Rotational flow flash evaporation self-heating gradient utilization device for preparing solid fuel from kitchen waste

A solid fuel, self-heating technology, applied in the field of waste recycling, can solve the problems of insufficient treatment capacity, high transportation cost, long treatment time, etc., and achieve the effect of reducing the amount of pollutants, achieving discharge standards, and shortening treatment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0024] The invention provides a device for making solid fuel from kitchen garbage by self-heating cascade utilization of cyclone flash evaporation.

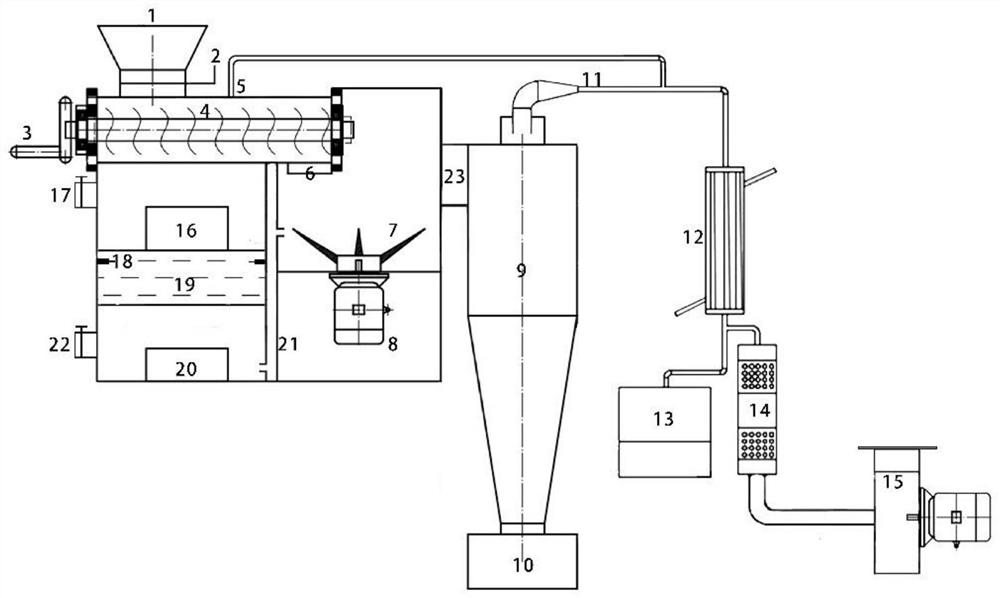

[0025] Such as figure 1 As shown, the device includes a heating and extrusion processing part, a combustion chamber, a high-speed crushing and swirling flash evaporation part, a condensation and tail gas treatment part, a gas-solid separation and a solid fuel collection part, wherein the heating and extrusion processing part includes kitchen waste Feed inlet 1, valve 2, hand lever 3, variable pitch screw propeller 4, steam exhaust port 5 and propeller outlet 6, the combustion chamber part includes upper air inlet 17, lower air inlet 22, combustion chamber grid 19. Feed door 16, dust removal door 20 and ign...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com