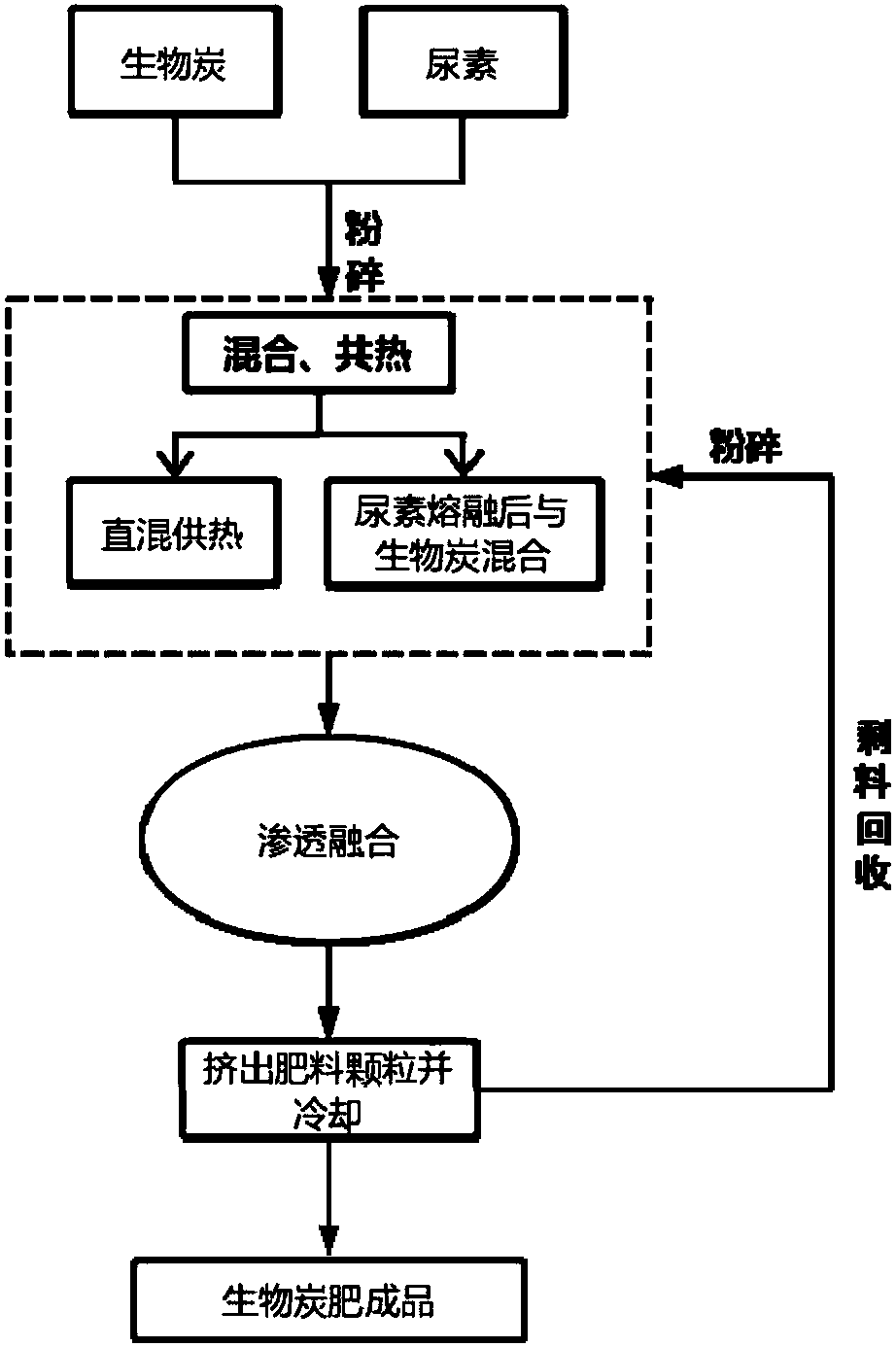

Permeation fusion method for preparing charcoal-based urea fertilizer

A biochar and urea-based technology, applied in the field of biomass resource utilization, can solve the problems of difficulty in combining chemical fertilizers and low strength of biomass charcoal fertilizers, and achieve the effects of easy adjustment and control, good carbonization effect, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Weigh 0.3g of biochar powder with a particle size of 0.075-0.1mm, and 0.2g of urea powder (ratio: 1.5:1) into the fertilizer tube with a diameter of 8mm and a closed bottom, and tap the tube to make the biochar The powder is in uniform contact with urea, and then the fertilizer tube is transferred to a vacuum oven, and the temperature is adjusted to 135°C. After preheating for 5 minutes, the temperature is raised to 140°C, 145°C, 150°C and 155°C respectively, and the reaction is 30, 25, and 20°C respectively. , Take it out after 15 minutes, cool it under the action of air at 25°C for 5 seconds and take it out to obtain biochar-based urea fertilizers with different melting reaction temperatures.

[0041] The above-mentioned biochar-based urea fertilizer was tested for compressive strength, and the compressive strengths were 72.91N, 207.5N, 98.45N and 86.67N, respectively.

Embodiment 2

[0043] Weigh 0.3g of biochar powder and 0.2g of urea powder (ratio: 1.5:1) with particle sizes of 0.125-0.18mm, 0.10-0.125mm and 0.075-0.1mm, respectively, and add them to the fertilization tube with a diameter of 8mm. In the fertilization tube with a closed bottom, tap the fertilization tube to make the biochar powder and urea evenly contact, then transfer the fertilization tube to a vacuum oven, adjust the temperature to 135°C, and raise the temperature to 155°C after preheating for 5 minutes. Take it out after 15 minutes, cool it under the action of air at 25°C for 5 seconds and take it out to obtain biochar-based urea fertilizers with different particle sizes of biochar powder.

[0044] The above-mentioned biochar-based urea fertilizer was tested for compressive strength, and the compressive strengths were 73.23N, 93.52N and 86.67N, respectively.

Embodiment 3

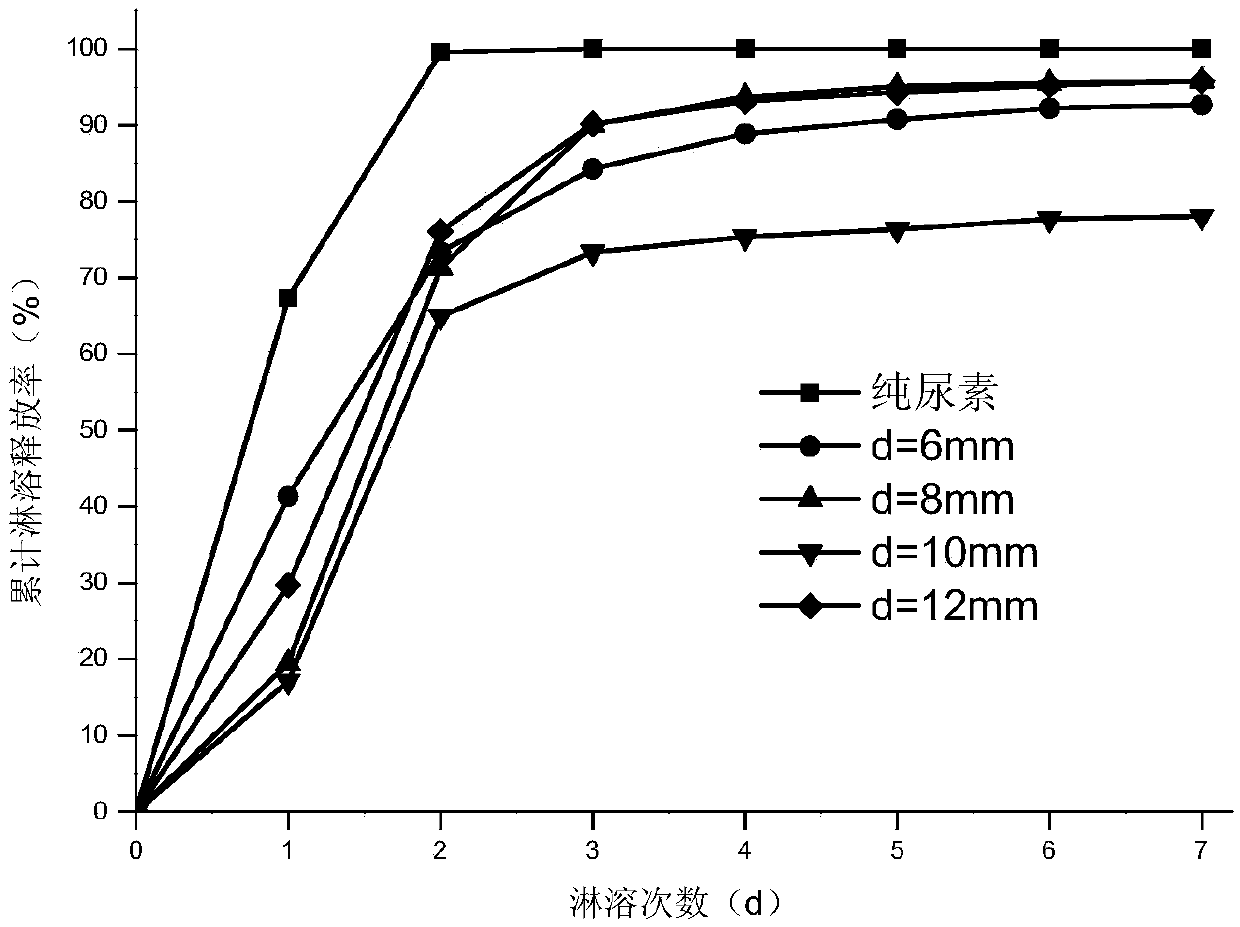

[0046] Weigh 0.3g of biochar powder with a particle size of 0.075-0.1mm, and 0.2g of urea powder (ratio: 1.5:1) into the fertilization tubes with diameters of 6mm, 8mm, 10mm, and 12mm, respectively, and the bottom is closed. Tap the fertilizer tube to make the biochar powder and urea contact evenly, then transfer the fertilizer tube to a vacuum oven, adjust the temperature to 135°C, preheat for 5 minutes and raise the temperature to 155°C respectively, take it out after 15 minutes of reaction, and put it at 25°C Cool for 5 seconds under the action of air and take it out to obtain biochar-based urea fertilizers with different particle diameters.

[0047] The above-mentioned biochar-based urea fertilizer was tested for compressive strength, and the compressive strengths were 55.61N, 86.67N, 97.47N and 89.75N, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com