Catalytic pyrolysis of biomass in an auger reactor

a technology of biomass and auger reactor, which is applied in the petroleum industry, coke ovens, liquid hydrocarbon mixture production, etc., can solve the problems of thermal instability and acidity of bio-oil, and achieve the effects of reducing overall costs, increasing throughput, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

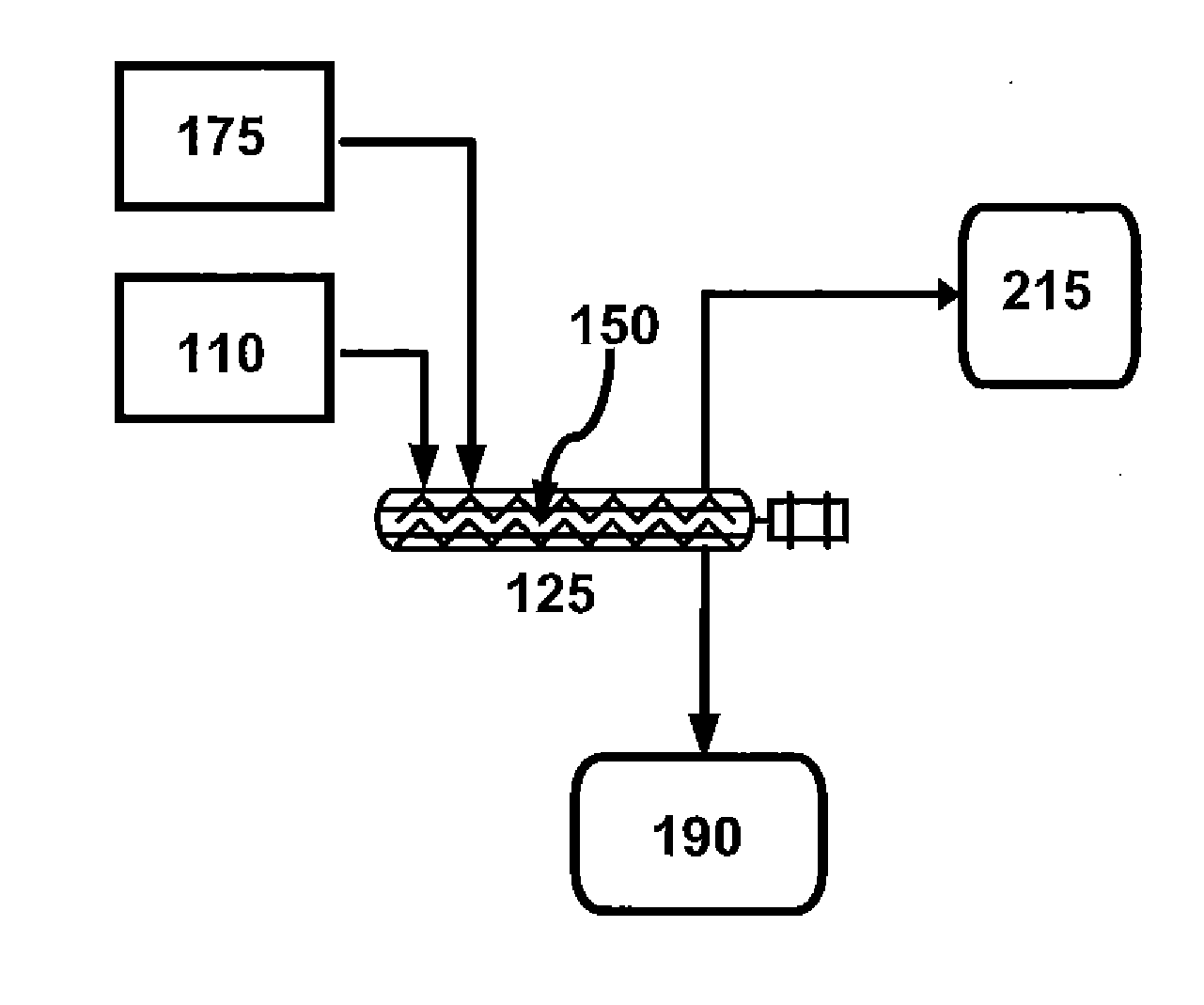

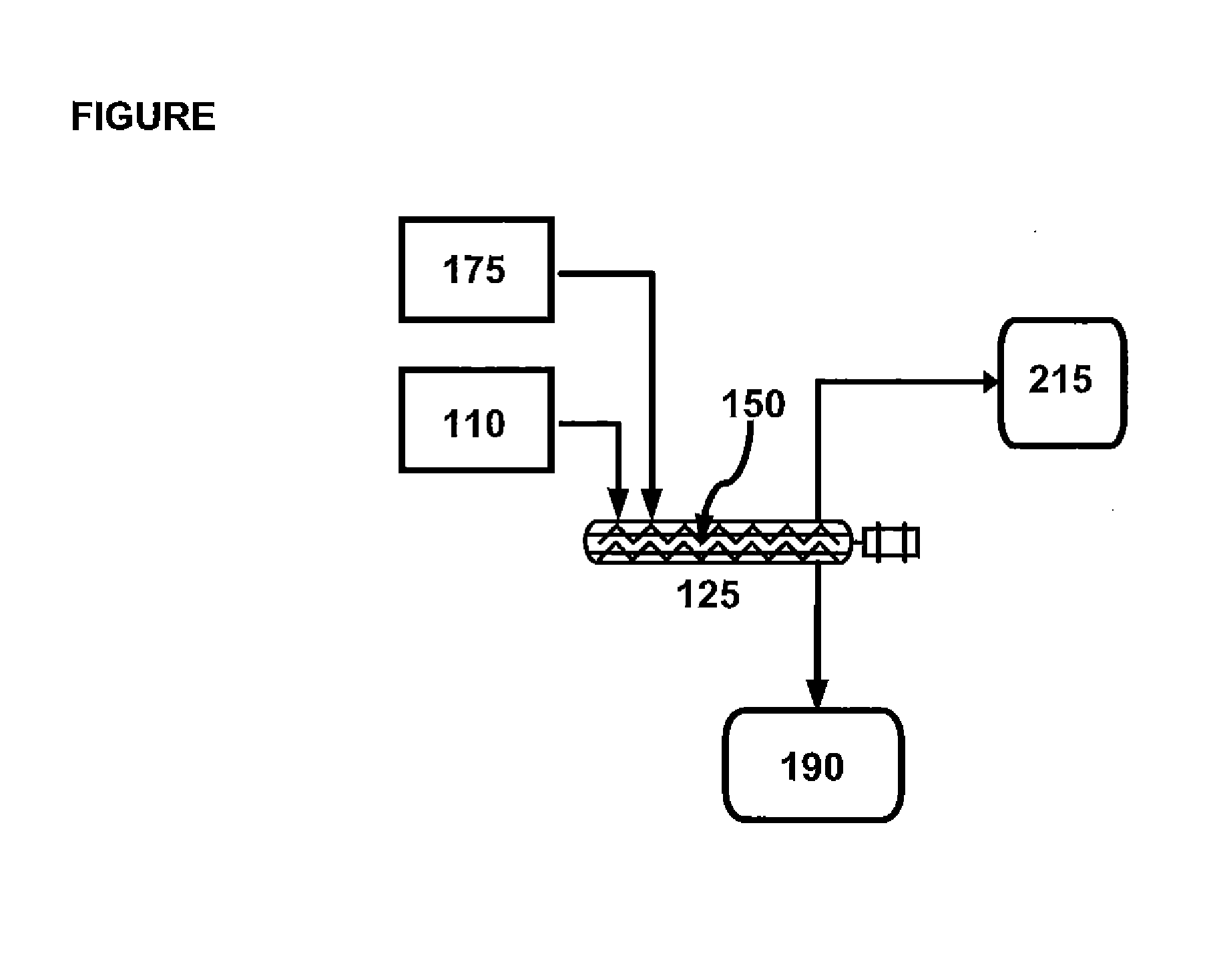

Image

Examples

example 1

[0036]Either micro-algal or lignin biomass was dried at 70° C. for 12 hours, then pyrolyzed with and without zeolite catalyst in inert (He) atmosphere. Pyrolysis was conducted at 475° C. pyrolysis temperature, heating rate ˜10,000° C. / s and a 5:1 catalyst ratio (when used). Vapors were analyzed by gas chromatography / mass spectrometry (GC / MS). Char was measured by gravimetric difference. All yields are on a mass basis.

[0037]The data (see Tables 1 and 2) show a greater than 60% yield of condensable vapors from both micro-algal (Table 1) and lignin (Table 2) biomass in un-catalyzed pyrolysis and 50% or greater yield during catalyzed pyrolysis. Adding a zeolite catalyst improved yield of hydrocarbons in the vapor phase, while also increasing char yield.

TABLE IYield of pyrolysis products from dried, whole microalgae.Yield %,Yield %,Productno catalystzeolite catalystNoncondensable gas*617Char*1928Condensable vapors*7455Hydrocarbons in vapor**944*Yield based on total biomass**Yield based o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com