Patents

Literature

44 results about "Desiccating chamber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

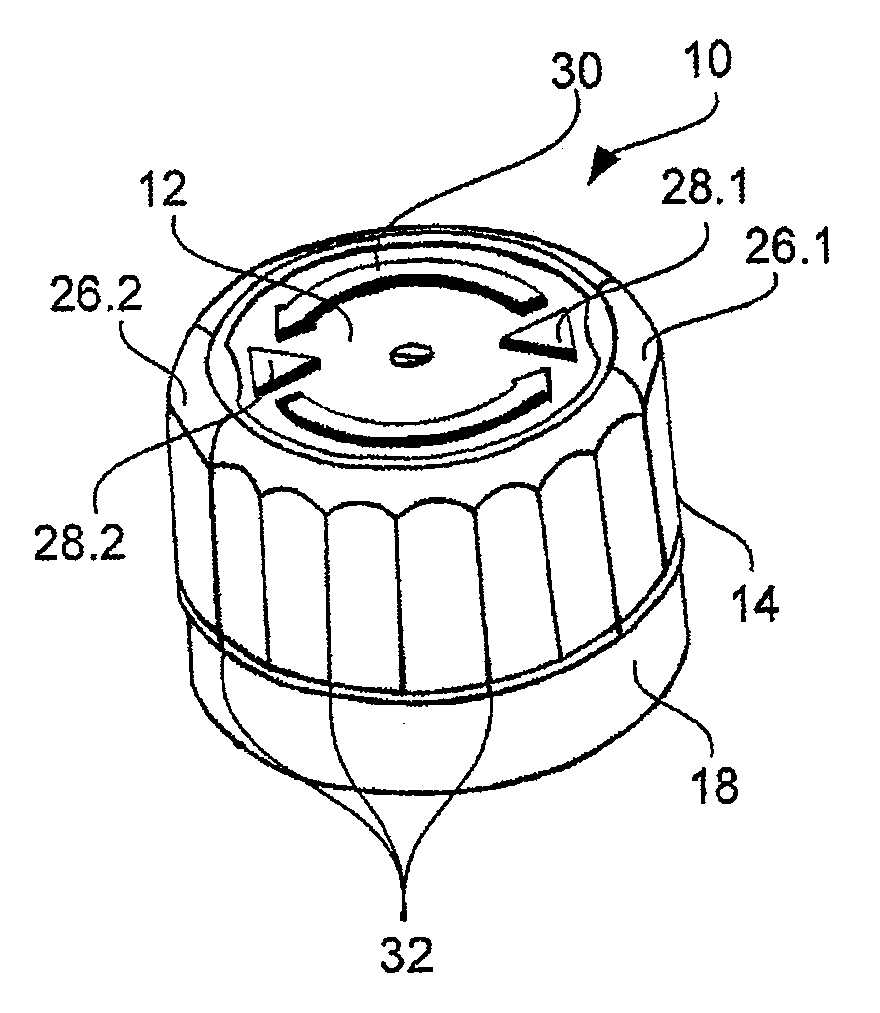

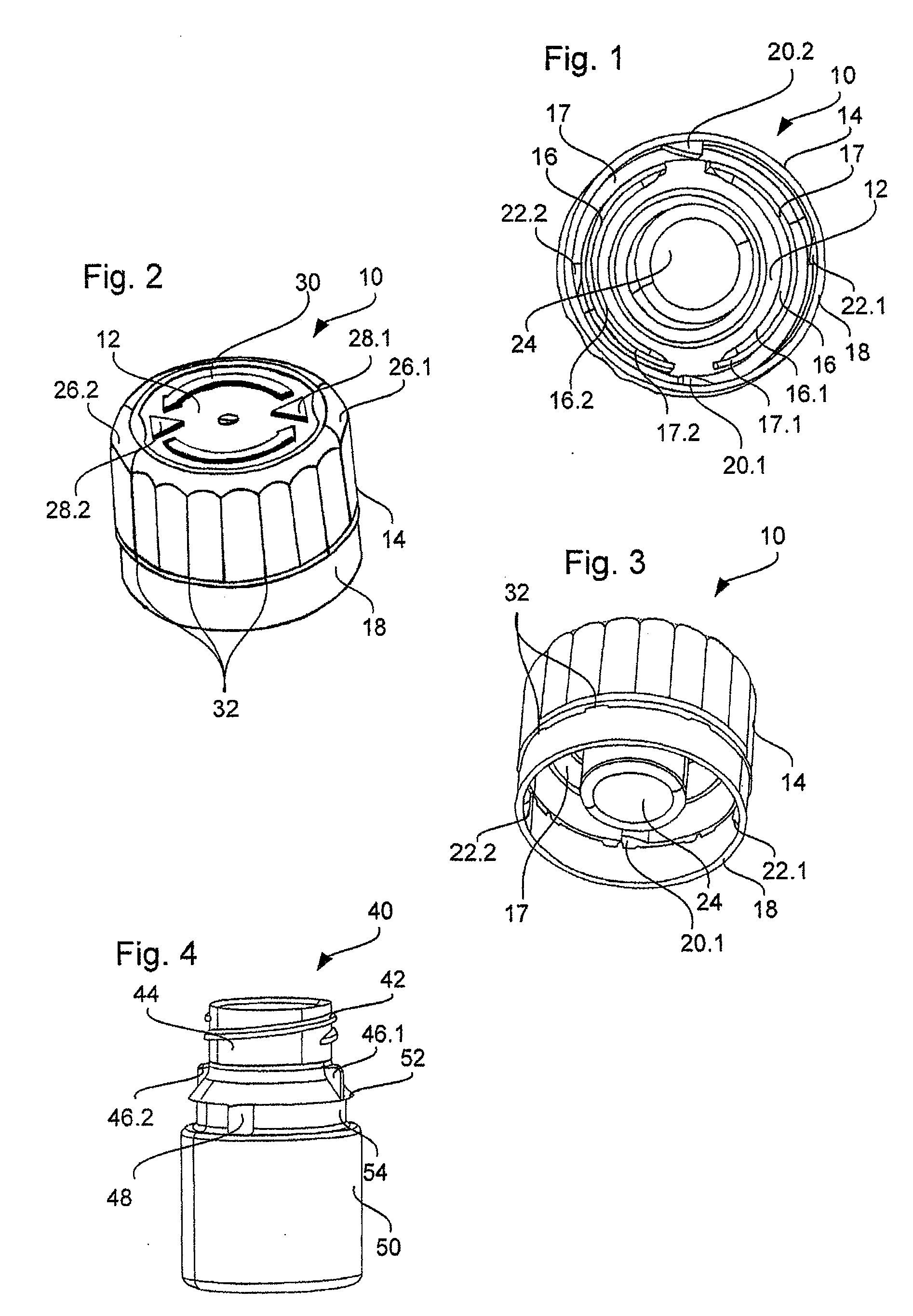

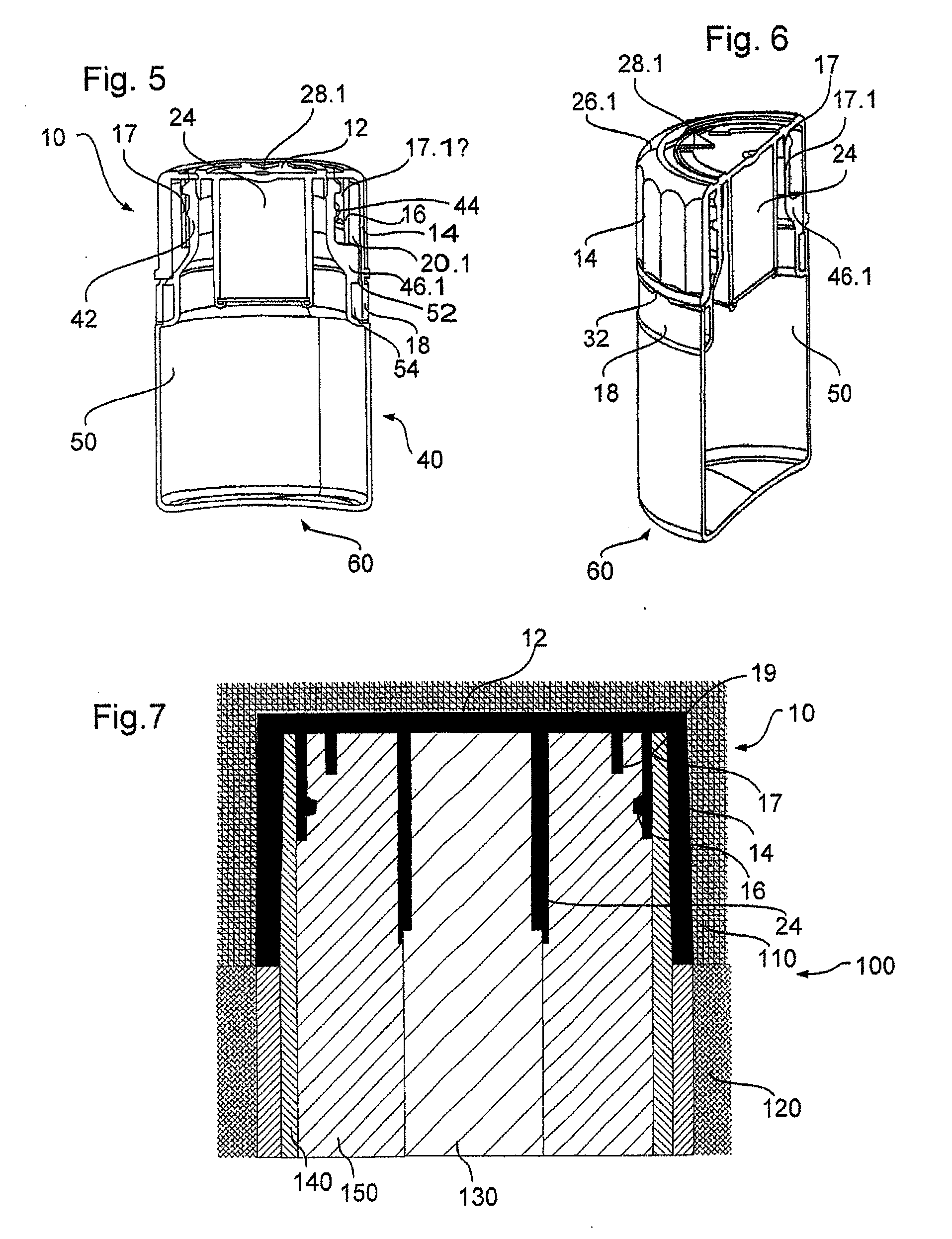

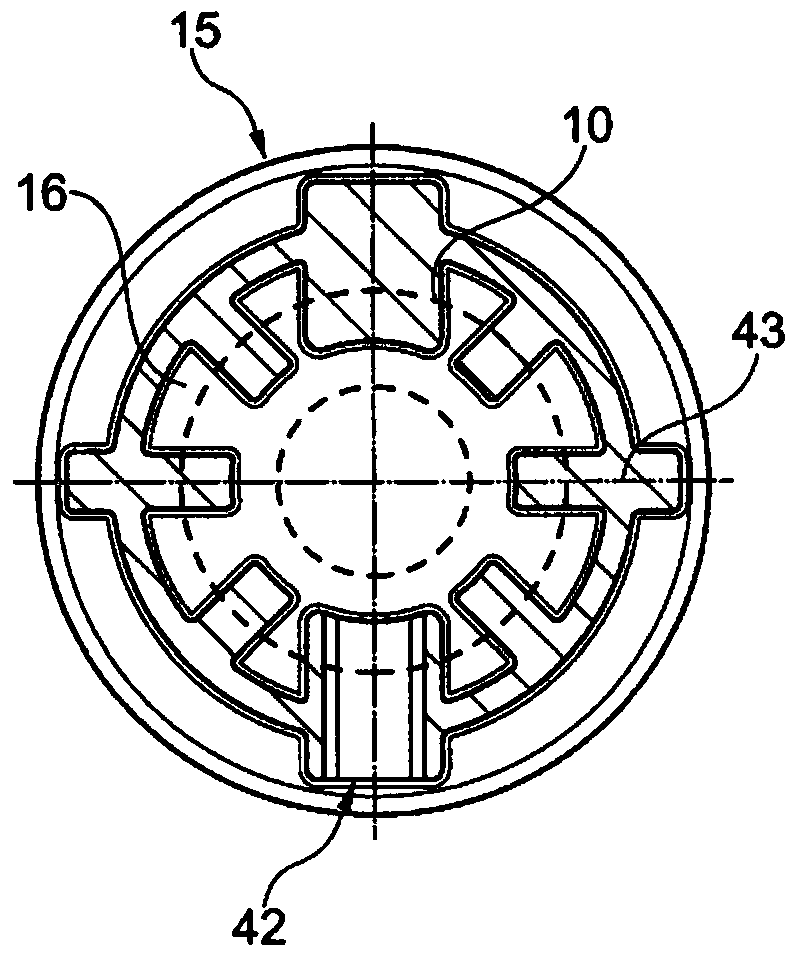

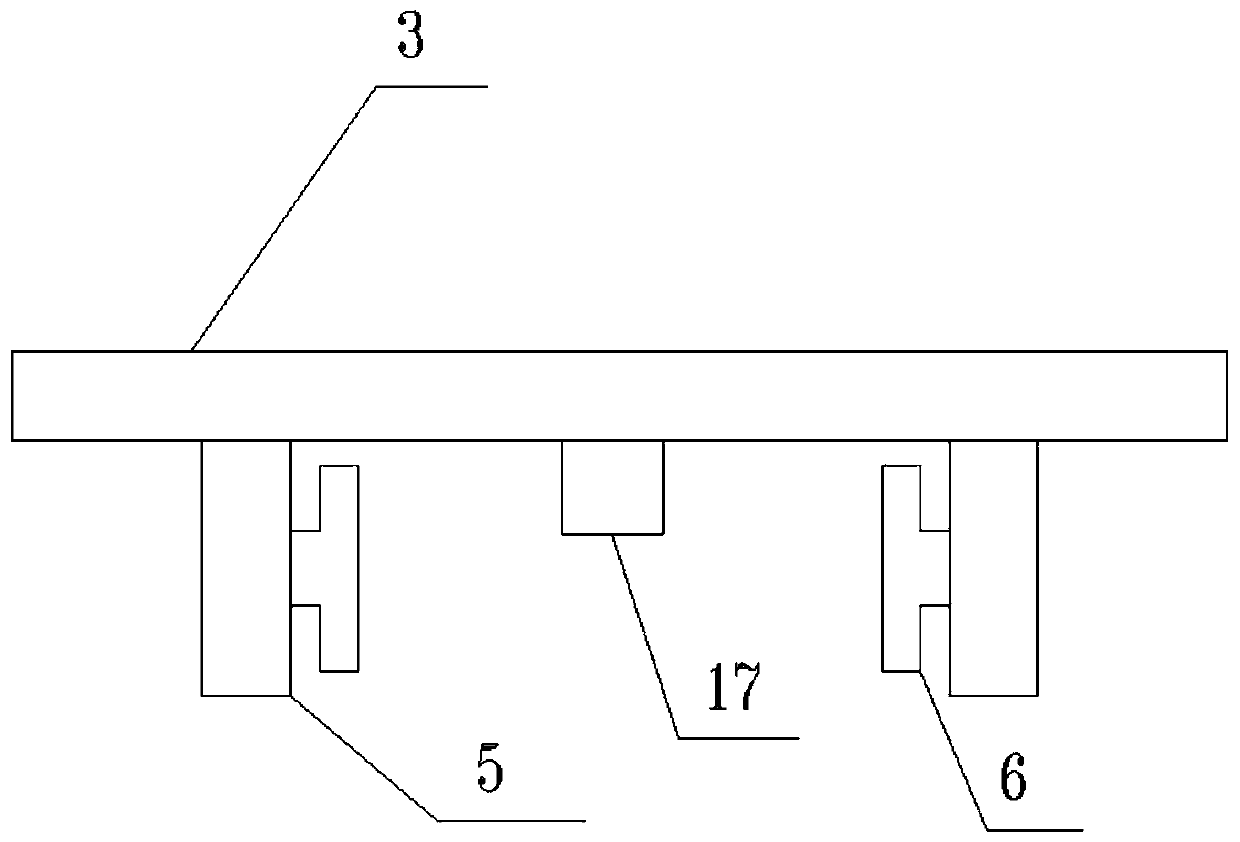

Screw cap, container body and container

ActiveUS20100102020A1Reliable and strong guidanceReliable demouldingCapsMouldsEngineeringScrew thread

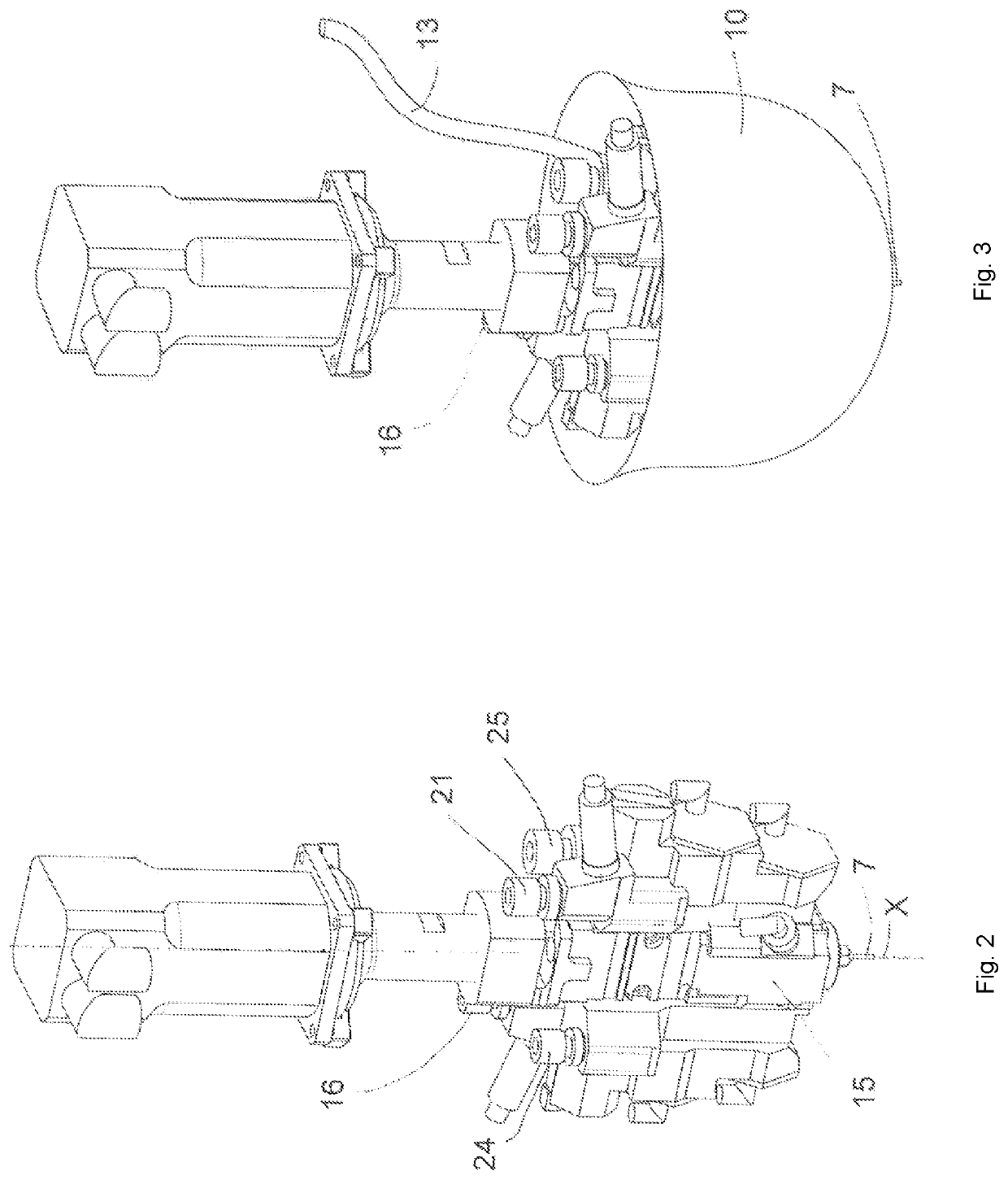

The invention relates to a screw cap (10) capable of being screwed onto the neck (44) of a container body (40), the screw cap comprising a substantially cylindrical screw section (17) comprising a screw thread (16) on its inner face, at least one tamper evidence member (18) for indicating an initial opening of the screw cap (10), and a desiccant chamber (24) located radially inwardly to the screw section, wherein the screw section (17) is radially resilient.

Owner:AIRNOV INC

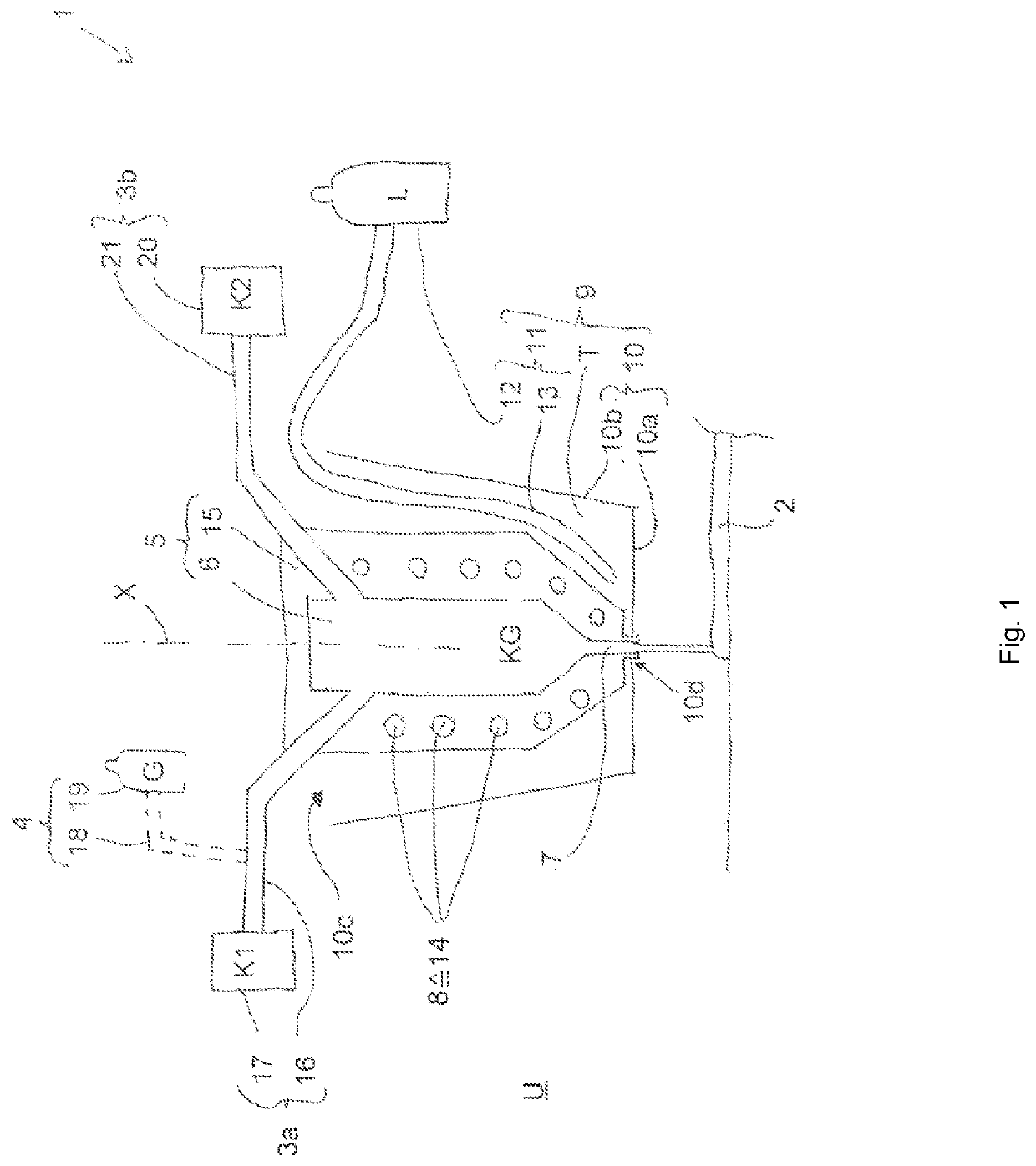

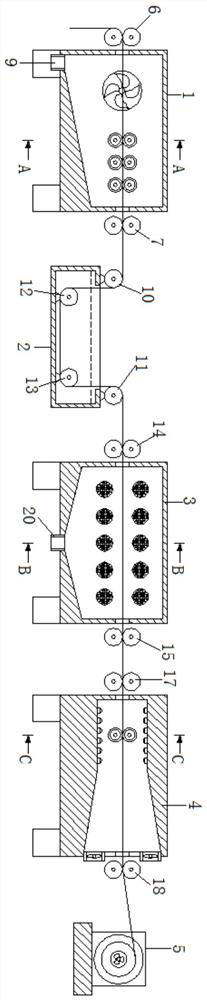

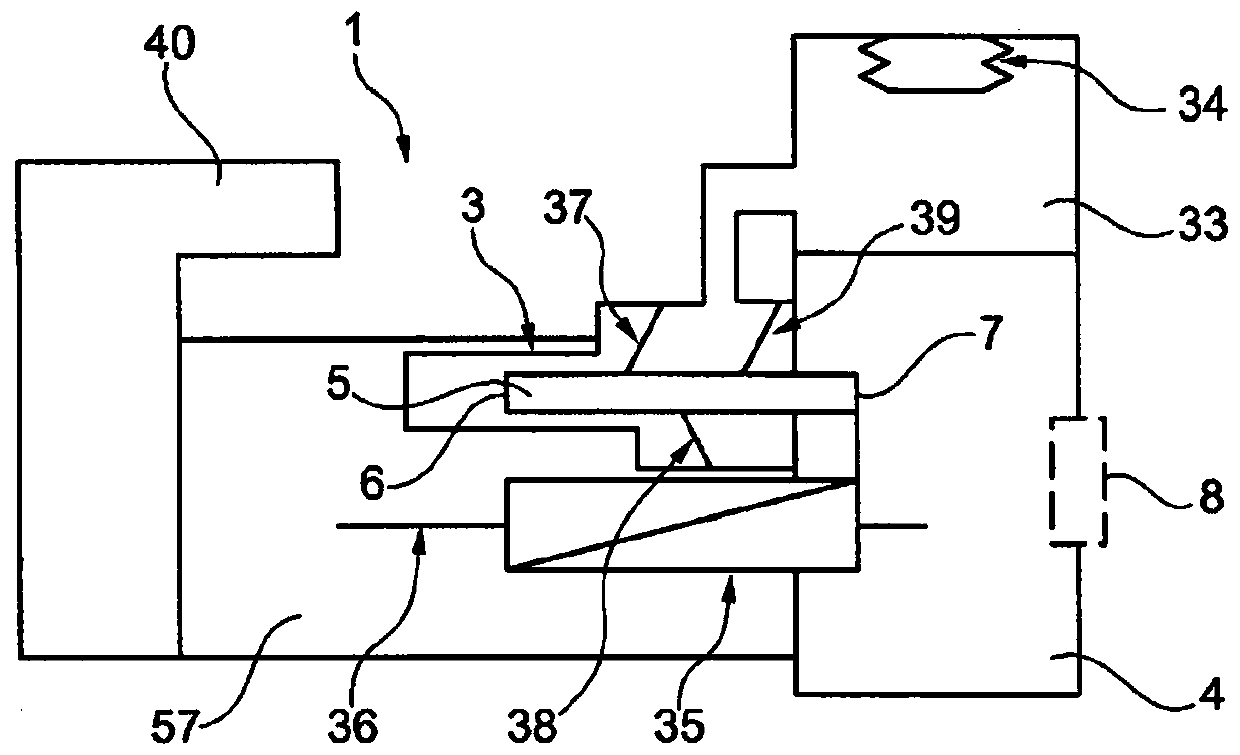

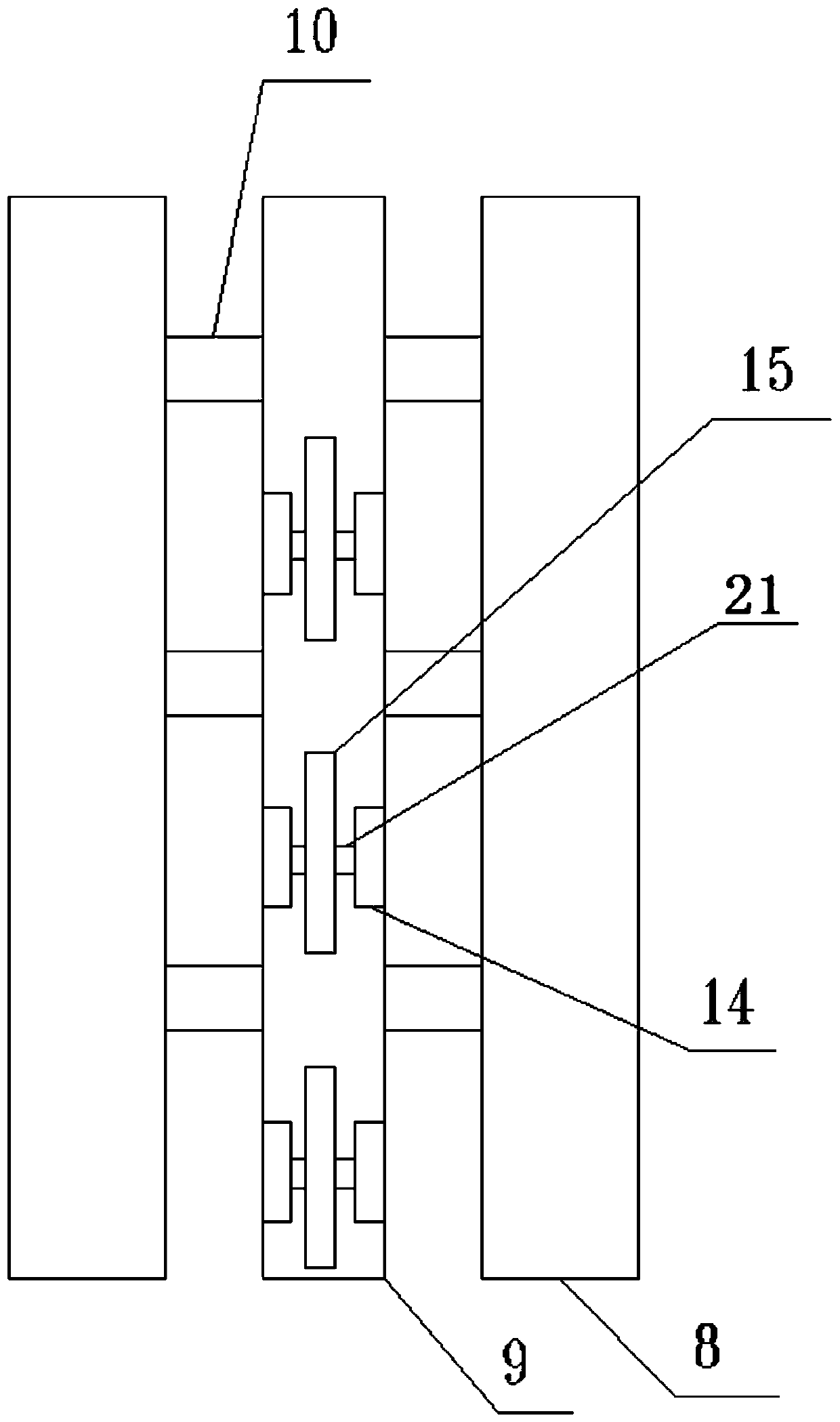

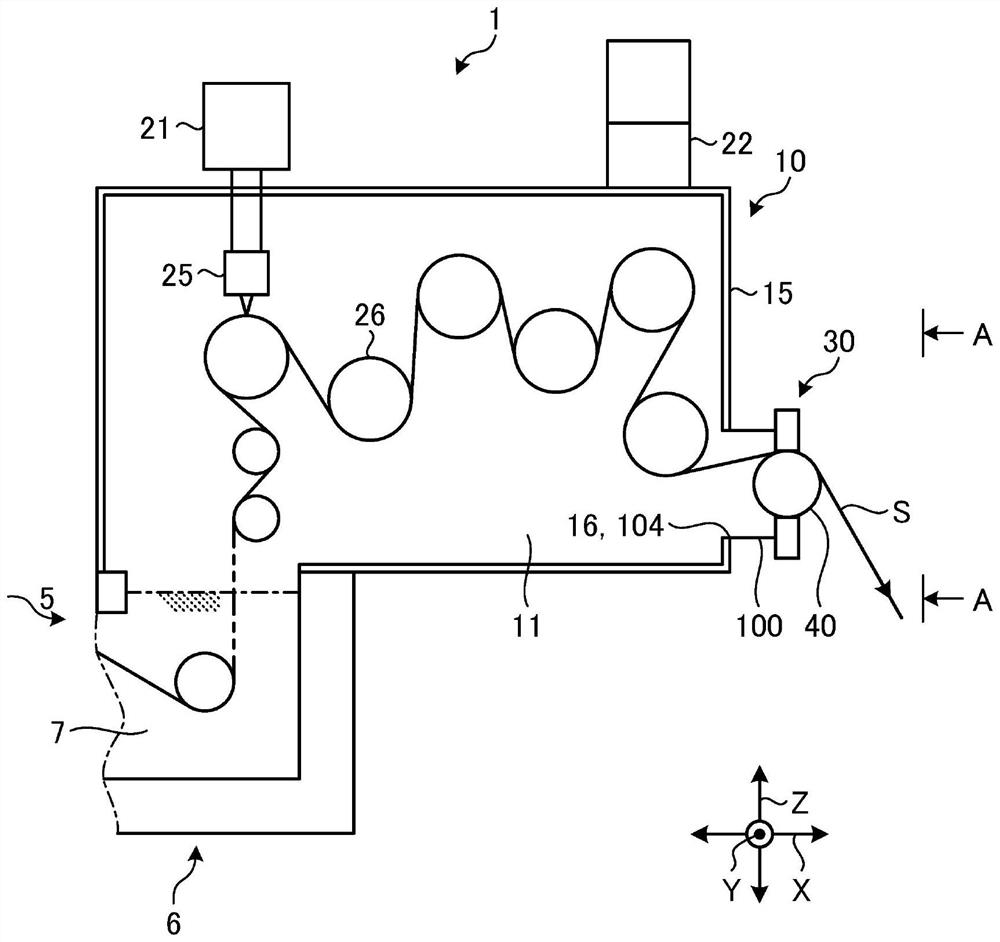

Device and method for the production of plastic parts, more particularly of adhesive applications

PendingUS20200307026A1Prolongs effectiveness of coolerMinimize air flowLiquid surface applicatorsTransportation and packagingDesiccantDesiccating chamber

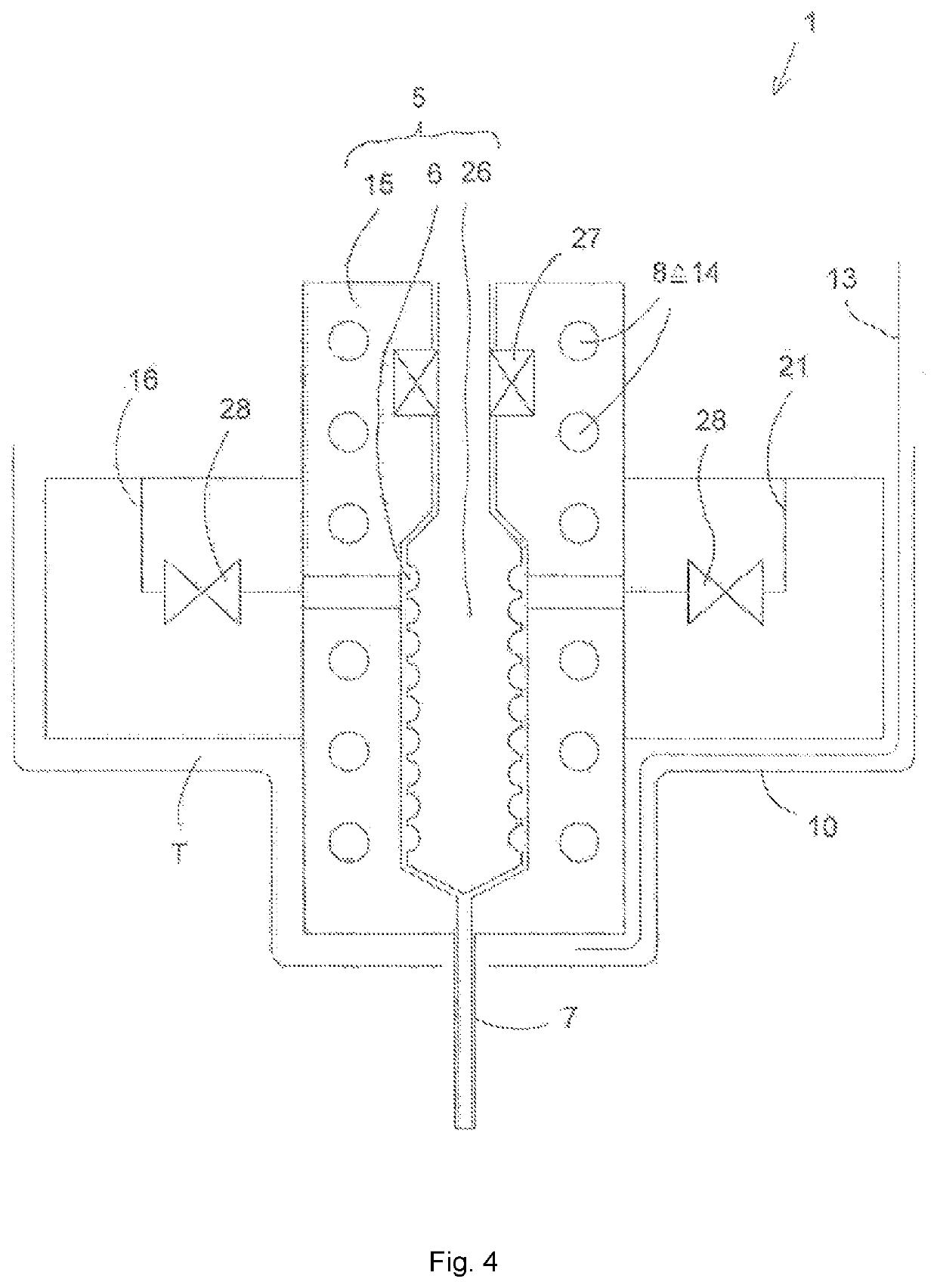

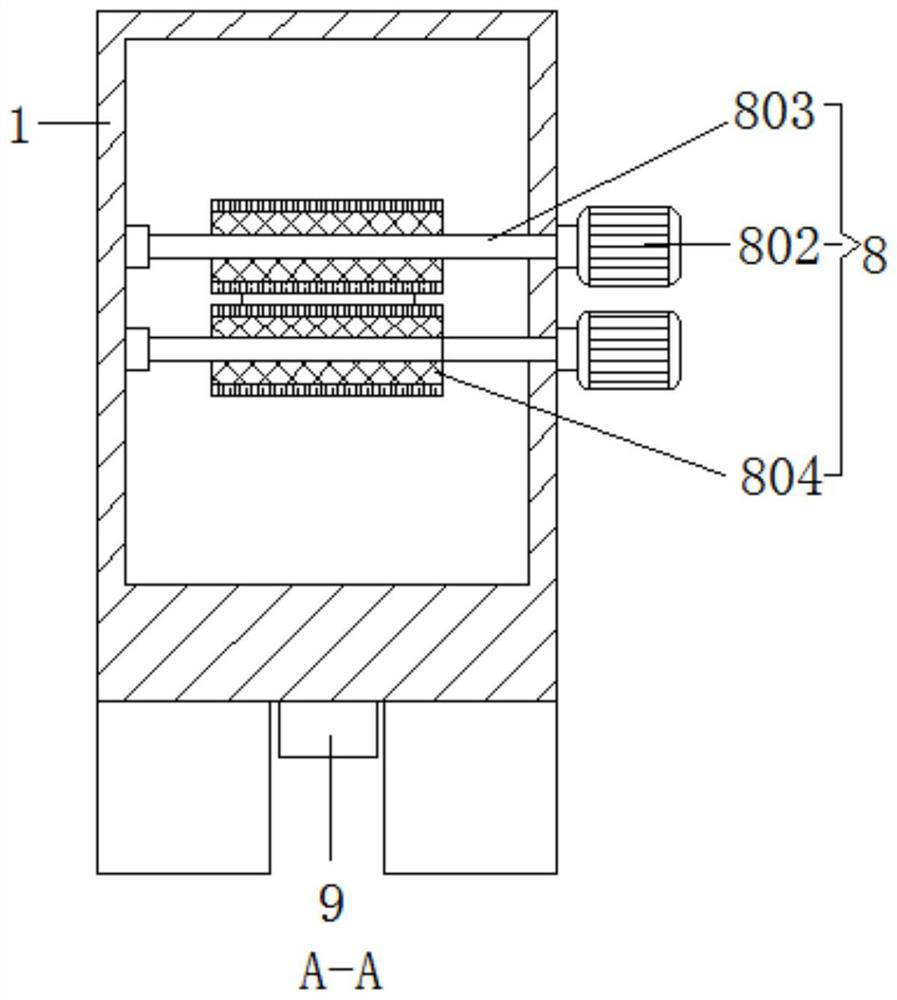

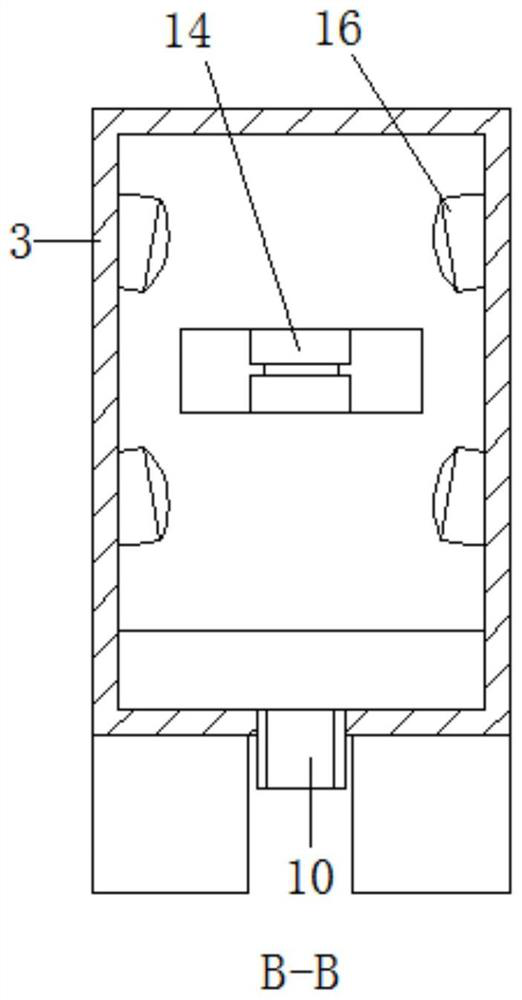

The invention relates to a device (1) and method for the production of plastic parts (2), having a first plastic feed device (3a) for feeding a first liquid plastic starting component (K1); a second plastic feed device (3b) for feeding a second liquid plastic starting component (K2); a mixing device (5) with a mixing chamber (6), wherein in the mixing chamber the liquid plastic starting components that can be fed by the plastic feed devices can be mixed to form a plastic mixture (KG); a discharge nozzle (7) for discharging the plastic mixture; and a cooling device (8) for the mixing device, wherein a drying device (9) surrounding the mixing device at least in regions is provided, wherein the drying device has a separating device (10), a drying chamber (T) formed between the separating device and the mixing device, and a desiccant feeding device (11) opening into the drying chamber.

Owner:HENKEL KGAA

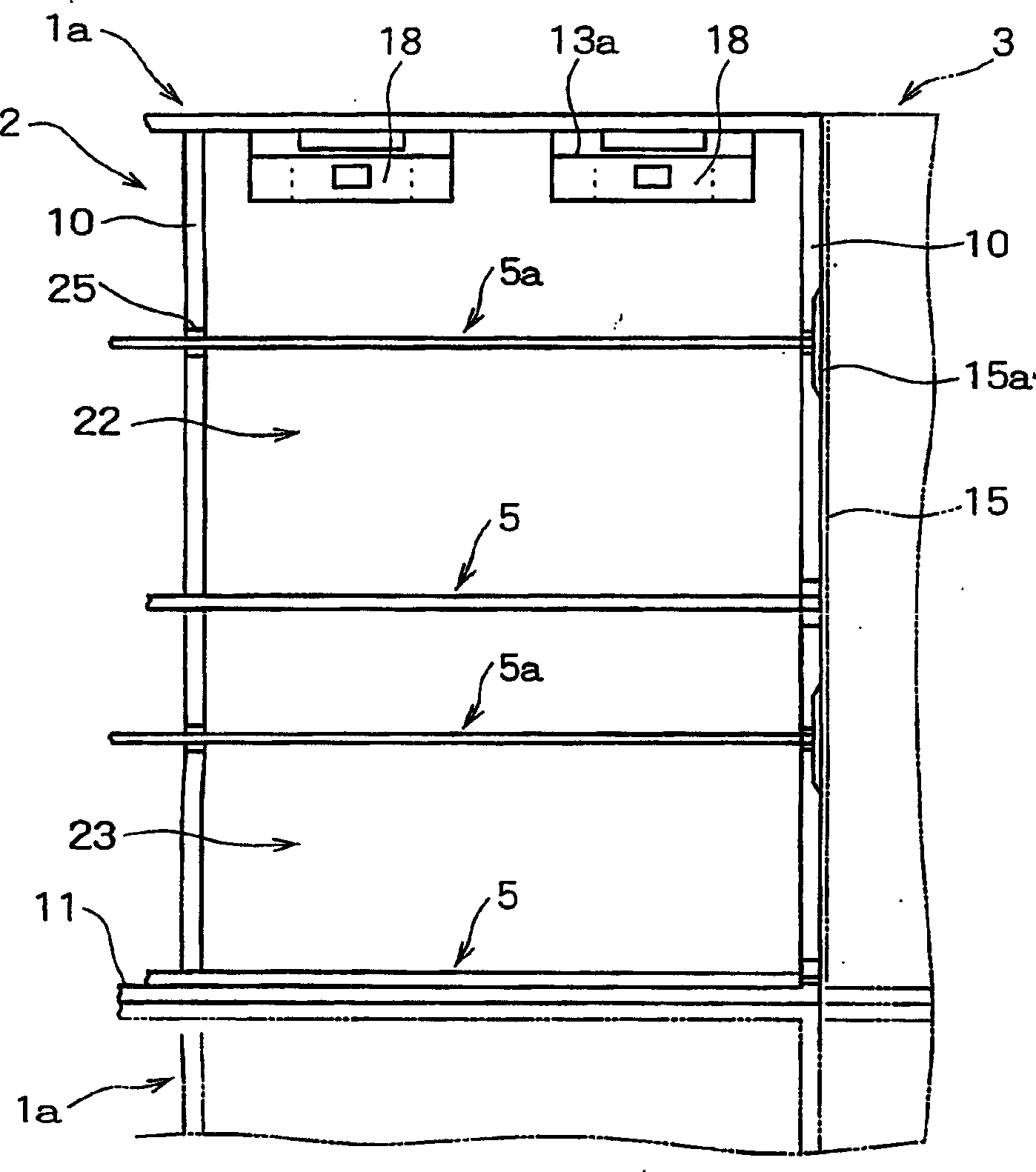

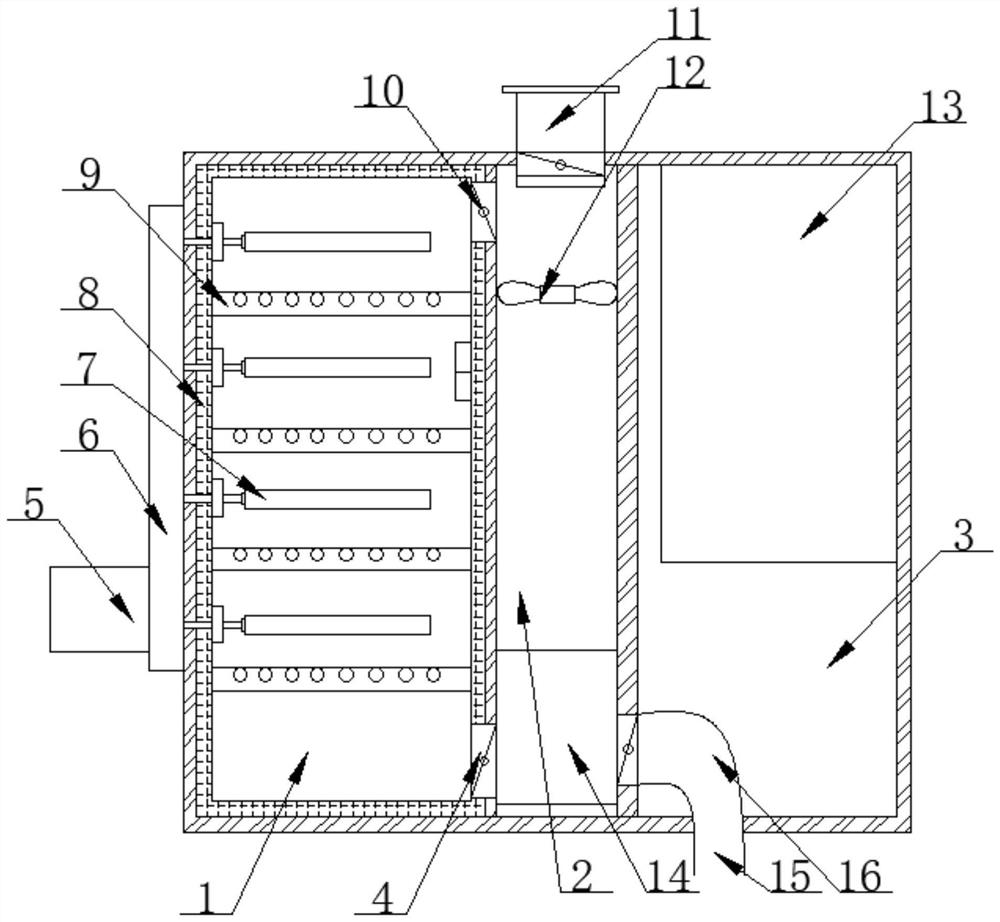

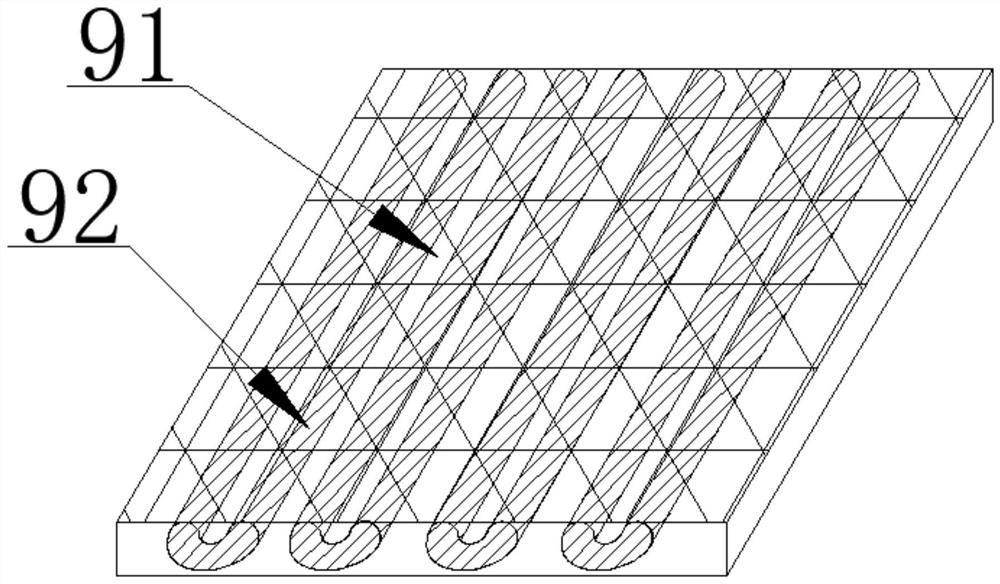

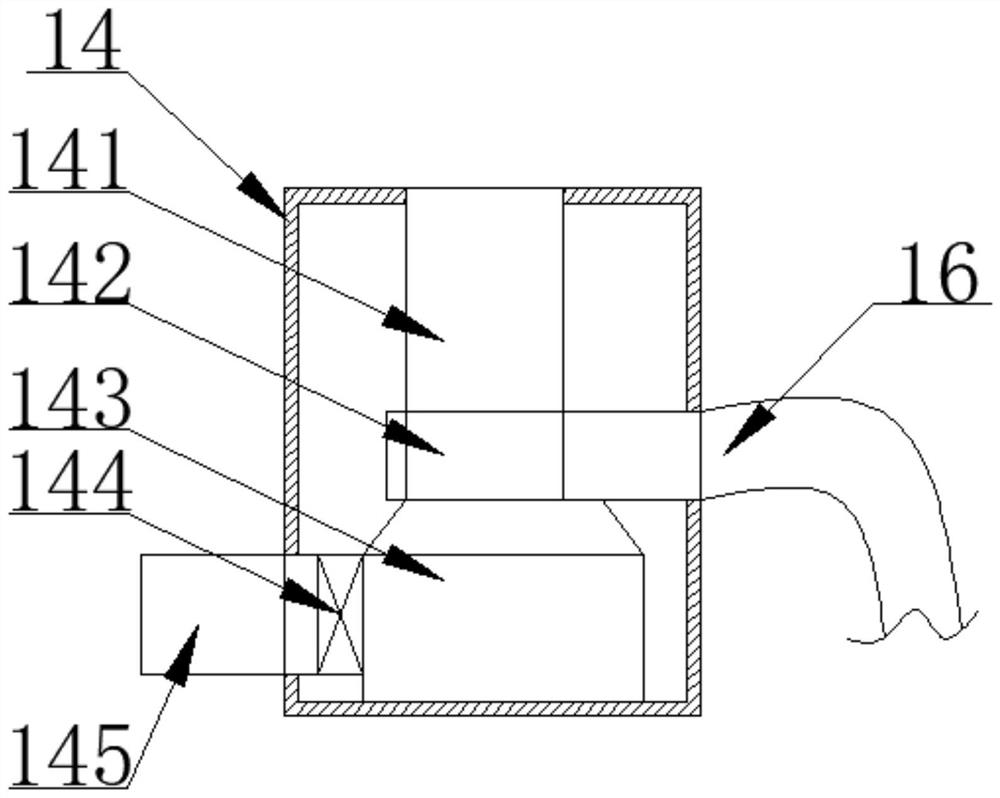

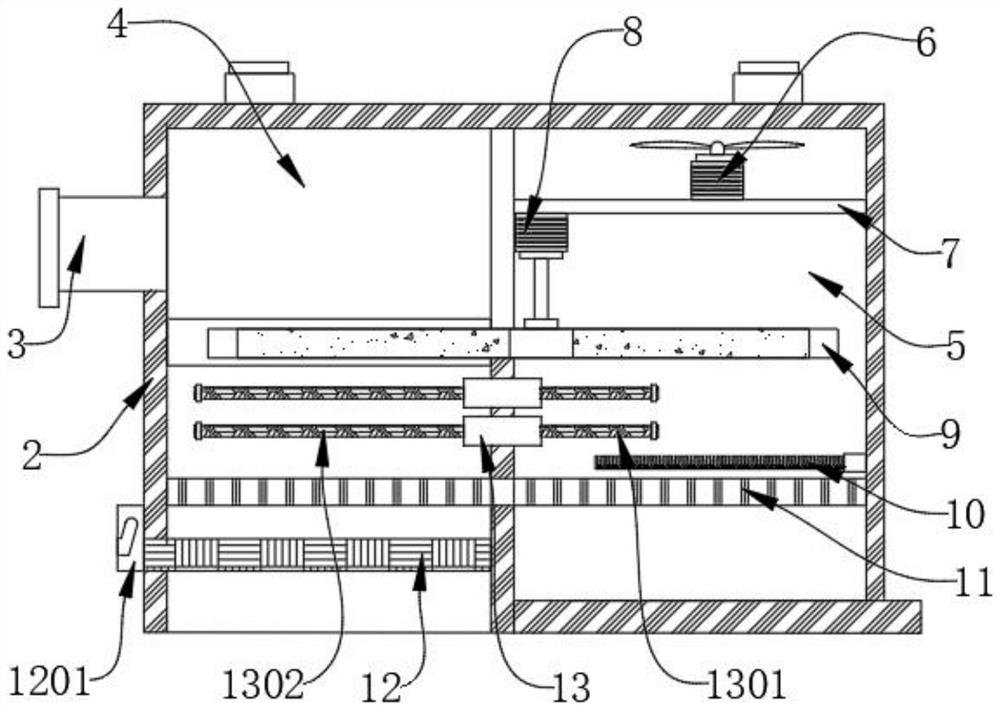

Drying device

InactiveCN1617684ATableware washing/rinsing machine detailsDrying gas arrangementsEngineeringLower body

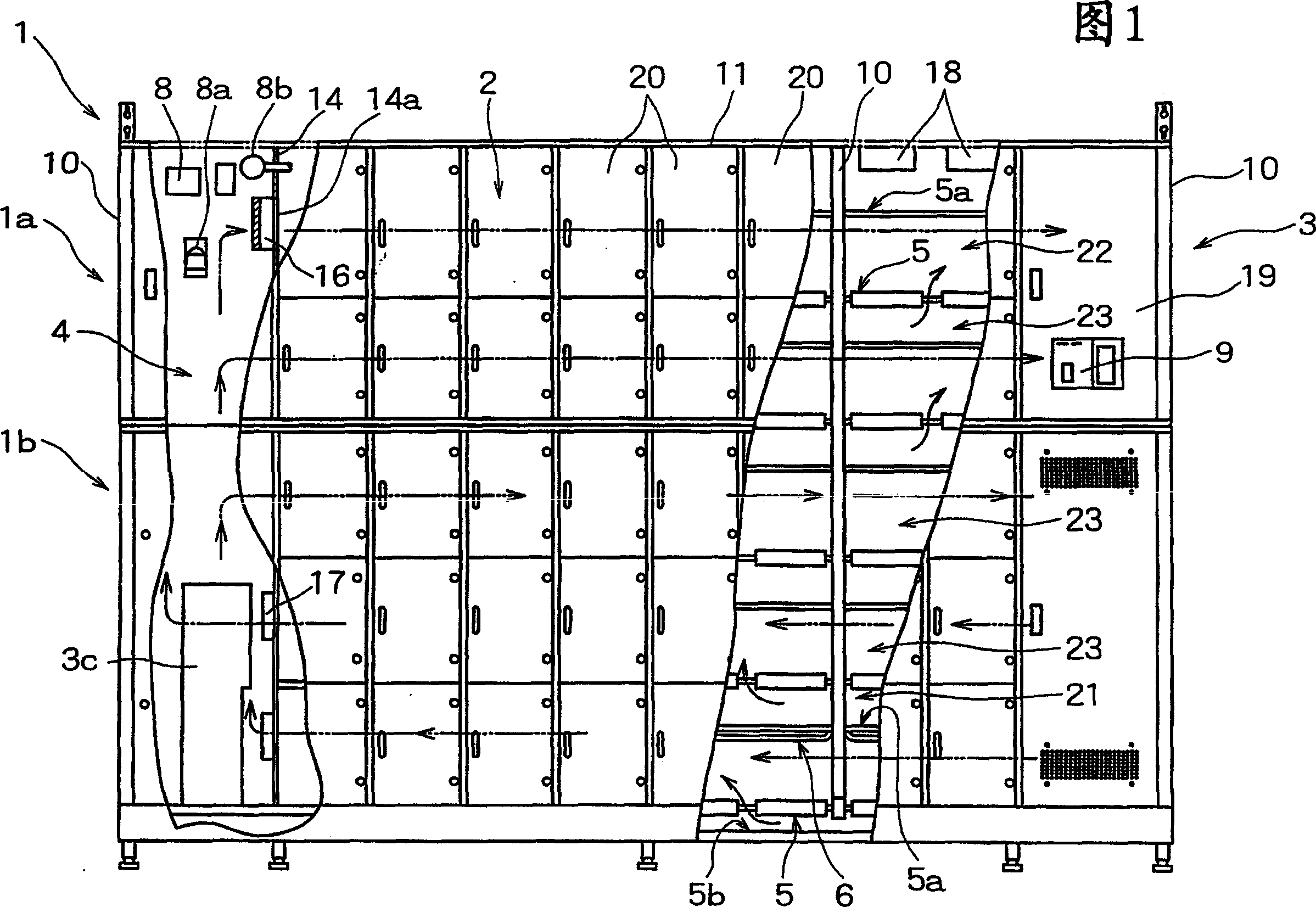

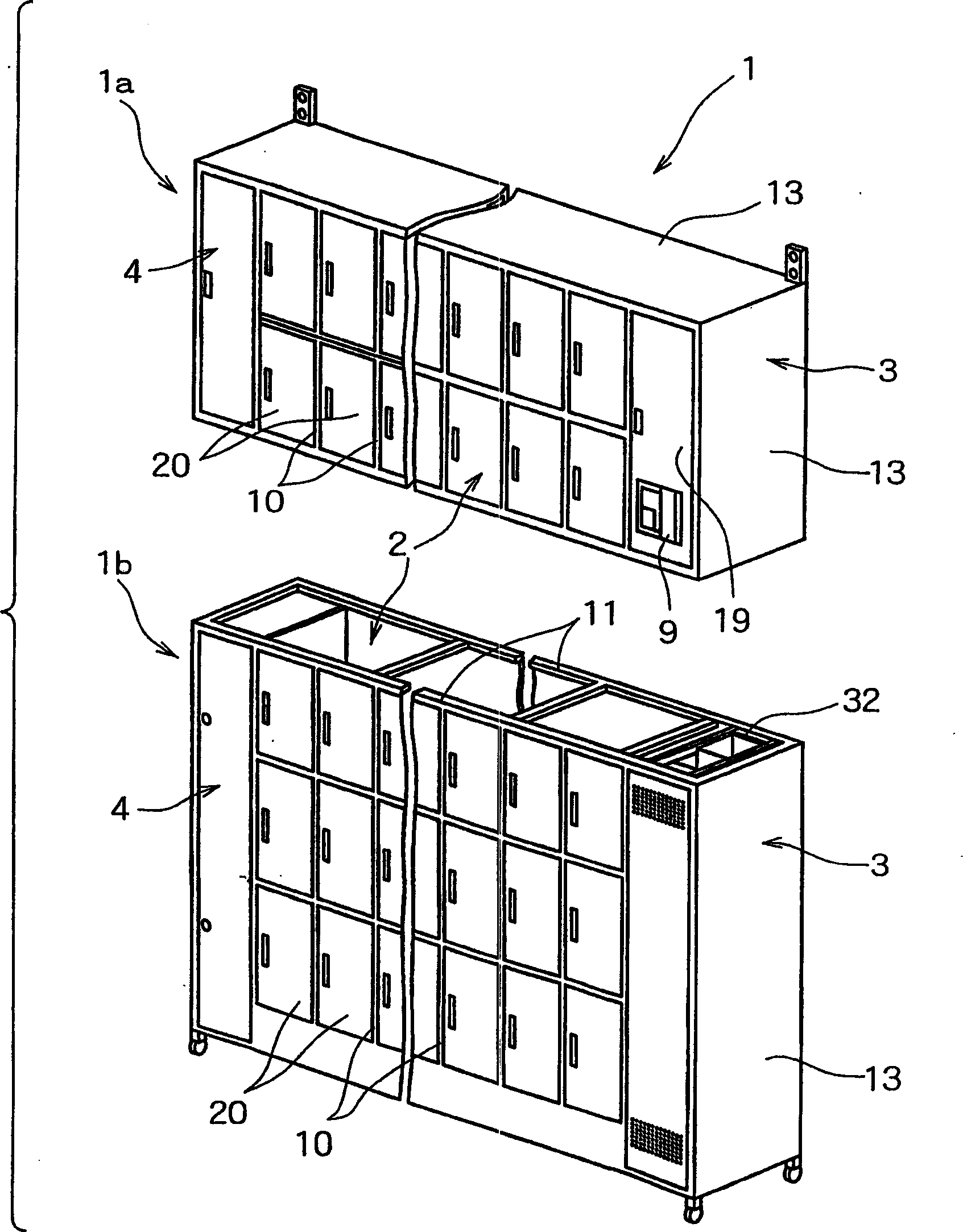

The present invention is a drying device (1) having a storage part (2), an air blowing part (3) and a heating part (3b). The above-mentioned storage part (2) forms the drying chamber that can be taken out to store the dried object into multiple layers; the above-mentioned air supply part (3) sends the air in the above-mentioned storage part (2) laterally from one side to the other side to make it Circulation: the aforementioned heating part (3b) heats the air circulating in the storage part (2). Above-mentioned blowing part (3) is formed the blowing chamber (30) of hollow up and down direction; In this blowing chamber (30) simultaneously, be set to be used for forming the air that heating part (3b) is heated and dry from either side up and down. The chamber side is sent to the blower (7) of the independent tubular air path (71) of the drying chamber on the other side. A heating unit (3b) is provided inside the blower tube (7), and a blower fan (32) is provided on the upstream side of the blower tube (7). The accommodating part (2) and the blower part (3) are divided and formed on the side of the upper body (1a) and the side of the lower body (1b).

Owner:KAISANBUTSUNO KIMURAYAKK

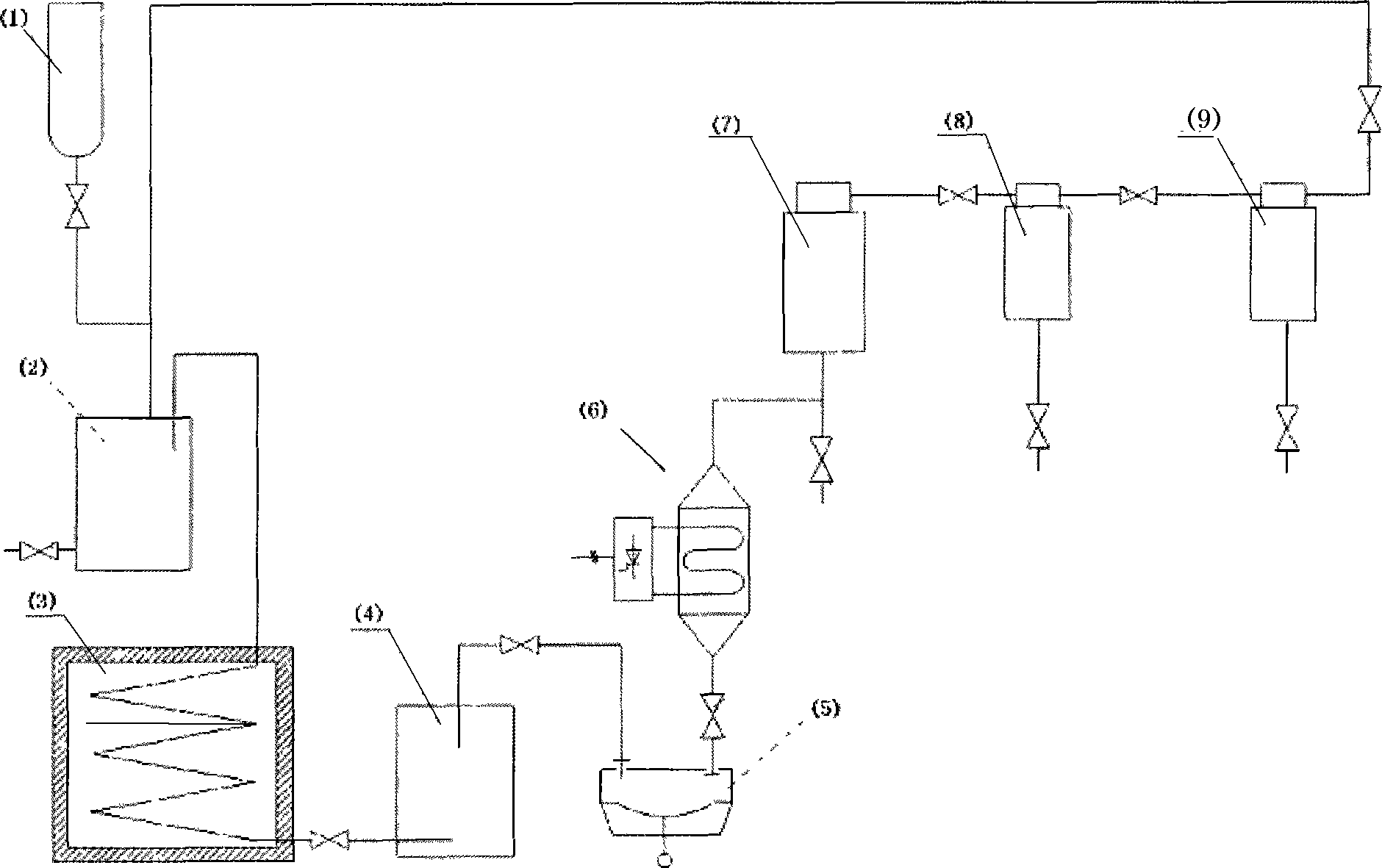

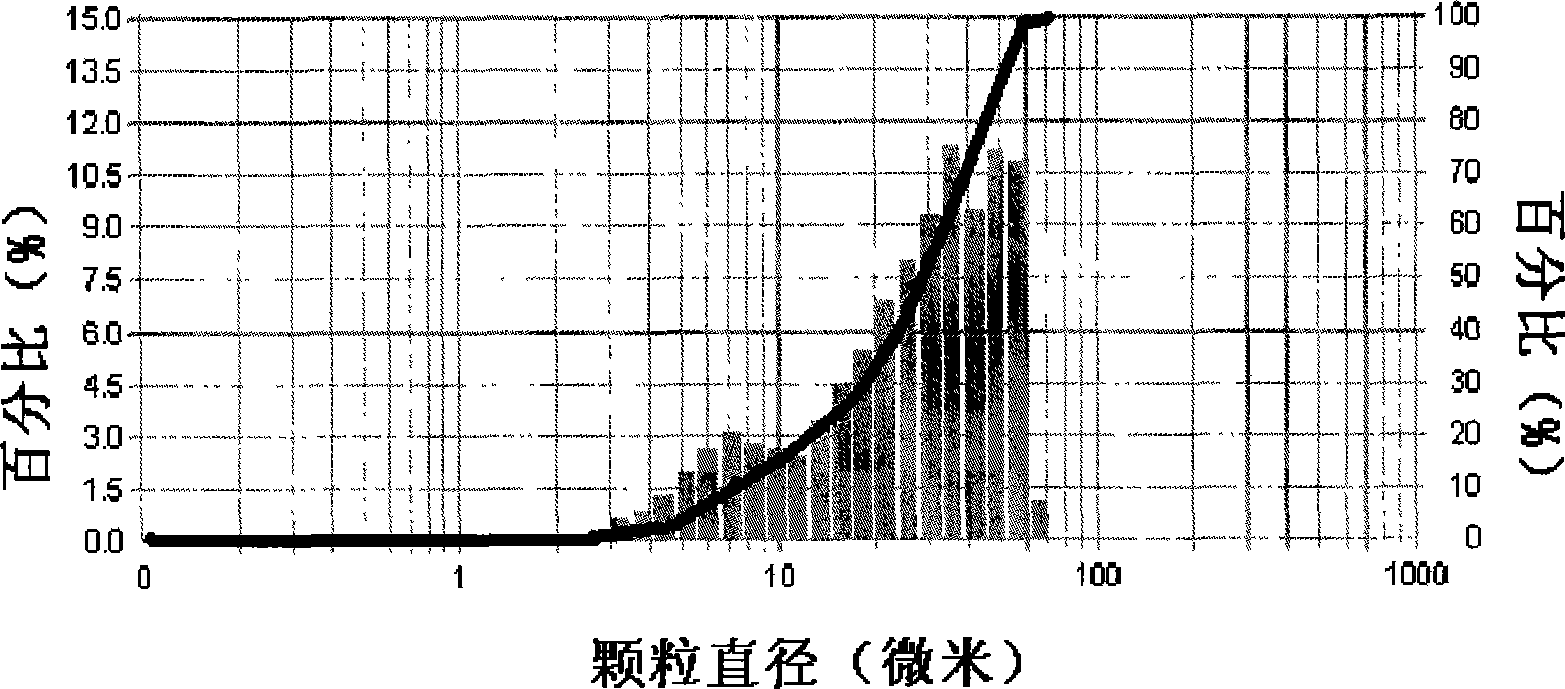

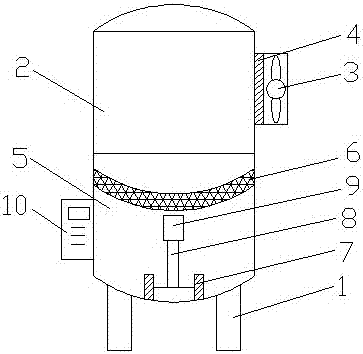

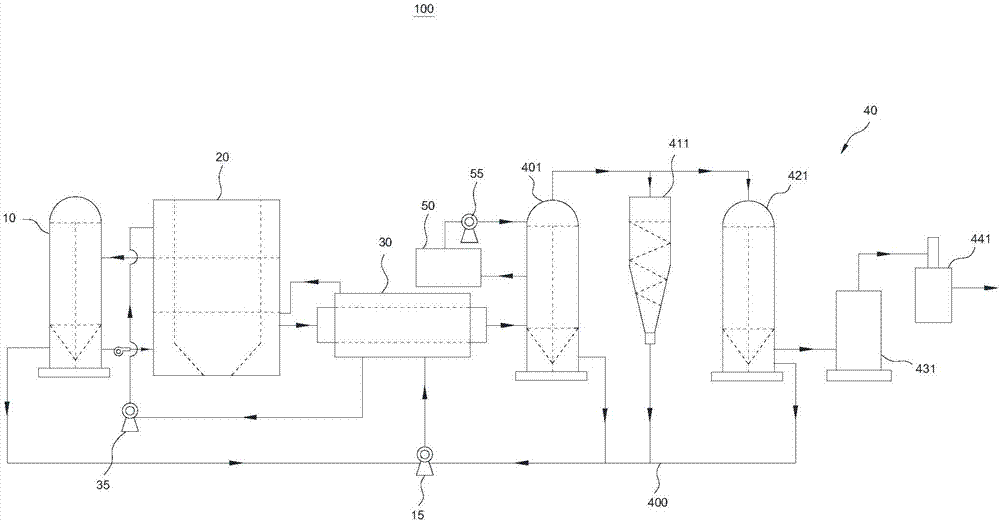

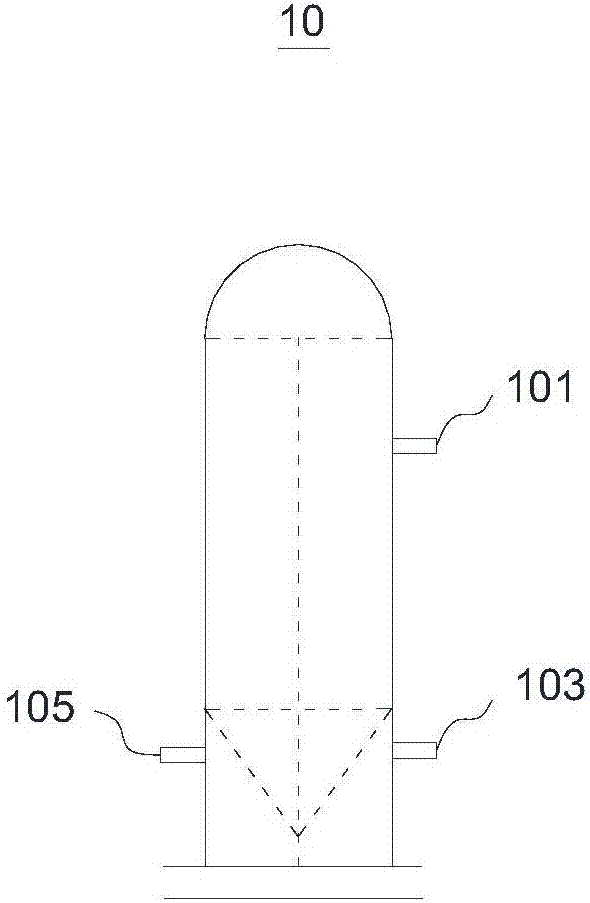

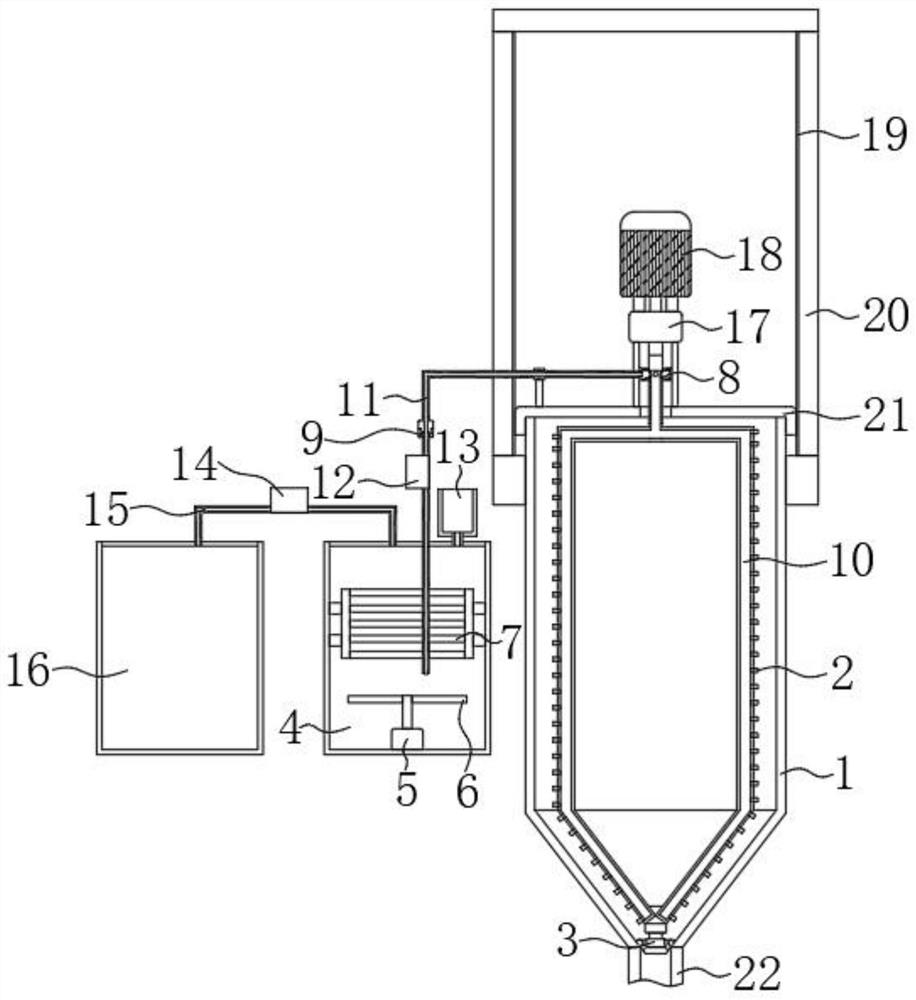

Method for preparing ginkgo leaf extract powder using supercritical liquid desiccation and device thereof

InactiveCN101433562AEliminate the disadvantages of destructionAvoid the problem of channel collapseDrying solid materials without heatPharmaceutical product form changeGinkgo bilobaBottle

The invention discloses a method for preparing ginkgo leaf extract powder by drying supercritical fluid and a device thereof. The method comprises the following steps: placing alcoholic solution of ginkgo leaf extract without impurity into a sealed dry chamber cylinder body, and then introducing carbon dioxide into the solution at a flow speed of 20 to 45 liters per hour, wherein temperature of the carbon dioxide is between 0 and 5 DEG C; controlling pressure of the dry chamber cylinder body at 10 to 30MPa and temperature of between 35 and 75 DEG C; and after the carbon dioxide becomes stable supercritical fluid, continuously displacing and drying the fluid for 4 to 8 hours to finally obtain light-yellow dry finished powder of the ginkgo leaf extract. The device comprises a carbon dioxide steel bottle, a gas-liquid separation container, a gas cooling unit, a transition container, a carbon dioxide transfer pump, a heater, the dry chamber cylinder body, a first-stage separation cylinder body, a second-stage separation cylinder body, valves and pipelines, and the components are mutually connected through the valves and the pipelines. The content of flavone in obtained power is more than 25 weight percent, the alcoholic solution in the extract can be reclaimed, and the carbon dioxide can also be recycled.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

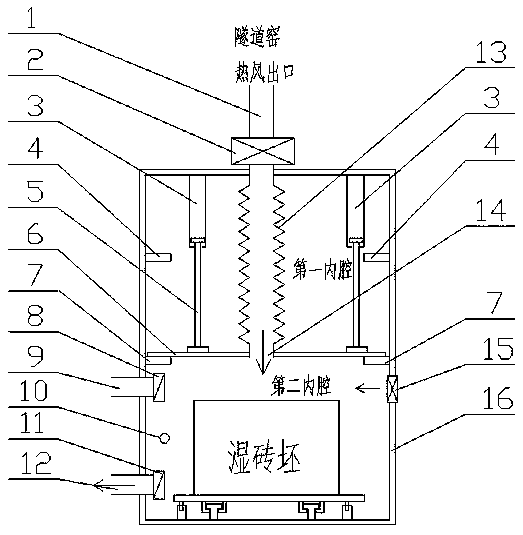

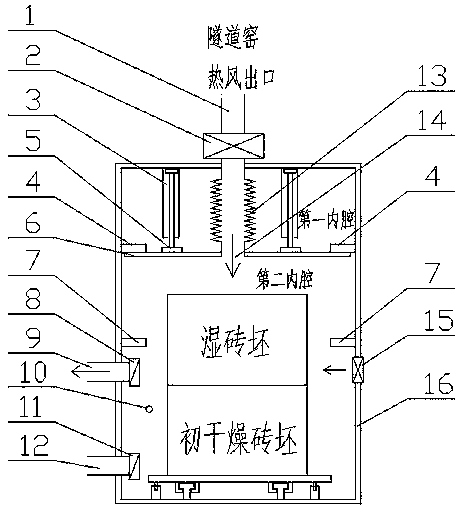

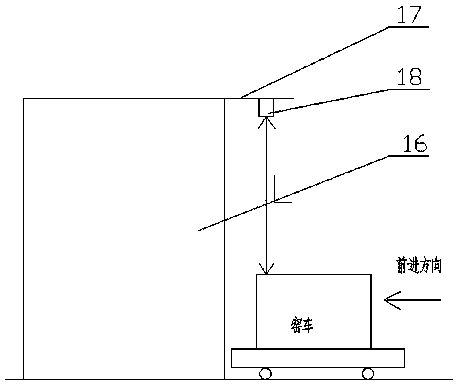

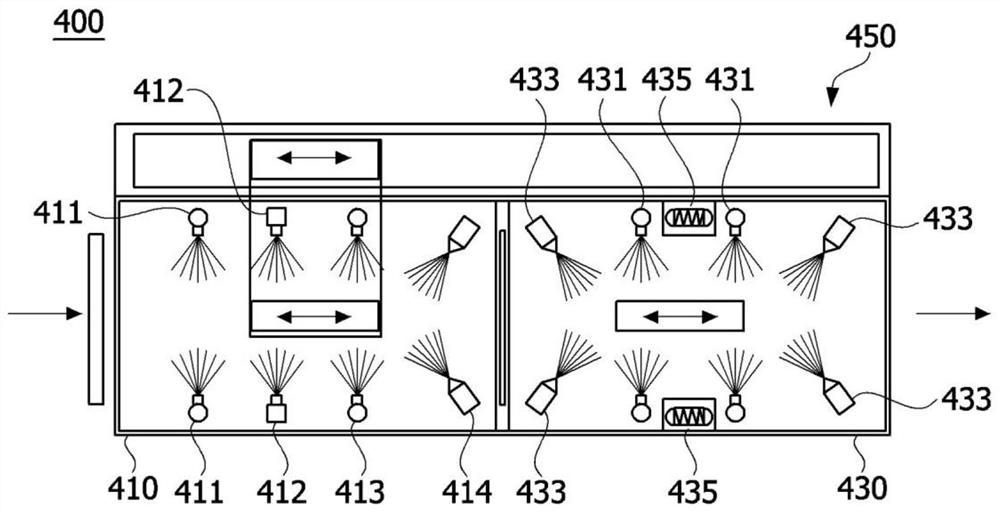

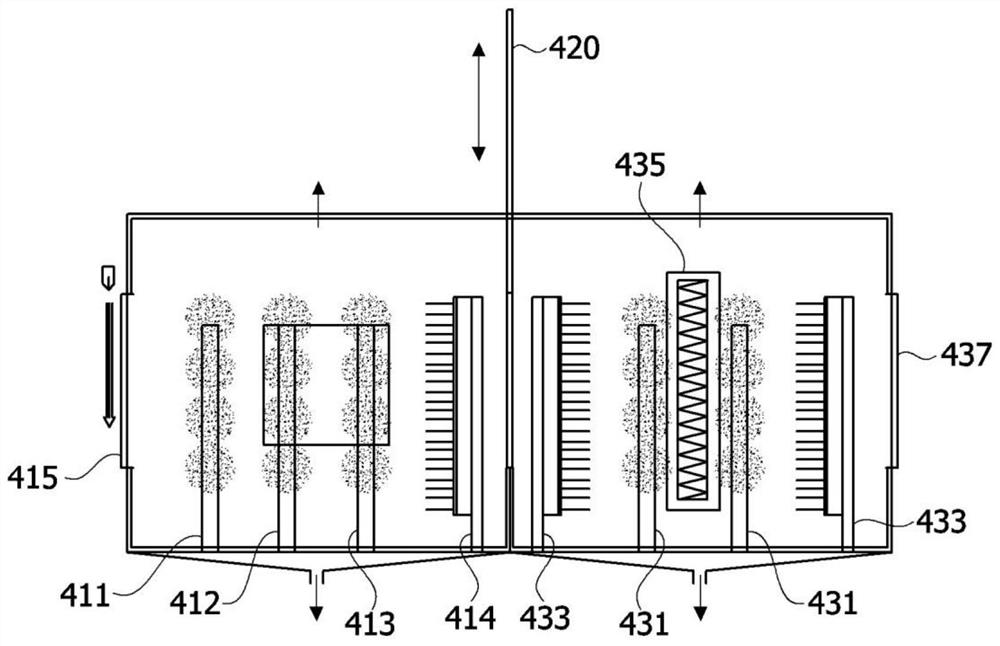

Multifunctional tunnel kiln type drying device and process by utilizing same for repeatedly drying and palletizing burning to manufacture sintered bricks

InactiveCN109539748AImprove heat utilizationImprove moisture removal effectDrying gas arrangementsDrying machines with progressive movementsTunnel kilnBrick

The invention provides a multifunctional tunnel kiln type drying device. The device comprises a drying chamber (16), a first air supply pipeline (1), a first air blower (2), a second exhaust fan (11)and a second moisture removal pipeline (12); the multifunctional tunnel kiln type drying device is further characterized by comprising a first exhaust fan (8), a first moisture removal pipeline (9), atelescopic air pipe (13), a movable partition plate (6) with a first opening (14) and an air cylinder (3), wherein an air inlet of the telescopic air pipe (13) communicates with an air outlet of thefirst air supply pipeline (1), an air outlet of the telescopic air pipe (13) communicates with the first opening (14) of the movable partition plate (6), the air cylinder (3) comprises a piston rod (5), one end of the piston rod (5) is fixedly connected with the movable partition plate (6) and is used for driving the movable partition plate to move up and down. According to the device, the structure is simple, wet blank bricks with different heights can be uniformly dried, and the yield of sintered bricks is effectively improved.

Owner:吴祥初

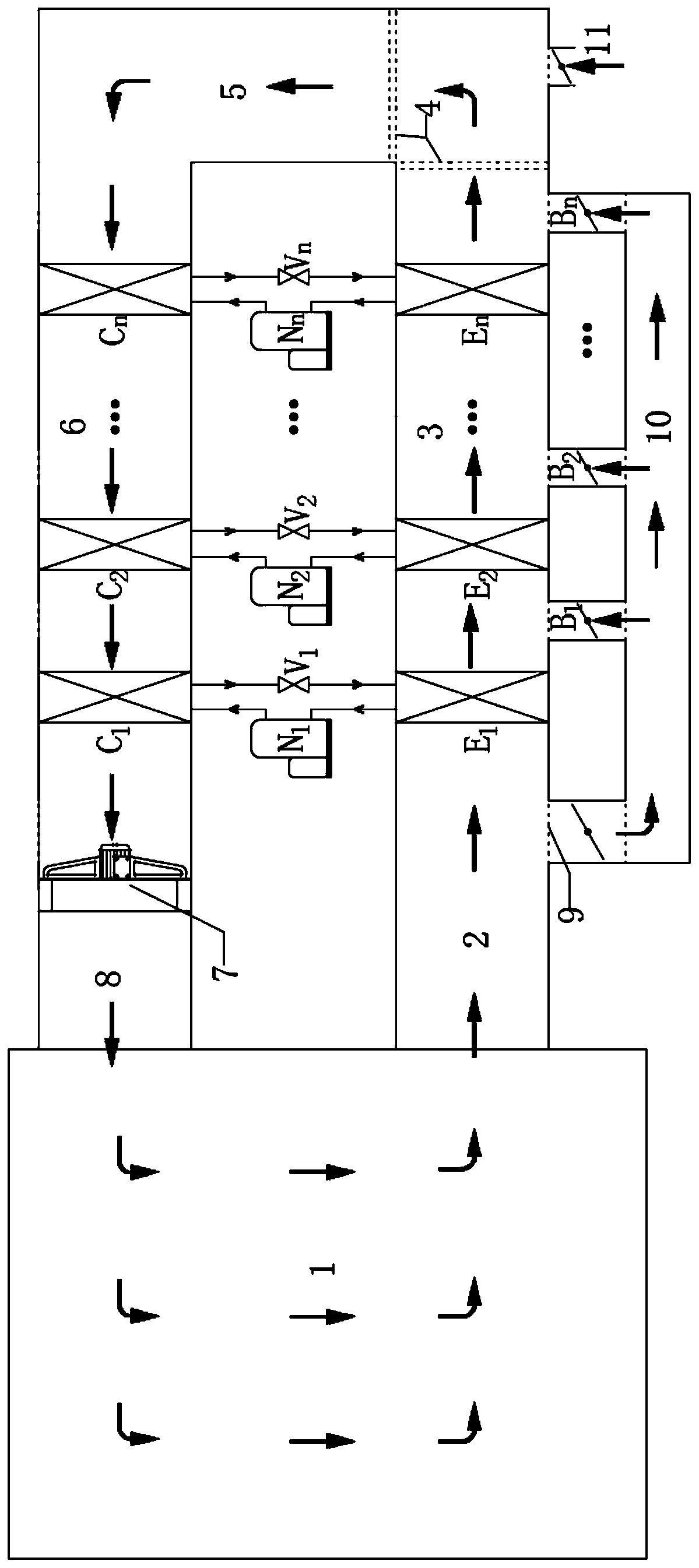

A multi-stage heat pump drying and dehumidification system with bypass pipeline

ActiveCN107642925BGuaranteed uptimeMeet drying requirementsMechanical apparatusDrying gas arrangementsAgricultural scienceAir volume

The invention belongs to the technical field of hot air drying of agricultural and sideline products, and discloses a multi-stage heat pump drying and dehumidification system with a bypass pipeline, comprising: a control unit, a main air duct and a drying room for placing materials to be dried, the drying room An air supply port for introducing gas and an air exhaust port for exhausting gas are provided; the two ends of the main air duct are respectively connected with the air supply port and the air exhaust port, and the main air duct is provided with a main fan and an air exhaust port. A dehumidification chamber, a water baffle, and a heating chamber are arranged in sequence along the airflow direction; it also includes a multi-stage heat pump unit and a bypass pipeline connected with the dehumidification chamber to realize multi-stage heating and multi-stage dehumidification. Compared with the single-stage heat pump drying system, the pressure ratio of the compressor is reduced, and the efficiency of the compressor is improved, and the air volume control based on the bypass pipeline can effectively adjust the dehumidification performance of the system, so that the system has a larger adjustment range.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

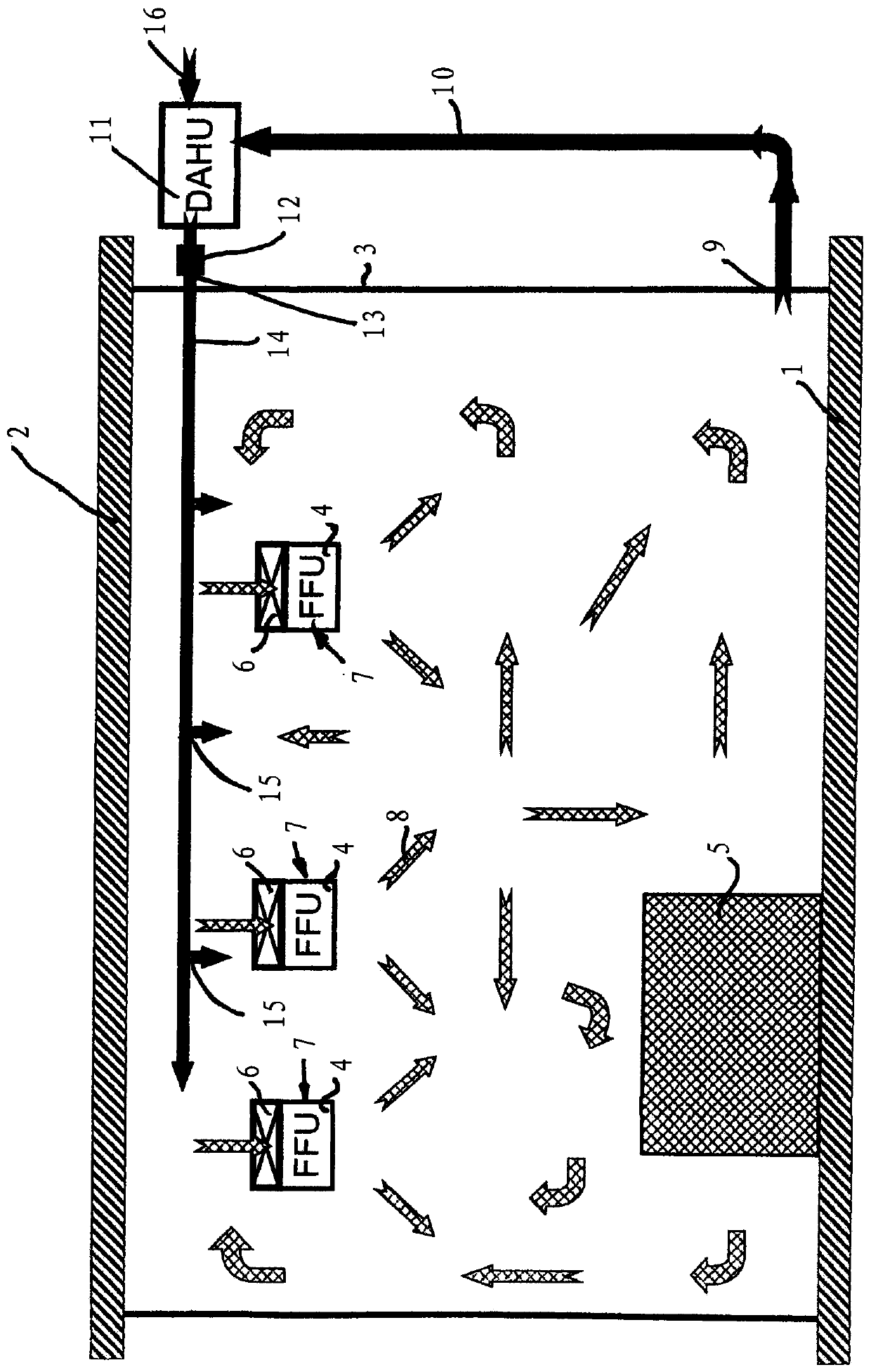

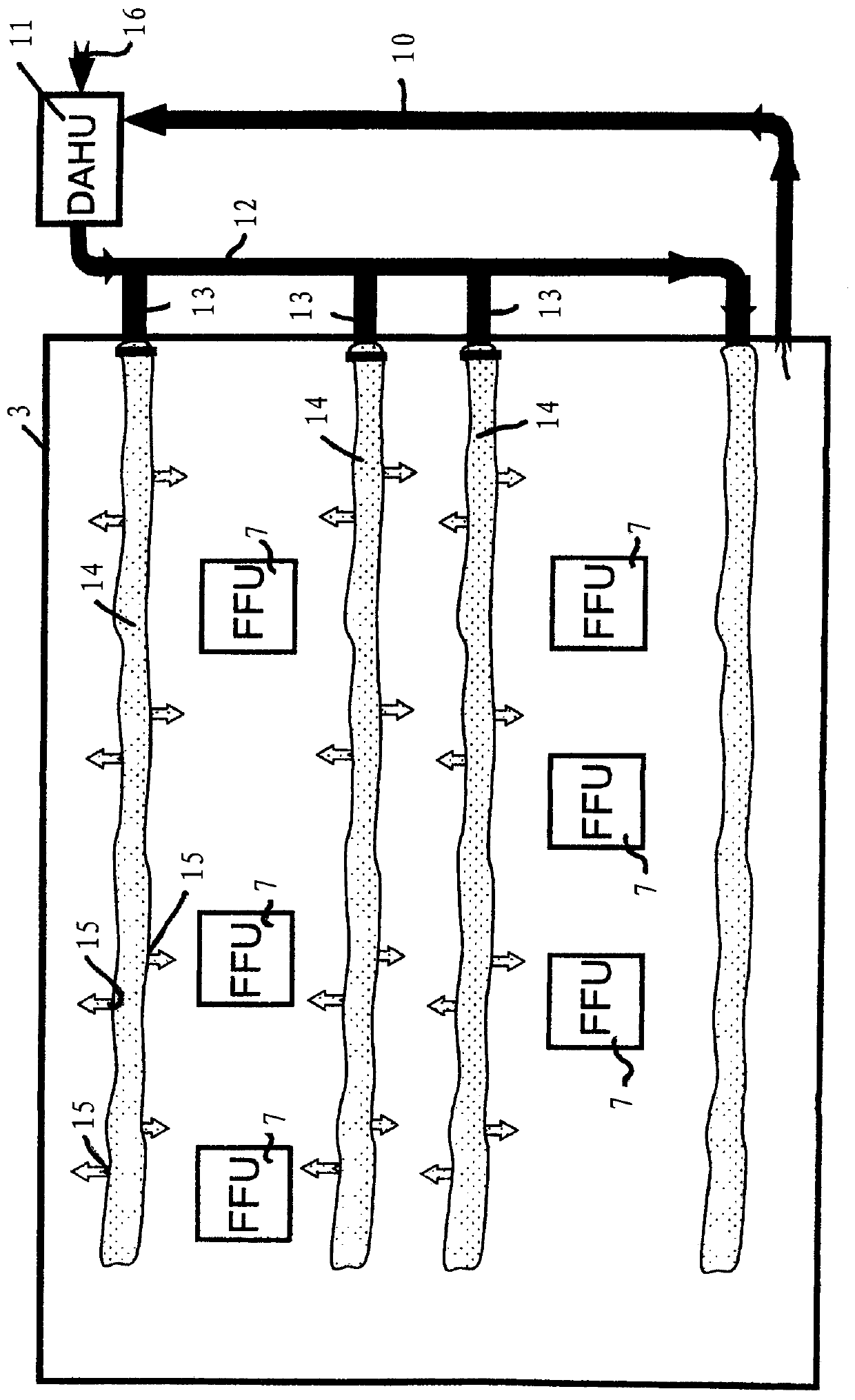

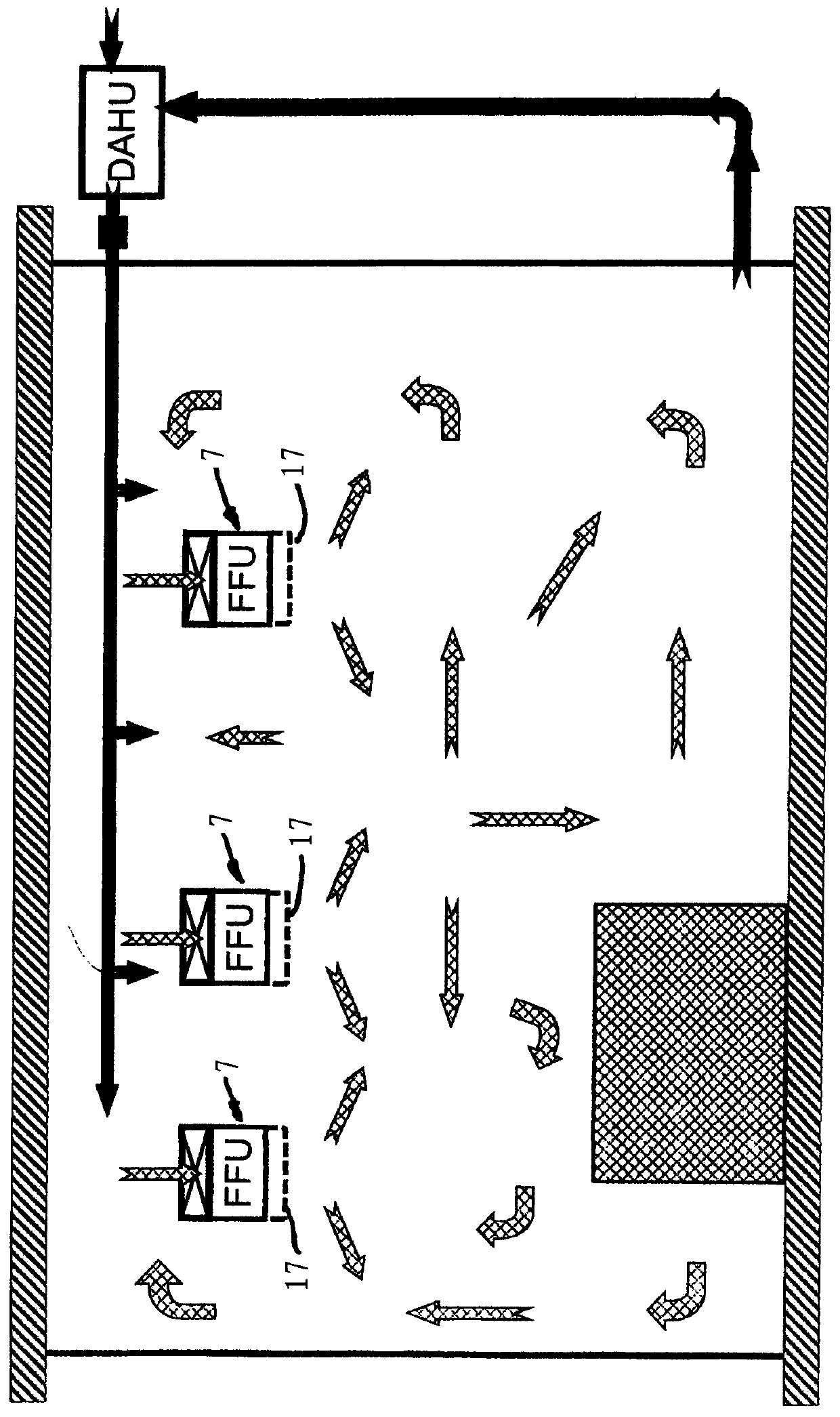

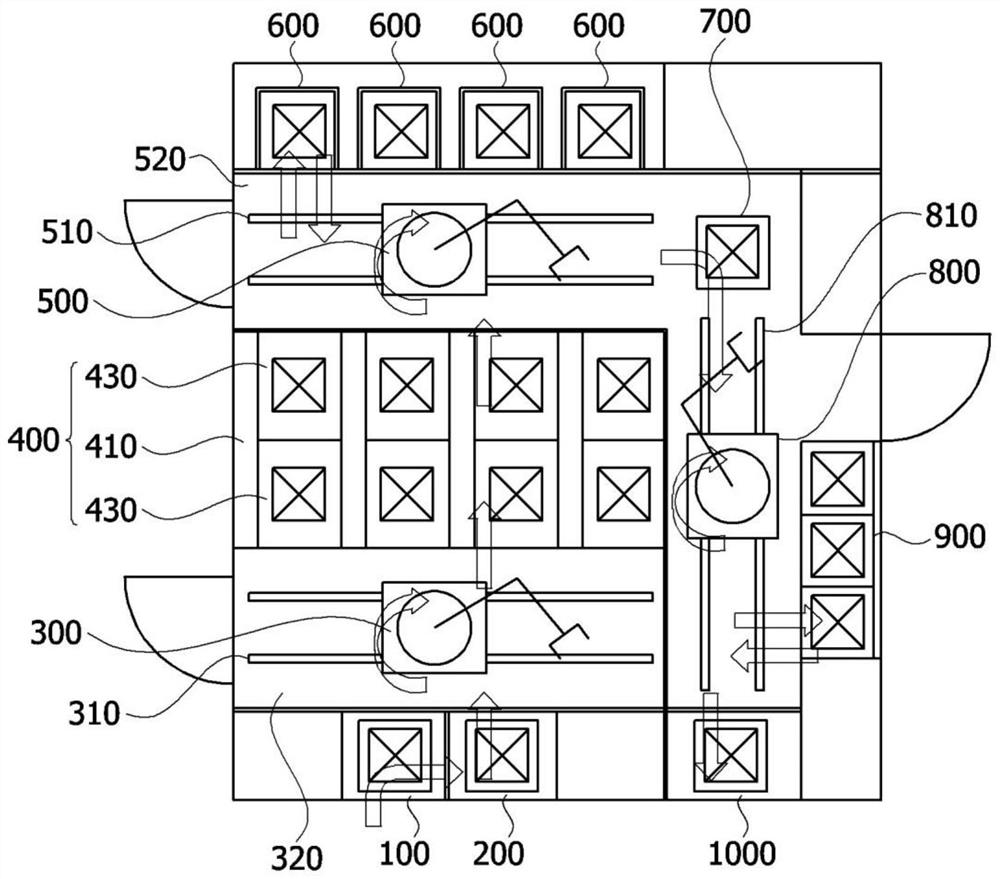

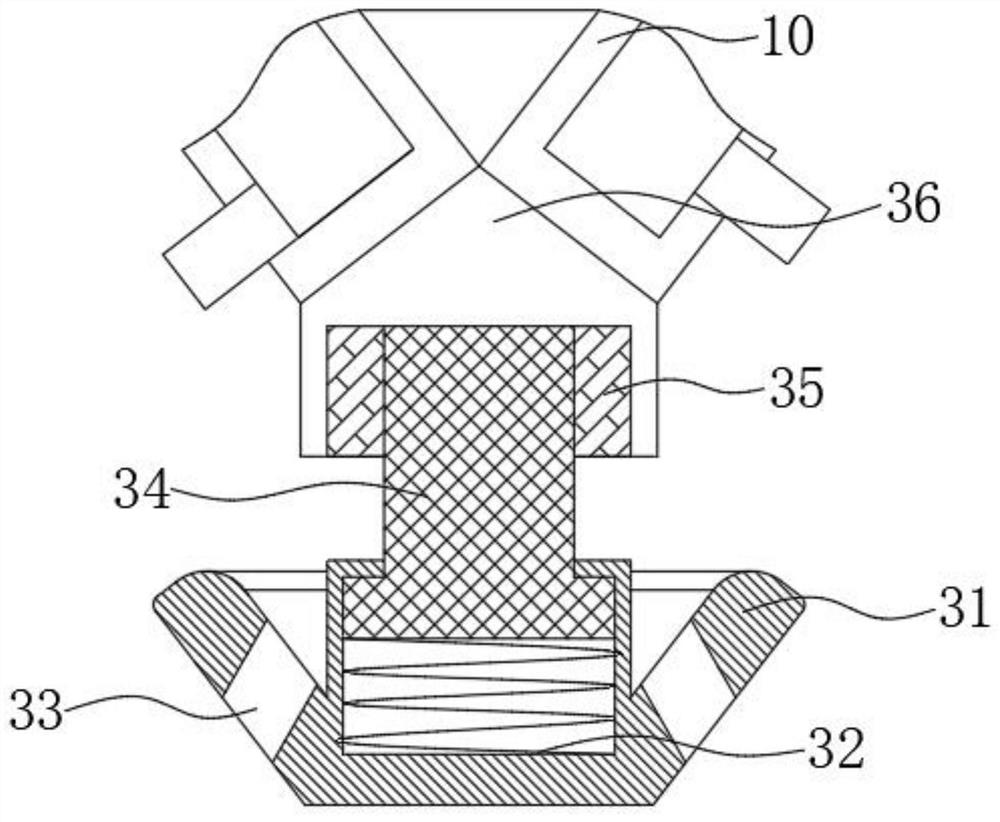

Drying chamber

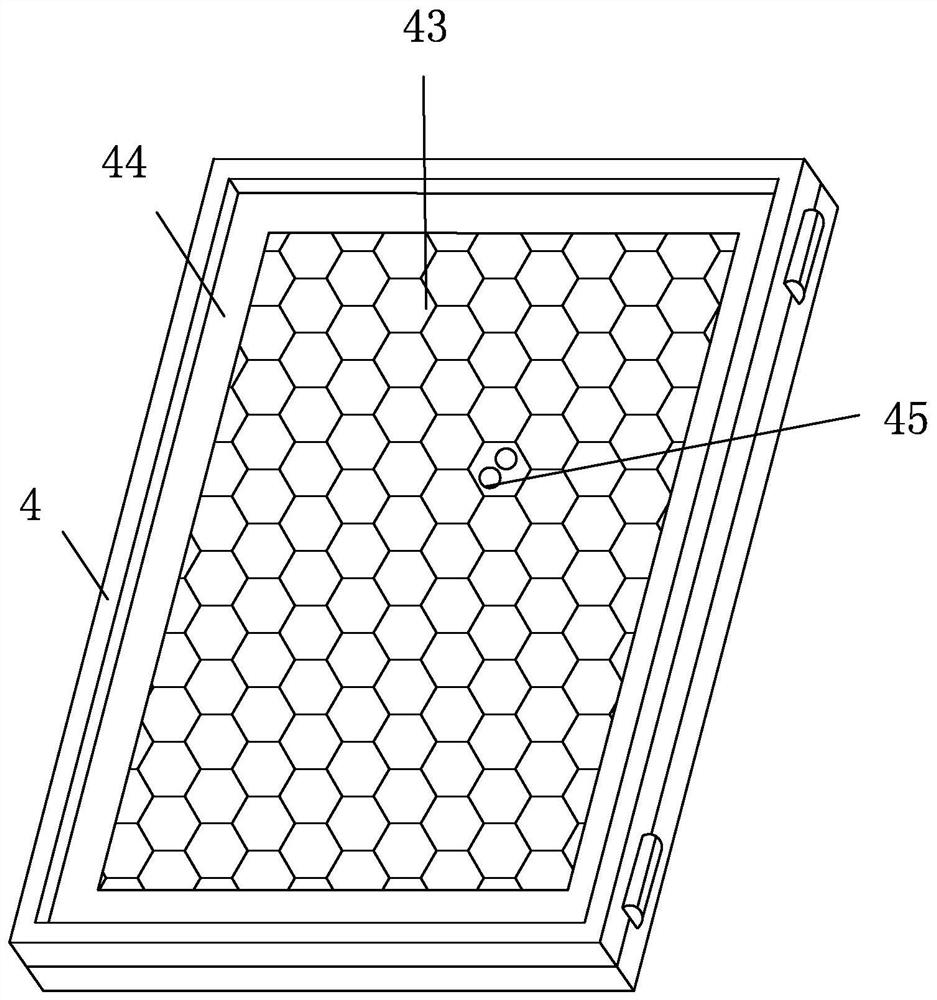

InactiveCN110402363ASimple costLow costMechanical apparatusDrying solid materials with heatCooling UnitsEngineering

The invention relates to a drying chamber comprising an air-conveying device which has at least one fan. The drying chamber also comprises a cooling device for the conveyed air. The air-conveying device is formed by individual air-conveying units (4), and the cooling device is formed by individual coolers (6). The air-conveying units (4) and the coolers (6) are combined to form autonomous air-conveyors / cooling units (7) respectively.

Owner:M加W集团有限公司

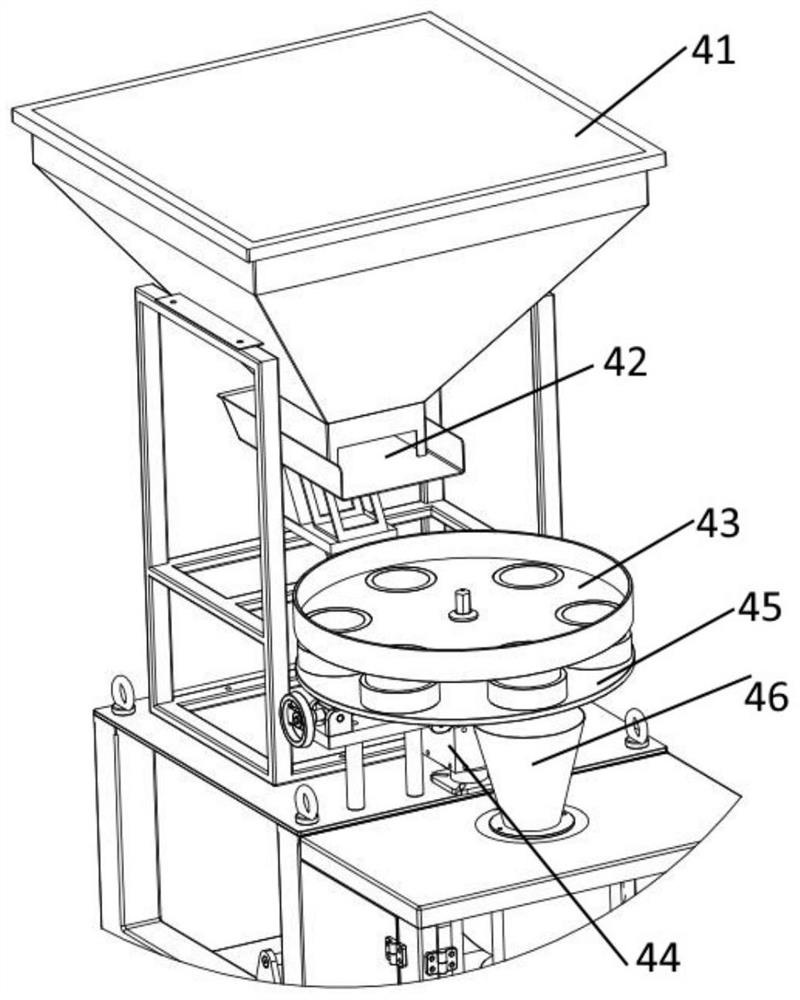

Cereal drying machine with deinsectization function

The invention discloses a cereal drying machine with a deinsectization function. The cereal drying machine comprises a machine body, wherein a drying chamber is formed in the upper end of the machinebody, an air inlet is formed in one side of the drying chamber, an air heater is arranged at the air inlet, a deinsectization chamber is formed in the lower end of the machine body, the deinsectization chamber communicates with the drying chamber up and down, a sieve is horizontally arranged in the deinsectization chamber, the middle of the sieve is sunk downwards, an air cylinder is arranged in the middle of the bottom end of the deinsectization chamber, a piston rod is vertically guided upwards from the air cylinder, one end of the piston rod is connected to the output end of the air cylinder, a hammer block is connected to the other end of the piston rod, the hammer block is arranged just below the sieve, a discharge opening is formed in the front end surface of the deinsectization chamber, and a cover door is hinged to the discharge opening. In the mode, injurious insects such as cadelle and the like which die in cereal during drying can be screened by the cereal drying machine byrepeatedly hammering the sieve.

Owner:WUXI SHANGDE DRYING EQUIP CO LTD

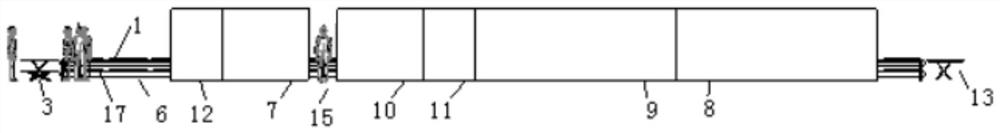

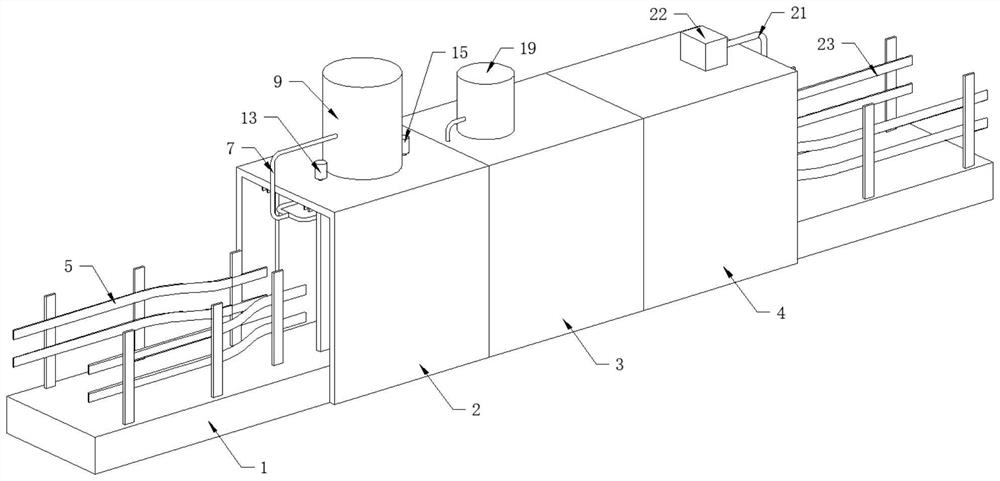

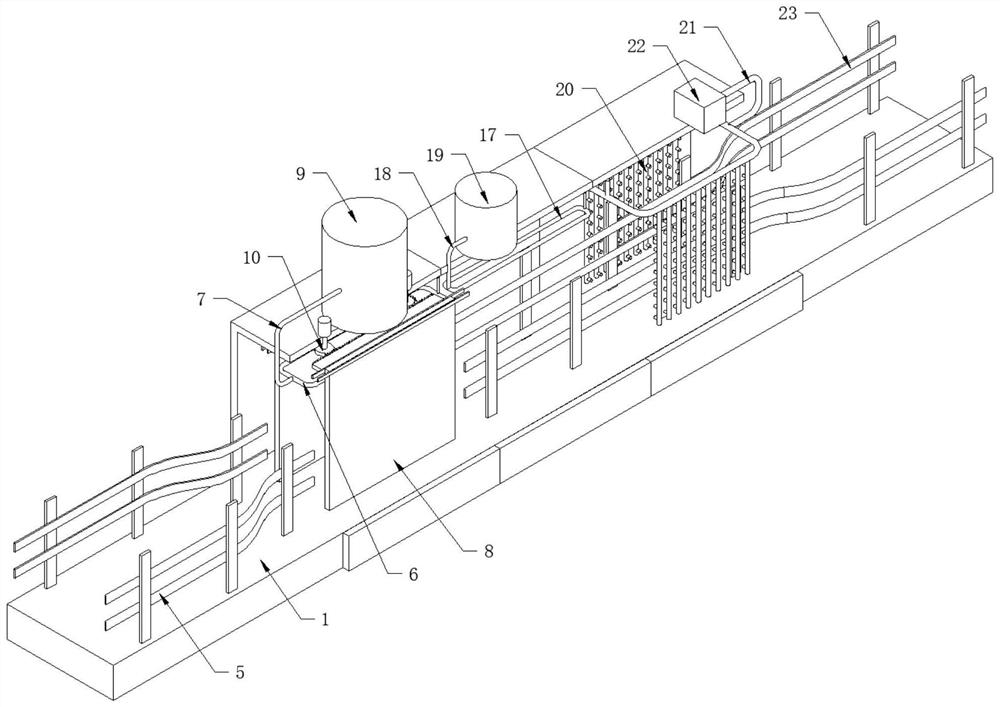

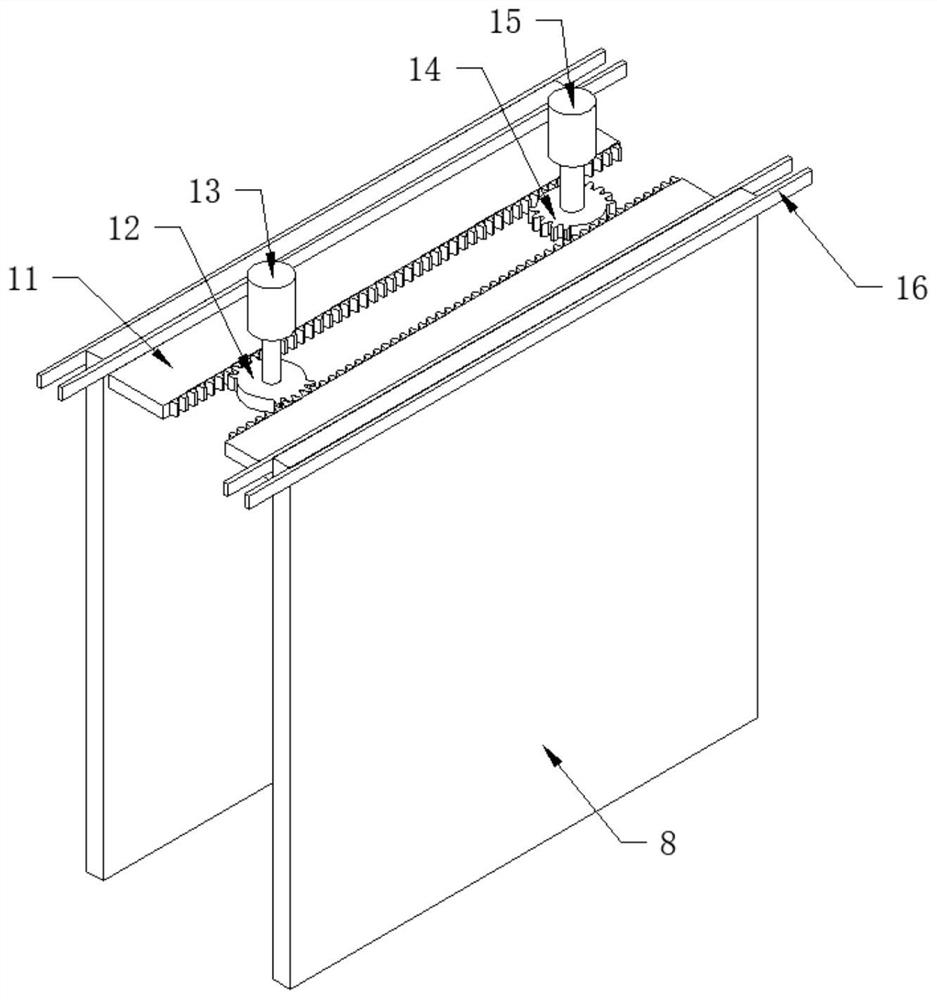

Fire hose cleaning equipment with winding device and cleaning method

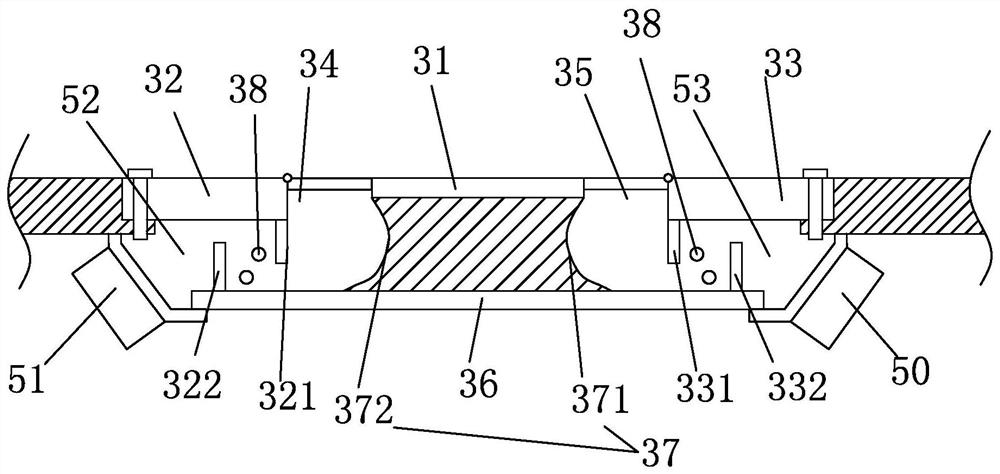

InactiveCN111921148AWash thoroughlyWhen cleaning and decontaminating, dry thoroughlyFire rescueWater rinsingSewage outfall

The invention discloses fire hose cleaning equipment with a winding device. The fire hose cleaning equipment comprises a drying decontamination chamber, an immersion cleaning chamber, a high-pressurewater flushing chamber, a drying chamber and a winding device body wherein a fire hose sequentially passes through the drying decontamination chamber, the immersion cleaning chamber, the high-pressurewater flushing chamber, the drying chamber and the winding device body, the drying decontamination device is arranged in an inner cavity of the drying decontamination chamber, a drain outlet is formed in the left side of the bottom of the drying decontamination chamber, a flushing device is arranged in an inner cavity of the high-pressure water flushing chamber, a water outlet is formed in the bottom of the high-pressure water flushing chamber, a drying device is arranged in an inner cavity of the drying chamber, the winding device body comprises a base, a winding driving motor is arranged onthe rear side wall of the base and connected with a limiting shaft through a third rotating shaft, the outer wall of the limiting shaft is movably sleeved with a fire hose shaft, and a movable limiting seat allowing the third rotating shaft to be inserted therein is movably arranged on the front side of the top of the base. According to the fire hose cleaning equipment, the fire hose can be driedand decontaminated, cleaning agent soaking can be conducted on the fire hose, the fire hose can be washed with high-pressure water for multiple times, the dirt removing effect is improved, drying andwinding are conducted at the same time, and the follow-up operation amount of personnel is reduced.

Owner:吴梅丽

Drying chamber air distribution structure capable of efficiently dehumidifying

ActiveCN105130157AReduce energy consumptionCloth design is simple and reasonableSludge treatment by de-watering/drying/thickeningAir volumeAir velocity

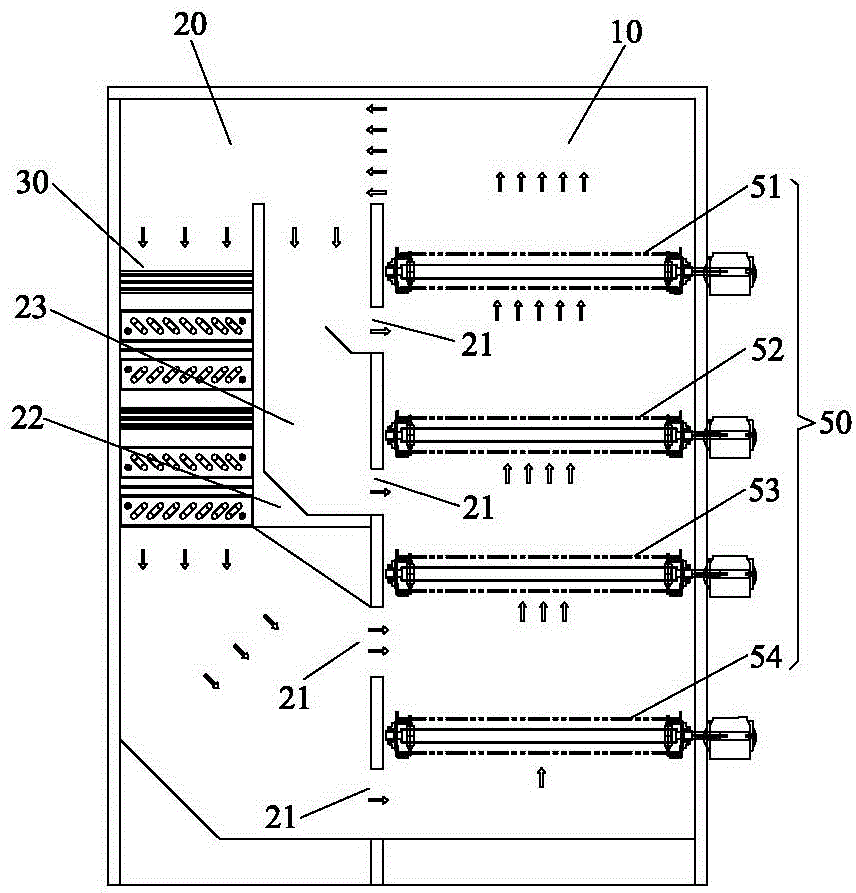

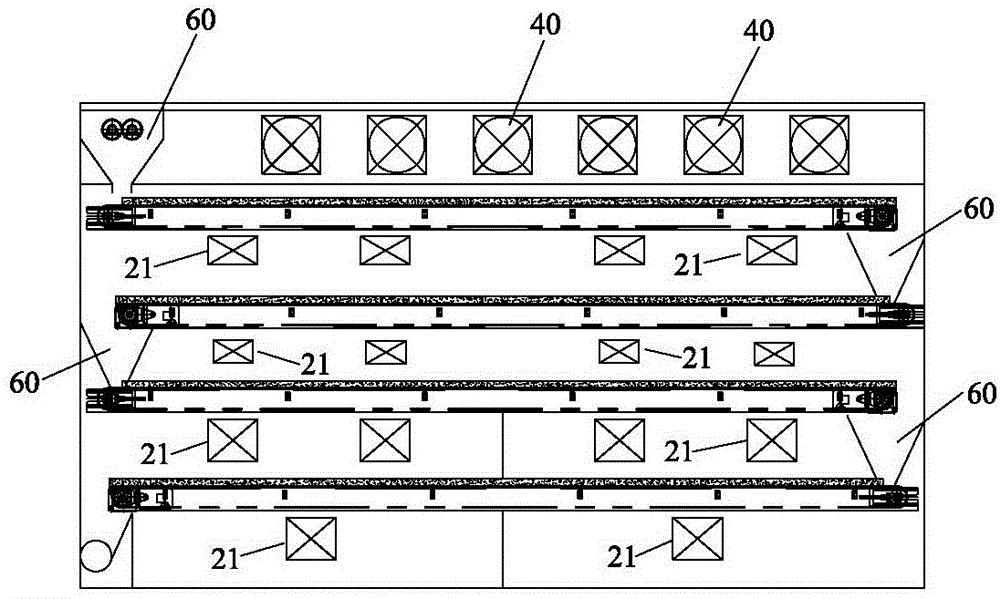

The invention discloses a drying chamber air distribution structure capable of efficiently dehumidifying, which comprises a first cavity, a second cavity, a heat pump, a circulation fan and a plurality of layers of net belts with meshes for conveying sludge; the first cavity is communicated with the space above the second cavity; the heat pump is arranged in the first cavity; the net belts are arranged in the second cavity; the circulation fan is arranged above the net belt at the top layer; vents aiming at all layers of net belts are formed in the side wall of the second cavity; an air guide plate extends on the side wall of the second cavity to the first cavity; an air flue communicated to the vent between two layers of net belts at the top is formed between the air guide plate and the side wall of the second cavity; one part of hot air generated by the heat pump returns back to the heat pump by the net belt at the top layer while the other part enters the vent between two layers of net belts at the top. Therefore, by adopting a hot air partition circulation mode, uniform distribution of air speed and air volume in the drying chamber is ensured, power consumption is reduced and the whole air distribution structure is simple, reasonable, energy-saving and efficient.

Owner:DONGGUAN DONGYUAN ENVIRONMENTAL TECH CO LTD

Drying air duct system of drying equipment

InactiveCN113007985AAvoid lostIncrease profitDrying gas arrangementsDrying chambers/containersCold airInsulation layer

The invention discloses a drying air duct system of drying equipment, and particularly relates to the field of the drying equipment. The drying air duct system comprises a drying chamber, a desiccation chamber and an evaporator chamber, wherein a drying chamber air inlet and a drying chamber air outlet are formed in one side of the drying chamber; a transmission box and a motor box are mounted on one side of the drying chamber; the inner wall of the drying chamber is lined with a thermal insulation layer; drying nets are mounted inside the drying chamber; an indoor unit and a dehumidifier are mounted inside the desiccation chamber; an air exhaust opening is formed in the top end of the desiccation chamber; and an outdoor unit and a fresh air duct are mounted inside the evaporator chamber. The drying air duct system of the drying equipment has the advantages of improving the heat exchange efficiency by virtue of a plate heat exchanger, reducing the temperature of high-temperature humid air by virtue of cooled external cold air, condensing the high-temperature humid air to recover moisture and increasing the temperature of the cold air at the same time to obtain dry cold air, eliminating the need for an additional cooling system for cooling the high-temperature humid air and the need for an additional heat source for heating the cold air, realizing self-heating, fully realizing comprehensive utilization of energy, and achieving the purposes of environmental protection and energy conservation.

Owner:常州市茂宏干燥设备有限公司

Tar gasification circulating device and gasification system

PendingCN107325841AHigh calorific valueGasification processes detailsCoking carbonaceous materialsTarProcess engineering

The invention relates to the technical field of solid fuel gasification and gasification collection utilization and provides a tar gasification circulating device. The device comprises a separator which is used for being connected with a gasification furnace, a tar gasification pipe and a filter device. A first liquid inlet, a first liquid outlet which is used for being communicated with a drying chamber of the gasification furnace and a second gas outlet which is used for being communicated with a gasification chamber of the gasification furnace are formed in a tar gasification channel, and a first flue gas outlet which is formed in a flue gas channel is connected with the filter device. Tar generated by the gasification furnace can be recycled into the gasification furnace, so that the tar is subjected to repeated splitting decomposition. The separator is provided with a first air inlet, a first air outlet and a first liquid drainage hole, the first air inlet is used for being communicated with the drying chamber and a pyrolysis chamber which are arranged in the gasification furnace, the first air outlet is used for being connected with the gasification chamber which is arranged in the gasification furnace, and the first liquid drainage hole is communicated with the first liquid inlet. Mixed gas generated in the gasification furnace is filtered and separated by the separator, the moisture in the mixed gas is removed, and the calorific value of the fuel gas can be increased.

Owner:湖南省环境保护科学研究院

Gas cooling device for vacuum drying box and vacuum drying box

ActiveCN112146360AExtended service lifeReduce pressureDrying solid materials without heatDrying gas arrangementsThermodynamicsEngineering

The invention discloses a gas cooling device for a vacuum drying box. The gas cooling device comprises a shell, and an expansion type cooling mechanism and a drying chamber which are communicated in sequence are arranged in the shell; and the shell is provided with an air inlet and an air outlet, the air inlet is in communication with the expansion type cooling mechanism, and the air outlet is incommunication with the drying chamber. The invention further discloses a vacuum drying box. The drying box comprises a box body, a working chamber arranged in the box body, a vacuum pump communicatedwith the working chamber and two gas cooling devices used for the vacuum drying box, and when the interior of the first gas cooling device is in the pressure reduction and temperature reduction stroke, the interior of the second gas cooling device is in an exhaust reset stroke, and the working states of the two gas cooling devices are alternately changed. According to the gas cooling device for the vacuum drying box, high-temperature and high-humidity gas can be prevented from directly acting on the vacuum pump, and the service life of the vacuum pump is prolonged.

Owner:CHENGDU INVATEU TEST EQUIP CO LTD

A pinch type glass cleaning machine and cleaning method thereof

ActiveCN108262323BSolve the problem of roller printingEasy to cleanDrying gas arrangementsFlexible article cleaningEngineeringWasher

A pinch-type glass cleaning machine includes a frame and an operating table. The frame is provided with a feed end, a high-pressure air cutting chamber, a first cleaning chamber, a second cleaning chamber, a deionized water cleaning chamber, a drying chamber and At the discharging end, the frame is also equipped with a transmission mechanism, which runs through the feed end and the discharging end of the frame; the transmission mechanism includes a pinching device for clamping and transmitting the glass, and the pinching device is on the left and right Rows are set up to form a conveying channel. The pinching device includes a slider, a support seat fixed on the slider and a conveyor wheel fixed on the support seat. The glass is clamped and drivingly connected between the left row of conveyor wheels and the right row of conveyor wheels. , the slider slides left and right and is connected to the upper surface of the rack. The pinch-type glass cleaning machine of the present invention uses a conveyor wheel to drive the glass, replacing the traditional roller-type transmission, solving the problem of glass contamination due to the dirt of the rollers during roller-type transmission, and improving the efficiency of the product during the cleaning process. Pass rate.

Owner:常州优和智能科技有限公司

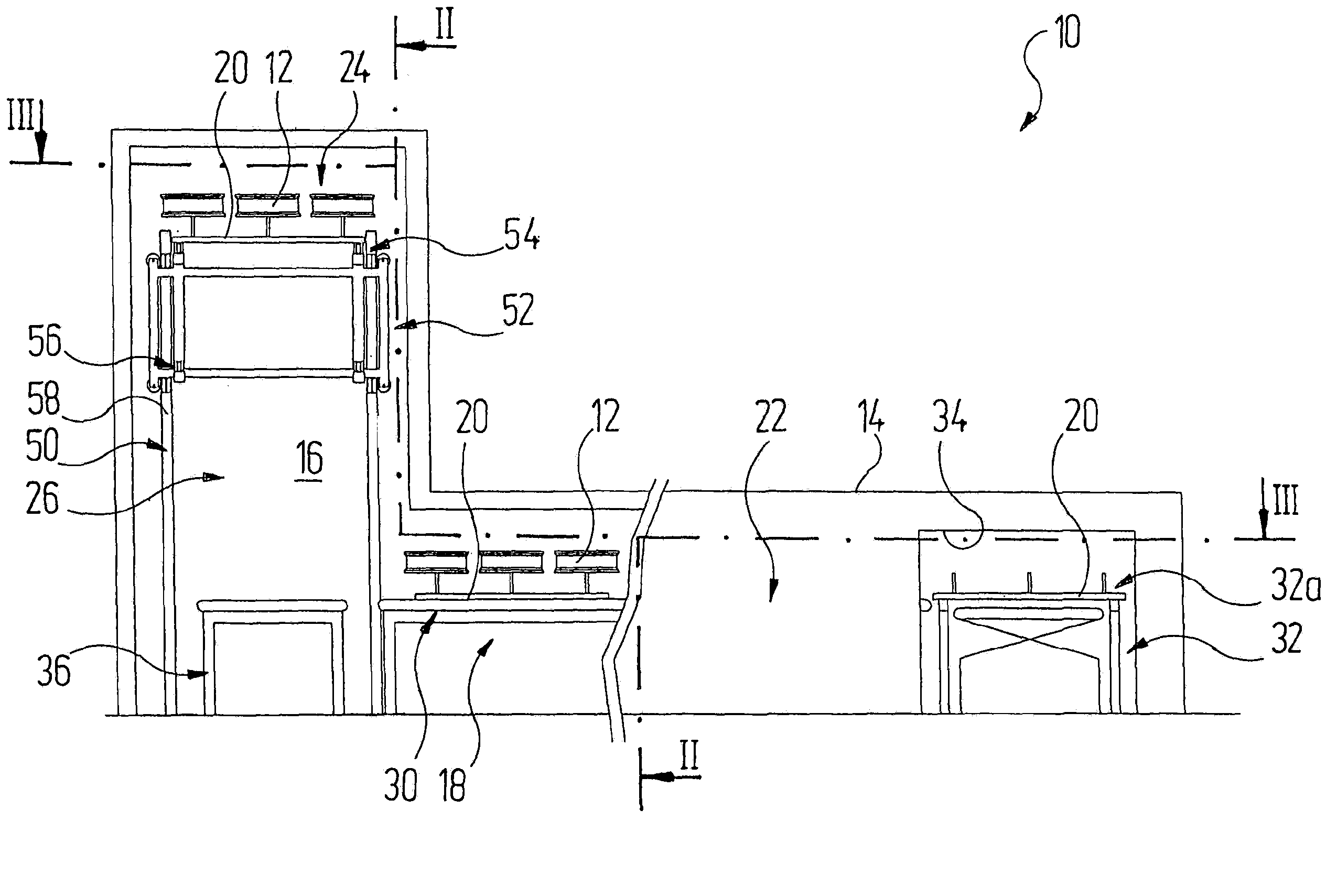

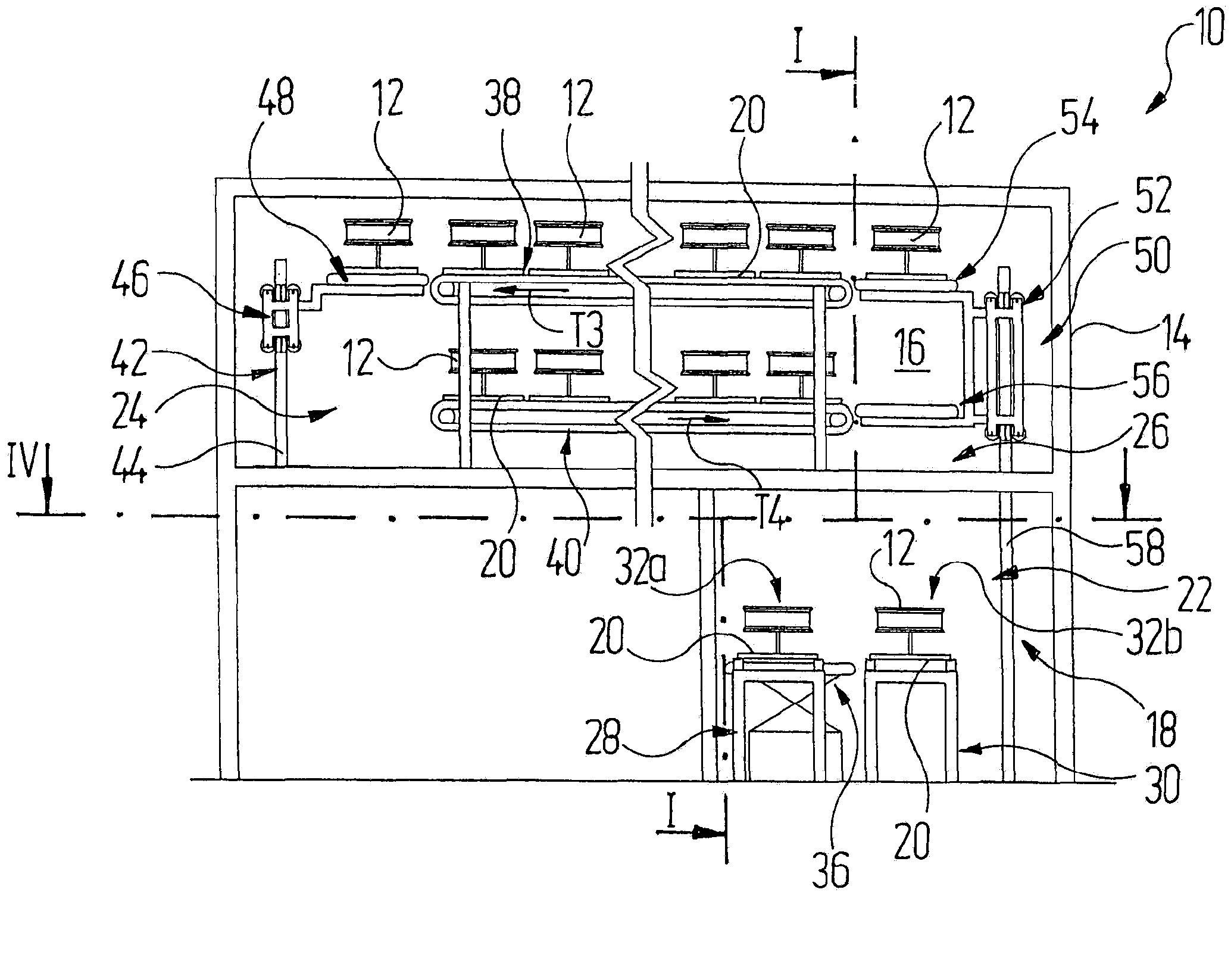

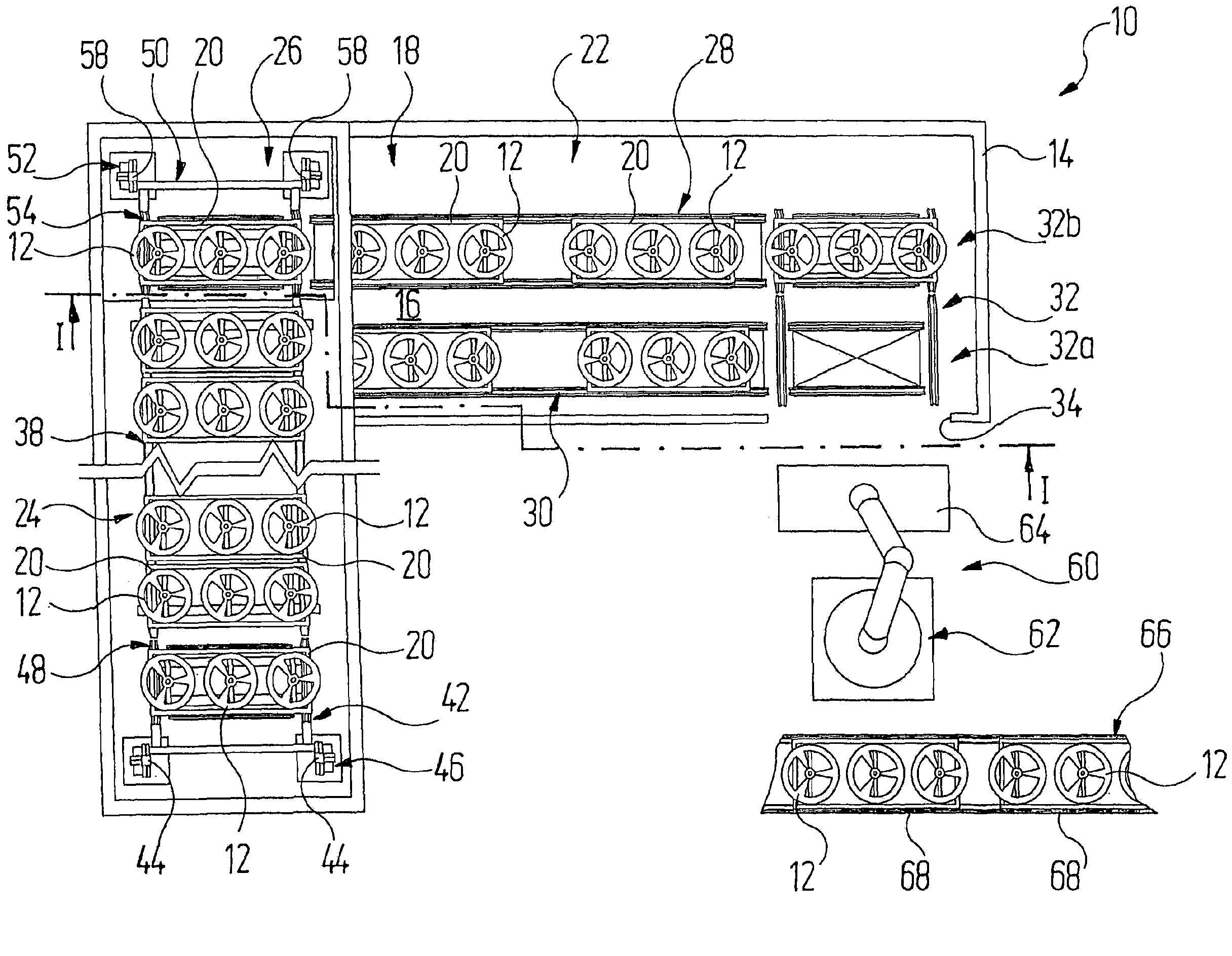

Device and method for drying work pieces

ActiveCN103518114AImprove energy balanceDrying machines with progressive movementsDrying goods handlingProcess engineeringMechanical engineering

Owner:EISENMANN GMBH

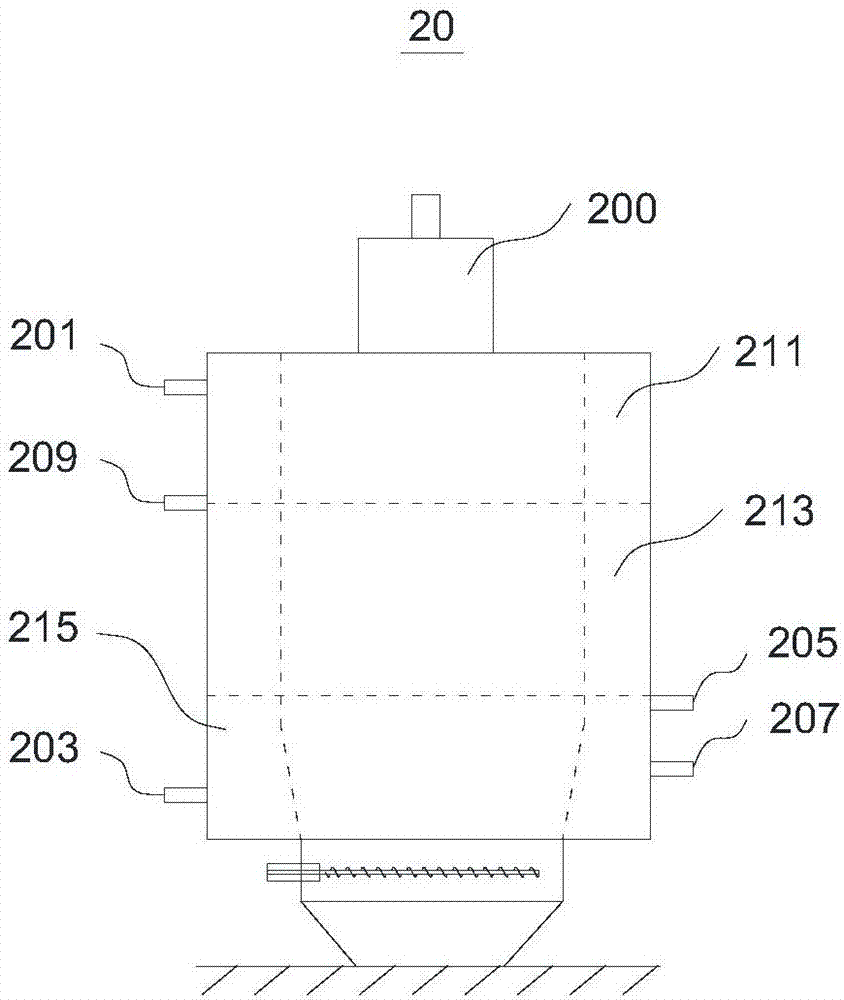

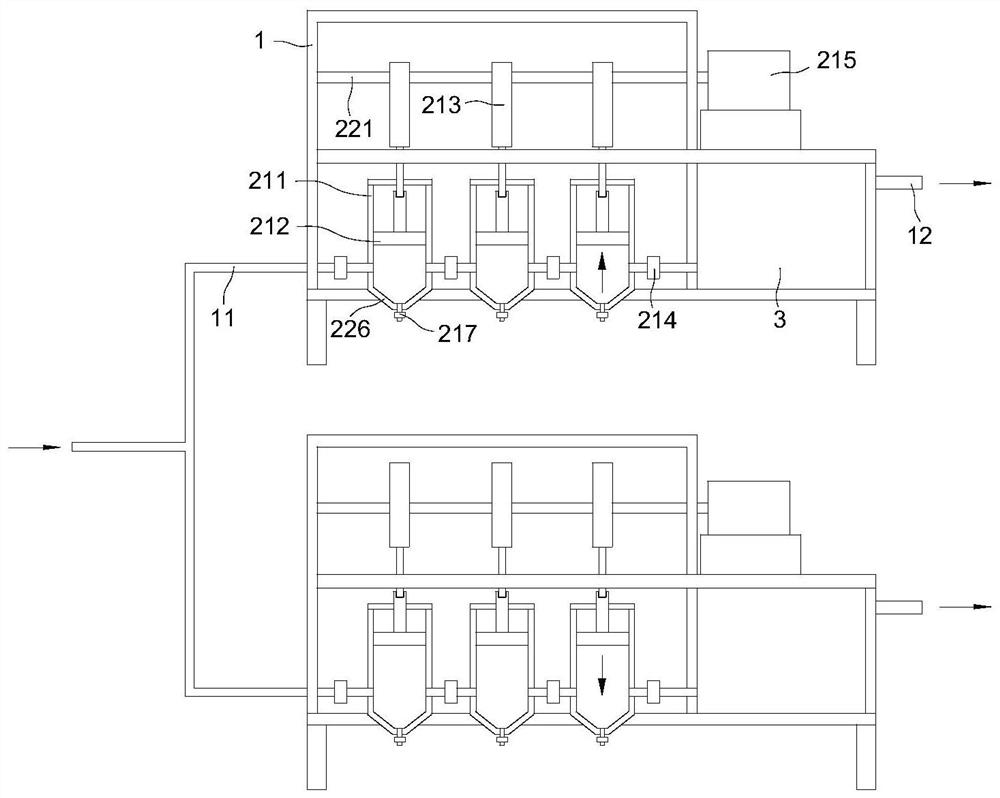

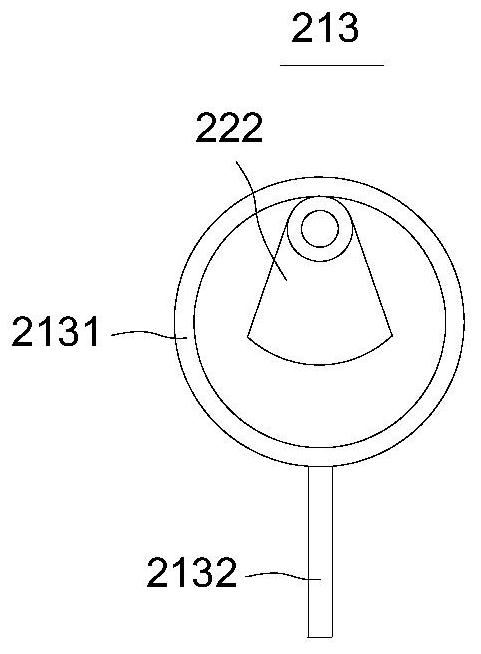

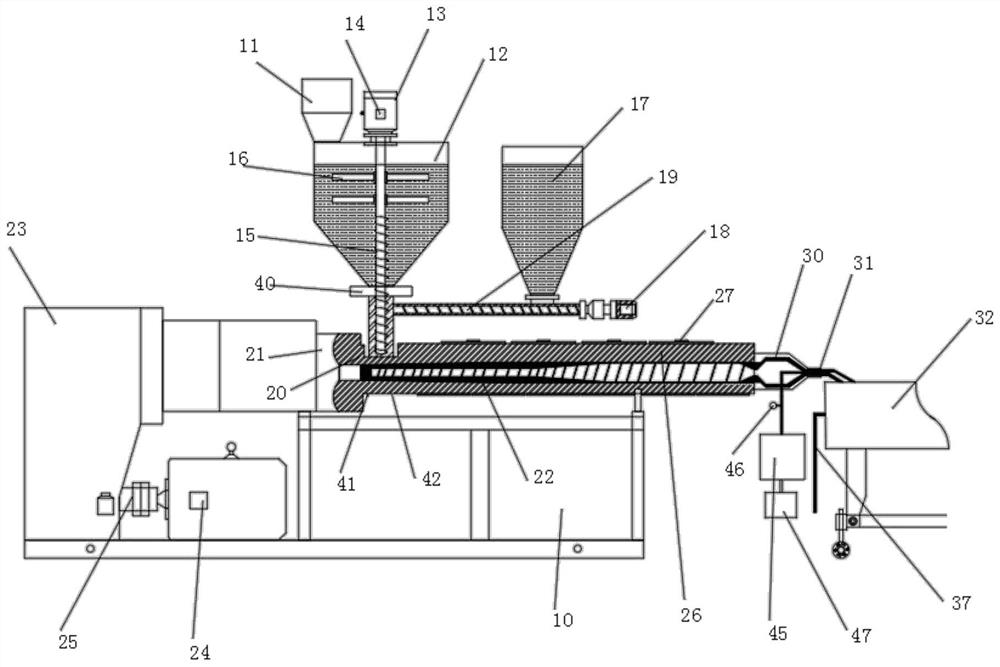

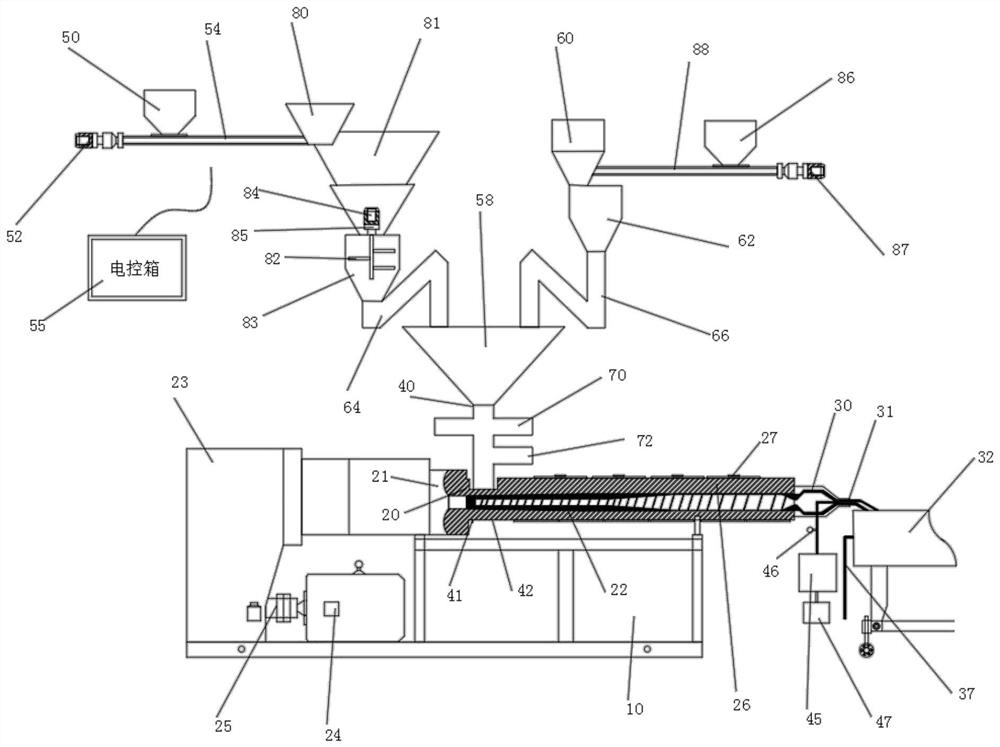

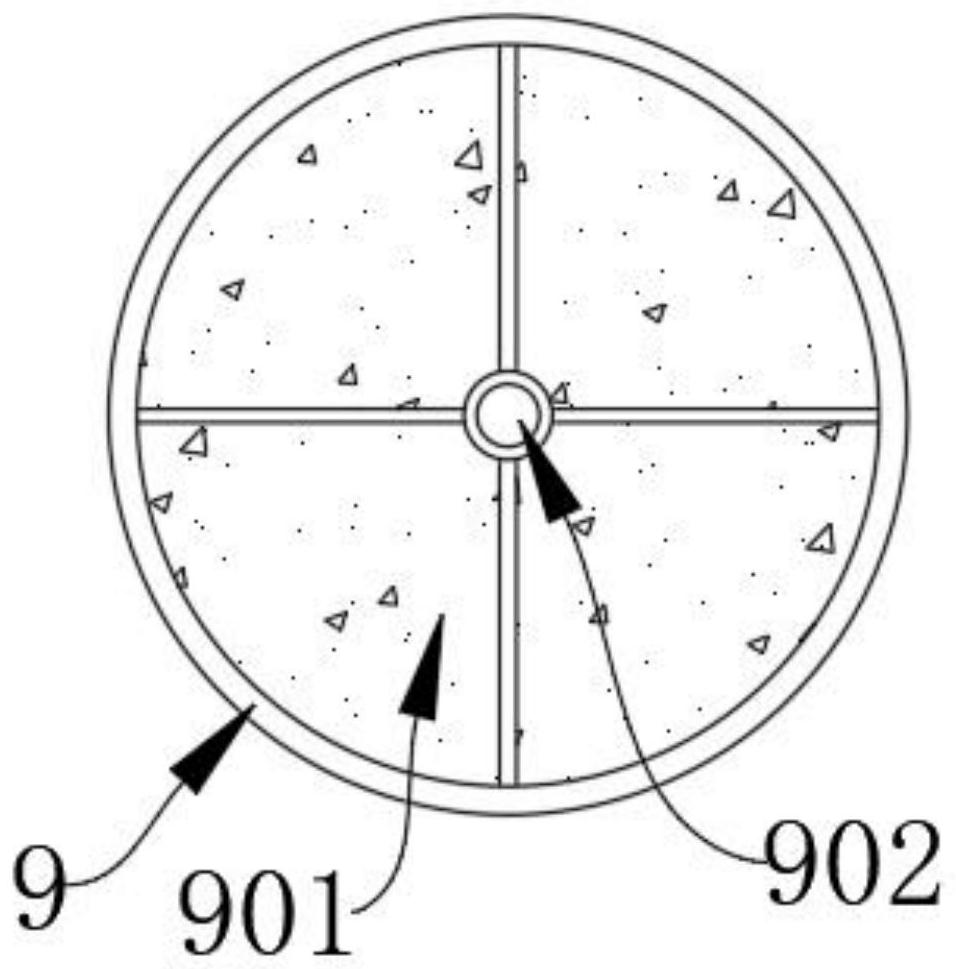

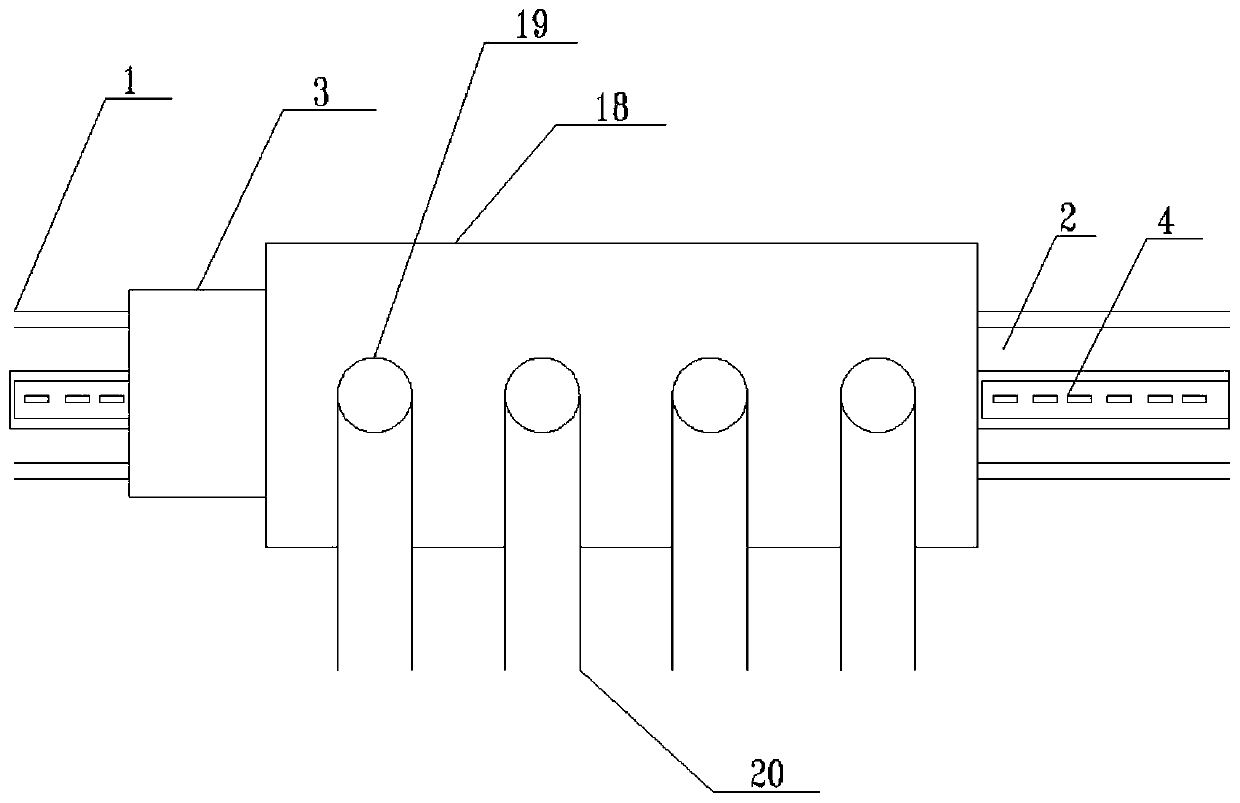

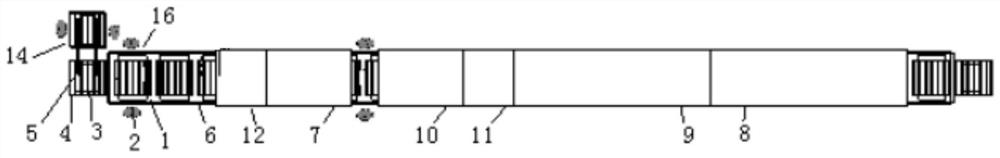

Flexible micropore uniformly-distributed oxygenation pipe

PendingCN113878832AImprove efficiencyHigh strengthWatering devicesPressurised distribution of liquid fertiliserElectric machineryWater jacket

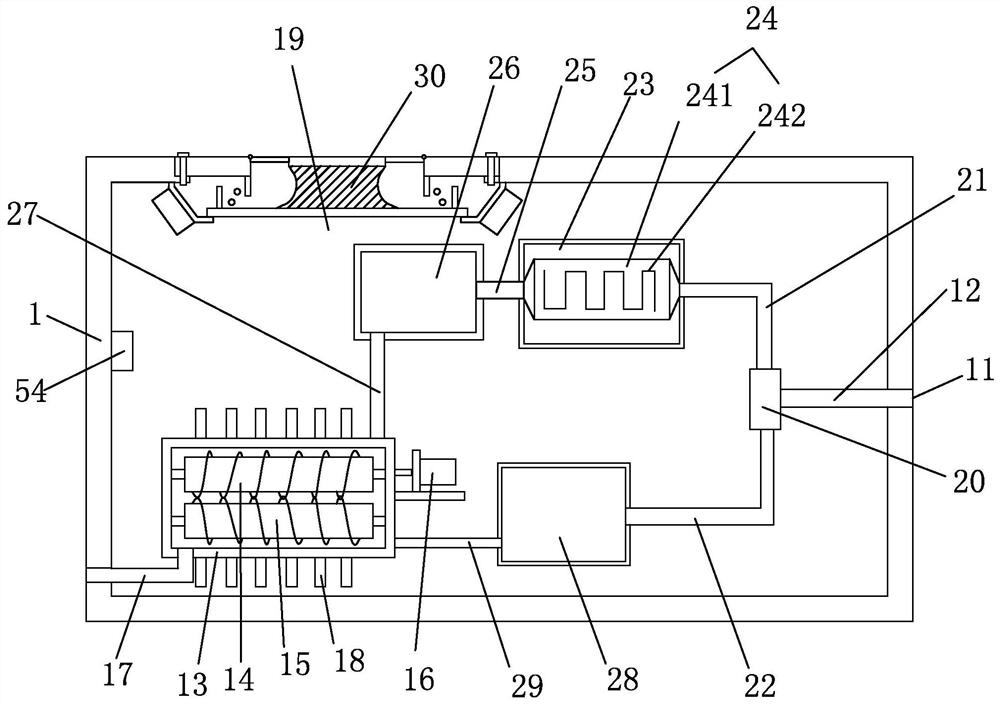

The invention discloses a flexible micropore uniformly-distributed oxygenation pipe which comprises an extrusion device. A gear box is arranged on the left side of the extrusion device, the gear box is driven by a relatively large motor by being connected with a driving belt, a stirring feeding hopper is arranged above the extrusion device, and a drying chamber is arranged on the left side of the top of the stirring feeding hopper. An outer ring of a screw is fixedly connected with an anti-bridging arm, a cold water jacket is arranged at the bottom of the stirring feeding hopper, an extruder is arranged at the bottom of the stirring feeding hopper, an extruder barrel is arranged on the right side of the extruder, a mixing screw is arranged in an inner cavity of the extruder barrel, an air cooling element is arranged on the top of the extruder barrel, and a mold is arranged on the right side of the extruder barrel. A pipeline prefabricated part is arranged on the right side of the mold, a cooling tank is arranged at the end head of one end of the right side of the pipeline prefabricated part, an inlet line is arranged on the left side of the cooling tank, a pressure regulator is arranged below the mold, a pressurization supply source is arranged below the pressure regulator, and a pressure gauge is arranged on the outer wall of a regulating pipeline of the pressure regulator.

Owner:HETIANTONG GLOBAL ECOLOGICAL TECH ENG CO LTD

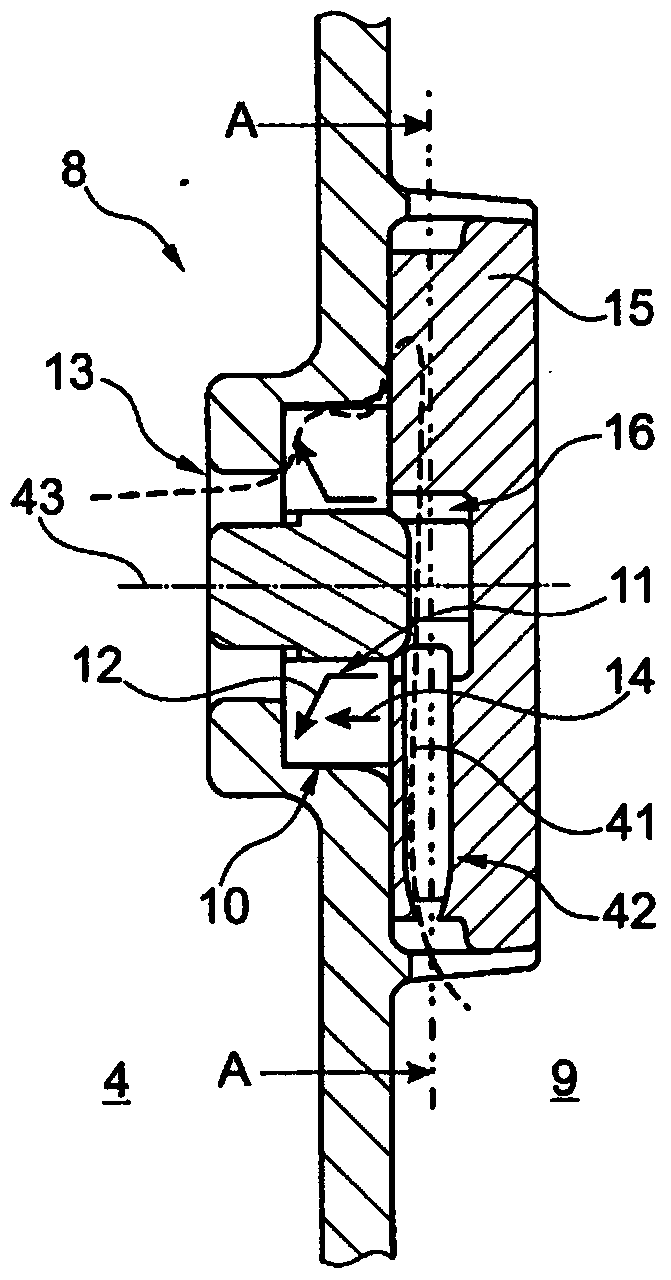

Hydraulic actuators for operating friction clutches

ActiveCN105485207BLarge structural spaceGuaranteed uptimeMechanical actuated clutchesFluid actuated clutchesHydraulic cylinderEngineering

The invention relates to a hydraulic actuator for actuating a friction clutch, said hydraulic actuator having at least the following components: at least one hydraulic cylinder for hydraulic fluid; at least one drying chamber; at least one movable in the hydraulic cylinder A hydraulic piston with an operating face facing the hydraulic fluid and a rear side facing the drying chamber; and at least one air outlet for pressure equalization between the drying chamber and the surrounding environment, characterized in that the at least one air outlet comprises at least A passive one-way valve. A reliable air outflow from the drying chamber is achieved by means of the hydraulic actuator proposed here, which is at the same time designed in a space-saving manner.

Owner:SCHAEFFLER TECH AG & CO KG

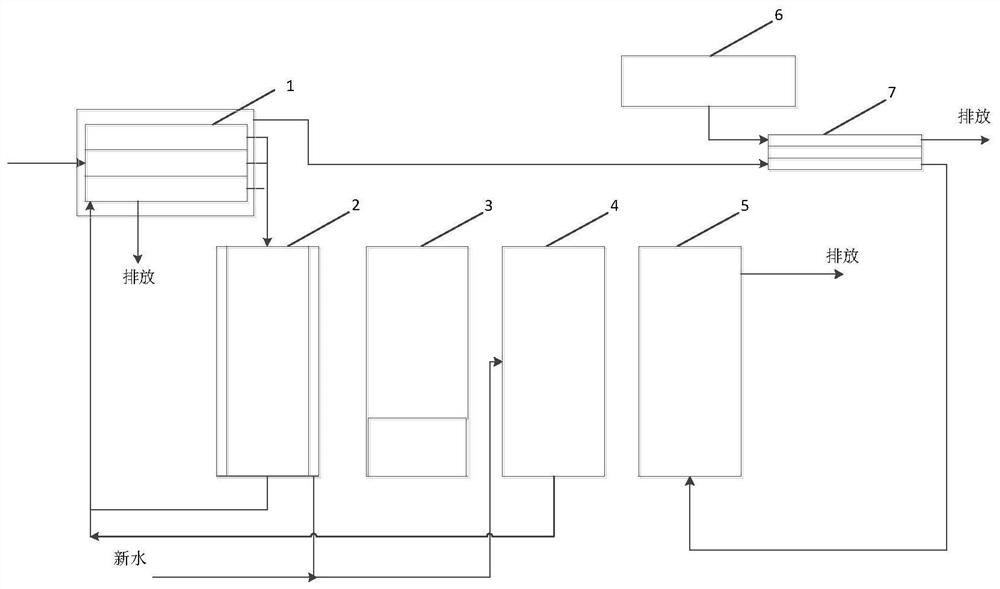

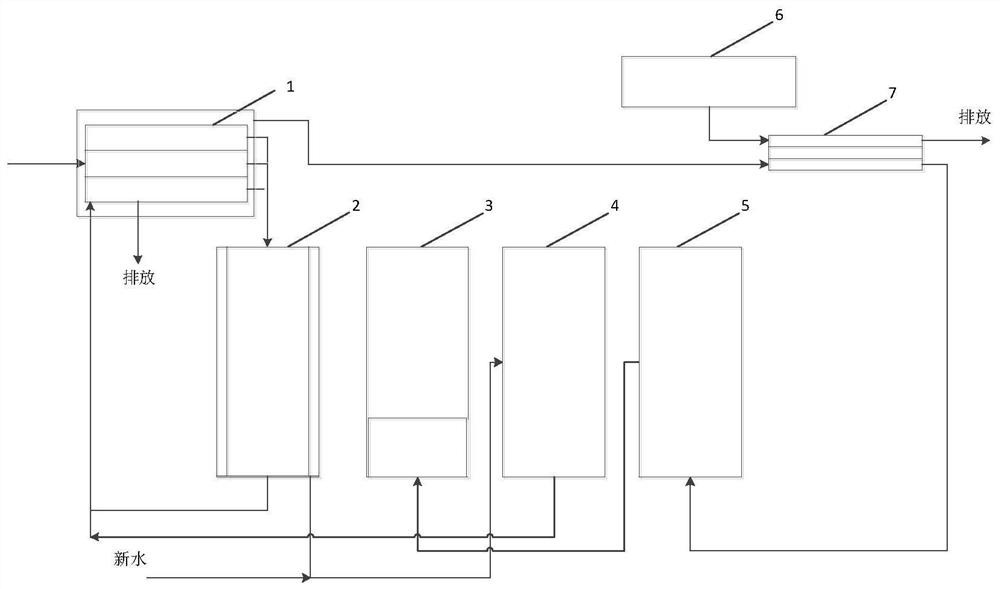

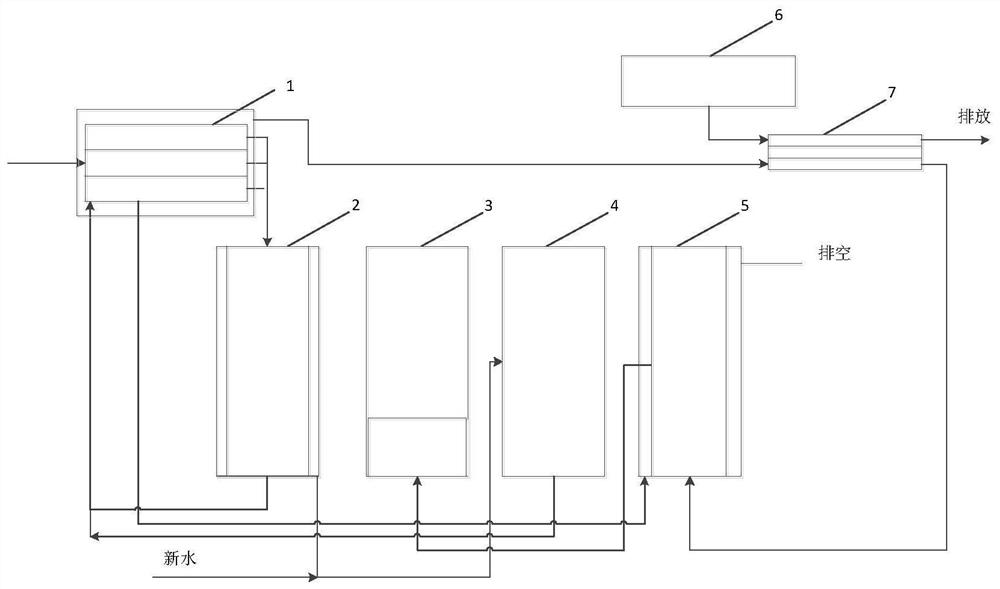

a cleaning system

ActiveCN111687111BAvoid cloggingRealize comprehensive utilizationRecuperative heat exchangersDrying gas arrangementsSewageHeat energy

This application relates to a cleaning system, which is composed of a gas boiler, a steam cleaning room, a cleaning liquid cleaning room, a clean water cleaning room and a drying room. Dirty condensed water and clean condensed water dripping on the wall of the cleaning chamber, and the relatively clean condensed water is sent to the clean water cleaning chamber for direct use. Dirty condensed water is returned to the gas boiler for re-evaporation, but part of the water is retained, and then the condensed water introduced into the middle collection tank of the steam cleaning chamber cleans the steam generating chamber to prevent impurities from clogging the gas boiler. Through the above settings, the comprehensive utilization of heat energy and water is realized, and the discharge of sewage is reduced.

Owner:WUXI ASIA ELECTRONICS INTELLIGENT EQUIP CO LTD

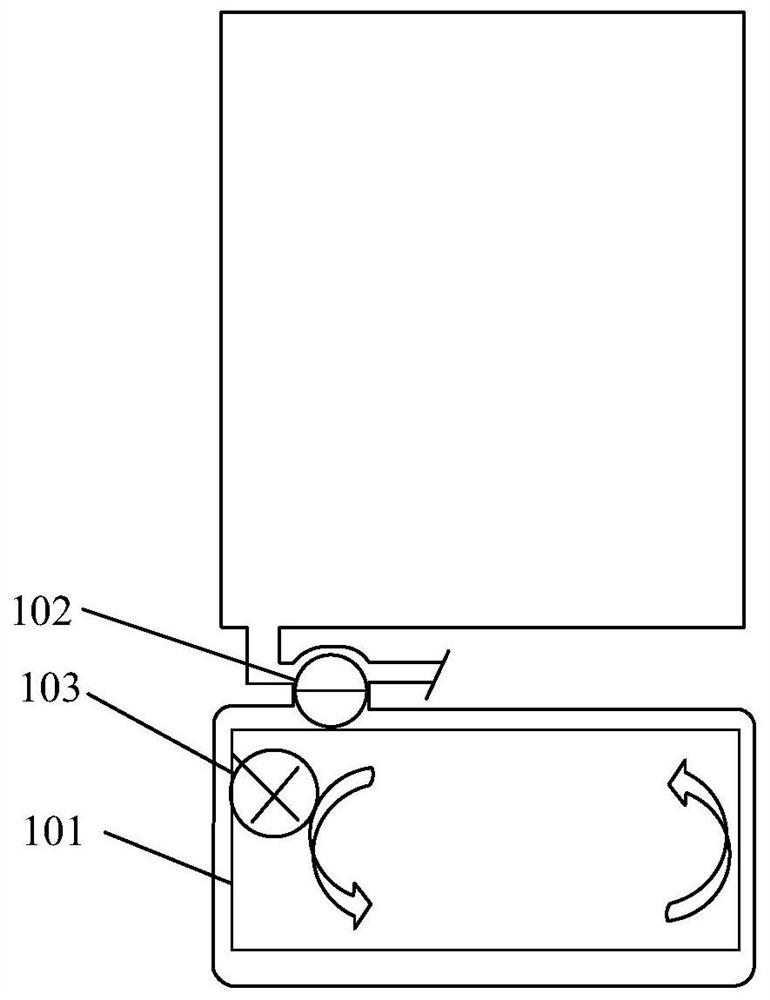

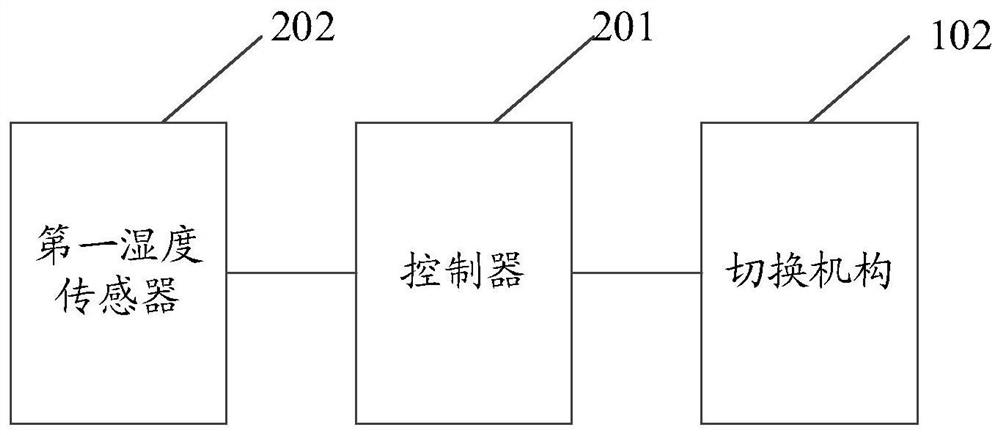

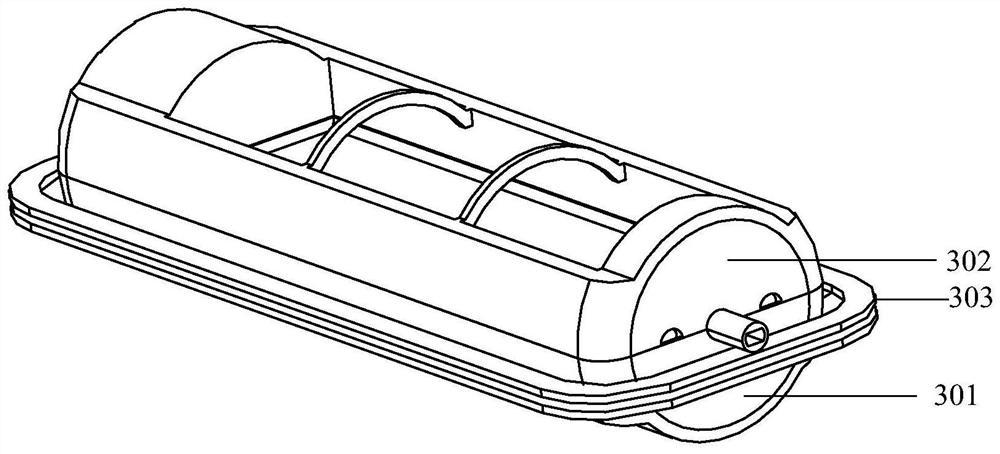

Dehumidification device in refrigeration equipment, refrigeration equipment and dehumidification method

ActiveCN111602019BAchieve dryingTemperature does not need to be loweredDomestic cooling apparatusLighting and heating apparatusDesiccantEngineering

Owner:GUANGDONG MIDEA WHITE HOME APPLIANCE TECH INNOVATION CENT CO LTD +1

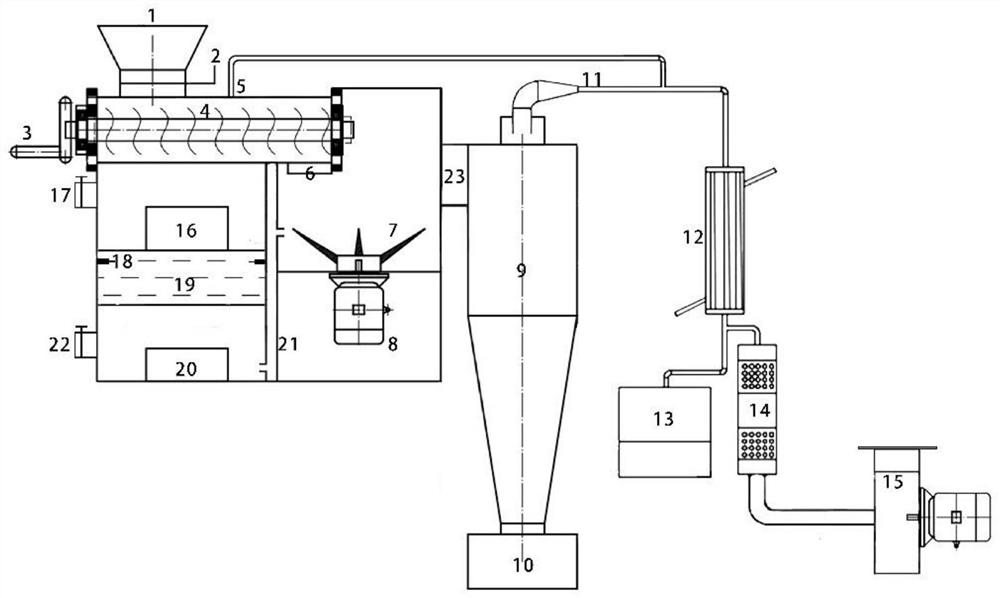

Rotational flow flash evaporation self-heating gradient utilization device for preparing solid fuel from kitchen waste

PendingCN111748393AFor subsequent crushingImprove processing efficiencySolid fuelsWaste based fuelCombustion chamberWaste recycling

The invention provides a rotational flow flash evaporation self-heating gradient utilization device for preparing solid fuel from kitchen waste, and belongs to the technical field of waste recycling.The device comprises a heating extrusion treatment part, a combustion chamber part, a high-speed crushing and rotational flow flash evaporation part, a condensation and tail gas treatment part and a gas-solid separation and solid fuel collection part, kitchen waste is put into a spiral propeller through the feeding port. After being extruded by a variable pitch and heated downwards, the materialsare pushed into the smashing device through a hand rocker and smashed through a high-speed rotating blade, the materials which are small enough enter the rotational flow drying chamber in the tangential direction of smoke to be dried and subjected to gas-solid separation, solid products can be used as fuel to supply drying heat, negative-pressure low-temperature flash evaporation is achieved in the device, and tail gas is exhausted after being condensed and adsorbed. According to the device, self-heating on-site rapid drying can be achieved, a downward ignition type combustion chamber is designed to achieve gradient utilization of flue gas heat, energy consumption is low, meanwhile, low-temperature combustion reduces the pollutant generation amount, a tail gas treatment system is arrangedto achieve up-to-standard emission, and secondary pollution is avoided.

Owner:UNIV OF SCI & TECH BEIJING

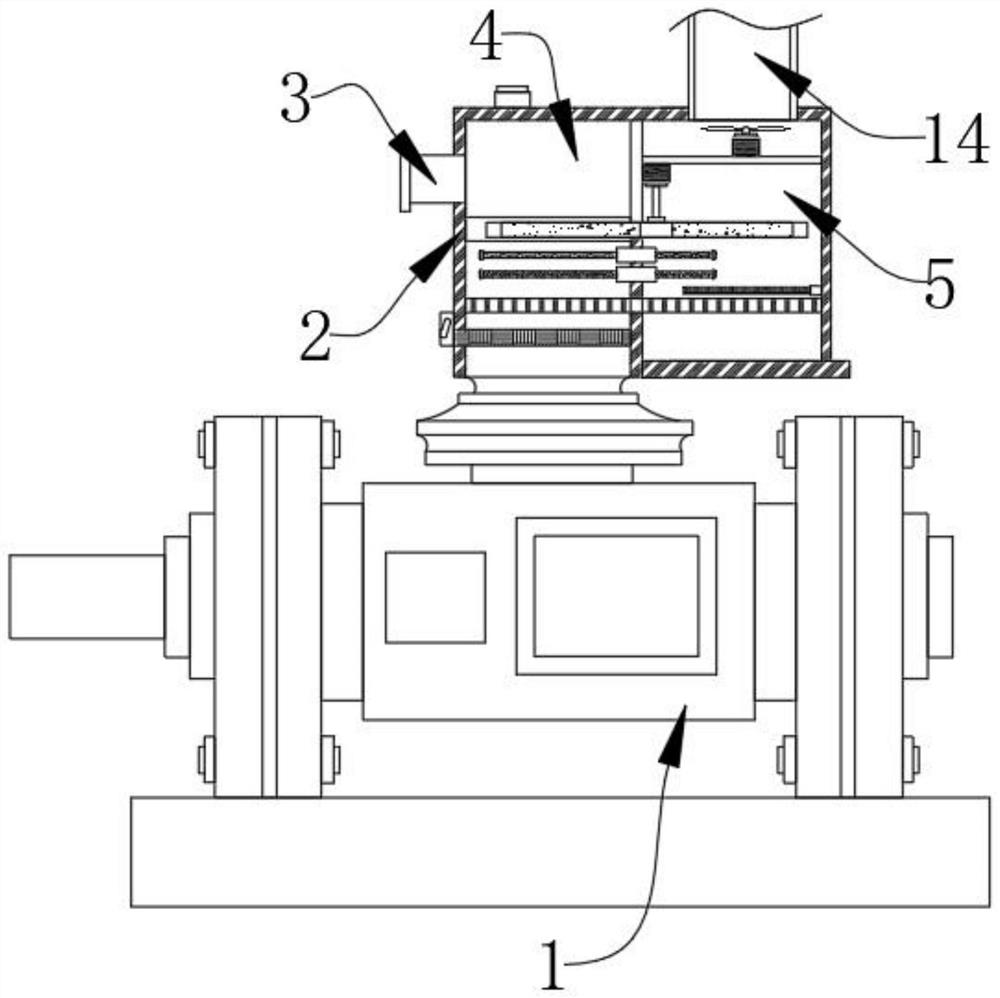

Marine diesel-driven screw air compressor and machining method thereof

InactiveCN113048053AAvoid enteringImprove cooling effectRotary piston pumpsFurnace typesCold airMarine engineering

The invention discloses a marine diesel-driven screw air compressor. The marine diesel-driven screw air compressor comprises a shell, an air inlet is formed in the side wall of the shell, a first air inlet pipe is arranged on the air inlet, a three-way air valve is arranged at the end of the first air inlet pipe, a second air inlet pipe and a third air inlet pipe are arranged at the other end of the three-way air valve, a cooling chamber is arranged at the other end of the second air inlet pipe, a condensation pipe is arranged in the cooling chamber and comprises an inner pipe and an outer pipe, cooling liquid flows in the inner pipe, the outer pipe is connected with the second air inlet pipe, a first cold air guide pipe is arranged on the cooling chamber, the first cold air guide pipe communicates with the other end of the outer pipe, a first drying chamber is arranged at the other end of the first cold air guide pipe, a second cold air guide pipe is arranged on the first drying chamber, a second drying chamber is arranged at the other end of the third air inlet pipe, an air guide pipe is arranged on the second drying chamber, a compression shell is arranged at the other end of the air guide pipe and the other end of the second cold air guide pipe, and a female rotor and a male rotor are arranged in the compression shell.

Owner:阙彰奕

Front air pretreatment device of air compressor

PendingCN113864194AImprove protectionExtended service lifeDispersed particle filtrationRotary/oscillating piston pump componentsElectric machineAir compressor

The invention discloses a front air pretreatment device of an air compressor, and relates to the field of air compressors. The device comprises an air compressor and a device body, wherein the interior of the device body is divided into a pretreatment chamber and a drying chamber, a fixing rod is installed on the upper portion of the interior of the drying chamber, an induced draft fan is installed on the top of the fixing rod, a motor is installed on one side of the bottom of the fixing rod, and the output end of the motor is connected with a center shaft. According to the invention, when a piece of sponge located in the pretreatment chamber is saturated through adsorption, a worker can start the motor, the motor drives the center shaft to rotate, so that a support rotates, the other piece of sponge is rotated to enter the pretreatment chamber, sealing gaskets are installed on the outer sides of the support, and the pretreatment chamber can be kept in a sealed state; after the sponge which is saturated through adsorption enters the drying chamber, the worker opens the induced draft fan and can attract hot air of refrigeration sheets so as to dry the wet sponge, and when the hot air of the refrigeration sheets is insufficient, the worker can open a heating plate to provide a heat source so as to achieve the purpose of automatically removing moisture in the sponge.

Owner:江西艾维斯机械有限公司

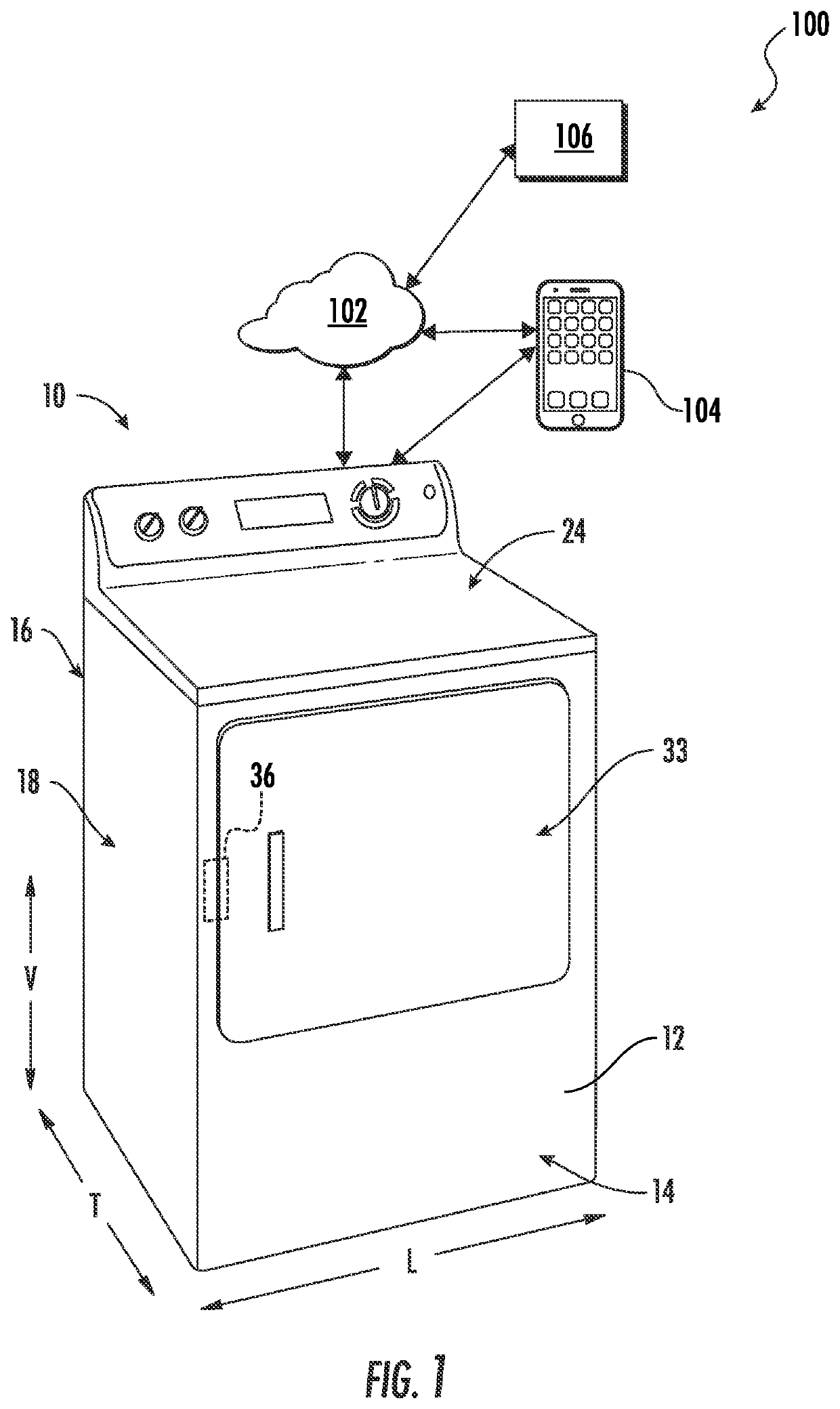

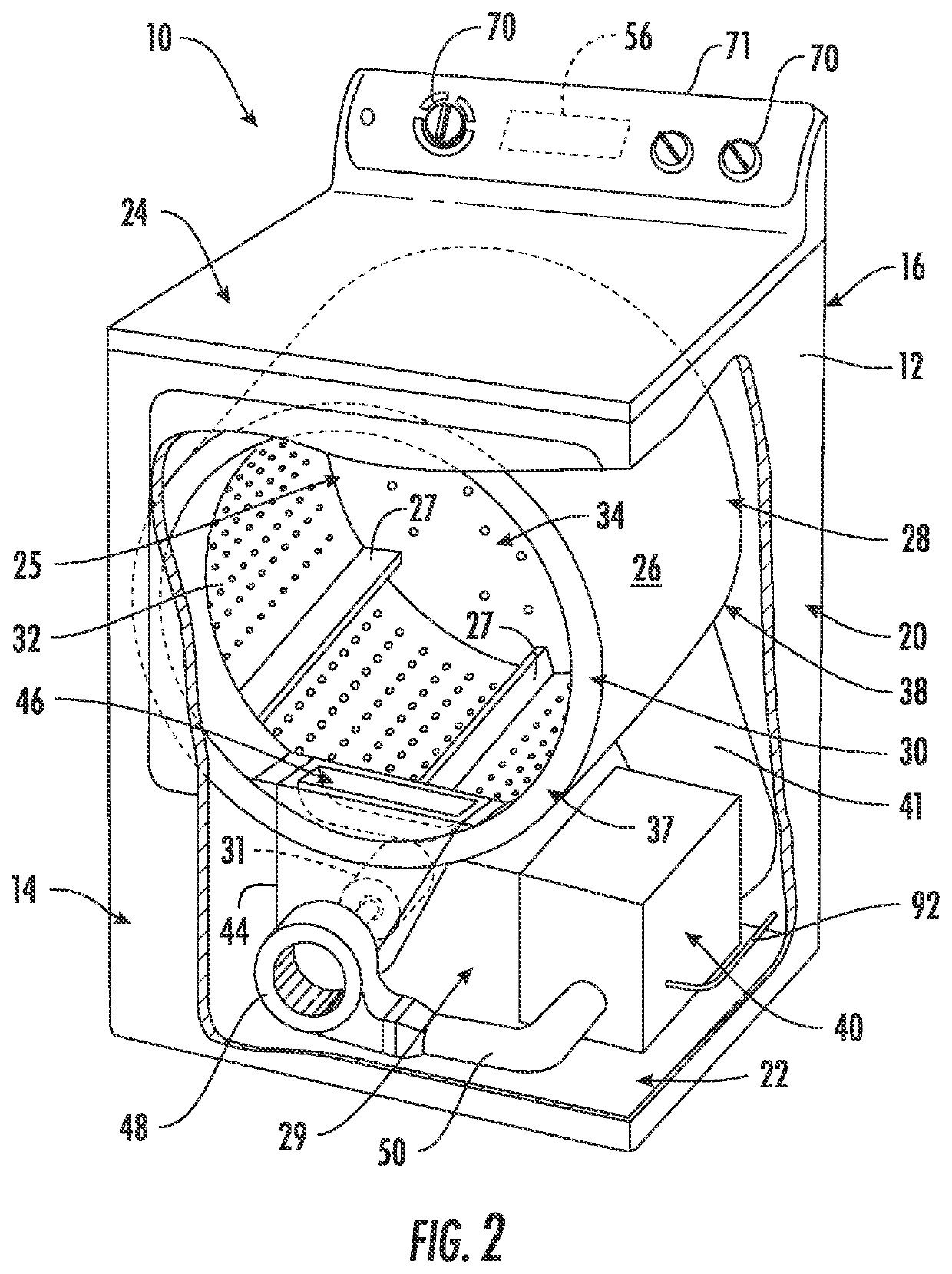

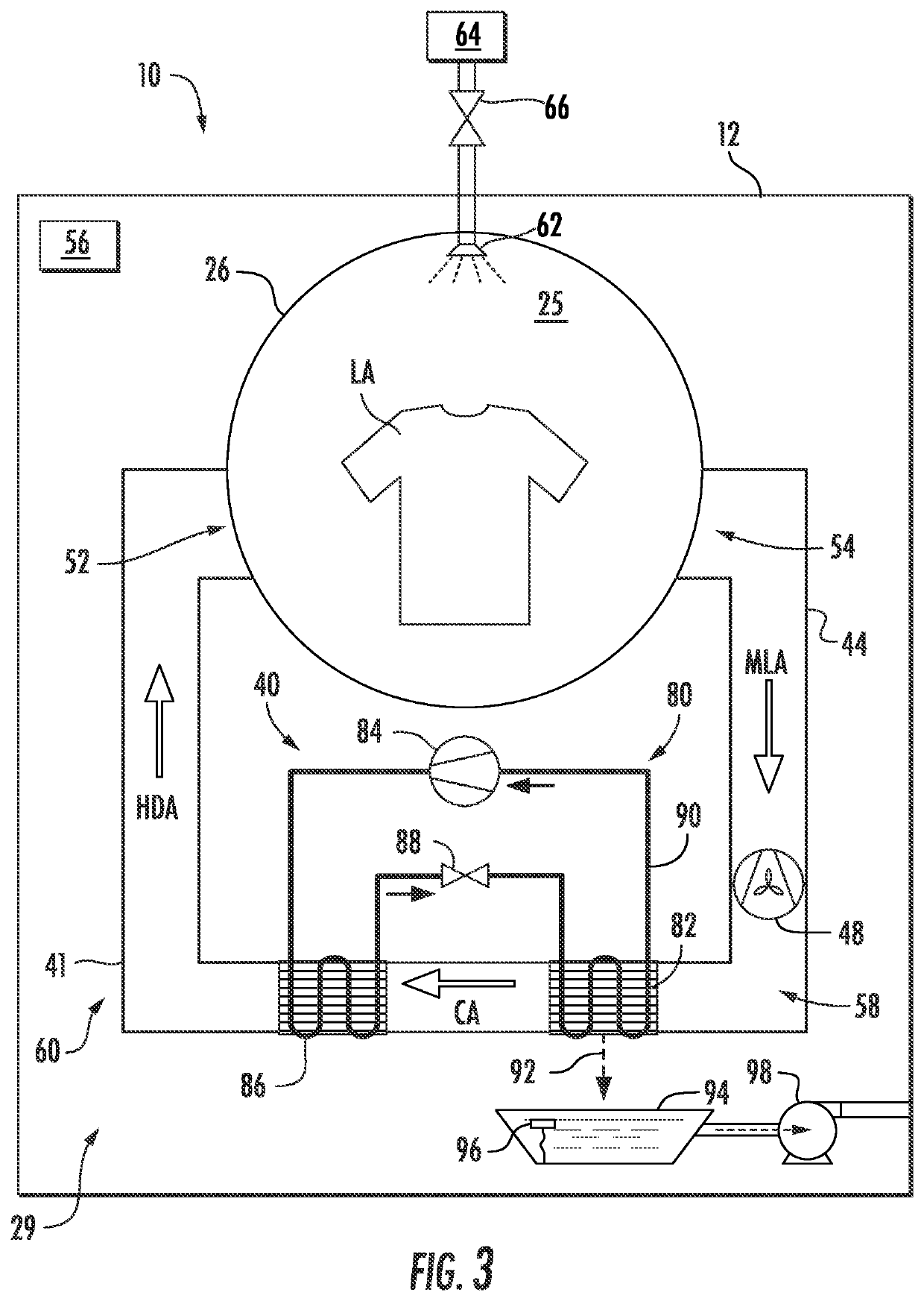

Travel cycle for a condenser or heat pump dryer appliance

A dryer appliance and a method of operating the same are provided. In one aspect, the dryer appliance includes a drum rotatably mounted within a cabinet. The drum defines a chamber that is in fluid communication with a conditioning system of the dryer appliance that circulates heated air through the chamber. A controller is configured to receive a command to initiate an appliance travel cycle and implement a responsive action to prepare the dryer appliance for travel. The responsive action may be the automated adjustment of one or more operating parameters of the dryer appliance, such as performing a load sensing procedure, drying the chamber, closing the water supply valves, etc. In addition, the responsive action may include providing a user instruction to prepare the dryer appliance, e.g., by cleaning the lint filter, emptying the condensate collection tank, removing hoses and cables, addressing any error codes, etc.

Owner:HAIER US APPLIANCE SOLUTIONS INC

Drying device for preparing brick body through raw bauxite

PendingCN110978243AEasy to manufactureIncrease productivityAuxillary shaping apparatusBrickStructural engineering

The invention discloses a drying device for preparing a brick body through raw bauxite. The drying device comprises a drying chamber, wherein the drying chamber is a hollow structure with openings atthe front end and the rear end, at least two suction holes are uniformly formed in the top of the drying chamber, corresponding air suction pipes communicate with the suction holes so as to realize the drying of the drying chamber, tracks traverse the whole drying chamber, a hollow structure is arranged between the tracks, a transport plate spans on the tracks, a driving device of the transport plate is arranged in the hollow structure, supporting legs are symmetrically arranged on the two sides of the bottom surface of the transport plate, rolling wheels are arranged on the inner sides of thesupporting legs, the rolling wheels are matched with the tracks to realize movement of the transport plate on the tracks, and the drive device is matched with the transport plate to achieve the driving of the transport plate to move back and forth on the tracks. The drying device is simple in structure and high in practicability, and conveniently manufactures the brick body.

Owner:贵州开阳三环磨料有限公司

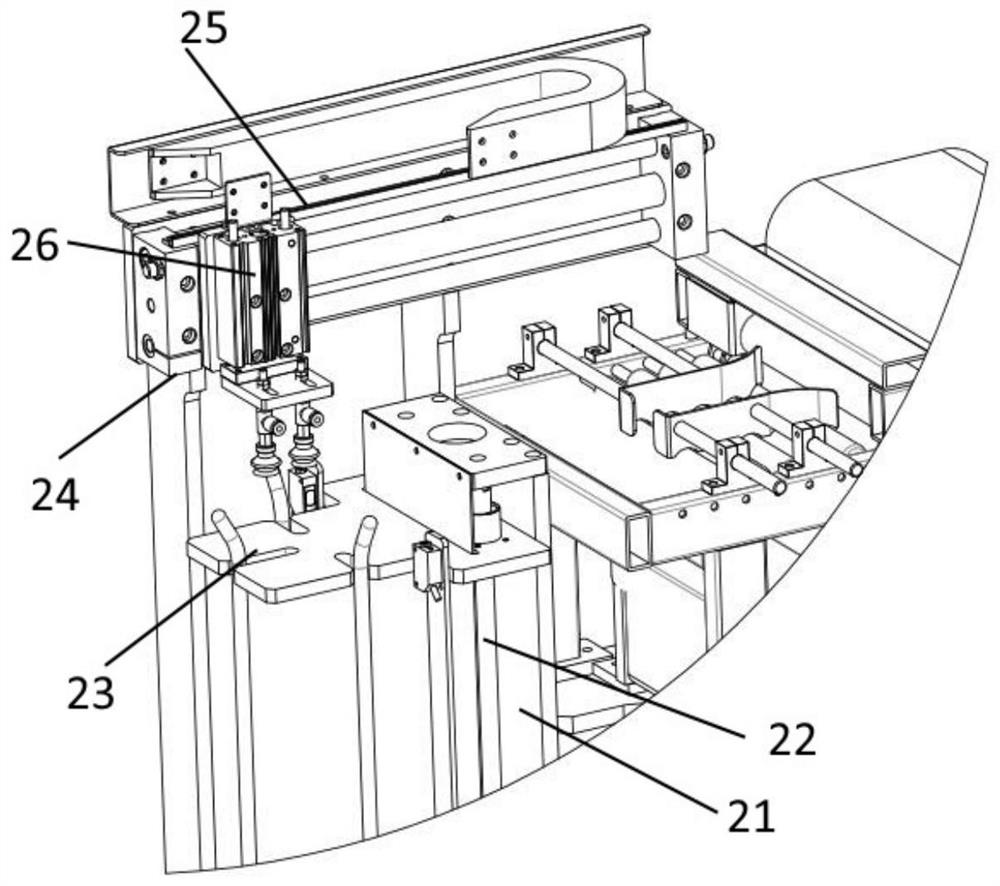

A cleaning device and cleaning method for parts after wave soldering

ActiveCN112547630BGuaranteed uptimeAvoid cloggingCleaning using liquidsProcess engineeringCleaning methods

The invention discloses a cleaning device for parts after wave soldering and a cleaning method thereof. The device for cleaning parts after wave soldering includes a handling assembly and a transportation device fixedly connected to the workbench. A quantitative component on one side, a limit component connected with the quantitative component, and a cleaning room and a drying room arranged on the transport device. Through the set quantitative components, the required cleaning solution can be automatically configured, thereby avoiding manual configuration work, thereby reducing the waste of manpower. When the water output of the device is not enough to complete the cleaning of the parts, the connection device can be connected at this time to complete the replacement of the cleaning device, thereby ensuring the smooth operation of the cleaning work.

Owner:南京江川电子有限公司

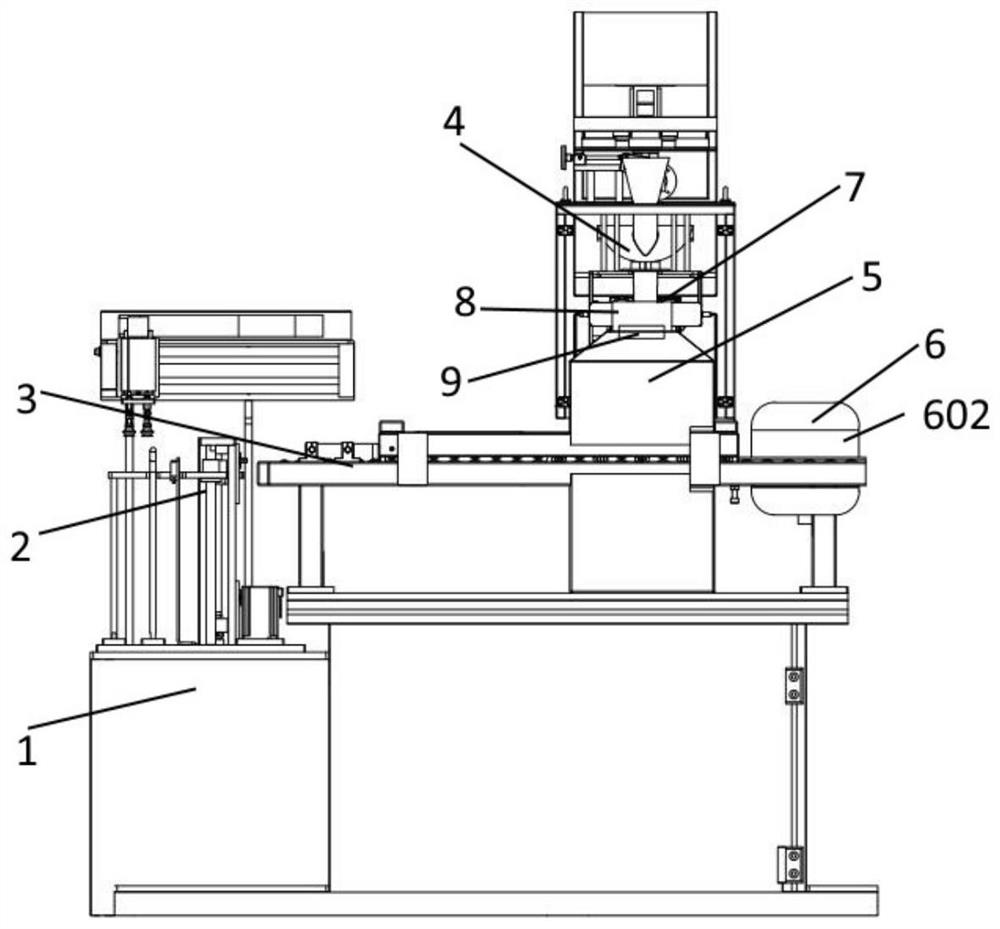

Dacromet treatment equipment and treatment method for fastener

PendingCN113581810ACompact structureCompressed footprintConveyorsPretreated surfacesProduction lineCooling chamber

The invention discloses Dacromet treatment equipment and a treatment method for a fastener. The Dacromet treatment equipment comprises a conveying line, a lifting table and a tooling disc; the conveying line is provided with a front spraying chamber A, a cooling chamber, a sintering drying chamber, a rear spraying chamber B, a front preheating chamber and a rear preheating chamber; the front preheating chamber, the front spraying chamber A, the rear spraying chamber B, the rear preheating chamber, the sintering drying chamber and the cooling chamber are arranged in a linear mode according to the working procedure; the conveying line comprises a supporting frame, an upper-layer roller conveying chain mechanism and a lower-layer roller conveying chain mechanism, and the upper-layer roller conveying chain mechanism and the lower-layer roller conveying chain mechanism are arranged up and down; the upper-layer roller conveying chain mechanism is arranged at the upper portion of the supporting frame; and the lower-layer roller conveying chain mechanism is arranged at the lower portion of the upper-layer roller conveying chain mechanism. By the adoption of the technological process, the station steps are reduced, the operation time is saved, the running time of the whole Dacromet production line is shortened, the working efficiency is improved, and compared with an assembly line structure and technology in the prior art, the occupied space is reduced by half.

Owner:济南中船设备有限公司

Automatic cleaning device for filled wine bottles

PendingCN114590454AWash thoroughlyImprove cleanlinessPackage sterilisationWine bottleProcess engineering

The automatic cleaning device comprises a disinfecting and cleaning chamber, a flushing chamber and a drying chamber which are sequentially connected from left to right and communicate with one another, a workbench sequentially penetrates through the disinfecting and cleaning chamber, the flushing chamber and the drying chamber from left to right, and a conveying belt used for conveying the wine bottles is arranged on the workbench; a disinfectant spraying pipe is arranged above the disinfecting and cleaning chamber, two washing plates which are oppositely arranged are arranged below the disinfectant spraying pipe, the two washing plates are located on the two sides of the wine bottle conveying direction respectively, and bristles used for washing the wine bottles are arranged on the washing plates; a driving mechanism for driving the two washing plates to do reciprocating rectilinear motion in the wine bottle conveying direction is arranged at the top of the disinfecting and cleaning chamber; a clean water spraying pipe is arranged above the washing chamber, and a plurality of air outlet pipes are arranged on the two sides in the wine bottle conveying direction in the drying chamber. The automatic cleaning device for the filled wine bottle can thoroughly clean, sterilize and disinfect the sparkling wine bottle which is filled, plugged and locked, and safety production of sparkling wine is achieved.

Owner:SINO FRENCH JOINT VENTURE DYNASTY WINERY

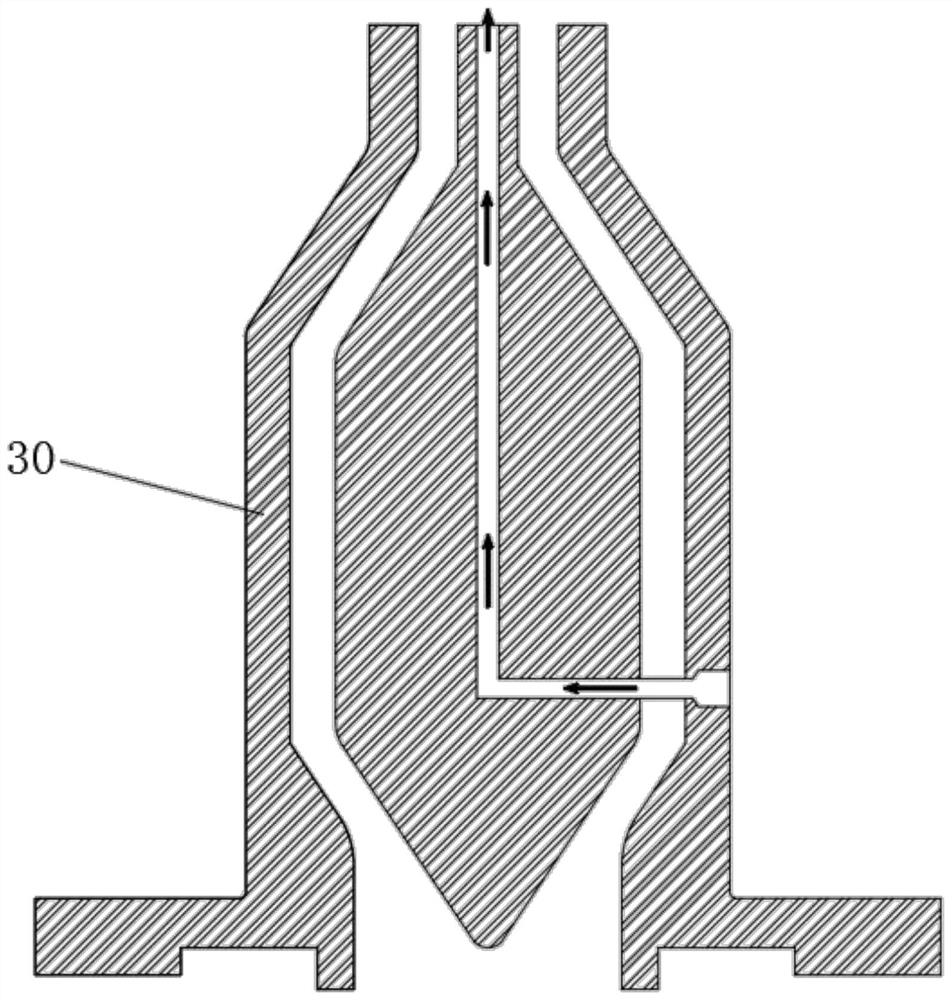

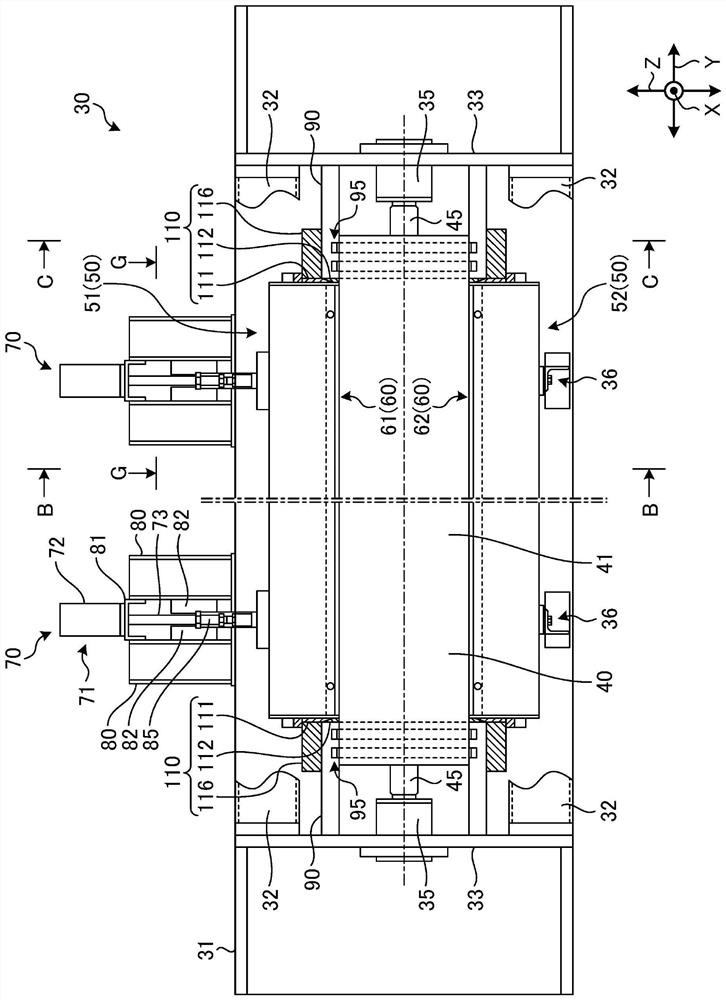

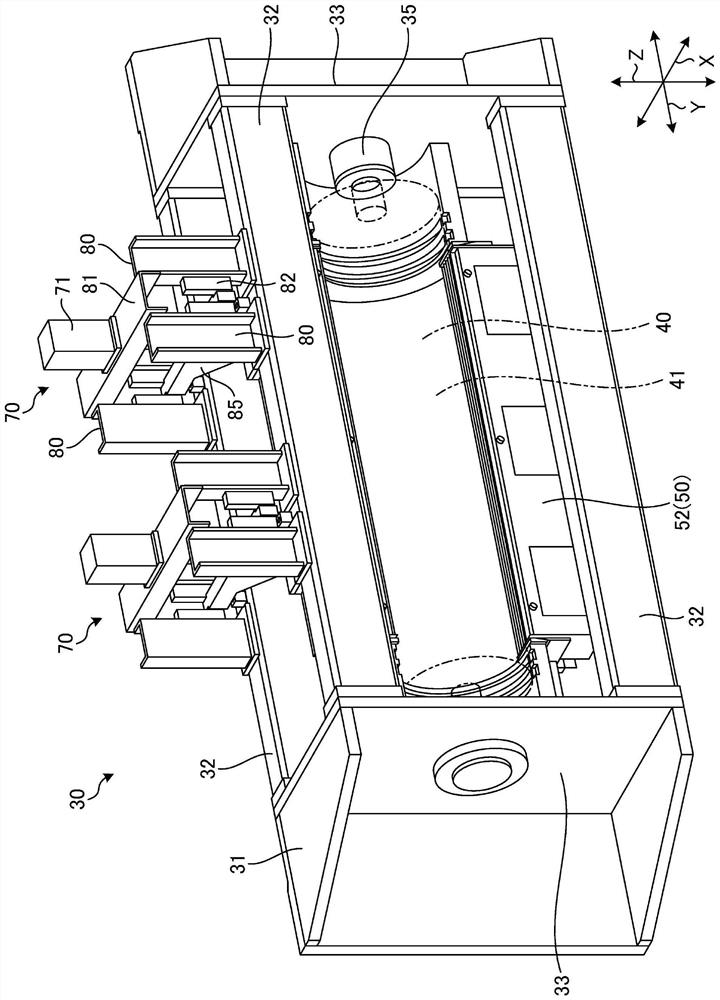

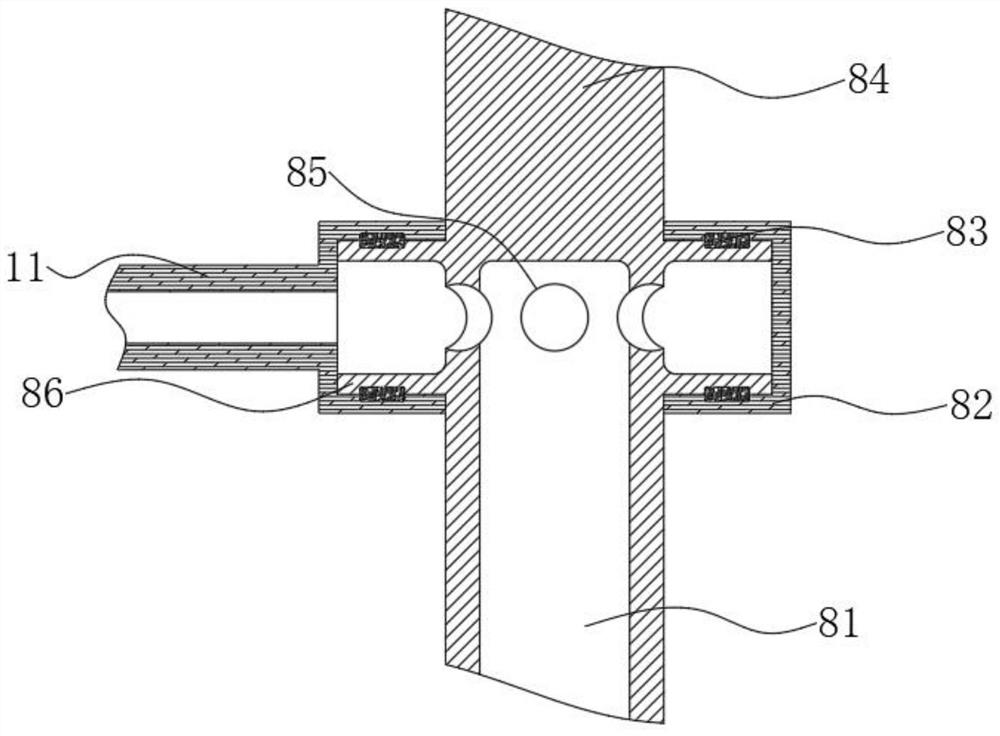

Gas sealing structure and extraction drying device

PendingCN114729783AGuaranteed tightnessEngine sealsDrying solid materials with heatStructural engineeringMechanical engineering

In order to easily ensure sealing properties, a gas sealing structure (30) is provided with: a sealing roller (40) which divides a drying chamber (11) and is disposed on the surface side opposite to the surface on the drying chamber (11) side of a partition wall (15) having an opening (16) through which a sheet-like member (S) passes; a conveyance section labyrinth seal (60) that is disposed at a position facing the outer peripheral surface (41) of the seal roller (40), that allows the sheet member (S) conveyed from the opening (16) to pass through to a position between the conveyance section labyrinth seal (60) and the seal roller (40), and that has a plurality of space sections (67) that are arranged in the conveyance direction of the sheet member (S) and that are open on the seal roller (40) side; and an exhaust duct (22) that causes the inside of the drying chamber (11) to have negative pressure with respect to the side where the seal roller (40) is disposed.

Owner:SHIBAURA MASCH CO LTD

Conveying box cleaning chamber

PendingCN114512418AImprove cleaning efficiencyAvoid pollutionDrying solid materials with heatDrying solid materials without heatProcess engineeringMechanical engineering

The present invention provides a transfer cartridge cleaning chamber, comprising: a cleaning chamber having an entrance door and accommodating a transferred transfer cartridge for cleaning; a drying chamber having an exit door and drying the transfer cartridge transferred from the cleaning chamber; a switch disposed between the cleaning chamber and the drying chamber for lifting; and a chamber moving unit that moves the transfer cartridge from the cleaning chamber to the drying chamber.

Owner:SUBARU TECNICA INTERNATIONAL

A spray drying equipment with cleaning mechanism

ActiveCN113020167BAvoid damageGuaranteed stabilityHollow article cleaningElectric machineEnvironmental engineering

The invention discloses a spray drying device with a cleaning mechanism, comprising a drying chamber, a discharge pipe is connected to the outer surface of the lower end of the drying chamber, a positioning buffer structure is pressed inside the bottom of the drying chamber, and the positioning buffer The upper and outer surface of the structure is connected with a cleaning water pipe frame, and the outer outer wall of the cleaning water pipe frame is uniformly equipped with spraying water guns, and the middle part of the upper end of the cleaning water pipe frame is connected with a rotating water injection structure, and the middle part of the upper end of the rotating water injection structure is connected with a deceleration device. The upper end of the reduction box is equipped with a rotating motor, and one side of the outer surface of the rotating water injection structure is connected with a hard water pipe. According to the nature of the dried product, the present invention can heat the purified water to a suitable temperature and add additives to improve the cleaning effect on the dried product, and can fully wash and clean the inner wall of the drying chamber, so as to ensure that the cleaning effect on the inner wall of the drying chamber is the same as that of Efficiency, reduce the time wasted by manual cleaning, and facilitate people's use.

Owner:江苏健达干燥工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com