Process and apparatus for preparing magnesium oxide and hydrogen chloride mixed gas by two-stage dynamic calcining of magnesium chloride

A technology of dynamic calcination and magnesium chloride production, applied in chlorine/hydrogen chloride, preparation with chloride, magnesium oxide, etc., can solve the problems of low concentration of hydrochloric acid product, high energy consumption, high cost of equipment anticorrosion, and achieve the effect of advanced technology, mature and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

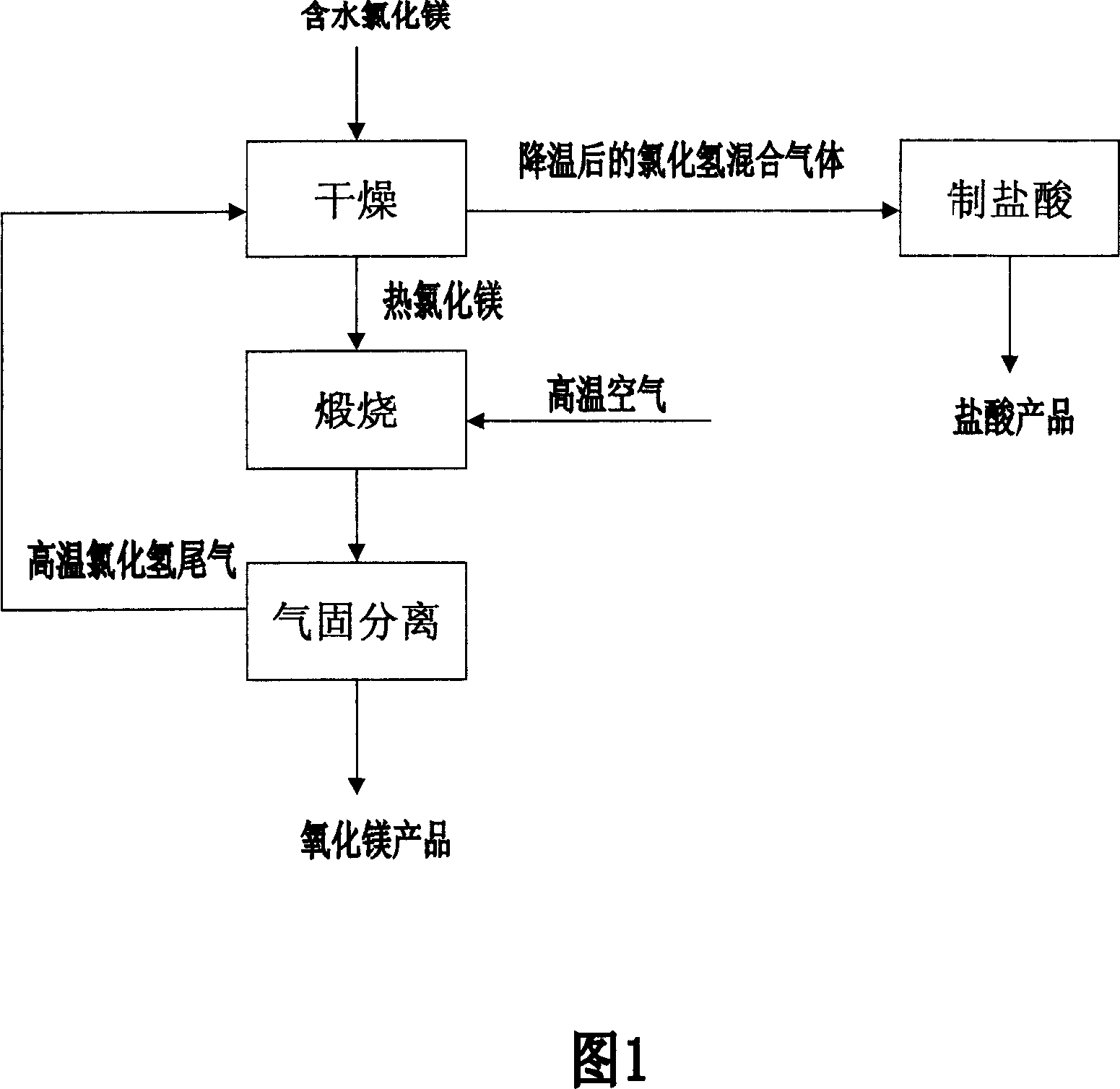

[0013] Embodiment 1: The process is to use high-temperature hydrogen chloride tail gas as the raw material of hydrated magnesium chloride to carry out one-stage dynamic calcination, also known as drying, and the heated hot magnesium chloride after drying is calcined in hot air at about 600 ° C to thermally decompose magnesium chloride into magnesium oxide hydrogen chloride Tail gas, after gas-solid separation, magnesium oxide products and high-temperature hydrogen chloride tail gas are obtained. The high-temperature hydrogen chloride tail gas is introduced into dry hydrous magnesium chloride raw materials through pipelines, and the cooled hydrogen chloride mixed gas enters the hydrochloric acid production process.

Embodiment 2

[0014] Embodiment 2: The process is basically the same as that of Embodiment 1, except that the heated hot magnesium chloride after drying is calcined in hot air at about 900°C. The subsequent process is the same.

Embodiment 3

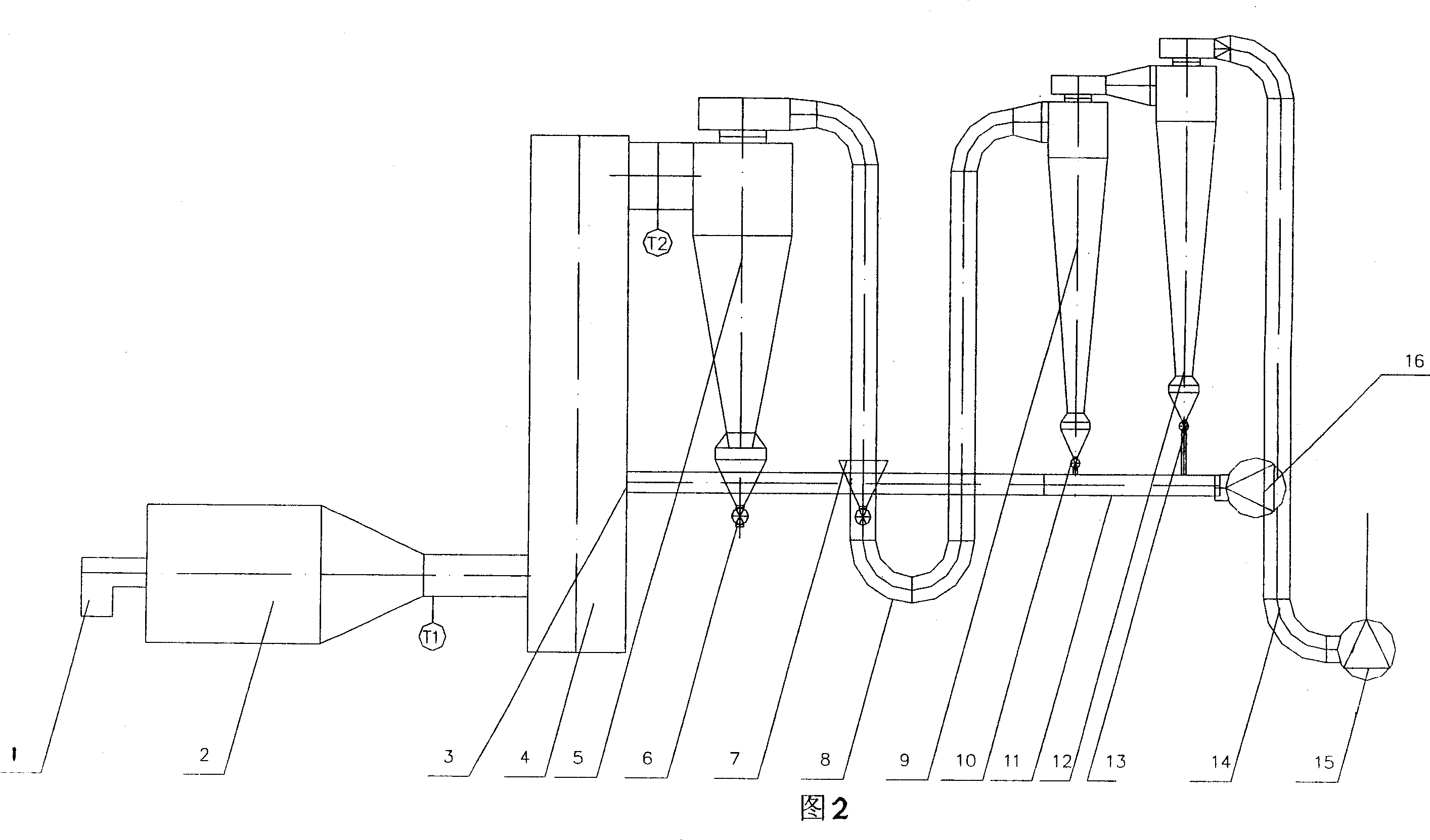

[0015] Embodiment three: the embodiment of equipment is as shown in Fig. 2, and T1 in Fig. 2 is the inlet air temperature of calcining tower 4, and the inlet air temperature of this embodiment is set as about 700 ℃, and T2 is the outlet air temperature of calcining tower 4 , the air outlet temperature of this embodiment is about 500 ° C, and the rest of the components have been described in the description of the drawings, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com