High-efficiency biomass treatment tar poly-generation pyrolysis furnace

A biomass treatment and polygeneration technology, applied in coking ovens, biofuels, petroleum industries, etc., can solve problems such as low thermal efficiency, inability to continue production, energy consumption, etc., to improve thermal efficiency, solve equipment expansion problems, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

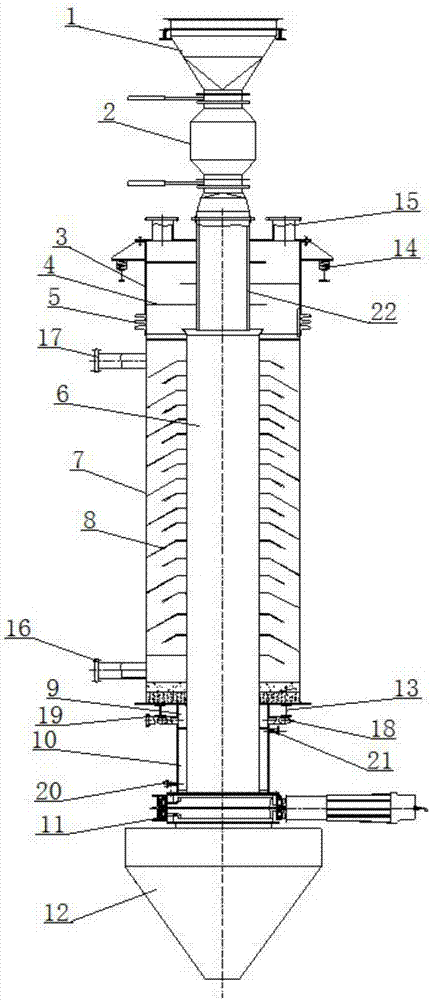

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] see figure 1 , a high-efficiency biomass treatment tar polygeneration pyrolysis furnace, including a feed bin 1, a lock hopper 2, a settling chamber 3, a reaction chamber, a cooling chamber, and a charcoal outlet bin 12. The upper end of the lock hopper 2 is provided with a feed pneumatic valve, the lower end of the lock hopper 2 is provided with a discharge pneumatic valve, and the settling chamber 3 is provided with a feed chute 22; The outlet of the bin 1 is connected, and the bottom end of the lock bucket 2 is connected with the inlet of the feed chute 22 of the settling chamber 3 . The lower end of the settling chamber 3 is connected with the reaction chamber, the lower end of the reaction chamber is connected with the cooling chamber, and the bottom end of the cooling chamber is connected with the charcoal outlet bin 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com