Drying air duct system of drying equipment

A drying equipment and air duct technology, applied in the field of drying equipment, can solve the problems of low energy utilization rate, exhaust waste heat waste, and increase drying cost, so as to improve energy utilization rate, improve heat exchange efficiency, and avoid heat loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

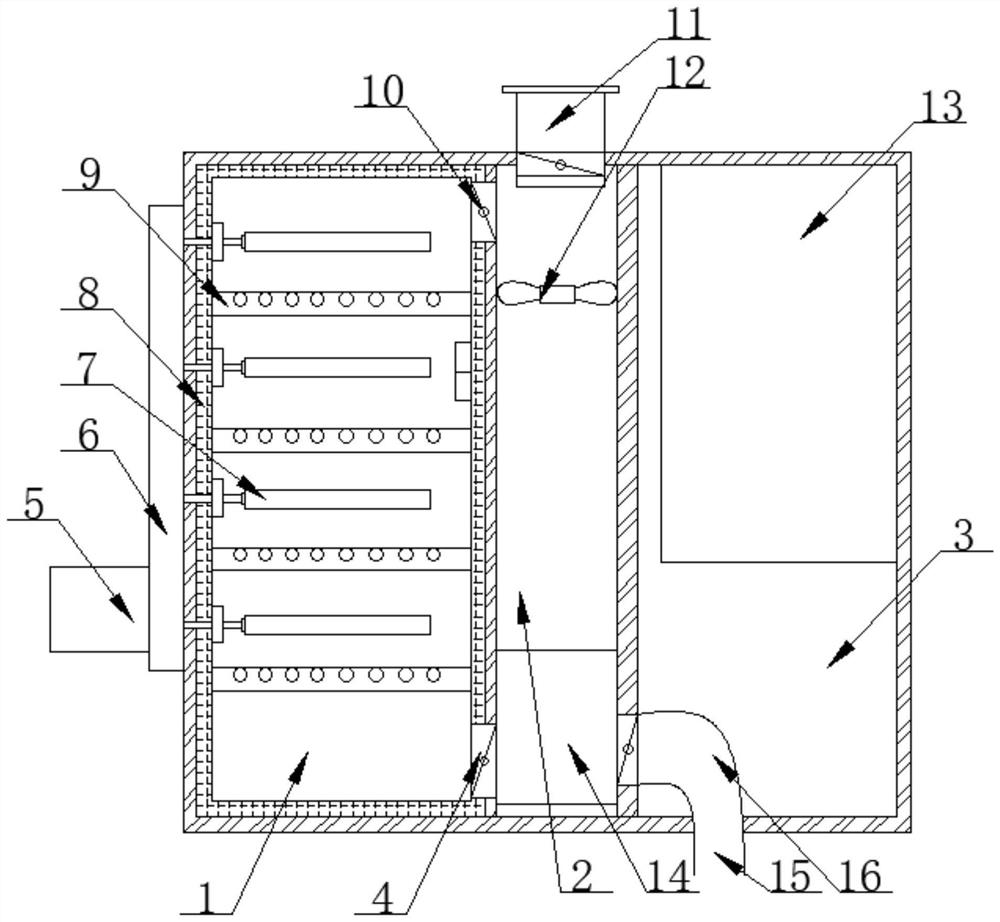

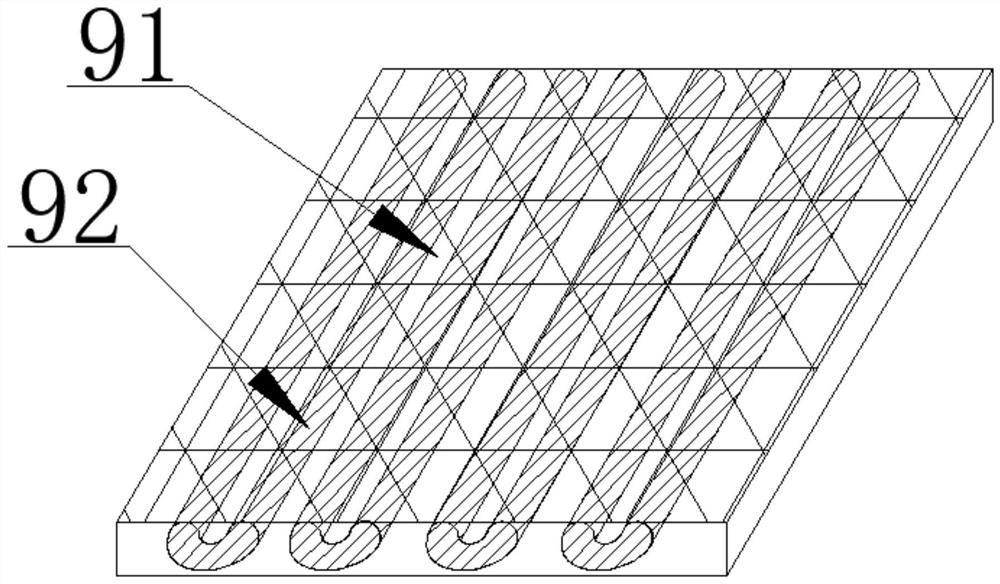

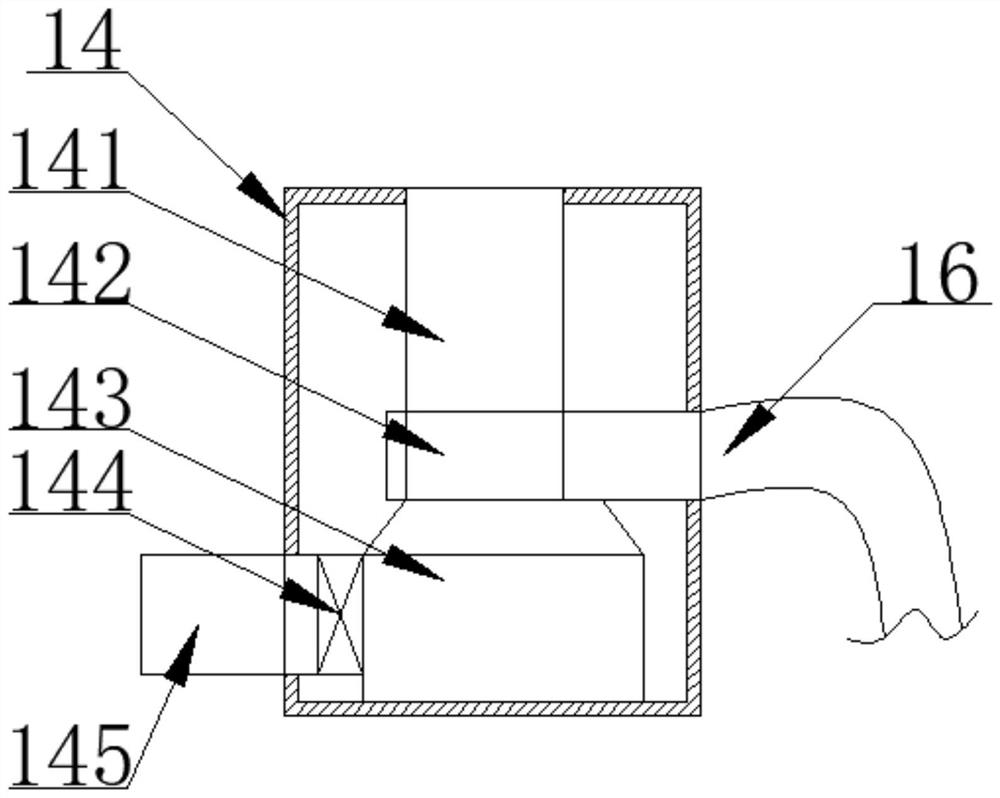

[0028] The implementation mode is as follows: by optimizing the structural layout, the heating device and the storage plate 91 are integrated in the drying chamber 1, and the heating pipe 92 is used to directly heat the gas in the drying chamber 1, so that the environment in the drying chamber 1 can be rapidly heated. Heat up, and cooperate with the insulation layer 8 to carry out continuous drying, avoid heat loss caused by traditional heating, drying and separation, improve energy utilization, and have higher drying efficiency and improve production efficiency; in addition, the present invention uses plate heat exchange The device 142 improves the heat exchange efficiency, uses the cooled external cold air to lower the temperature of the high-temperature humid air, condenses the high-temperature humid air to recover moisture, and at the same time increases the temperature of the cold air to obtain dry cold air without additional refrigeration system cooling The high-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com