Combustion device facilitating directly injecting water-coal slurry into low-oxygen flames to reduce NOx

A combustion device and coal-water slurry technology, which is applied to the combustion of lump fuel and liquid fuel, the combustion of lump fuel and gaseous fuel, the combustion of lump fuel and powder fuel, etc., which can solve the problem of high investment cost , complex structure, narrow reaction temperature window, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

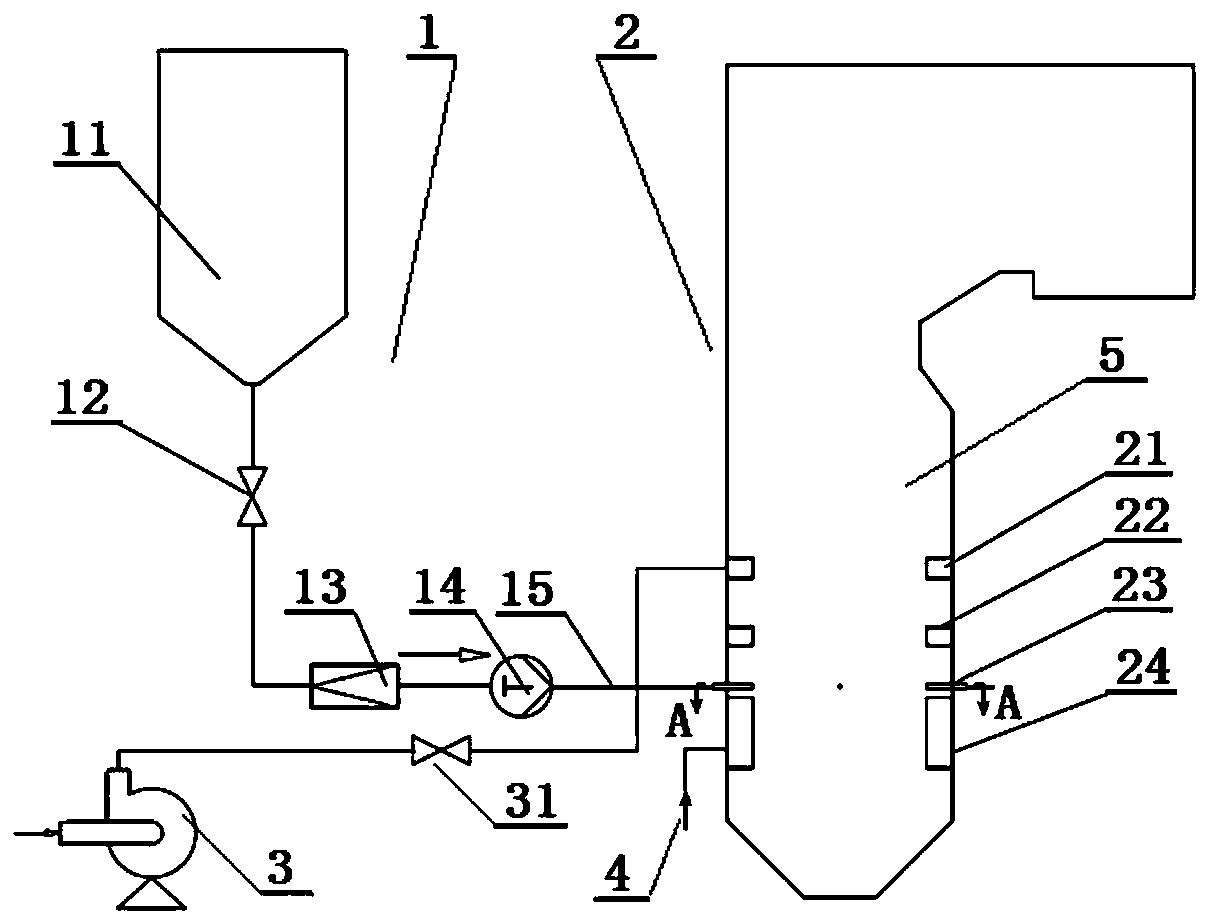

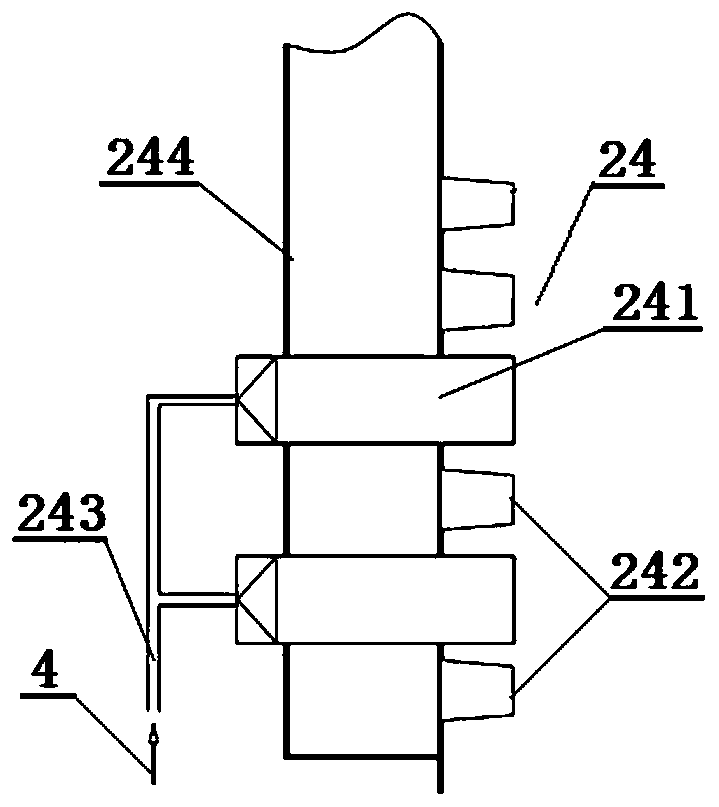

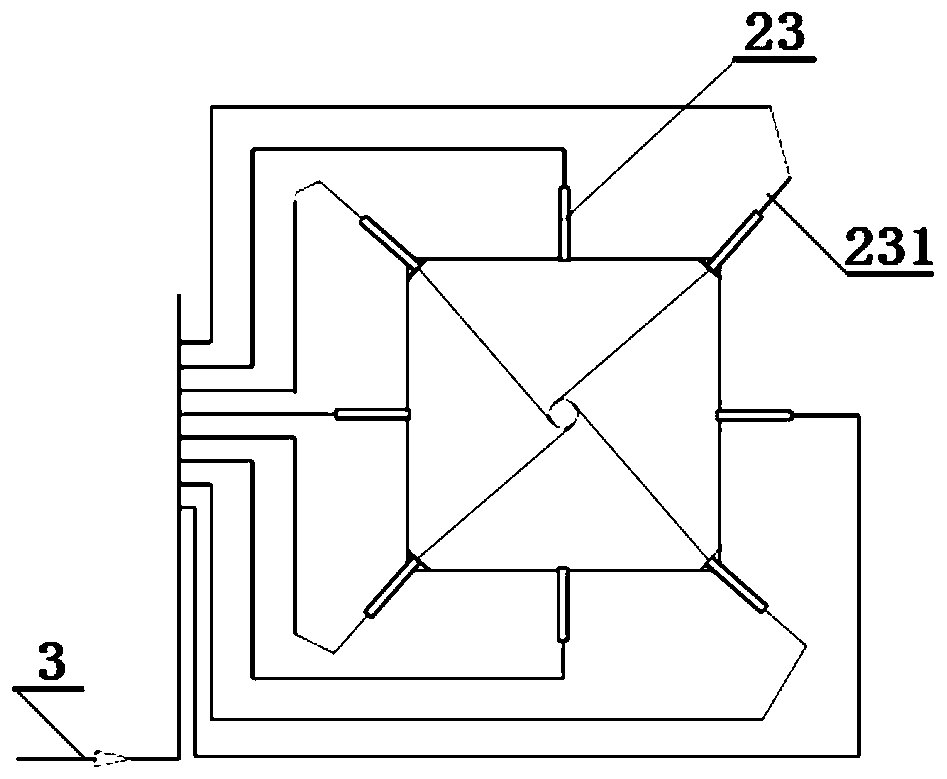

[0024] exist figure 1 , figure 2 and image 3 Among them, the combustion device of the present invention that is convenient to directly inject coal-water slurry to reduce NOx in a low-oxygen flame is characterized in that the main body includes a coal-water slurry supply mechanism 1, a combustion mechanism 2, a high-pressure blower 3 and a pulverizing system 4, wherein:

[0025] Described coal-water slurry supply mechanism 1 mainly comprises coal-water slurry preparer 11, the coal-water slurry flow control valve 12 that is arranged on the output pipeline of coal-water slurry preparer 11 successively, coal-water slurry filter 13, coal-water slurry increaser Pressure pump 14 and coal water slurry output main pipe 15;

[0026] The combustion mechanism 2 mainly includes a high-level separation air nozzle 21, a low-level separation air nozzle 22,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com