An assembly device and an assembly method of a rotor shaft of a motor

A technology for motor rotor shafts and assembly equipment, which is applied in the direction of electromechanical devices, manufacturing motor generators, manufacturing stator/rotor bodies, etc., can solve the problems of cumbersome operation, high danger, and workers being scalded by steel sheets, so as to improve safety, Heating speed is fast and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

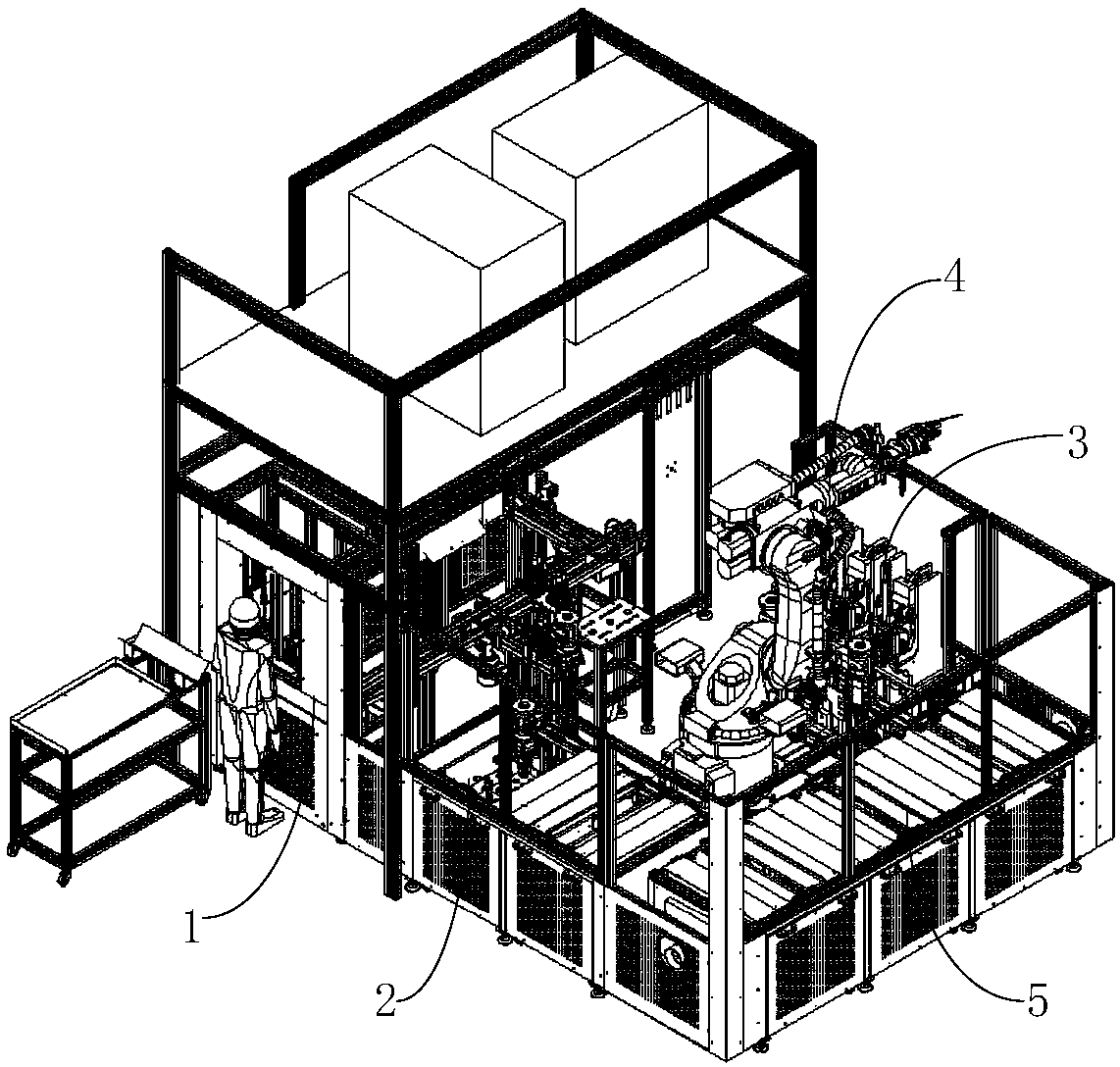

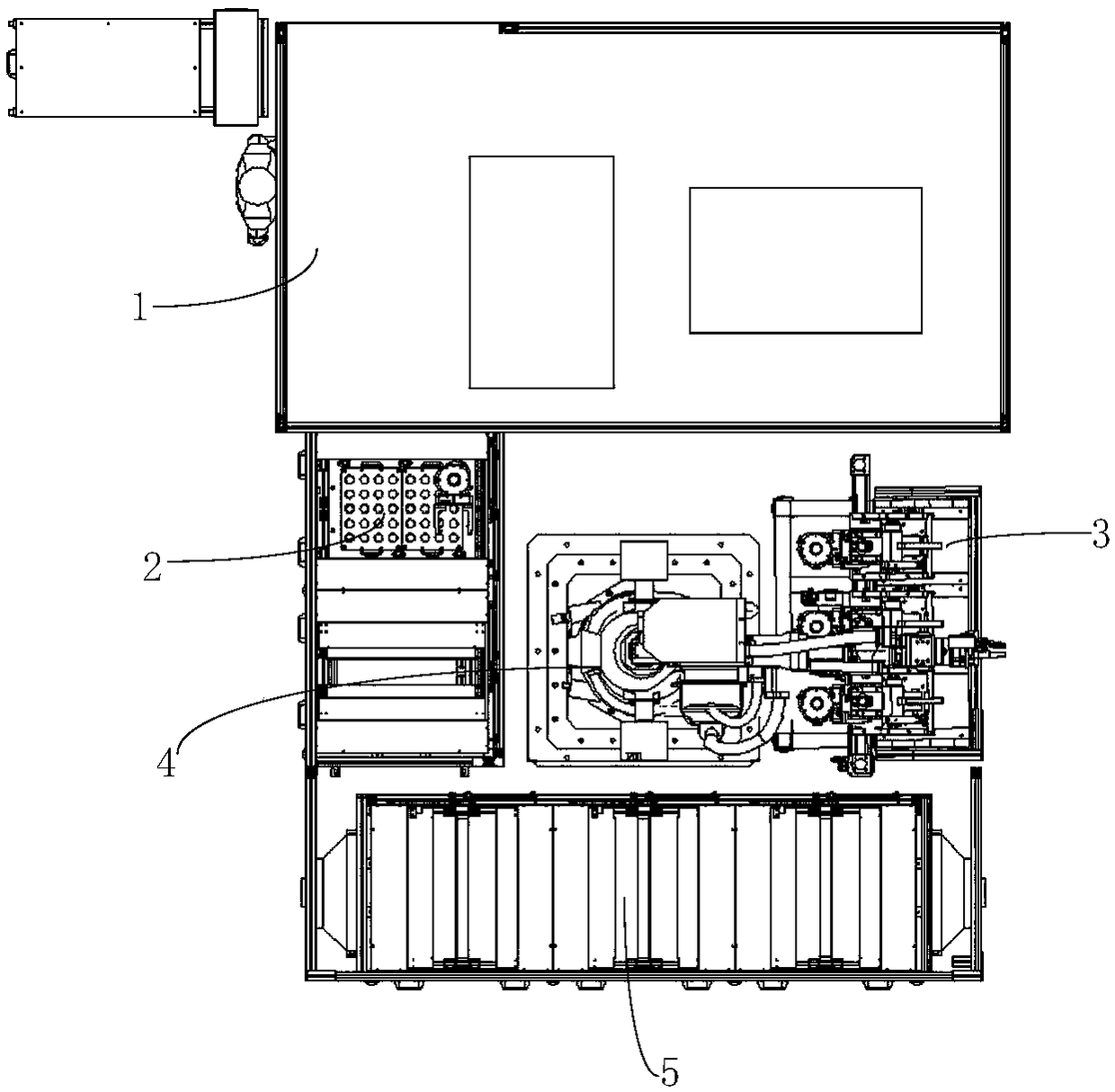

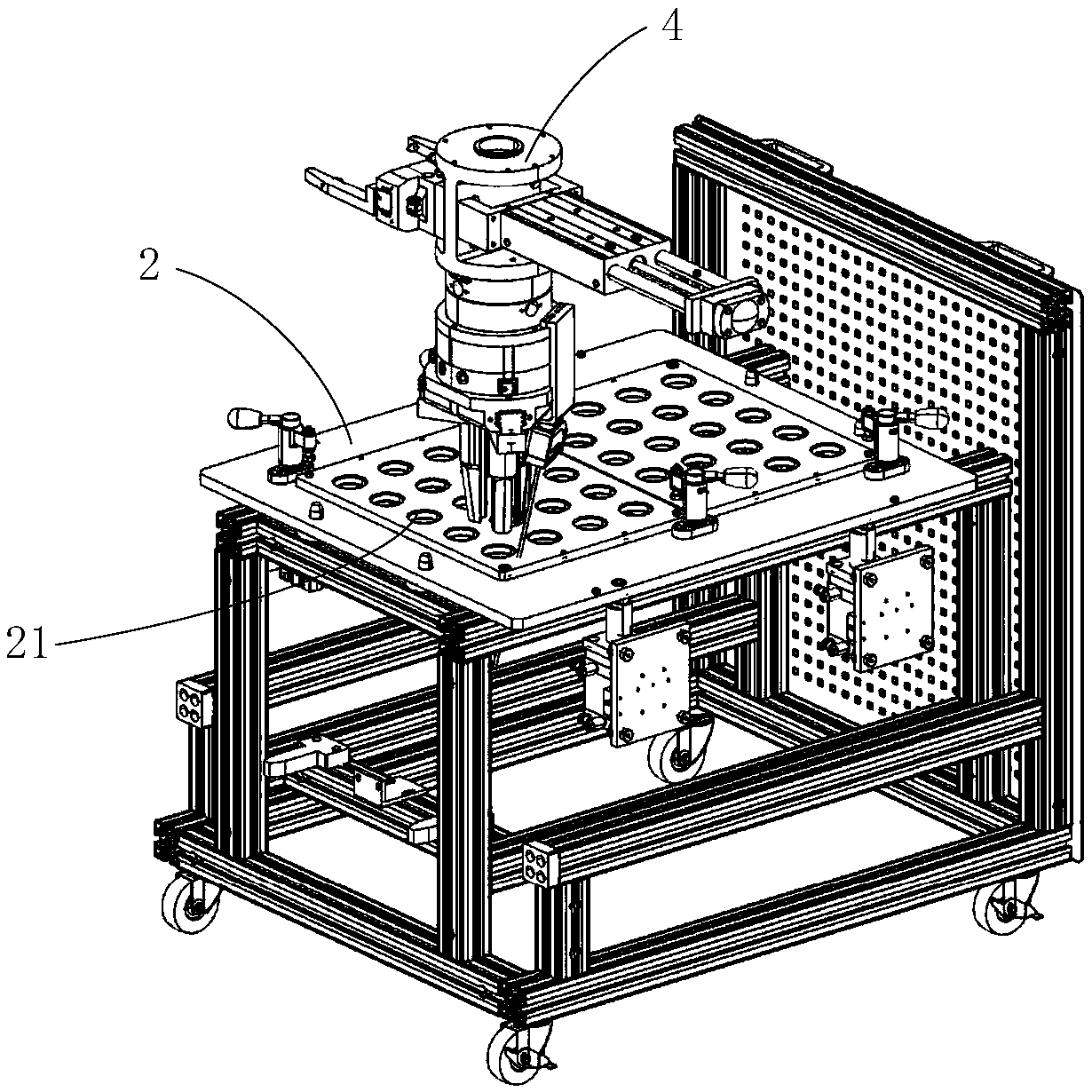

[0044] see Figure 1 to Figure 9 As shown, they are respectively the perspective view of the overall structure of the rotor shaft of the motor of the present invention, the top view of the overall structure, the structural diagram of the rotor shaft feeding station, the partial structural diagram of the manipulator, the structural diagram of the heating assembly station, and the structural diagram of the press-fitting device , A partial diagram of the heating assembly station, a structural diagram of the heating device and a structural diagram of the heating rod.

[0045] combine Figure 1 to Figure 9 As shown, an assembly equipment for a motor rotor shaft includes a manipulator 4 and a silicon steel sheet feeding station 1 arranged around the manipulator 4, a rotor shaft feeding station 2, a heating assembly station 3, and a rotor cooling station 5. The material station 1 includes a manual assembly station, a pressing device for pressing the motor rotor semi-finished product...

Embodiment 2

[0054] As for the assembly equipment of the motor rotor shaft described in Embodiment 1, the difference of this embodiment is that the two ends of the spiral conductive member 331 are provided with conductive connecting rods, and the conductive connecting rods are electrically connected so as to facilitate the connection of the spiral conductive member. 331 power supply.

Embodiment 3

[0056] As the assembly equipment of the motor rotor shaft described in the second embodiment, the difference of this embodiment is that, as Figure 10 As shown, the number of metal rods 332 is two, respectively the first metal rod 3321 and the second metal rod 3322; one end of the first metal rod 3321 is connected to one end of the spiral conductive member 331, and the other One end is electrically connected; one end of the second metal rod 3322 is connected to the other end of the spiral conductive member 331 , and the other end of the second metal rod 3322 is electrically connected.

[0057] The assembling equipment of the motor rotor shaft in the present invention directly connects the metal rods 332 electrically, saves two conductive connecting rods, has a simple and compact structure, and has a beautiful appearance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com