Method for catalyzing oriented conversion of cellulose into composite carbon source by using nickel-doped copper-aluminum hydrotalcite catalyst

A composite carbon source, hydrotalcite technology, applied in heterogeneous catalyst chemical elements, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low catalyst stability, failure to achieve industrialization, and low methanol quality. , to achieve the effect of improving product value, superior anti-coking performance, improving yield and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

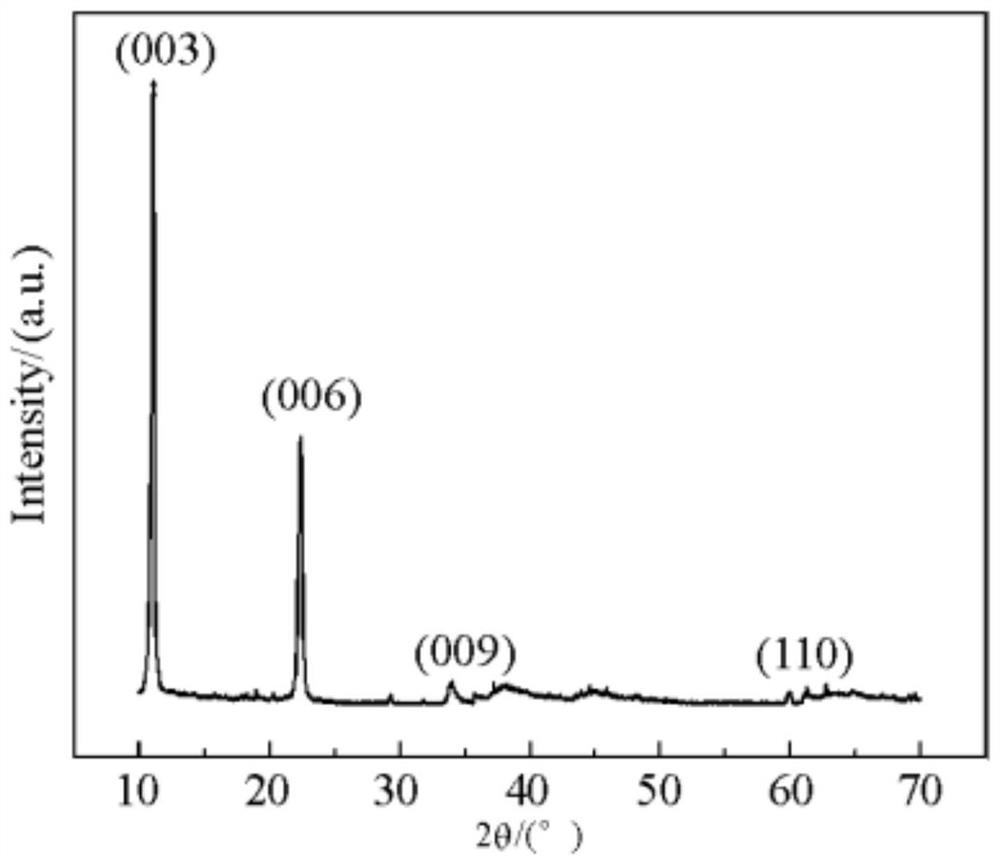

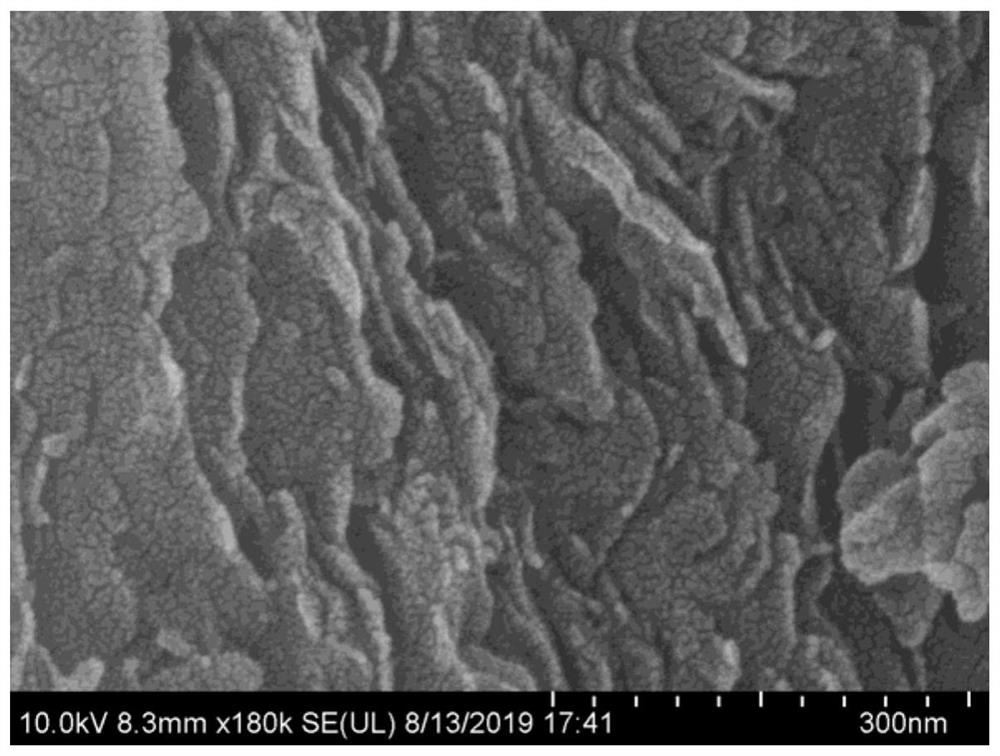

[0028] In this embodiment, the specific steps of the method for catalyzing the directional conversion of cellulose into a composite carbon source by the nickel-doped copper-aluminum hydrotalcite catalyst are as follows:

[0029] (1) Dissolve nickel nitrate, copper nitrate and aluminum nitrate in water under stirring conditions to prepare metal mixed salt solution A. The molar ratio of copper nitrate and aluminum nitrate in the solution is 1:1, and the total amount of copper nitrate and aluminum nitrate The ratio of the molar weight to the molar weight of nickel nitrate is 5:1;

[0030] (2) adding dropwise a sodium hydroxide solution with a concentration of 0.01mol / L in the solution A, adjusting the pH=9, stirring to prepare a suspension A;

[0031] (3) Pour the suspension A into a reaction kettle with a polytetrafluoroethylene liner, and crystallize at 90°C for 18 hours. After the crystallization is completed, transfer the reaction solution to centrifuge, wash and dry to obtai...

Embodiment 2

[0036] In this embodiment, the specific steps of the method for catalyzing the directional conversion of cellulose into a composite carbon source by the nickel-doped copper-aluminum hydrotalcite catalyst are as follows:

[0037] (1) Dissolve nickel nitrate, copper nitrate and aluminum nitrate in water under stirring conditions to prepare metal mixed salt solution A. The molar ratio of copper nitrate and aluminum nitrate in the solution is 2:1, and the total amount of copper nitrate and aluminum nitrate The ratio of molar weight to the molar weight of nickel nitrate is 6:1;

[0038] (2) adding dropwise a sodium hydroxide solution with a concentration of 0.02mol / L in the solution A, adjusting the pH=10, stirring to prepare a suspension A;

[0039] (3) Pour the suspension A into a reaction kettle lined with polytetrafluoroethylene, and crystallize at 100°C for 20 hours. After the crystallization is completed, transfer the reaction solution to centrifuge, wash and dry to obtain ni...

Embodiment 3

[0044] In this embodiment, the specific steps of the method for catalyzing the directional conversion of cellulose into a composite carbon source by the nickel-doped copper-aluminum hydrotalcite catalyst are as follows:

[0045] (1) Dissolve nickel nitrate, copper nitrate and aluminum nitrate in water under stirring conditions to prepare metal mixed salt solution A. The molar ratio of copper nitrate and aluminum nitrate in the solution is 3:1, and the total amount of copper nitrate and aluminum nitrate The ratio of the molar weight to the molar weight of nickel nitrate is 7:1;

[0046] (2) adding dropwise a sodium hydroxide solution with a concentration of 0.03mol / L in the solution A, adjusting the pH=11, stirring to prepare a suspension A;

[0047] (3) Pour the suspension A into a reaction kettle lined with polytetrafluoroethylene, and crystallize at 110°C for 22 hours. After the crystallization is completed, transfer the reaction solution to centrifuge, wash and dry to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com