are connected on the material mixing pipeline, and the supply pipelines are provided on the reaction kettle 1. control mechanism.

Embodiment 2

[0024] Embodiment 2, with reference to figure 1 , the acetonitrile production reactor described in embodiment 1, described material mixing pipeline comprises the feed pipe 7 that joins with one chamber top and the discharge pipe 13 that joins with another chamber bottom, discharge A mixing pump 8 is provided between the pipe 13 and the feed pipe 7 .

Embodiment 3

[0025] Embodiment 3, with reference to figure 2 , the acetonitrile production reactor described in embodiment 1, described material mixing pipeline is provided with the backflow pipeline 15 that has backflow pump 16, and the liquid inlet of backflow pipeline 15 is connected with two chambers by liquid outlet split pipeline 17 The bottoms are connected, and the liquid outlet of the return pipe 15 is connected to the tops of the two chambers through the liquid inlet split pipe 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com