Catalytic device for preparing U(IV) solution

A catalytic device and solution technology, which is applied in the field of catalytic reaction equipment for preparing U solution, can solve problems such as hidden safety hazards and complex structures, and achieve the effects of improved safety, less wear and tear, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

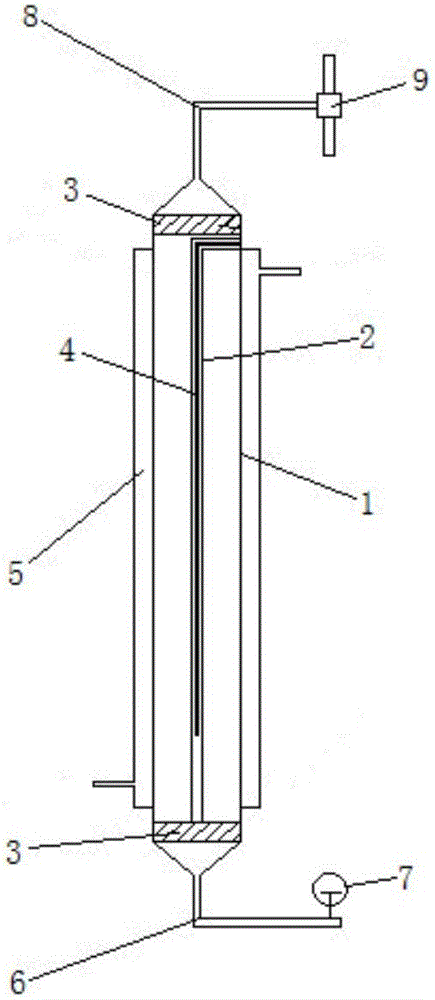

[0024] The annular zone between the inner tube 2 and the outer tube 1 is the reaction zone, which is filled with Pt / SiO 2 Catalyst, the loading of Pt was 1%; the filling height of the catalyst was 600 mm. Pt / SiO 2 The catalyst was prepared by impregnation method.

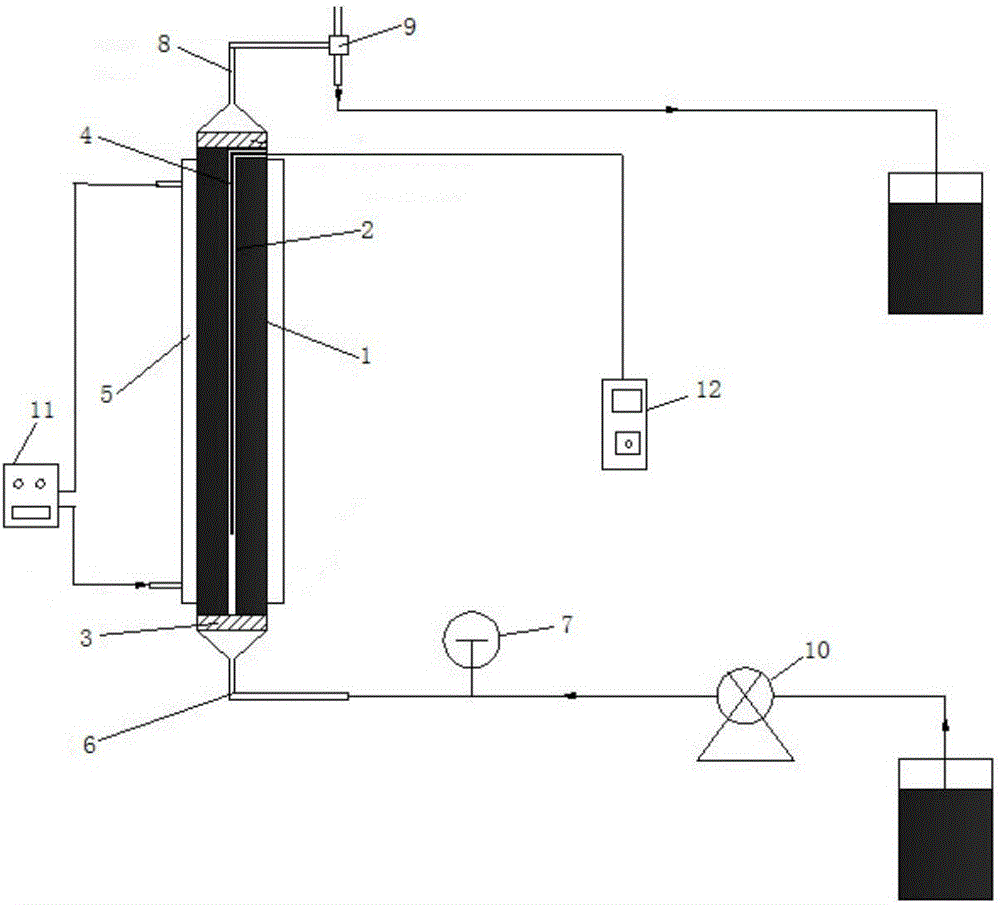

[0025] The process of preparing U(IV) by adopting the present invention is as follows: firstly inject the prepared raw material liquid from the bottom feed port 6 of the catalytic reaction device through the feeding pump 10, and the composition of the raw material liquid is: 203g / L UO 2 (NO 3 ) 2 -0.80mol / LHNO 3 -1.0mol / LN 2 H 5 NO 3 ; After the material and liquid are uniformly distributed through the holes of the sintered stainless steel plate 3, it enters the annular reaction zone, reacts with the catalyst, and controls the reaction temperature through a circulating water bath to obtain U(IV) solution and gas product, and the product is discharged from the outlet of the reaction column. 6 flows out and pa...

Embodiment 2

[0028] The implementation of this example is the same as that of Example 1, except that in this example, the diameter of the inner tube 3 of the reaction column is 6 mm, the diameter of the outer tube 2 is 30 mm, the filling height of the catalyst is 300 mm, and the Pt / SiO filled in between is 30 mm. 2 The loading of Pt in the catalyst is 3%, and the composition of the raw material liquid is 201g / L UO 2 (NO 3 ) 2 -0.83mol / LHNO 3 -1.3mol / L N 2 H 5 NO 3 , the temperature of the water bath is 50°C, the concentration of U(IV) at the outlet is 198 g / L, and the yield of U(IV) can reach 98.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com