Self-heating measuring structure and measuring method for FinFET device, and electronic device

A self-heating and device technology, used in measurement devices, semiconductor/solid-state device testing/measurement, electrical measurement, etc., can solve the problems of reduced driving current, poor heat dissipation performance of fins, and difficult detection of self-heating effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

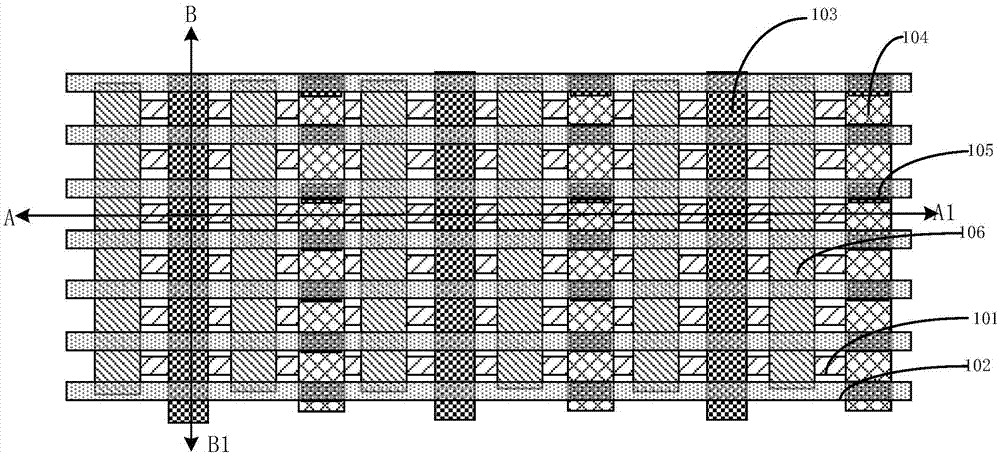

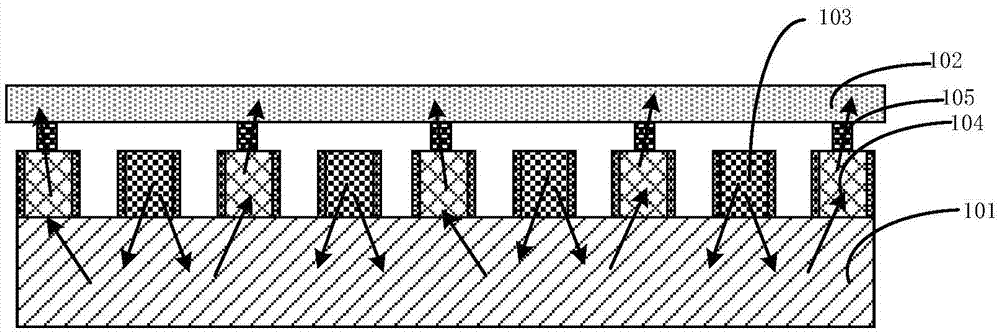

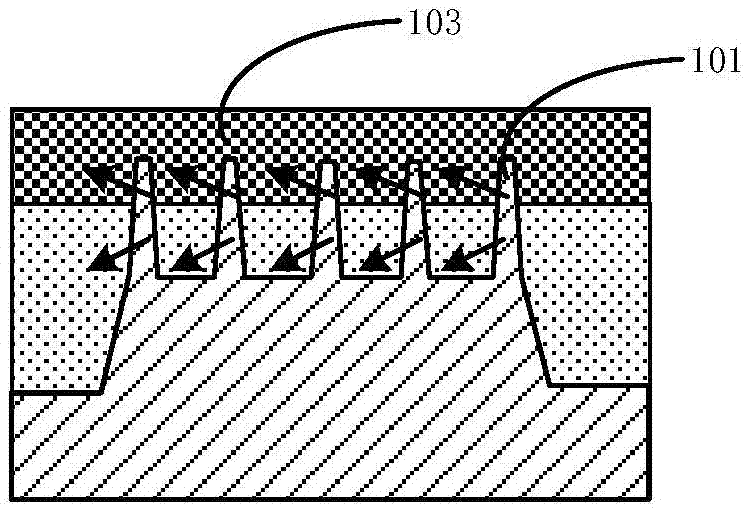

[0037] In order to solve the problems in the prior art, the present invention provides a self-heating measurement structure in a FinFET device. The measurement structure will be further described below in conjunction with the accompanying drawings, wherein figure 1 It is a schematic diagram of the self-heating measurement structure in the FinFET device described in the embodiment of the present invention; figure 2 It is a schematic cross-sectional view along A-A1 of the self-heating measurement structure in the FinFET device described in the embodiment of the present invention; image 3 It is a schematic cross-sectional view along B-B1 of the self-heating measurement structure in the FinFET device described in the embodiment of the present invention.

[0038] Such as Figure 1-3 As shown, the self-heating measurement structure includes:

[0039] semiconductor substrate;

[0040] Several rows of fins 101 are located on the semiconductor substrate;

[0041] A grid array, lo...

Embodiment 2

[0068] In order to solve the problems existing in the prior art, the present invention provides a method for measuring resistance in a FinFET device, including:

[0069] Step S1: Disconnect the FinFET device, so that the gate is in an off state, and measure the resistance value R of the thermal variable resistance layer 0 ;

[0070] Step S2: Turn on the FinFET device, so that the gate is in a conduction state, at this time, the gate will emit heat, and the heat will be transmitted to the thermal variable resistance layer along the dummy gate, as Figure 2-3 As shown, the resistance of the thermal variable resistance layer changes, and the resistance value R of the thermal variable resistance layer is measured;

[0071] Step S3: Calculate the temperature of the thermal variable resistance layer after the temperature rise according to the increase of the resistance of the thermal variable resistance layer and the temperature coefficient of resistance α.

[0072] Optionally, th...

Embodiment 3

[0080] The present invention also provides an electronic device, including the test structure described in the first embodiment.

[0081] The electronic device of this embodiment can be any electronic product or equipment such as mobile phone, tablet computer, notebook computer, netbook, game console, TV set, VCD, DVD, navigator, camera, video recorder, voice recorder, MP3, MP4, PSP, etc. , can also be any intermediate product that includes the test structure. The electronic device of the embodiment of the present invention has better performance due to the use of the above test structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com