A high-efficiency and environmentally friendly waste pyrolysis process

A waste and pyrolysis technology, applied in lighting and heating equipment, combustion types, combustion methods, etc., can solve the problems of waste affecting combustion efficiency and insufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

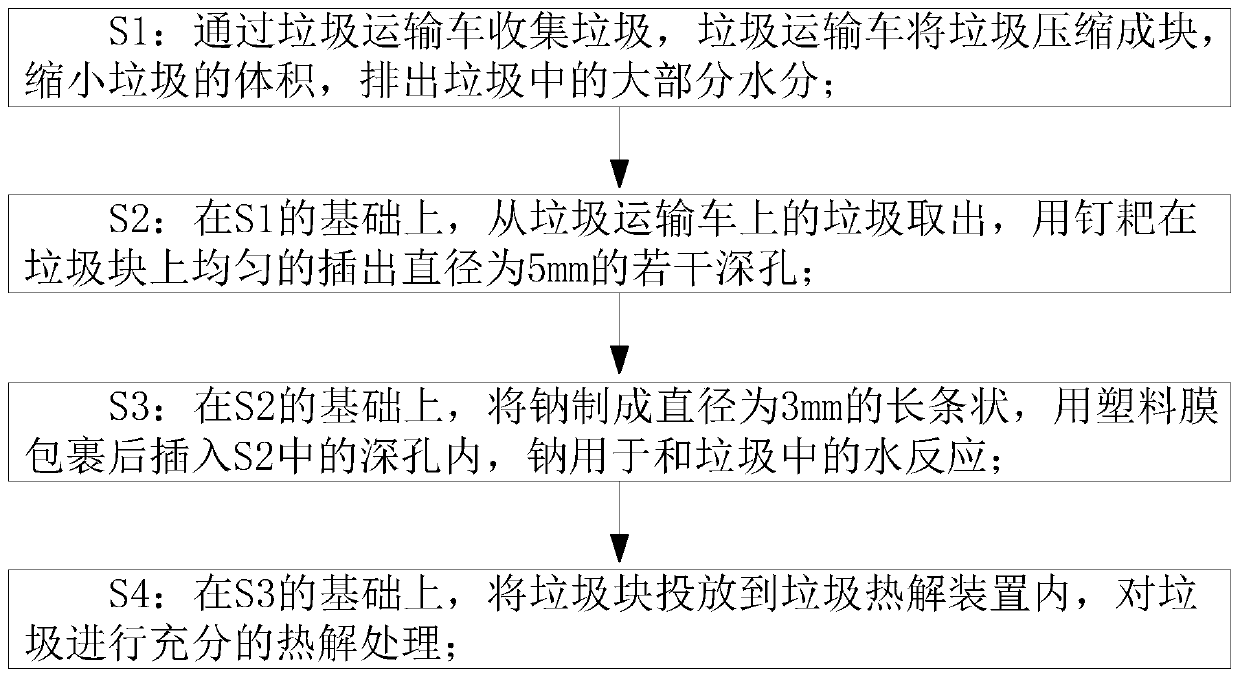

Method used

Image

Examples

Embodiment approach

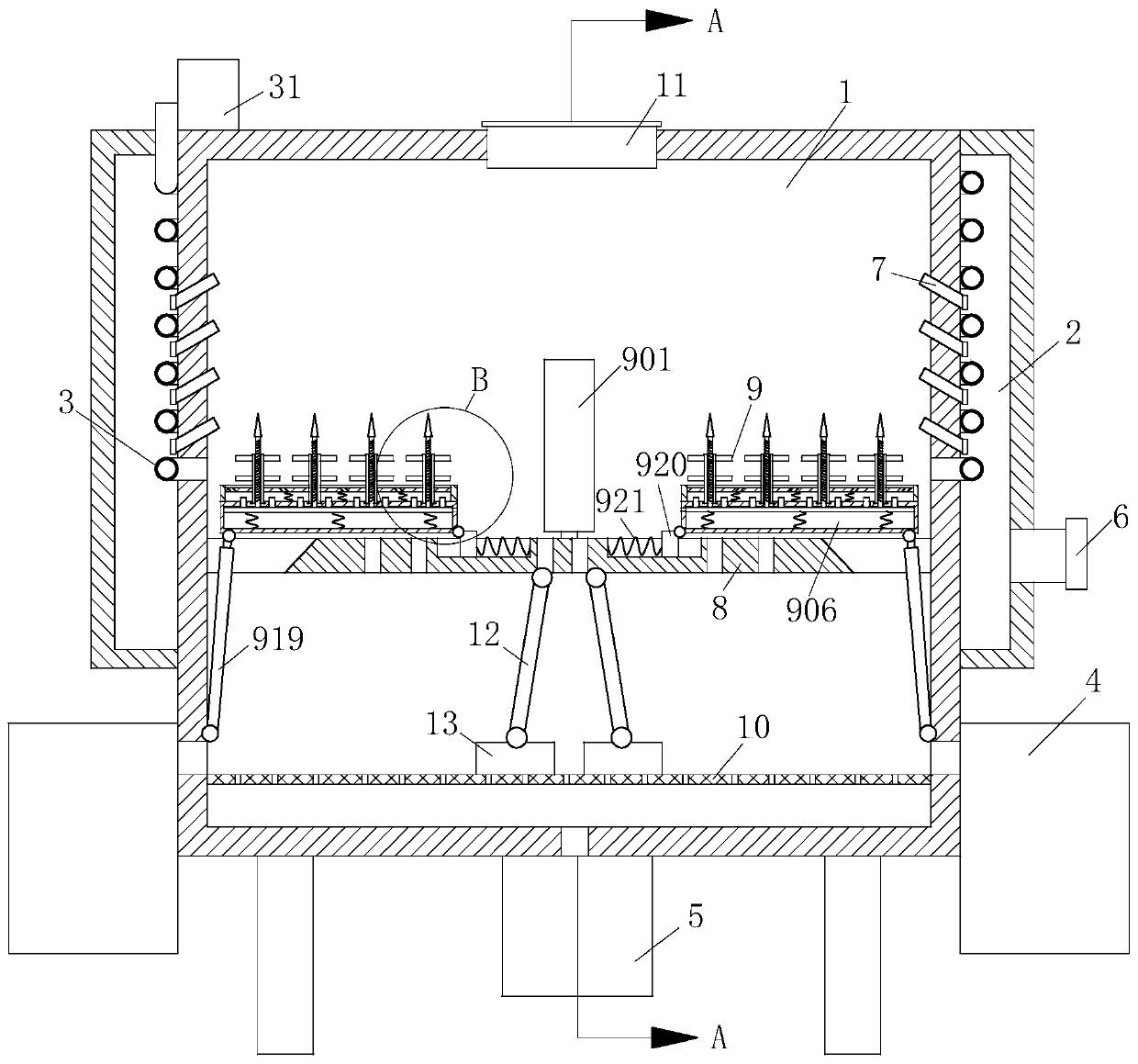

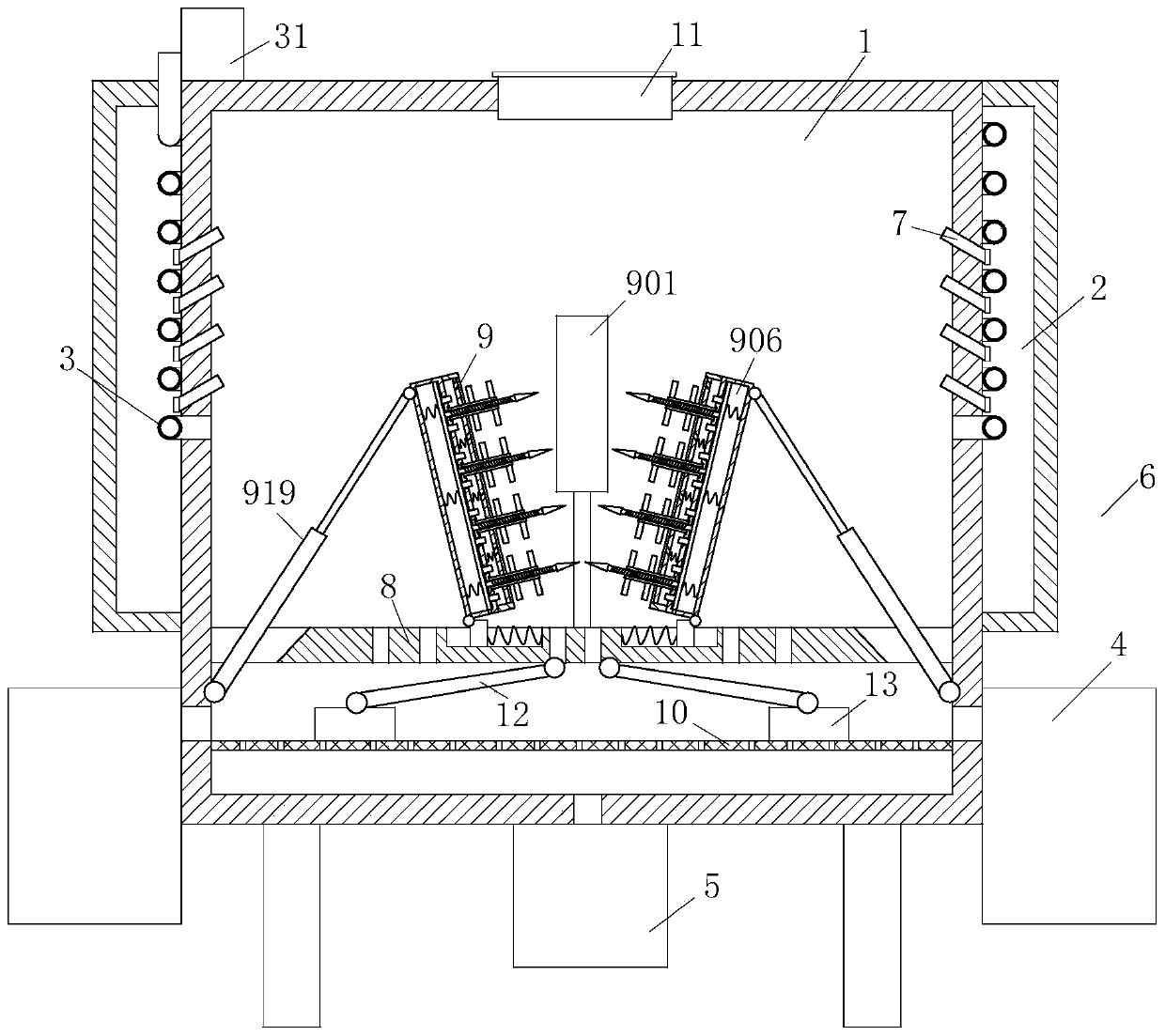

[0040] As an embodiment of the present invention, one end of the connecting rod 12 is symmetrically hinged on the lower side of the partition 8; the other end of the connecting rod 12 is hinged with a brush 13; the brush 13 is arranged on the filter screen 10 Above, the brush 13 is used to wash the filter screen 10. When dividing plate 8 moves down, can drive hairbrush 13 to brush on filter screen 10 by connecting rod 12, on the one hand brush 13 can push the slag on filter screen 10 in the slag collecting box 4, on the other hand brush The brush 13 can wash the filter screen 10 to prevent slag from blocking the filter screen 10 meshes and improve the collection efficiency of garbage water.

[0041] As an embodiment of the present invention, the air inlet of the smoke exhaust pipe 3 is set in the middle of the incineration chamber 1, and when the high-temperature flue gas reaches saturation upwards, it will diffuse to the middle of the incineration chamber 1 to pyrolyze the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com