Power battery heating control method, electric vehicle and medium

A power battery and heating control technology, which is applied to electric vehicles, battery/fuel cell control devices, vehicle components, etc., can solve the problems of low battery life of electric vehicles, improve the car experience, reduce charging time, and solve high demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0038] At present, one type of methods for self-heating of power batteries is based on the remaining power of the power battery. When the power of the power battery is exhausted or the power is extremely low, the self-heating of the power battery cannot be realized. The neutral point of the three-phase motor winding is required to be drawn out, and the neutral point of the motor of most electric vehicles is not drawn out.

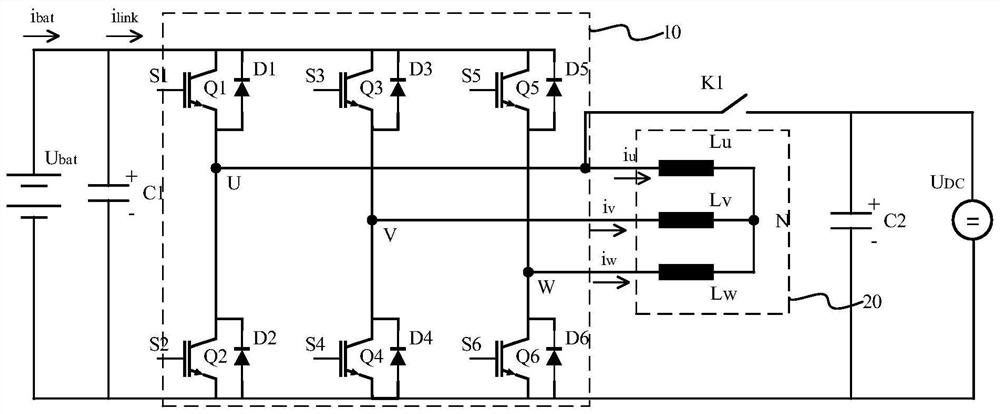

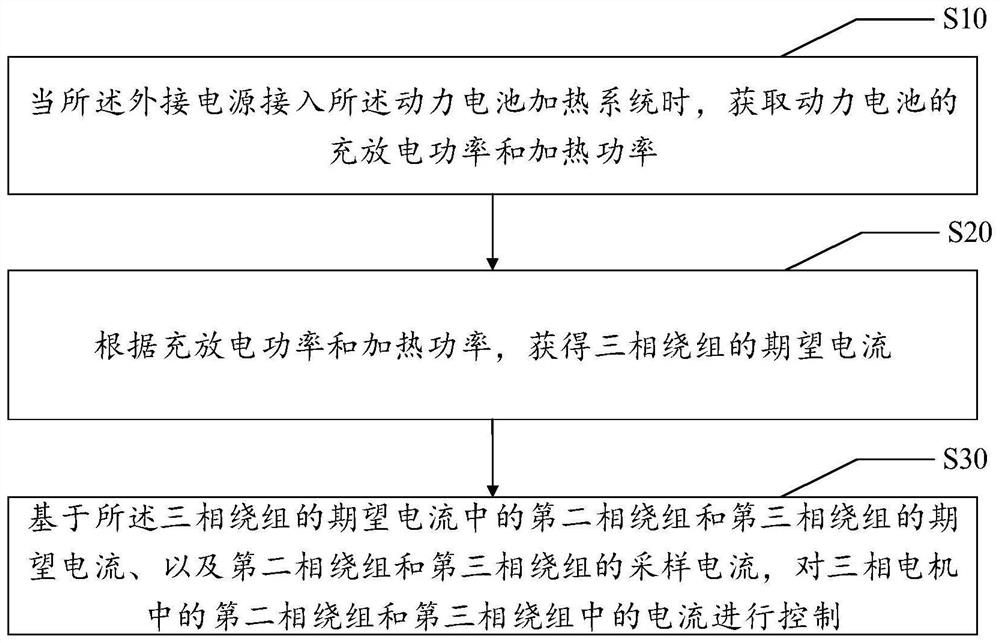

[0039] The main solution provided by the embodiments of the present application is to heat the power battery by using an external power supply, and to connect the switching element with the external power supply through one of the phase windings in the three-phase motor to form a circuit for multiplexing boost charging. Structural control not only solves the high requirements of the existing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com