A method of pyrolyzing high-protein algae and waste plastics to produce carbon by gas-solid two-phase mixed chlorine removal

A waste plastic, high protein technology, used in chemical instruments and methods, solid waste removal, biofuels and other directions, can solve problems such as pollution, complex garbage composition, hazards, etc., achieve high quality, alleviate energy crisis, and high calorific value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

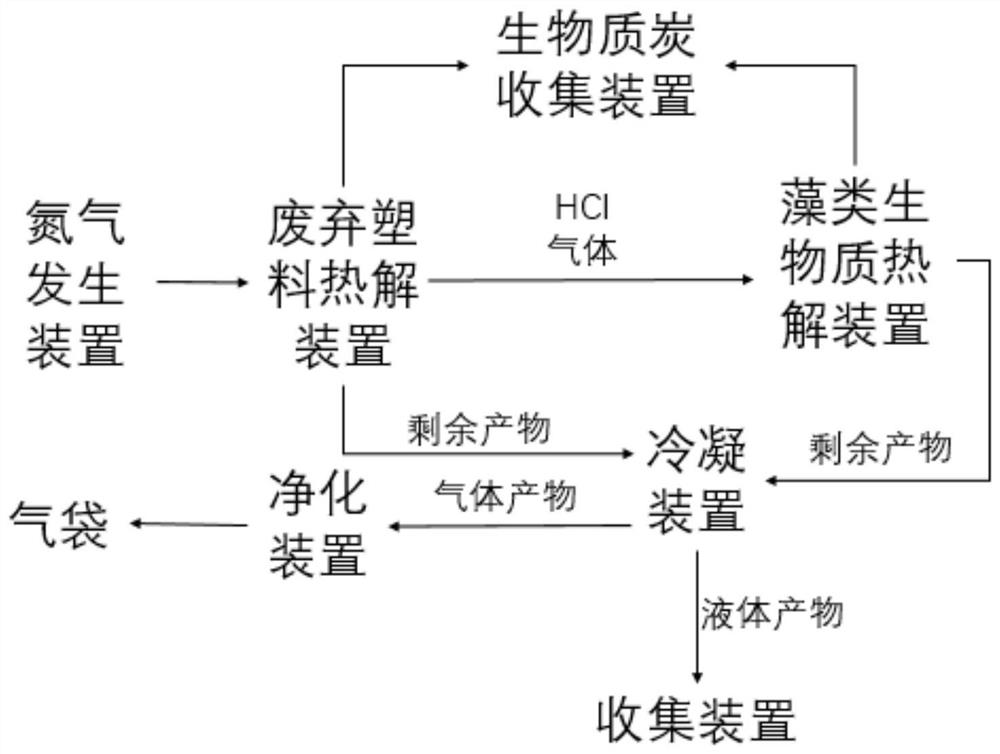

[0031] Such as figure 1 Shown, is a kind of high-protein algae biomass of the present invention and the method for pyrolysis dechlorination of waste plastics charcoal, comprises the following steps:

[0032] ⑴Crush and grind waste plastics (the main component is PVC (polyvinyl chloride)) and high-protein algae biomass (chlorella) to particles with a particle size of 0.5mm, and weigh 0.4kg according to the mass ratio of 2:3 Waste plastics and 0.6kg of high-protein algae biomass, after drying, were put into their respective pyrolysis devices, and both pyrolysis devices were in the form of fixed beds.

[0033] (2) Introduce carrier gas—nitrogen gas into the pyrolysis device where the waste plastic is located (waste plastic pyrolysis device), the flow rate of the carrier gas is set by the flow controller, and the set reaction flow rate is 100ml / min;

[0034] (3) Set the temperature of the two pyrolysis devices respectively through two temperature controllers. The temperature set ...

Embodiment 2

[0039] In this embodiment, a method for producing charcoal by pyrolysis of high-protein algae biomass and waste plastics comprises the following steps:

[0040]⑴Crush and grind waste plastics (the main component is PVC (polyvinyl chloride)) and high-protein algae biomass (enteromorpha and shield fruit algae) to particles with a particle size of 1mm, and weigh them according to the mass ratio of 3:2 After drying, 0.6kg of waste plastics and 0.4kg of high-protein algae biomass were put into their respective pyrolysis devices, both of which were in the form of fixed beds.

[0041] (2) Introduce carrier gas—nitrogen gas into the pyrolysis device where the waste plastic is located (waste plastic pyrolysis device), the flow rate of the carrier gas is set by the flow controller, and the set reaction flow rate is 150ml / min;

[0042] (3) Set the temperature of the two pyrolysis devices respectively through two temperature controllers. The temperature set for the waste plastic pyrolysis...

Embodiment 3

[0047] In this embodiment, a method for producing charcoal by pyrolysis of high-protein algae biomass and waste plastics comprises the following steps:

[0048] ⑴Crush and grind waste plastics (the main component is PVC (polyvinyl chloride)) and high-protein algae biomass (asparagus and red leek) to particles with a particle size of 1.2mm, according to the mass ratio of 3:1 Weigh 0.75kg of waste plastics and 0.25kg of high-protein algae biomass, and after drying, put them into their respective pyrolysis devices. Both pyrolysis devices are in the form of fixed beds.

[0049] (2) Introduce carrier gas—nitrogen gas into the pyrolysis device where the waste plastic is located (waste plastic pyrolysis device), the flow rate of the carrier gas is set by the flow controller, and the set reaction flow rate is 60ml / min;

[0050] (3) Set the temperature of the two pyrolysis devices respectively through two temperature controllers. The temperature set for the waste plastic pyrolysis devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com