Full-automatic production process of fireproof glass

A technology of fire-resistant glass and production process, which is applied to the device and coating of the surface coating liquid, which can solve the problems of low production efficiency and poor quality of fire-resistant glass, and achieve the improvement of product life, appearance quality and batch stability , less material residue, avoid loss and outflow of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

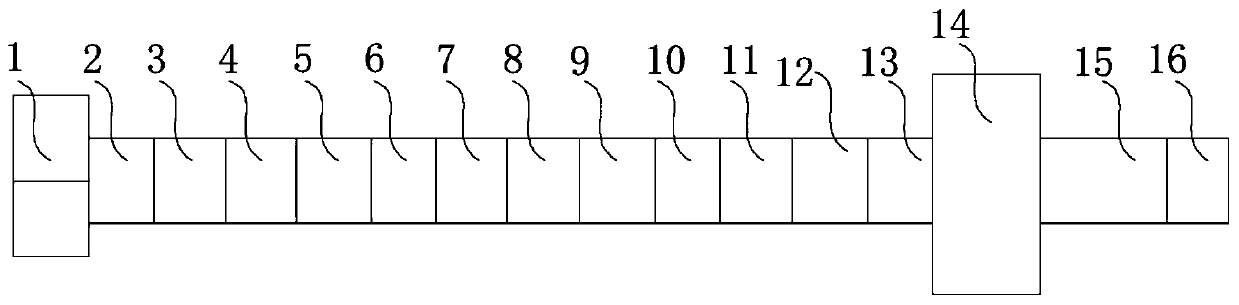

Image

Examples

Embodiment 1

[0042] Embodiment 1 of the present invention comprises:

[0043] A fully automatic production process for fireproof glass, mainly comprising the following steps:

[0044] S1. The first piece of glass is sucked and flipped by the automatic loading table A and then sent to the cleaning machine. After cleaning, it is dried first, and then quickly enters the transition section A for temporary storage. Among them, tap water is used for cleaning liquid, and heating is used when the temperature is too low. The device heats the tap water to prevent freezing;

[0045] S2. After the first piece of glass is positioned by the automatic positioning machine A, it enters the horizontal gluing machine, and the infrared detection device of the horizontal gluing machine detects the size of the first piece of glass;

[0046] S3. After the detection of the first piece of glass is completed, it quickly enters the automatic positioning machine B through the transition section B, and the automatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com