Battery pack circuit and battery pack heating method

A technology of battery packs and circuits, which is applied in the direction of secondary battery charging/discharging, circuits, secondary batteries, etc., can solve the problems of troublesome production and assembly, unevenness, etc., and achieve the effect of increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

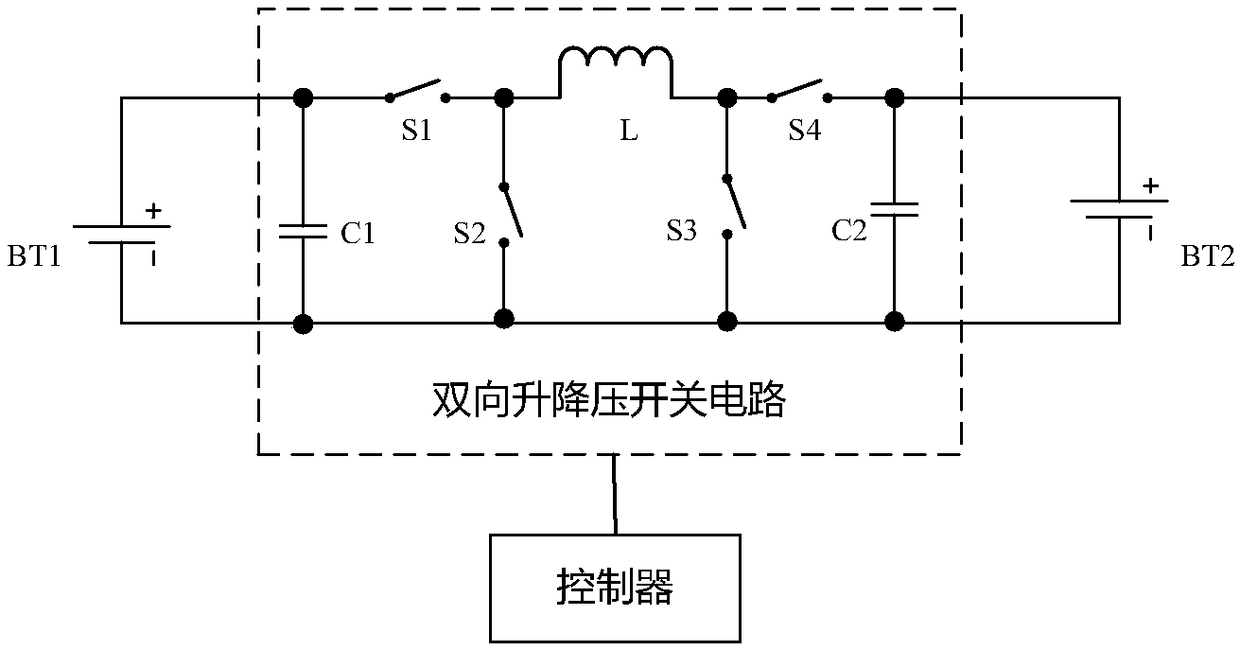

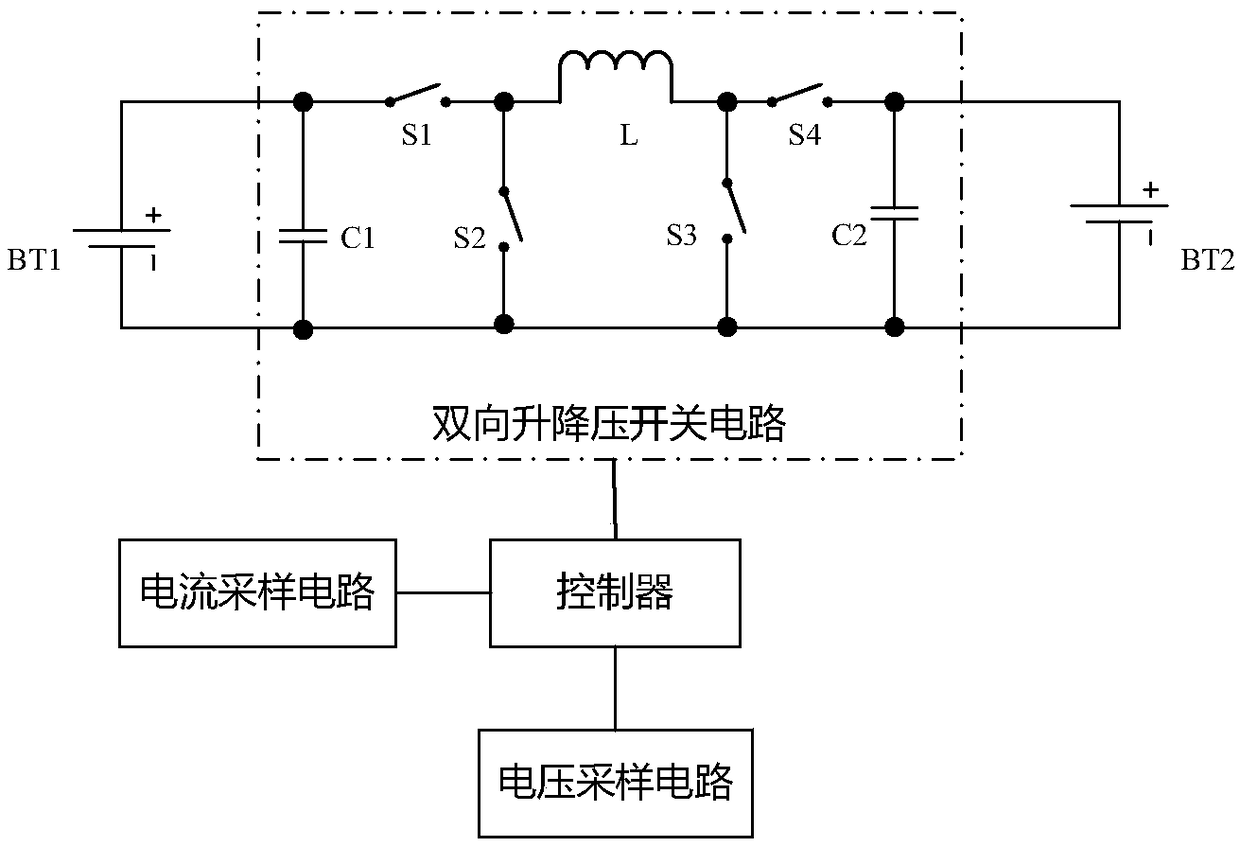

[0034] see figure 1 As shown, this embodiment provides a battery pack circuit, which includes: a battery pack, a bidirectional buck-boost switch circuit, and a controller.

[0035] The battery pack is composed of at least two battery cells, wherein each battery cell can be a battery cell, or a battery pack composed of at least two battery cells.

[0036] Moreover, the battery units in the embodiments of the present invention are not limited to be the same, and may also be different from each other.

[0037] The bidirectional buck-boost switch circuit in this embodiment includes a first input / output terminal, a second input / output terminal, and a voltage conversion circuit arranged at the first input / output terminal and the second input / output terminal.

[0038] When one of the first input / output terminal and the second input / output terminal is an input terminal, the other terminal as an output terminal can be used as an output terminal or an input terminal respectively, that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com