Vertical type regenerative oil furnace

A regenerated oil, vertical technology, used in incinerators, combustion methods, lighting and heating equipment, etc., can solve problems such as difficulty in effectively controlling the oil content of solid residues, unreasonable exhaust gas and solid residue emissions, and unreasonable structural design. , to achieve the effect of excellent temperature adjustable performance, ensuring uniformity and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

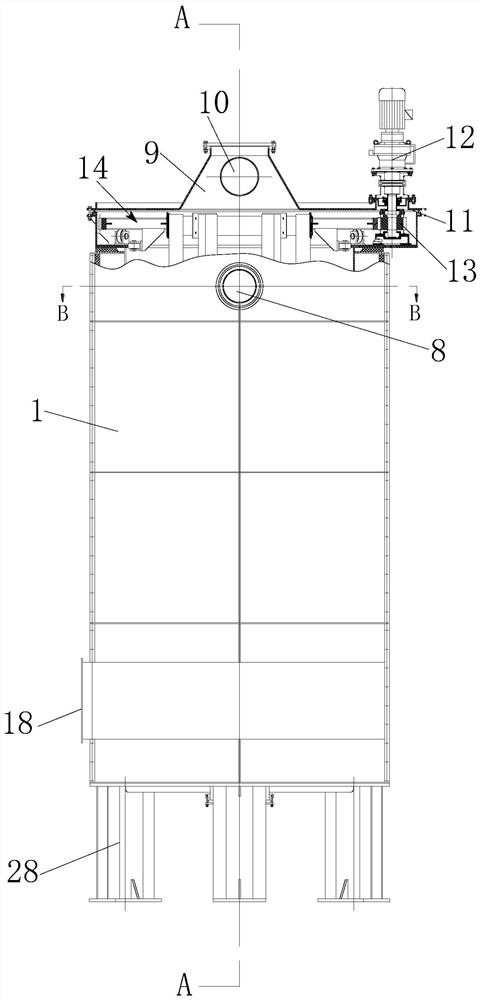

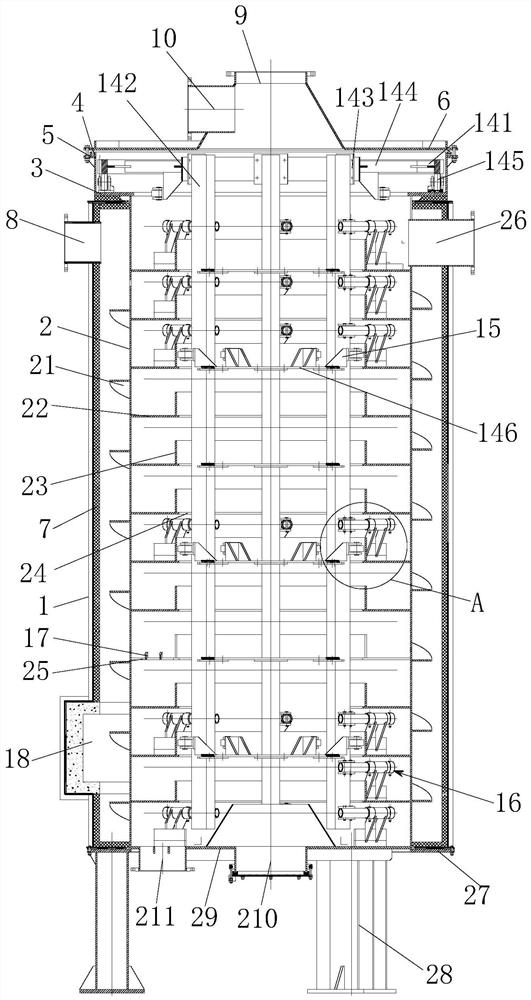

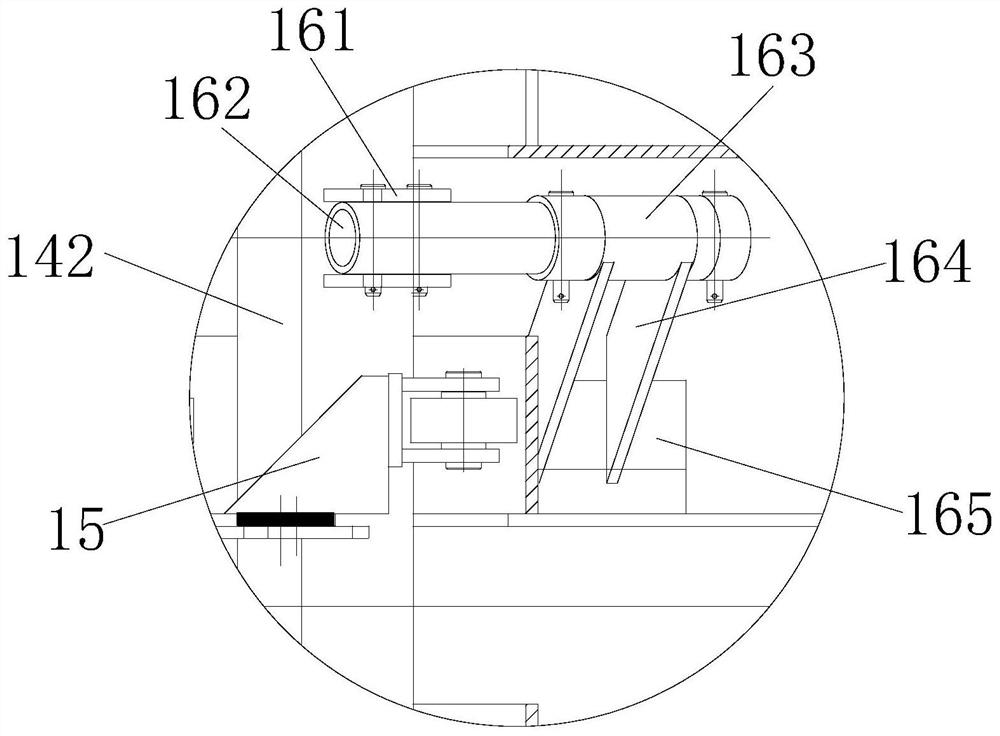

[0026] see Figure 1-7 , the present invention provides a technical solution: a vertical regenerated oil furnace, including a furnace body 1, a material trough cylinder 2 is arranged inside the furnace body 1, and the top of the material trough cylinder 2 extends out of the furnace body 1 and is welded with a special-shaped bracket The lower surface of the plate 3 and the outer periphery of the upper surface of the special-shaped supporting plate 3 are fixedly connected with a special-shaped vertical cylinder 4, and the top of the special-shaped vertical cylinder 4 is fixedly installed with a furnace upper cover 6 through a special-shaped flange 5, and the inner wall of the furnace body 1 is installed. The shell 7, the top of the front of the furnace body 1 is fixedly connected with a waste gas discharge pipe 8, and the waste gas discharge pipe 8 is connected with the heat preservation shell 7, and the middle part of the furnace upper cover 6 is fixedly connected with an upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com