Fluidized bed continuous reaction regeneration system and method for converting C3-C9 alkane into aromatic hydrocarbon

A technology of C3-C9, reaction regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

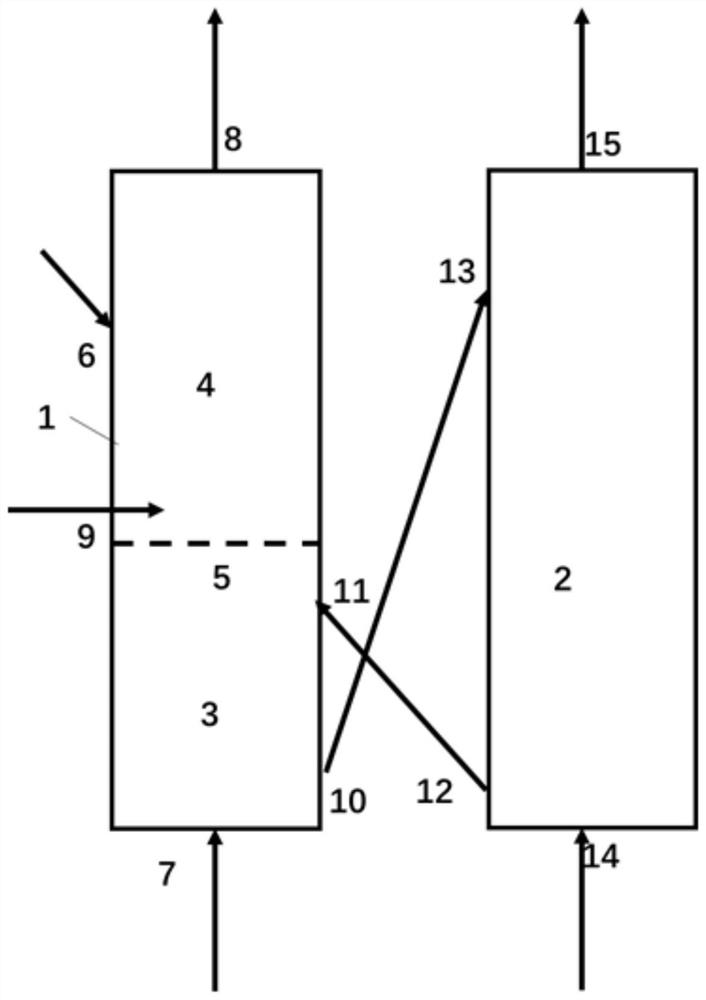

[0034] Will C 3 -C 9 The two-stage fluidized bed (1) for producing aromatics from alkanes is connected with the catalyst regeneration fluidized bed (2) with pipelines to form a complete system; the C 3 -C 9 The catalyst for producing aromatics from alkanes (2% gallium oxide-3% yttrium oxide-75% ZSM-5-20% β molecular sieve) is loaded into C 3 -C 9 In the two-stage fluidized bed (1) for producing aromatics from alkanes and the catalyst regeneration fluidized bed (2), first realize the smooth circulation flow of the catalyst in the system;

[0035] Hot air is passed into the catalyst regeneration fluidized bed (2) so that the temperature in the catalyst regeneration fluidized bed (2) reaches 600°C. In an atmosphere that ensures the safety of the system, the catalyst in the catalyst regeneration fluidized bed (2) is circulated to C 3 -C 9 In the two-stage fluidized bed (1) for preparing aromatics from alkanes, the temperature of the two-stage fluidized bed is gradually incre...

Embodiment 2

[0042] Will C 3 -C 9 The two-stage fluidized bed (1) for producing aromatics from alkanes is connected with the catalyst regeneration fluidized bed (2) with pipelines to form a complete system; the C 3 -C 9 The catalyst for producing aromatics from alkanes (3% zinc oxide-0.3% lanthanum oxide-1% chromium oxide-24% ZSM-5-20% Y molecular sieve-51.7% SBA-15) is loaded into C 3 -C 9 In the two-stage fluidized bed (1) for producing aromatics from alkanes and the catalyst regeneration fluidized bed (2), first realize the smooth circulation flow of the catalyst in the system;

[0043] Hot air was passed into the catalyst regeneration fluidized bed (2) so that the temperature in the catalyst regeneration fluidized bed (2) reached 720°C. In an atmosphere that ensures the safety of the system, the catalyst in the catalyst regeneration fluidized bed (2) is circulated to C 3 -C 9 In the two-stage fluidized bed (1) for preparing aromatics from alkanes, the temperature of the two-stage...

Embodiment 3

[0050] Will C 3 -C 9 The two-stage fluidized bed (1) for producing aromatics from alkanes is connected with the catalyst regeneration fluidized bed (2) with pipelines to form a complete system; the C 3 -C 9 Catalyst for producing aromatics from alkanes (1% gallium oxide-45% ZSM-22-20% MCM-41-34% MCM-22) loaded into C 3 -C 9 In the two-stage fluidized bed (1) for producing aromatics from alkanes and the catalyst regeneration fluidized bed (2), first realize the smooth circulation flow of the catalyst in the system;

[0051] Pass hot air into the catalyst regeneration fluidized bed (2) so that the temperature in the catalyst regeneration fluidized bed (2) reaches 650°C. In an atmosphere that ensures the safety of the system, the catalyst in the catalyst regeneration fluidized bed (2) is circulated to C 3 -C 9 In the two-stage fluidized bed (1) for preparing aromatics from alkanes, the temperature of the two-stage fluidized bed is gradually increased.

[0052] When C 3 -C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com