Method of producing fuel oil by coal tar hydrogenation modifying

A hydrogenation reforming and coal tar technology, which is applied in the fields of hydrogenation treatment process, petroleum industry, gasoline stabilization, etc., can solve the problems of unguaranteed long-term operation, unresolved strong exothermic effect, high asphaltenes and benzene insolubles, and achieves The effect of improving product quality, reducing olefin and aromatic content, and reducing total temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021]The raw material oil is a mixture of catalytic diesel oil and medium and low temperature full distillate coal tar I in a weight ratio of 1:10. The properties are shown in Table 1. The first hydrogenation reactor is filled with HG-1 hydrogenation protection agent and pre-hydrogenation catalyst from top to bottom, and the second hydrogenation reactor is filled with the main hydrogenation catalyst. The filling volume ratio of the three catalysts is 2: 3:10, the hydrogenation reaction conditions and test results are shown in Table 2 and Table 3. The products were cut into light oil fraction (≤205°C), diesel fraction (205°C to 325°C), and heavy oil fraction (>325°C). The composition of gasoline, diesel, and heavy oil after cutting is shown in Table 4.

[0022] Table 1. Properties of hydrogenation raw materials

[0023] project All distillate coal tar I Catalytic diesel Raw oil Exterior color Black, sticky, foul smelling maroon Dark black, foul smell ...

Embodiment 2

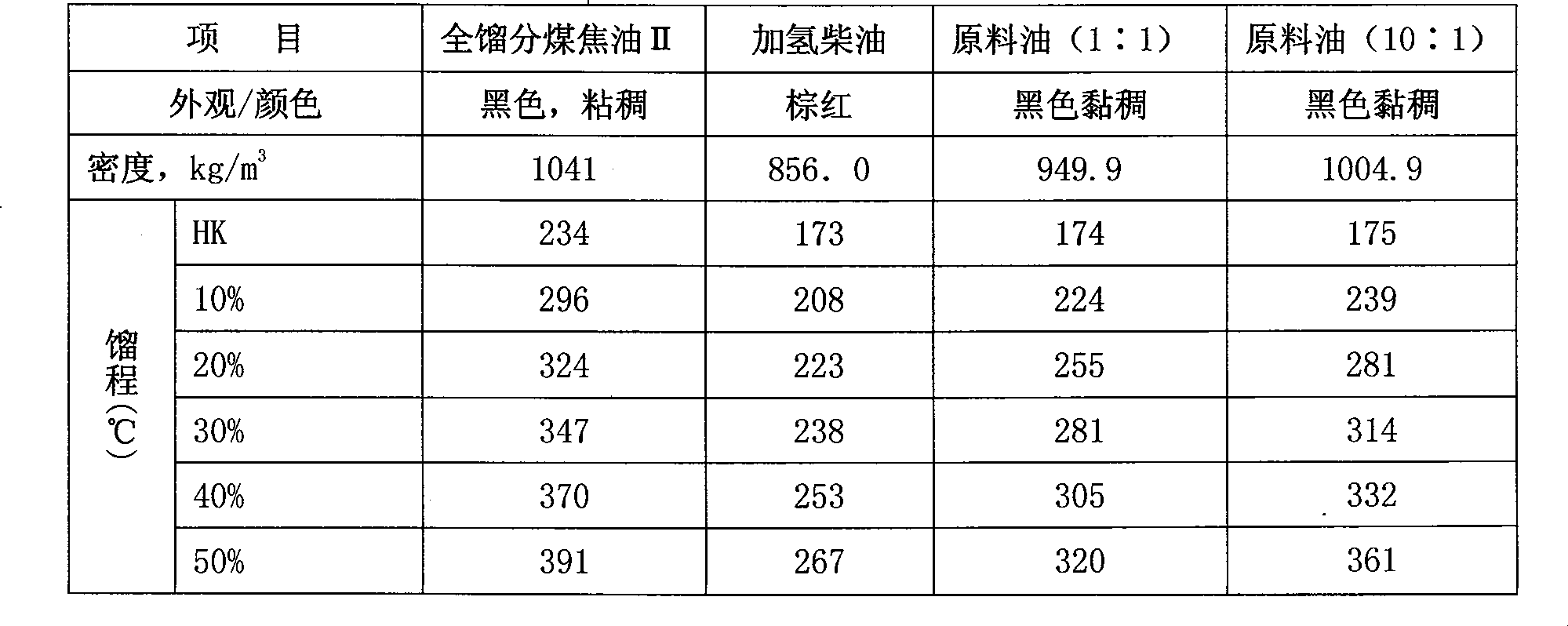

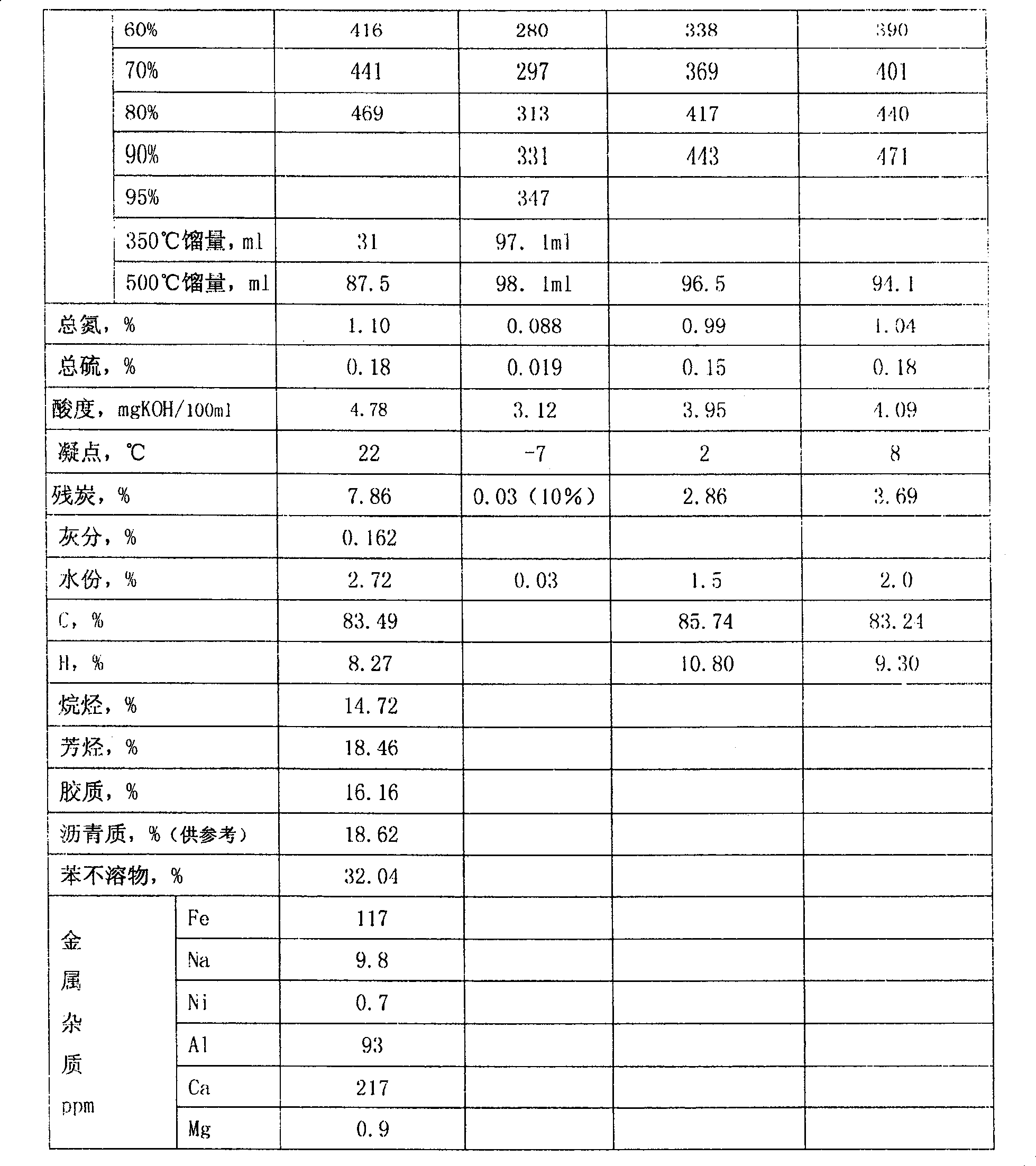

[0033] The raw material oil is a mixture of hydrogenated diesel oil and medium and low temperature full-cut coal tar II in a weight ratio of 1:1 and 10:1 respectively. The properties are shown in Table 5. The first hydrogenation reactor is filled with HG-1 hydrogenation protection agent and pre-hydrogenation catalyst from top to bottom, and the second hydrogenation reactor is filled with the main hydrogenation catalyst. The filling volume ratio of the three catalysts is 3: 3:10, the hydrogenation reaction conditions and test results are shown in Table 6 and Table 7. The products were cut into gasoline fraction (≤205°C), diesel fraction (205°C~325°C), and heavy oil fraction (>325°C). The composition and properties of gasoline, diesel, and heavy oil after cutting are shown in Table 8, Table 9, and Table 10. And table 11.

[0034] Table 5. Properties of hydrogenation raw materials

[0035]

[0036]

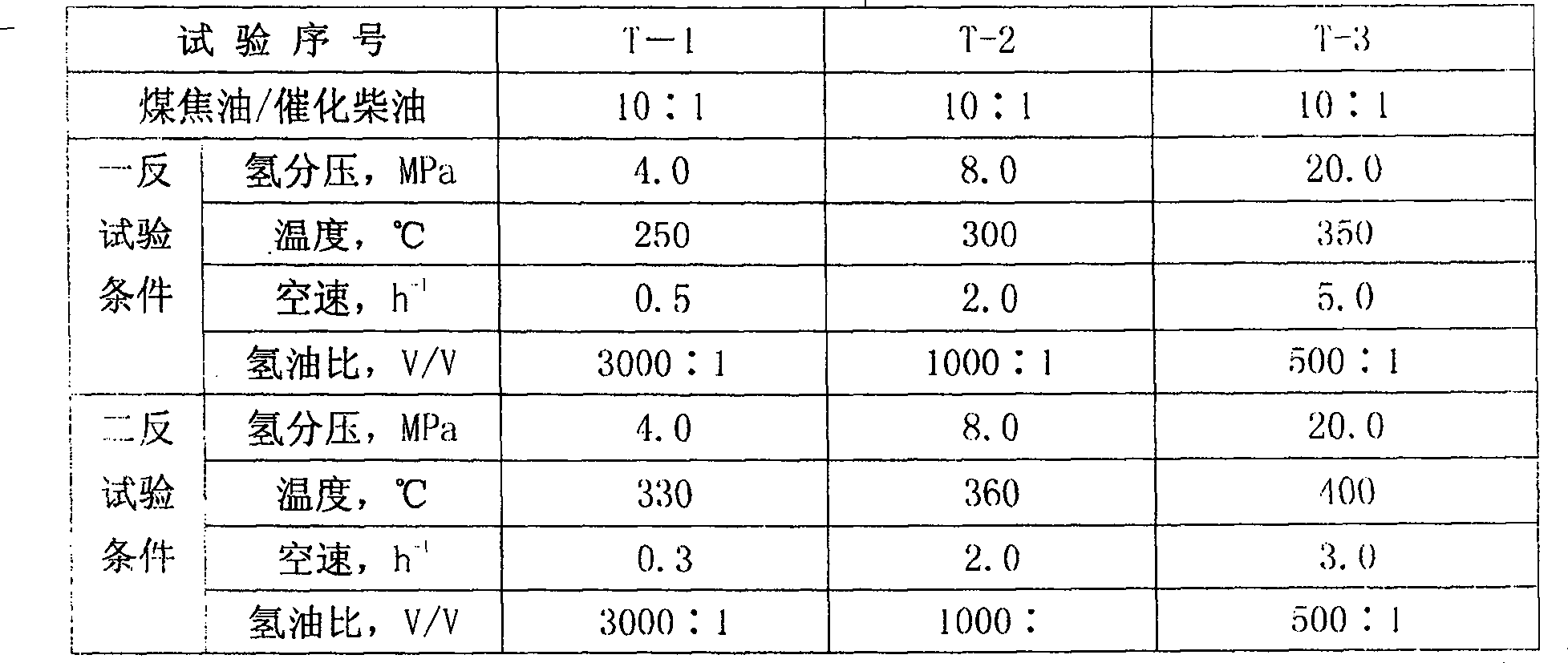

[0037] Table 6. Coal tar II hydrogenation reaction conditions

[0038]

[0039...

Embodiment 3

[0054] The feedstock oil is a mixture of hydrogenated diesel oil and high-temperature full-distillate coal tar III in a weight ratio of 1:1. The first hydrogenation reactor is filled with HG-1 hydrogenation protection agent and pre-hydrogenation catalyst from top to bottom, and the second hydrogenation reactor is filled with the main hydrogenation catalyst. The filling volume ratio of the three catalysts is 3: 3:10, the hydrogenation reaction conditions and test results are shown in Table 12 and Table 13.

[0055] Table 12, Coal tar III hydrogenation reaction conditions

[0056]

[0057] Table 13 Hydrogenation raw materials and product properties

[0058]

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com